For Silverside Detectors (and all of humanity), the stakes couldn’t be higher. The Boston-based R&D company develops next-generation nuclear radiation detection technology for the defense and homeland security market. As the world becomes an increasingly more dangerous place, law enforcement and intelligence agencies must do everything they can to keep one step ahead of potential threats.

Onshape is helping Silverside speed up its design process, and consequently, speed up the process of deploying this counterterrorism technology wherever it is needed most.

“We switched to Onshape because we urgently needed help with data management,” says Silverside VP of Hardware Engineering Philip Taber. “With our previous CAD system, we’d have engineers trying to figure out which version was the latest version of a design. With separate files for the front, back, the side plates and the base, each part would get a letter and number code so we could try to keep them straight, but they’d get all mixed and matched.”

“Onshape allows us to keep everything much more organized without needing a PDM system,” Taber adds. “Onshape probably cuts our design time in half because we’re designing our parts together in one place versus flipping back and forth between files. We can make changes without worrying about breaking the assembly.”

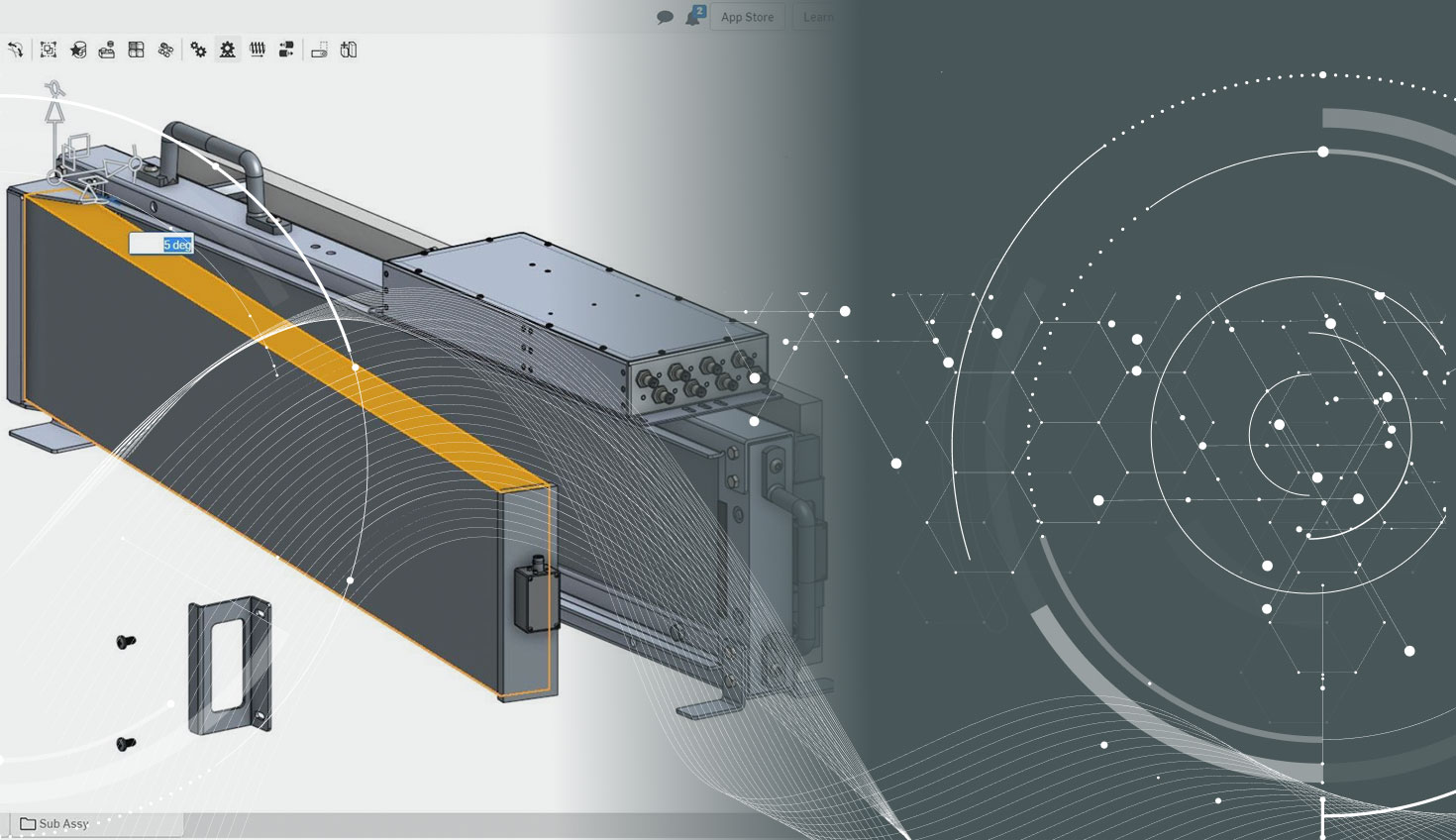

Silverside Detectors designs its compact nuclear radiation detection equipment in Onshape, the leading 3D cloud CAD platform with built-in data management.

As WIRED magazine reports, the U.S. government has been trying to boost the number of nuclear sensors since 9/11, but the best isotope for detecting radioactive “dirty bombs,” Helium-3, is too scarce to deploy at every border crossing, port and national landmark.

Based on Lithium-6, a metal highly reactive with neutrons, Silverside’s detectors are the next-generation of technology for sensing nuclear material, meeting performance standards at a fraction of the cost. The modular detector design allows plug-and-play integration in a range of detection systems, from ports to vehicles to backpacks.

By dramatically reducing the cost of sensors with more plentiful lithium, Silverside is making it possible to deploy radiation detectors at many more high-risk locations.

As Silverside Detectors co-founder and COO Sarah Haig puts it, her dream is “what if something doesn’t happen because our product was in the right place at the right time.”

“Silverside Detectors is genuinely making the world a much safer place,” adds Onshape CEO Jon Hirschtick. “We’re proud that Onshape is playing a role in speeding up the production of their nuclear radiation detectors and getting them deployed on the ground as quickly as possible.”

Silverside’s compact detectors can be discreetly installed in permanent locations or transported to high-risk events, such as a presidential visit or the Super Bowl. (Image courtesy of Silverside Detectors)

Onshape’s Approach to In-Context Design

Silverside VP of Hardware Engineering Philip Taber estimates that Onshape cuts his design time in half compared to his previous CAD system.

Taber adds that his design team also highly values Onshape’s In-Context Design feature, which allows engineers to edit parts in the context of a higher-level assembly without them unpredictably changing due to motion.

“With our previous CAD system, I had to be extremely cautious when editing moving parts because something would accidently break on me,” he says. “With Onshape, the software gets out of my way. It lets me make these changes and everything just works.”

Developed with funding from the Department of Defense (DARPA), Silverside Detectors is dedicated to the emerging needs of security agencies, law enforcement, and private infrastructure. The R&D company fuses expertise in detection physics, product engineering, and manufacturing to deliver a versatile building block for countering nuclear terrorism.

For more information on Silverside’s mission, watch this video from the Massachusetts Manufacturing Extension Partnership (MassMEP):