If you’re at the Pacific Design and Manufacturing 2017 conference today in Anaheim, California, please stop by the Onshape Agile Design Pavilion (Booth 3401) to see the first live demo of our soon-to-be released “Simultaneous Sheet Metal” tools!

If you’re unable to say hello in person, there’s good news. You can still get a sneak preview of Onshape Sheet Metal by watching this video.

Just on the heels of releasing In-Context Editing, which eliminates the pains of top-down assembly design in traditional CAD, the live demos will explore how sheet metal professionals can speed up their design process in the following ways:

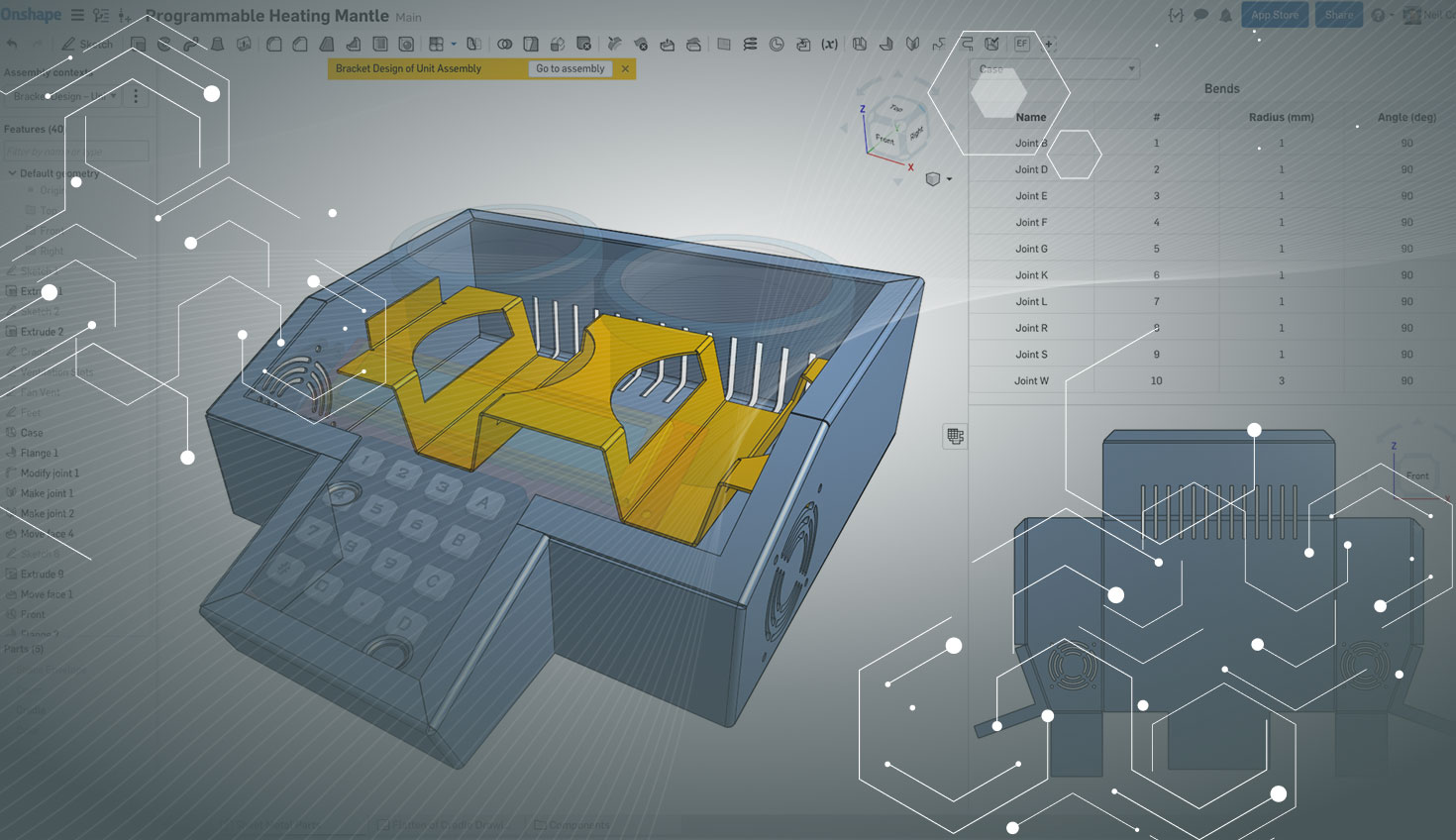

- Simultaneous Sheet Metal Views: Unlike traditional desktop-installed CAD systems that calculate flat, folded and tabular information in three separate unsynchronized views, Onshape shows all representations in one simultaneous view. When designers edit one view, the other two are synchronized automatically using Onshape’s full-cloud database architecture. Seeing the flat and folded views side-by-side allows you to visualize errors and interferences immediately, consider alternatives and ultimately, reduce scrap and wasted time.

- Editing Sheet Metal in Table View: The manufacturer can quickly change the parameters of a model in table view – such as the radius or order of individual bends – while preserving the original design intent and seeing the impact immediately on the flat and folded views. No other CAD system offers the ability to edit this information in an easily accessible table view.

Rethinking the Way Sheet Metal Gets Done

Take a look at the Onshape Sheet Metal screenshot at the top of this blog. Designers and manufacturers no longer have to bounce back and forth between screens to see how changes in one view will impact another view. Everything you need is right there in front of you. If you pick bends in the wrong place, you’ll see an immediate visual warning that the flat pattern won’t work and get the tools to fix it.

“Simultaneous Sheet Metal Views allow you to create your model easier with more flexibility,” explains Scott Harris, Onshape’s VP of Product Definition and User Experience. “Part of the beauty here is that you can start down one path and if things aren't right, you can just change it around without having to start over again. In fact, you can refactor your model by switching around rips and bends."

Principal software engineer Lana Saksonov, project leader on Onshape’s Sheet Metal team, notes that the new sheet metal workflow capitalizes on the unique collaboration capabilities of full-cloud CAD and brings designers and manufacturers closer together.

“Designers and manufacturers work on the same CAD models with different concerns,” she says. “Communication often breaks down, which sometimes causes manufacturers to completely rebuild models from scratch.”

“Our goal was to combine parametric tools for designing sheet metal with tools that allow manufacturing process-driven changes without violating the design intent,” Saksonov adds. “Onshape’s sheet metal functionality is able to automatically take care of details like corner and bend reliefs, letting designers focus on higher-level features.”

Meet Onshape’s Partners

Onshape’s application partners at the Pacific Design and Manufacturing conference, who share our mission of helping companies become more agile, include the following:

- MathWorks, the maker of MATLAB and Simulink, will show the power of combining mechanical design in Onshape with dynamic simulation. MathWorks will integrate a robotic arm designed in Onshape with electrical actuation, conveyor belts, and supervisory logic to optimize system performance.

- openBoM is a new cloud data collaboration tool to manage Bills-of-Materials (BOMs) and remove the pain of tracking product data spreadsheets across networks of engineers, supply chain managers and contract manufacturers. The company will be showing a preview of “BOM for Onshape Drawings,” an upcoming feature that will automatically update the BOM as changes to an Onshape design are made.

- SimScale is a cloud-based engineering simulation platform that makes FEA and CFD tools accessible to a much broader audience by removing the high-budget hardware and know-how requirements of traditional simulation tools. The SimScale team will demonstrate how to use Onshape and SimScale together to validate the flow characteristics of a vortex damper in different operating conditions. What would have required complex and expensive software and hardware five years ago, can now simply be done via a web browser.

- OneRender is a cloud-based render engine that creates photorealistic images from your 3D CAD models. OneRender will be demonstrating its full integration with Onshape and will be offering rendering consulting services to attendees.

- MecSoft develops CAD/CAM software for the CNC Machining industry. MecSoft will be showing a brand new cloud-hosted CAM add-on application to Onshape that allows the user to create 2 ½ Axis and 3 Axis milling cutter paths for Onshape part files. This product leverages the proven manufacturing capabilities of MecSoft’s desktop-based VisualCAM product running remotely on the cloud.

- Propel and Zero Wait-State – Propel is a cloud-based Product Lifecycle Management (PLM) software company. Zero Wait-State helps businesses implement PLM systems. The companies will be unveiling “CloudState for Design,” an integrated Onshape app to enable engineers, salespeople, partners and customers to simultaneously update 3D CAD models and instantly see how those updates impact their products. The integrated PLM solution will be available in the Onshape App Store in Spring 2017.

The Agile Design Pavilion is also sponsored by Amazon Web Services, which provides Onshape’s global network of servers.

Early Praise for Simultaneous Sheet Metal Views

Onshape’s new sheet metal tools were created to streamline the collaboration between designers and fabrication shops. Product developer Wes Johnson calls the new capabilities “amazing.”

South Carolina engineer Wes Johnson, co-founder of Parmetric, a new rapid prototyping service, has been one of Onshape’s early visibility testers for sheet metal. His company is devoted to helping product designers get parts made faster and easier than ever before.

“The live flat-pattern view and bend table is simply amazing,” he says. “This paradigm emphasizes designing parts, versus designing just geometry. From a manufacturing perspective, this will greatly reduce the headache of going from CAD design to finished parts for both part designers and fabrication shops.”

Parmetric will soon be offering a sheet metal app in the Onshape App Store that allows designers to get automated quotes for their parts, select materials and finish options, and finally order the parts.

Onshape’s new precision sheet metal features will be made available to all full-cloud CAD users in the next release. You can watch the video now!