4:13

Theo Richardson, Founding Partner and Director of Development at Rich Brilliant Willing (RBW), recently faced a looming issue as his Brooklyn-based decorative lighting company matured — they needed to figure out the best way to streamline the flow of information between customer orders and installation.

RBW gives architects and interior designers the ability to customize and configure orders for unique lighting fixtures in offices around the world. Adding in voltage protocols that adhere to lighting industry standards, the company was dealing with a choppy information stream all the way from design to manufacturing.

“Our products, which are modular and highly configurable and customizable, are, in essence, a big data management challenge to be able to provide those solutions,” Richardson told Dave Corcoran, Head of Products at Onshape, and James White, VP of Digital Innovation Research at Tech-Clarity, during an Onshape webinar, “Transforming CAD Data Management.”

From left: James White, Theo Richardson and Dave Corcoran

To solve this issue, Richardson and his team adopted Onshape in early 2020, joining the growing number of companies moving to cloud-native systems.

Going with the Data Flow

It is important for RBW’s teams to “have a continuous, seamless information flow” to fix issues along the production line. With Onshape, the team is able to quickly update information without waiting on other processes.

“We can create a change request, update, CAD, and then simultaneously push that to ERP. And back to other entry points of that data stream,” Richardson said. “The reason why we moved to the cloud was because we were looking for a tool that could do both our CAD data and add a layer of control for versions and revisions.”

In the past, product data management (PDM) software tried to contain and control data by only letting one user have access at a time, Corcoran said.

“That really restricted, you know, visibility, you didn't really know what was happening until it got checked in again,” he said. “So there were these big gaps in knowledge, plus the gap of ‘I don't know,’ you know, ‘do I have the right data or not?’”

Cloud-native data management systems can remove that uncertainty.

Trek, a global leader in bicycle design and manufacturing, is on a journey to migrate to cloud-native systems, including Onshape, in order to increase their efficiency and agility. This mindset allows the design and manufacturing teams to pivot and meet the demand for more bicycles last year despite an expected downturn in demand, Corcoran said.

“They thought they were going left, [then] very suddenly, they'd found out they had to go right. And they were able to do it very, very quickly,” Corcoran said. “One of the key things is being able to react quickly, like being able to get a steady stream of information and process it and have it affect what you're doing.”

Easing Collaboration with Better Access to Data

Cloud has been the technology enabling remote work, coping with travel restrictions, meetings, and more, giving businesses the ability to look forward, White said.

The RBW team fully switched to Onshape in March 2020, easing the transition to remote work without breaking stride. “This cloud-based working method feels so much more natural to use,” he said.

With Onshape, RBW is now able to easily share project information with third-party contractors and freelancers without having to dole out licenses or go through an internal IT team, Richardson said. New collaborators were able to onboard quickly and work on a project simultaneously with the RBW team.

“We didn’t expect how far along we would get in our digital transformation journey and being able to then expand our vision,” Richardson said.

Corcoran shared an example from Dixie Iron Works, a Texas-based oil field flow control equipment manufacturer. For Dixie Iron Works, switching to cloud-native product development tools wasn’t about having “to be on the cloud,” but trying to become more responsive, have less downtime, and less miscommunication.

“It's really about being able to access data more efficiently, being able to communicate more efficiently knowing you're working on the right thing,” Corcoran said.

Better Data Management Begets Better Time Management

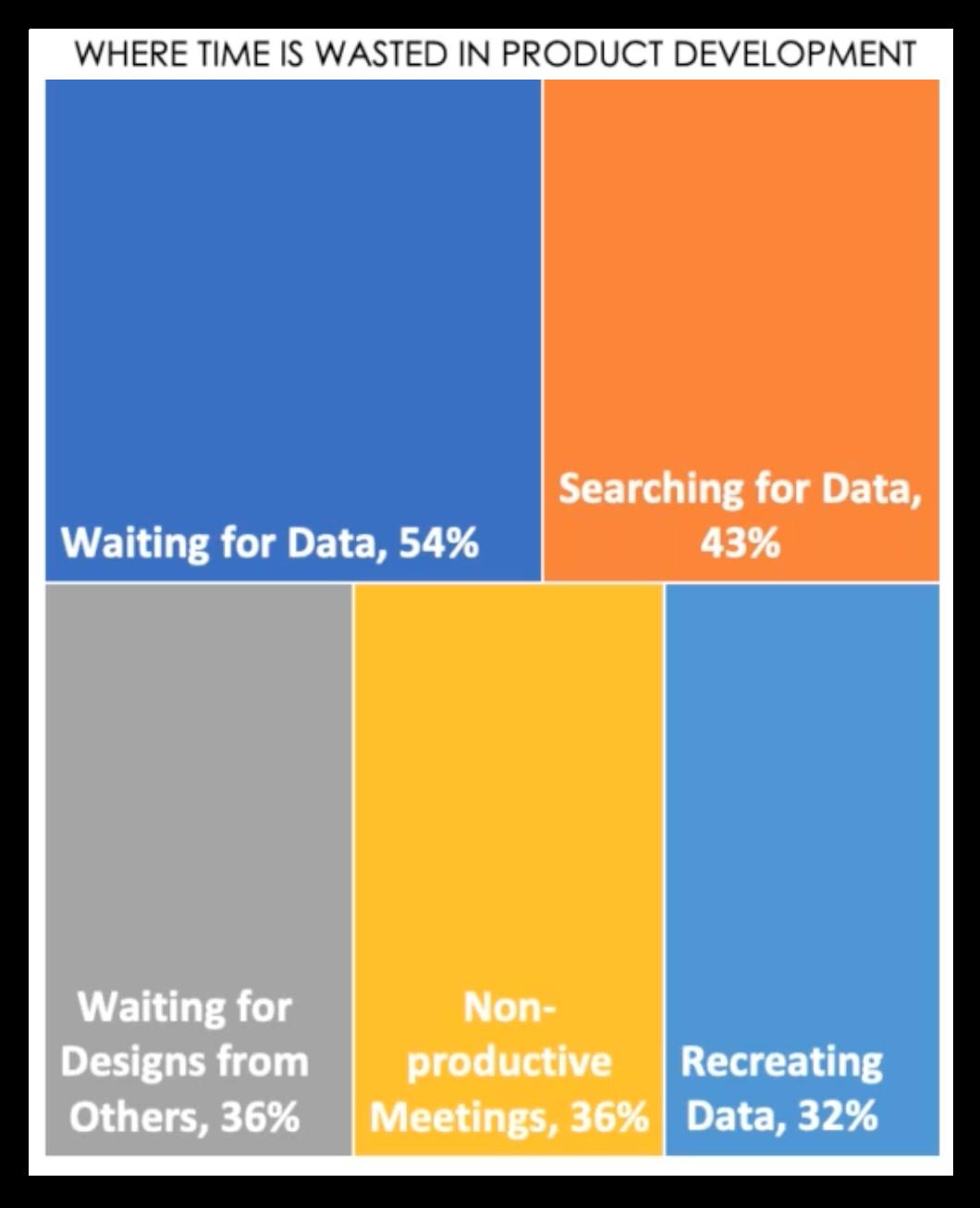

Tech-Clarity research shows that 47% of an engineer's day is spent doing productive value-added work. The other half includes these top time-wasters: waiting for data, searching for data, waiting for designs from others and non-productive meetings.

The top time wasters reported by engineers. Source: Tech-Clarity

“One of the things that's different about cloud technologies is that you can always have access,” Corcoran said.

And more firms are catching on. According to McKinsey and Company, 85% of business leaders said they have advanced their digital strategy to better employee collaboration and communication.

“The cloud is enabling and freeing up more time,” White said. “That means engineers and designers can do more innovative thinking and create better designs, which is better, all the way down into revenue and commercial success.”

Get more insights on how cloud technologies are changing collaboration and data management. Watch the full webinar, “Transforming CAD Data Management.”

Latest Content

- Case Study

- Industrial Equipment & Machine Design

Reframe Systems: Transforming Homebuilding with Digital Automation and Cloud-Native Onshape

09.25.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more