8:22

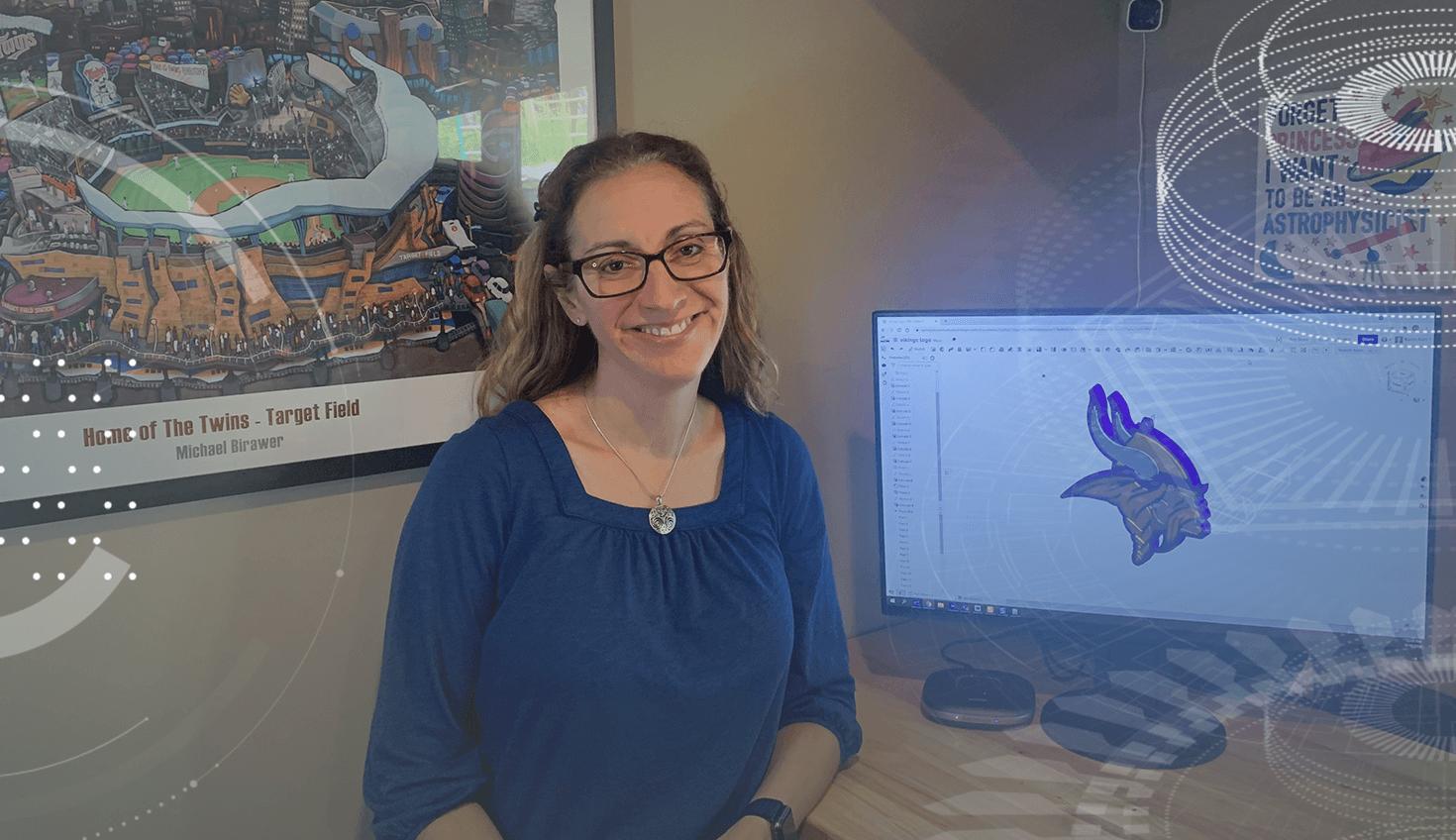

When Karen Kutz (rhymes with boots) left the corporate world after more than 20 years, she had no way of knowing that her expertise – teaching adults a management system that leads to improved manufacturing processes – would translate so well to launching once technology-shy kids on a STEM path.

Kutz teaches two courses at Spring Lake Park High School near St. Paul, Minnesota, in her role as a Technology Engineering and Design teacher. By freshman year, certain students already know they’ll be using CAD in their future careers. For them, her yearlong “deep dive” Introduction to Engineering Design course offered in conjunction with the national nonprofit Project Lead the Way is a given. PLTW helps STEM teachers in all 50 states better prepare kids for college and careers by exploring real-world challenges.

And then there are the approximately 250 students (grades 9-12) who take her trimester-long How to Make Almost Anything (HTMAA) classes each year. Many of these kids are placed in class to meet an elective requirement needed for graduation. They’re more anxious about STEM and their ability to use technology. These are the kids Kutz had in mind in 2018 when she, as a first-year teacher, helped design the class for the school’s inaugural Technology, Engineering and Design (TED) Pathways Program.

Spring Lake Park High School is on the trimester system, which typically means there are three sessions in one school year: fall, winter and spring.

Kutz’s How to Make Almost Anything classes are open to all students — not just STEM-oriented kids.

The kids taking the HTMAA class remind Kutz of herself. “When I was growing up, I never thought I was good at mechanical stuff. In middle school, I’d taken an aptitude test that said I didn’t have good mechanical reasoning. I always thought physics and engineering were not for me,” she says.

She knows how such early, erroneous messaging can close down opportunities for certain populations and is devoted to contributing to more diversity in engineering. She learned of her own natural aptitudes by chance through her decades at Medtronic, a medical device manufacturer. She began in customer service, moved into IT, and then switched to operations, where she became an instructor of Lean Six Sigma, a management system of continual process improvement made famous by Toyota and Motorola. She loved mentoring people in the STEM fields, but the relentless travel led the mother of two to pursue her earlier ambition of becoming a teacher.

With her own experiences in mind, Kutz designed the TED exploratory class “to try and hook kids on the idea that they might be interested in STEM and engineering, even if they don’t think so coming into it.” The “hook” is a project of their own choosing designed in PTC’s Onshape, a cloud-native CAD software, and then 3D printed. By the end of class, many students find their anxiety is gone; their curiosity is piqued.

“Then we can get them into Introduction to Engineering Design, and we can start to move them along the TED Pathway,” Kutz says. “That’s super rewarding.”

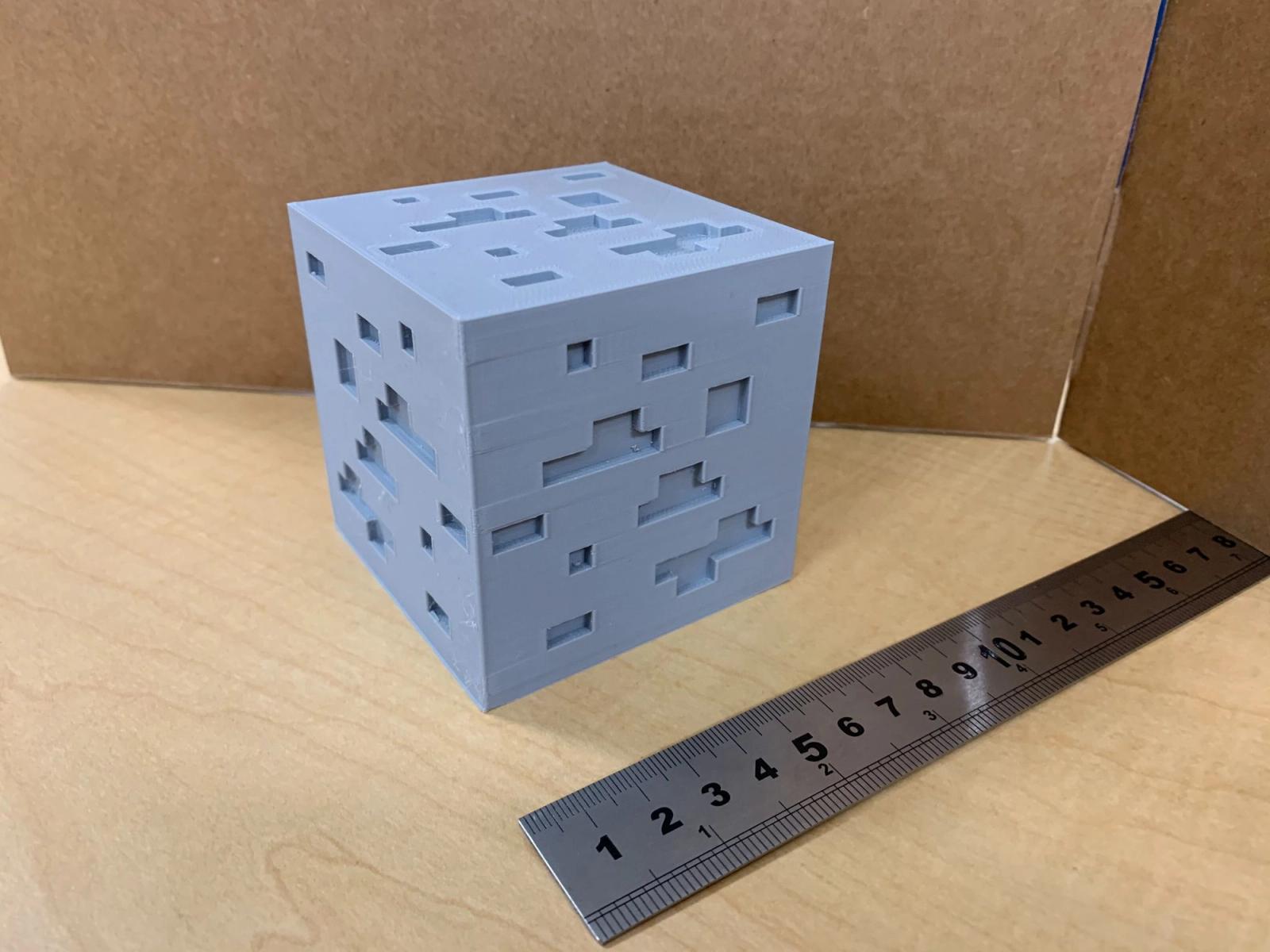

A Minecraft cube by one of Kutz’s students.

Cloud-Based CAD the Key to Imagination – and Opportunity

For Kutz, teaching students the engineering design process and how to use CAD to solve problems is similar to teaching an adult workforce how to improve manufacturing efficiency. It’s all about being immersed in a continuous learning environment and following a set process to achieve results. In engineering, that’s defining the problem, researching the problem, proposing and designing a solution, building a prototype, and then testing and evaluating the prototype. And, for Kutz and the kids, having fun while they’re at it.

She doesn’t prescribe what the students should make. Instead, she encourages and supports them while they brainstorm a product that expresses who they are.

“I tell all my students, ‘You can be successful. You just need to follow and trust the process. Don’t worry if you don’t have the best idea right now or you don’t know how to solve the problem. Applying the process is what’s going to get you there.’”

HTMAA classes typically contain a high proportion of freshmen. Kutz finds the younger students often attempt riskier projects, keeping things fun. “I am amazed at the complexity of what some of them have been able to do with some basic instruction,” she says.

Examples of recent 3D printed projects include a mini fridge with a hinged door that opens and closes, a Minecraft cube, a trio of dancing figures on a textured platform, and a d20 (20-sided) die used for role-playing games.

A trio of dancing figures on a textured platform by one of Kutz’s students

She recalls a 10th-grader whom she’d been worried about during COVID because she hadn’t heard much from him. In the final month of class, he decided to build a chess set.

“I gave him a hint. I said, ‘You want to look at the Revolve tool when you’re making your chess pieces because they’re symmetrical.’” He completed all of the chess pieces and also created a wooden chess board with the school’s laser cutter.

One ninth-grader told Kutz he wanted to make keycaps for his computer. He was having difficulty learning Japanese and thought if he could see the Kanji characters it would help. Kutz told him to prototype a single keycap.

“He figured it out. He used the Loft and Shell tools as well as a lot of really cool features I hadn’t shown them in class,” she says. “But when he asked about them, I was able to steer him towards those tools.”

He now uses his computer with a full set of keycaps with the Japanese characters on top and the English characters on the sides.

It is due to such diverse and creative CAD projects that Kutz, known to her students as “Ms. K,” was recently awarded the First Annual Onshape Educator Award for 3D Printing.

Onshape Makes CAD Accessible Using School-Issued iPads

When the COVID-19 pandemic hit in the spring of Kutz’s second year of teaching, she didn’t have time to find a new CAD solution. She’d been using on-premise installed Autodesk Inventor, PC-based software, in the computer lab, and there was no way to send it home with the kids or access it remotely. As a result, that batch of HTMAA students focused primarily on learning the design process as opposed to using technology, building projects at home with duct tape and cardboard.

“Hopefully, they had a bit of fun and learned a few things,” Kutz says.

Students returned to the classroom in the fall of 2020, but on-site learning proved short-lived. That’s when Kutz discovered Onshape, a robust CAD system that could run on any computer, tablet, or phone (iOS or Android), including the school-issued iPads.

A keyboard with Kanji characters created by a student interested in learning Japanese.

The Onshape Education Plan requires no downloads or installation. As a Software-as-a-Service (SaaS) platform, upgrades are automatically added in the cloud every three weeks, requiring no IT support or downtime.

“I was super excited when I saw that. I quickly shifted gears,” Kutz says.

She created YouTube videos about using Onshape on the iPad so students could see how to maneuver on Onshape without needing to use a mouse. It was an easy transition for the kids, who were used to iPads.

In trimester three, the school moved to Onshape’s Education Enterprise plan, which further simplified issues that had been challenging due to the mixed-class environment (in-person, online, hybrid) during COVID. Just getting everyone signed on and set up could be a hassle, so moving to Education Enterprise with its single sign-on was key, Kutz says.

Many students also had a hard time correctly exporting their STL files for 3D printing.

“While I still try to help them learn how to do that because I think it’s an important skill, when push came to shove and we were having troubles communicating over long distance, it was easy for me to just go in and get their file,” Kutz says.

Along with Education Enterprise came improved teacher visibility into not just what but how the kids were learning.

“I was able to give an Onshape test or assessment to my students because I knew I would be able to see if there was any dishonesty. It gave me that level of transparency. It empowered me to help them become better at Onshape as well, because I could go in and see all of the moves they’ve made, how they’ve made a particular part, and if they did it in the most efficient way. That has huge benefits for learning,” Kutz says.

A student designed this mini fridge with a hinged door that opens and closes.

Some uncertainties linger for this school year, but for now, Kutz’s classes meet in person in a socially distanced computer lab with students able to work from computers and their iPads, which they can also bring home without having to worry about version control issues thanks to Onshape’s cloud-based platform.

Kutz admits that constantly adapting to the changing landscape of COVID has been difficult. But she likes that it forces her to constantly “think of new and better ways to make learning accessible for students. That goes back to my continuous improvement background. Now I feel like I have all these tools and modalities that I can choose from to create the best experience for students possible.”

For Kutz, Onshape’s iPad capability and Education Enterprise plan offer “indispensable” tools that, combined with the self-paced videos she’s created, maximize her most valuable one-on-one time with students just starting their STEM journeys.

“We’ve freed time up to do more value-add work where I’m helping them realize what it is they want to do and make,” she says. “It’s reduced a lot of anxiety for them and administrative heartache for me.”

Learn about the benefits of Onshape’s modern CAD platform and explore the two different Onshape plans available to meet your classroom’s needs here.

Latest Content

- Case Study

- Consumer Products

BOA Technology: Redefining Outdoor Fit Equipment with Cloud-Native Onshape

11.03.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more