3:52

Creating a complex three-dimensional shape in CAD can be a time-consuming task. Although Onshape has made modeling and collaboration considerably easier, designers who wish to incorporate accurate manufacturers’ models into their design still devote a considerable amount of effort into recreating them accurately. The effort expended remodeling standard components detracts from the amount of time that can be spent designing.

Having access to dedicated, pre-made 3D models of the components that are needed for a particular design, such as a standard parts library, can save a significant amount of time, allowing the design process to be shortened. Component manufacturers have long understood the importance of providing these models to customers, and many provide real-time and self-service access to their design data.

Most manufacturers choose to publish their models directly in a small range of neutral file formats. Neutral formats are designed to be universal, created to allow 3D information to be shared between companies and collaborators. Almost all 3D design software platforms enable the importing and exporting of neutral formats, but there are pitfalls of sharing this kind of design data that need to be considered.

While the accuracy of the 3D model is imperative, neutral formats cannot always be relied upon. Errors can occur as software systems translate neutral files, requiring the user to either perform additional checks, or discover these errors too late.

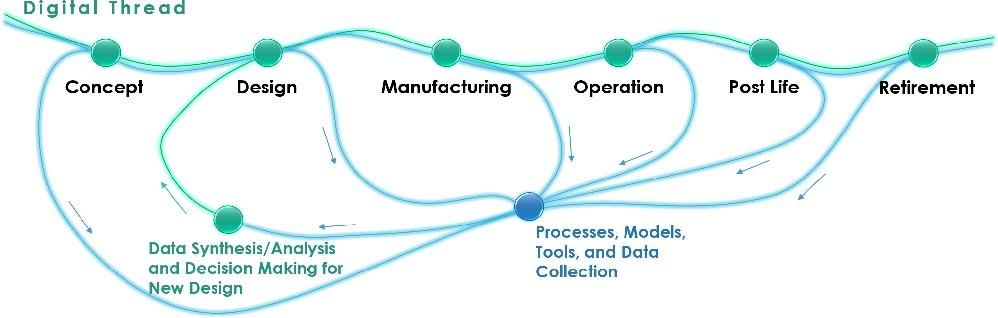

The Digital Thread and the Native Format

Another important aspect of product design is the digital thread. This is the record of the component and is woven through every stage of its life. The digital thread begins when a 3D model is incorporated into a design, but it depends on the correct information being available at the start of the process. Modern 3D CAD software can collate this data into a Bill of Materials (BOM), but the use of neutral CAD formats does not allow this information to be automatically integrated. The use of neutral formats requires the designer to enter this BOM data manually. Not only does this consume valuable design time, but human error also risks breaking the digital thread at the very start of the process.

Fortunately, there is an alternative to neutral formats: the native file format.

Models created using the native format will conform to all of the software’s internal rules and will contain all of the information needed to design it – along with a complete list of the components used. This guarantees the highest level of integration with design software and includes the correct data to maintain the digital thread throughout the lifetime of the design. It will provide a fully detailed BOM to help the procurement and purchasing process.

TraceParts Standard Parts Library Seamlessly Integrates with Onshape

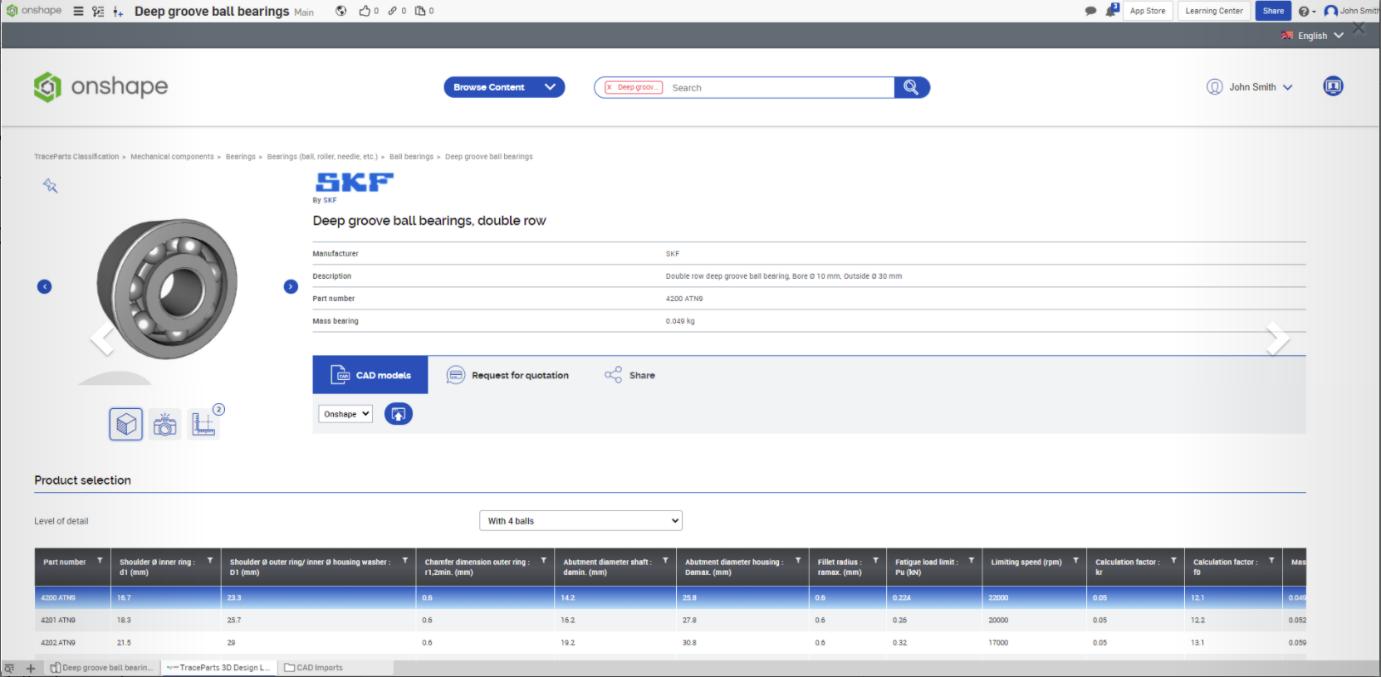

This is the functionality that Onshape has embedded into its cloud-based CAD and data management platform. Onshape’s new TraceParts native app, now available free in the Onshape App Store, provides users with instant access to the huge TraceParts standard parts library. This library offers 3D models of over 130 million part numbers of industrial components from more than 1,100 leading manufacturers.

The integration between TraceParts and Onshape is seamless. Once a product has been selected from the standard parts library, the user can view a real-time 3D preview of the model and its associated data and choose to insert it directly into the active design. The component is integrated into the BOM using the Onshape-native data format, immediately bypassing any concerns over compatibility or accuracy of the model. Because Onshape hosts the design as a database entry in the cloud, there is also no need for a conventional file download.

The TraceParts 3D Design Library user interface is seamlessly integrated into Onshape.

Onshape’s integration with the TraceParts library provides a powerful new tool to boost collaborative design. Users can share concepts and designs with colleagues or customers in real time around the world. The ability to quickly compare alternative solutions while viewing the model means that all participants can influence the design process. Whether this is part of the concept stage, the design cycle or even the sales pitch, this groundbreaking integration of online part catalogues with cloud-based CAD will revolutionize your design workflows.

With TraceParts, designers can save valuable time by eliminating the need to re-model existing components. Non-designers can also more easily provide input into the design, ensuring the best possible outcome for manufacturers and customers.

Subscribe to the TraceParts 3D Design Library for free directly from the Onshape App Store!

(David Pike is better known as Connector Geek. With nearly 30 years of experience in the world of interconnect, David enjoys helping engineers understand more about exciting engineering solutions.)

Latest Content

- Case Study

- Consumer Products

BOA Technology: Redefining Outdoor Fit Equipment with Cloud-Native Onshape

11.03.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more