03:55

We all know that CAD means computer-aided design, don’t we? But there’s also an alphabet soup of other computer-aided technologies with similar CAx acronyms, some of them being directly related to the CAD and PLM workflows.

Let’s take a look at one example, computer-aided engineering or CAE, which is also known as finite-element analysis (FEA).

What is CAE?

FEA is a mathematical method for understanding and quantifying how a model would perform under various physical conditions, more often than not eliminating the need to do these tests on a physical prototype.

Sometimes, as in the Onshape App Store, CAE is referred to plainly as “simulation,” although I prefer the term “modeling.” In any case, here are five reasons why it’s a good idea to leverage the CAD-CAE duo.

1. Get a Better Understanding of Your Product

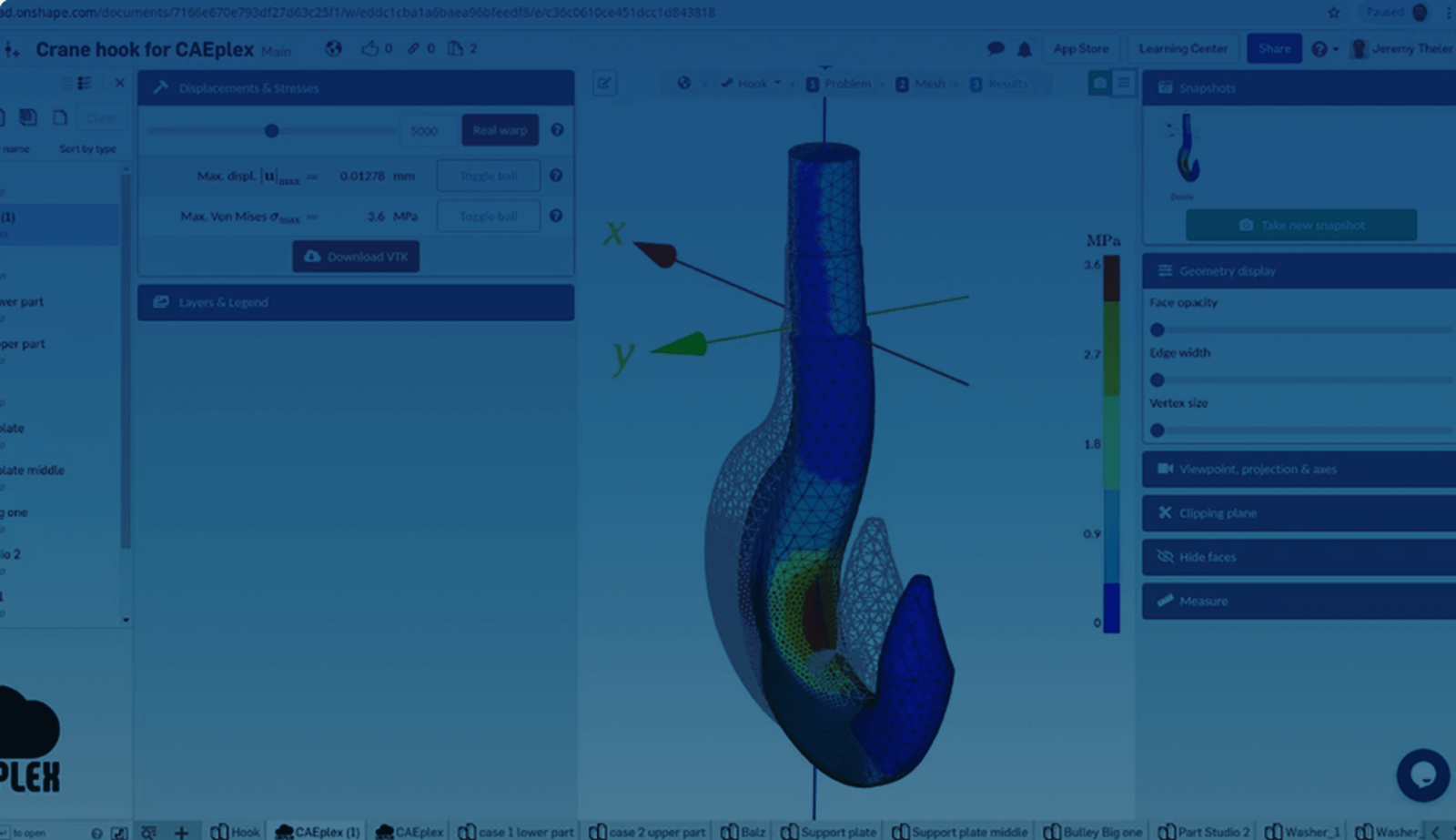

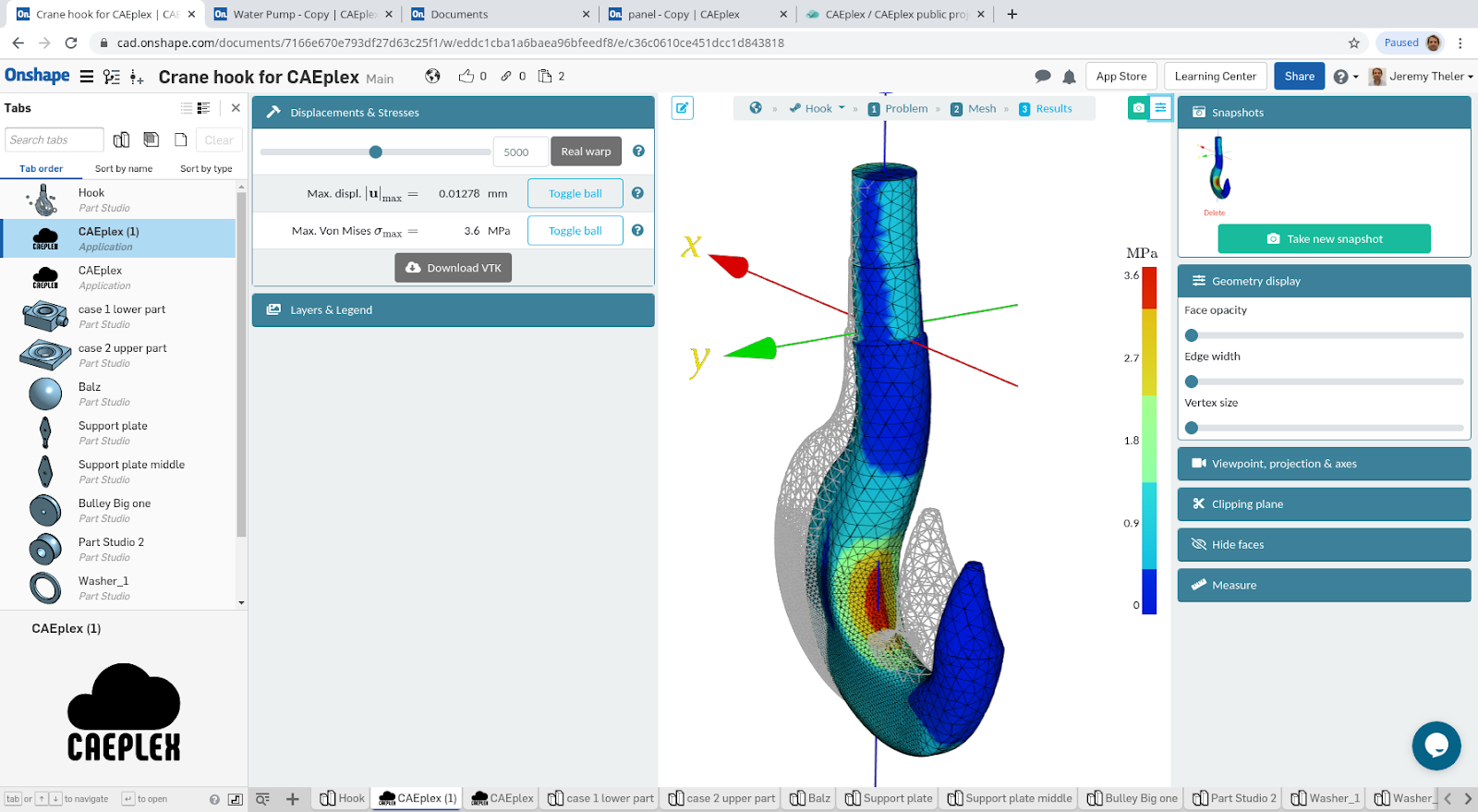

Let’s say you manufacture crane hooks and you design them with a CAD tool, hopefully from your web browser directly on the cloud. Do you know how many tons the hook can withstand? If you use the CAD-CAE combo, you can tell.

In the crane hook CAD model above, the red spot shows where the maximum stresses are and the scale shows the actual numerical values.

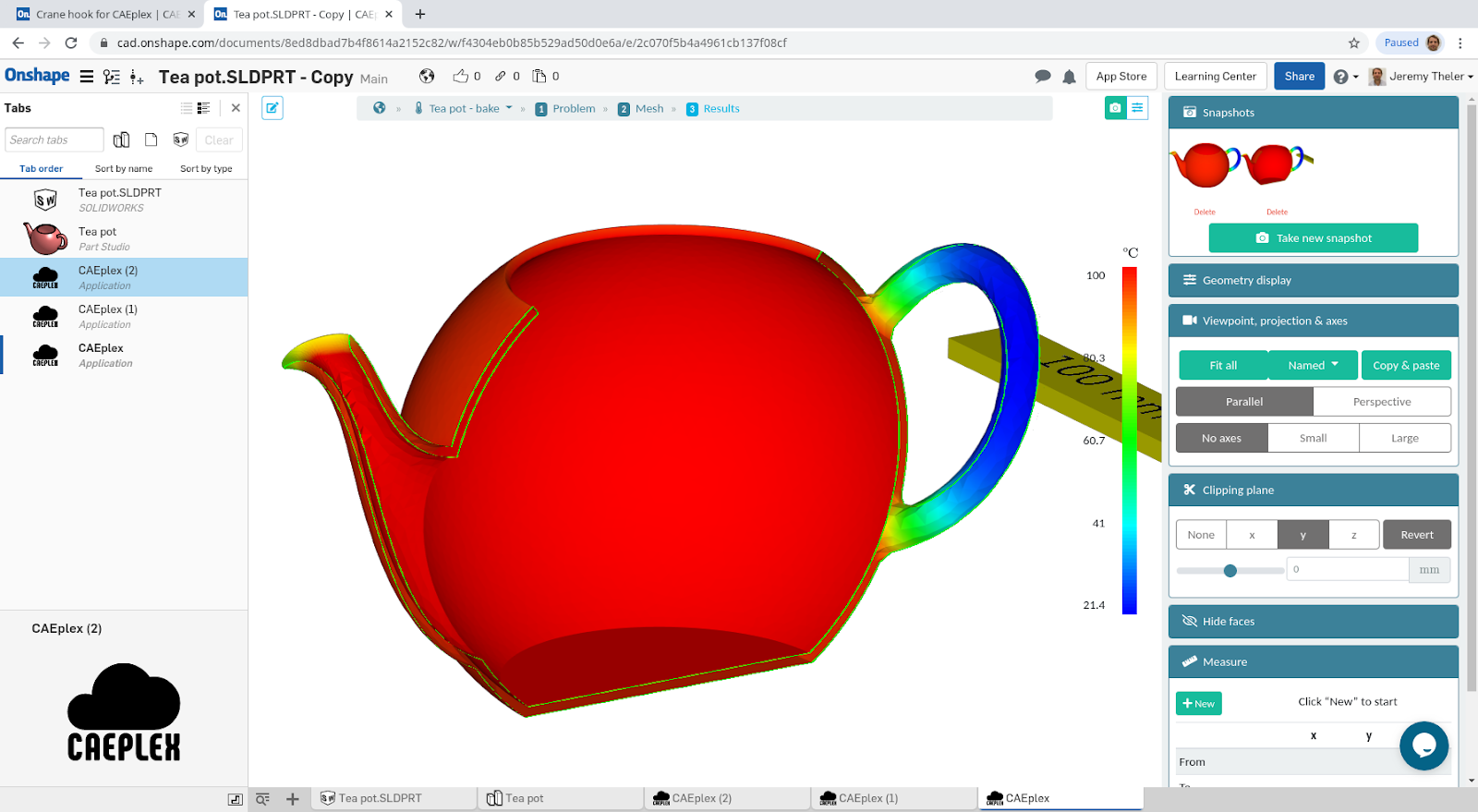

Or maybe you have designed a teapot from scratch. Do you know the temperature of the handle when the pot is filled with boiling water?

The inner surface of the teapot in contact with the boiling water is at 100ºC, yet the handle remains a couple of degrees above room temperature.

2. Reduce Your CAD-CAE Costs

Product Developer A has designed a hook crane in CAD and wants to sell it, but when the customer asks for its resistance, he cannot provide an answer. In contrast, Product Developer B used a CAE tool after CAD and can tell how many tons the hook can withstand.

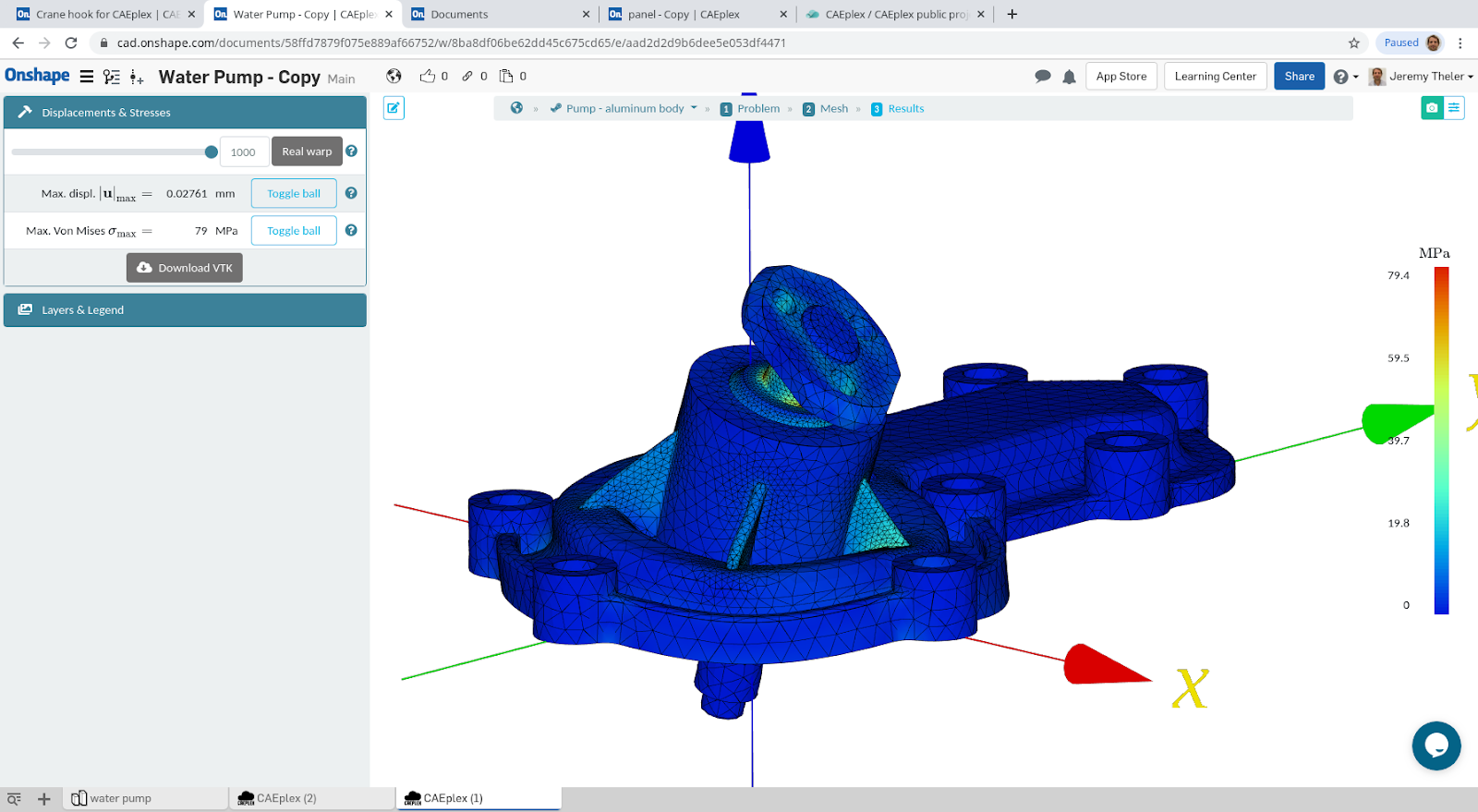

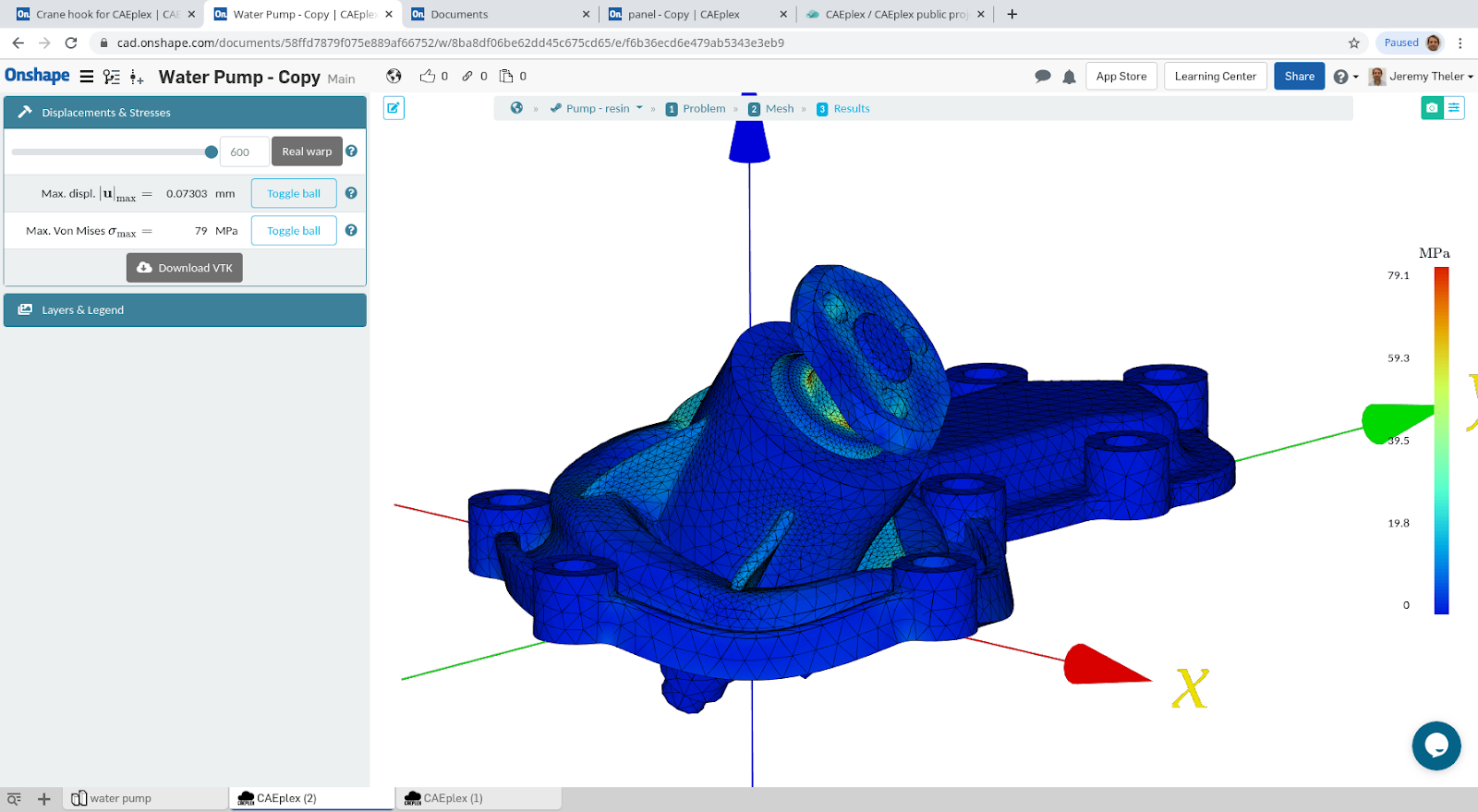

But how would your parts behave if the design changed a little bit in order to make the part cheaper? What if the body of a water pump for cooling an internal combustion engine was changed from aluminum to sintered polymeric resin? Would the new material resist the mechanical load from the belt through the pulley?

In the model of an aluminum car water pump above, we see exaggerated displacements and distribution of stresses due to the tension in the pulley.

CAE analysis for the same water pump made from a sintered polymer. The displacements here are a little bit higher than the aluminum pump, but the stresses are still within acceptable limits.

A few other questions to consider:

- Can some mass be removed from the casted body without significantly affecting the overall mechanical behavior?

- What if the water pump design changed so it would need fewer machining steps?

3. Improve Your Product’s Performance

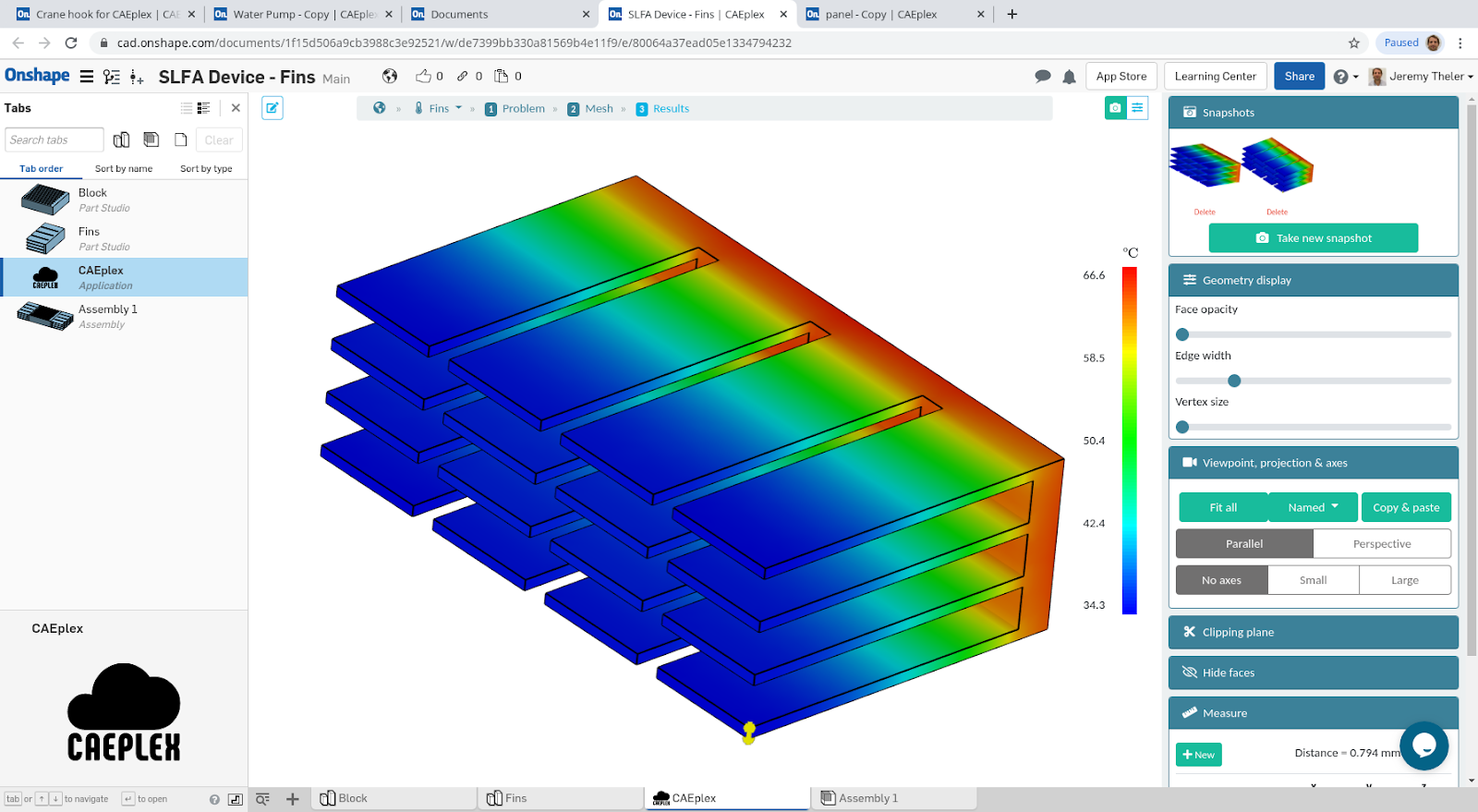

Once you know how your designs behave and how to reduce your manufacturing costs, the next issue to consider is performance. Consider electronic components that generate a lot of heat and need to be cooled. Looking at the fins below, are they dissipating heat using natural convection to lower the core temperature (i.e., removing thermal power) as much as possible?

This CAD-CAE analysis shows the temperature distribution for a set of dissipative fins in contact with electronic equipment.

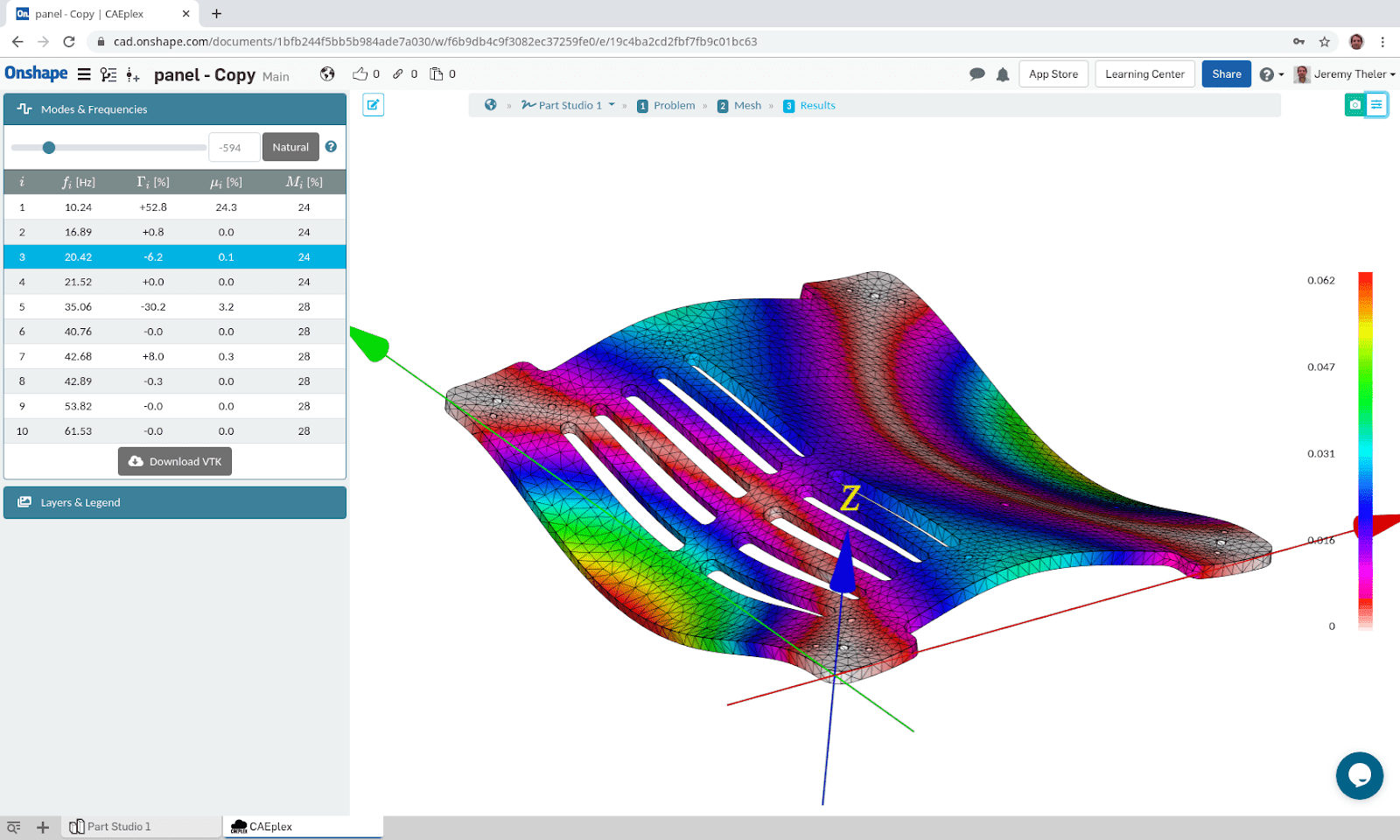

What if small protuberances shift the natural oscillation frequency of a panel such that it does not get excited by the rotation of nearby machinery?

The third natural oscillation mode of a panel fixed on the corner holes. The table on the left shows the frequencies and modal masses of the first ten modes.

4. Improve Your Career Skills

Developing your skills in computer-aided engineering will surely increase your value to your company and benefit your future career. If you are new to the world of engineering analysis, taking the small step from CAD to CAE can help your capabilities leap forward. And if you are already a seasoned analyst, adding CAD-CAE skills to your 3D modeling foundation will allow you to practice and recall what you already know.

There are plenty of sites, blogs and platforms that will enable you to either get onboard into the world of CAE or get in touch with other specialists to discuss theory and practice. For starters, I recommend the EnterFEA Blog and the Q&A site, SimShelf.

5. Because it is Quick & Easy

This is my favorite reason! If presented correctly, CAE is quick, easy and fun. Dive in and see for yourself:

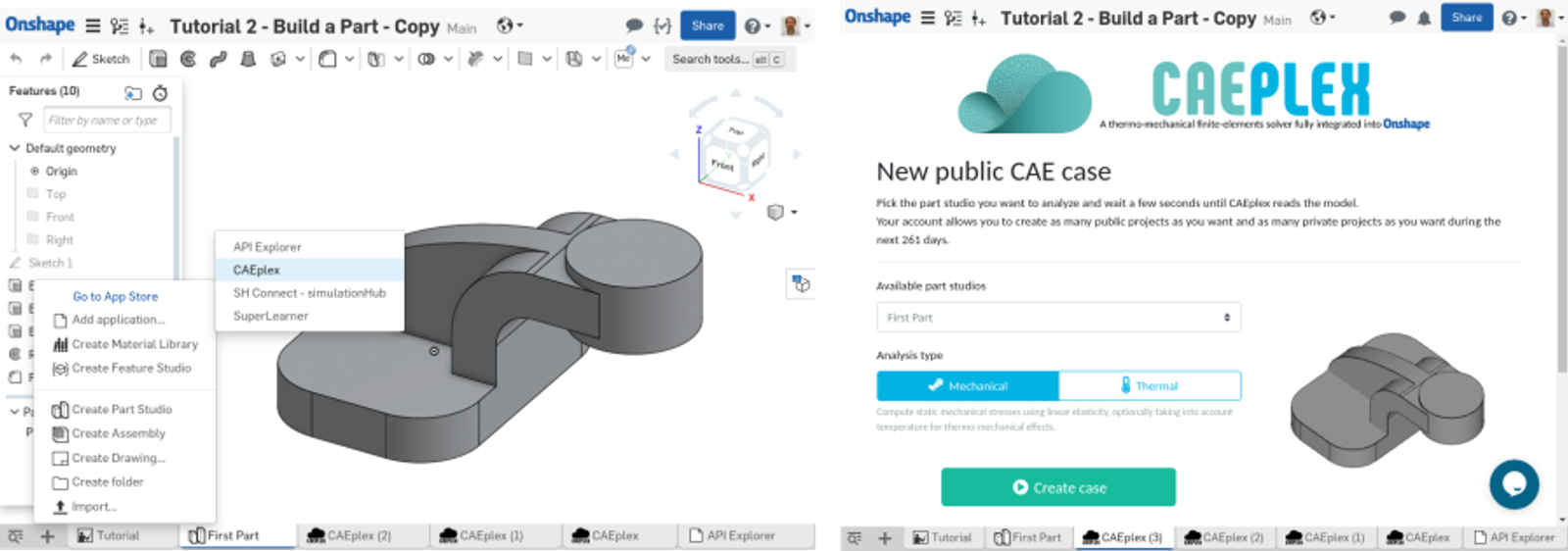

- Subscribe toCAEplex in the Onshape App Store.

- Open your part, click on the plus sign, select “Add application,” and choose “CAEplex.”

- Pick the Onshape Part Studio to analyze, select the analysis type, and click “Create case.”

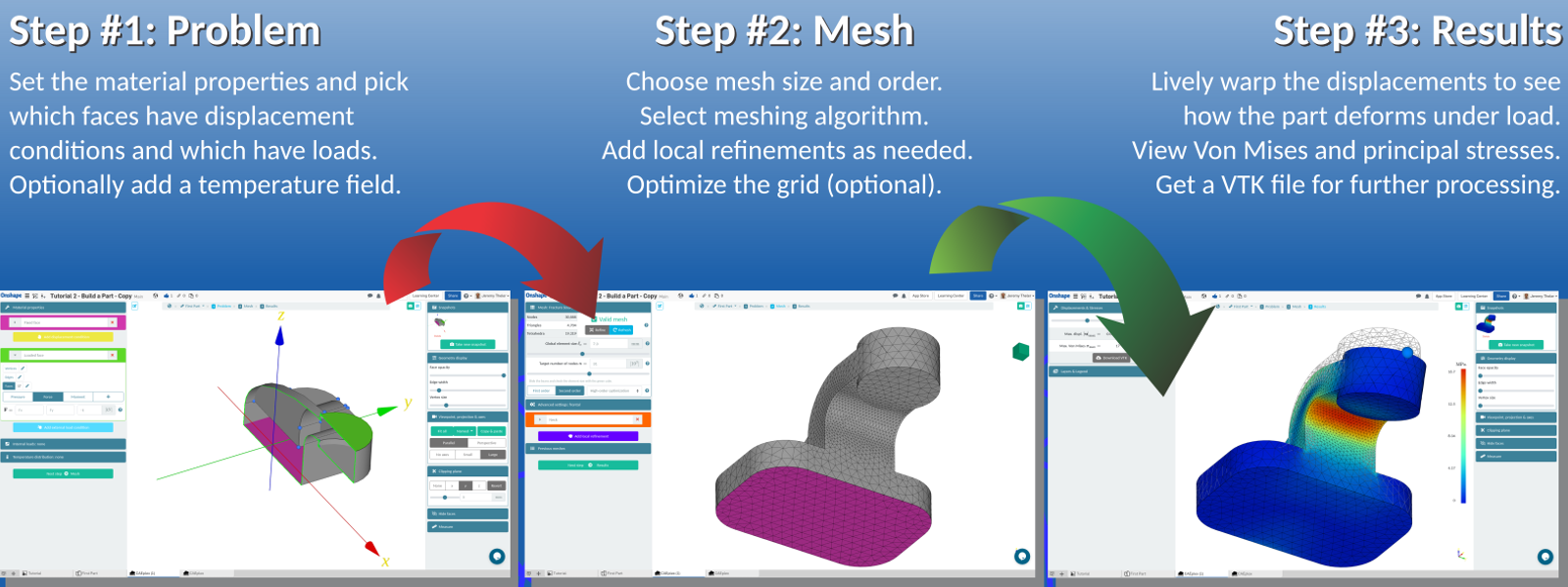

You can then obtain results in less than one minute (!) with CAEplex’s 3-step workflow:

To see the CAEplex app in action, watch the video below:

Happy computer-aided engineering in the cloud!

The Onshape App Store

Extend the power of Onshape with integrated cloud partner apps for PLM and more.

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more