The Challenge

OX Delivers, a UK-based e-mobility startup, is the creator of the first purpose-built electric truck for developing nations in the Global South. Their rugged vehicles are delivered "as-a-service" to enable businesses of all sizes to prosper where motorized transport is scarce.

In 2021, OX was seeking a cloud-native CAD and PDM system to speed up collaboration between its engineering and technician teams in England and Rwanda. When using its previous file-based CAD software, OX engineers experienced significant issues locating needed data and keeping track of their latest design versions.

Results

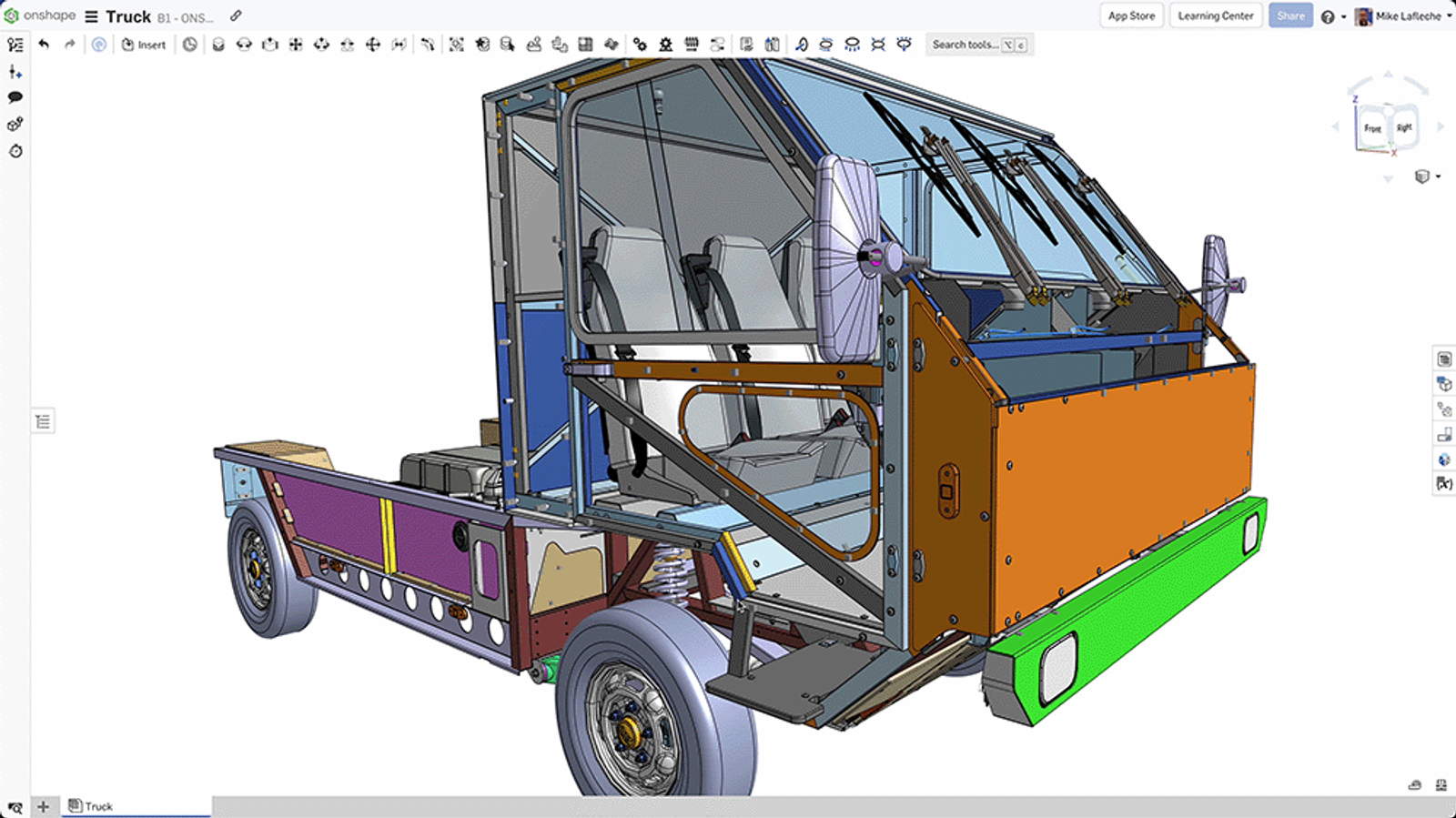

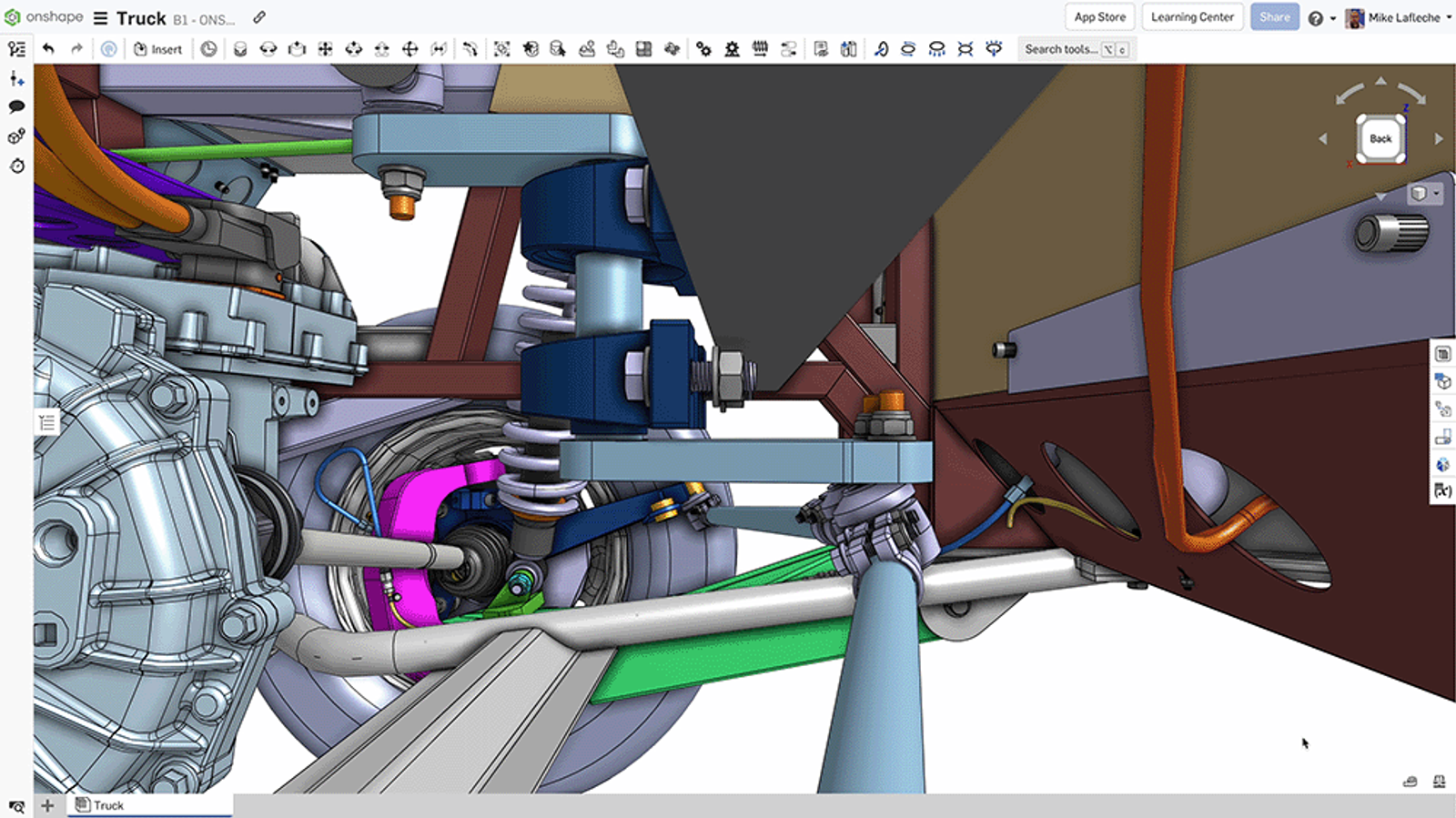

- Cloud-native Onshape’s Part Studios enables OX engineers to model product parts together organically in one workspace versus needing to create parts in separate files.

- Onshape’s real-time Product Data Management (PDM) allows everyone on the team to see design updates as they happen, without the hassles and delays of checking files in and out of a vault.

- Cloud-native CAD and PDM enables the OX engineering team to speed up communication with the company’s auto maintenance technicians in Rwanda as well as share design changes with non-CAD users who are important stakeholders.

Onshape's Part Studios makes it so easy to visualize and see all of the different components that will be interacting with one another further down the line. In our old CAD system, you had to make a part on its own. You could make it in some form of context, but it's never as intuitive as seeing it in the Part Studio.’’

Rwandan farmers have one of the toughest commutes in the world.

The landlocked East African nation is notorious for its mountainous, rocky terrain which makes it difficult for transportation between rural and urban areas. Much of the country’s agricultural harvest is still delivered from the fields to the marketplace by bicycle – with riders bearing up to a 100-kilogram payload.

OX Delivers, a UK-based e-mobility startup, is devoted to making that treacherous journey not only far less dangerous, but also more economically viable for Rwanda’s businesses.

OX has taken inspiration from other "as-a-service" sectors (e.g. AirBnB, Uber) and brings transport to the market via a pay-as-you-go business model. This enables lowering the price of motorized transport from thousands of dollars to buy a truck or hundreds of dollars to rent, down to less than $1 to transport a sack of goods.

At the center of the solution is the unique electric OX truck, the world’s first purpose-designed truck for the Global South, which is 10X cheaper to operate than existing alternatives. The company started with two dozen diesel trucks to prove its business model and is replacing their fleet with all electric trucks.

“Transport has been unaffordable for our customers due to a combination of second-life vehicles, poor road infrastructure and a lack of formal logistics options. We provide purpose-built technology that is affordable due to our as-a-service model,” says Natalie Dowsett, co-founder of OX Delivers. “Our customers pay for only the space they need and how far they need to travel on our trucks.”

“And the benefit of the electric powertrain doesn’t stop with the environment," she adds. "The trucks are also cheaper to run due to much lower fuel and service costs.”

Switching to Cloud-Native Product Data Management (PDM)

To design their electric trucks, OX Delivers relies on Onshape, a cloud-native CAD and PDM system that includes real-time collaboration and simulation tools. The company switched to Onshape in 2021, after sometimes experiencing difficulty locating the latest data with their old file-based CAD system.

“It was incredibly hard to find files in our old system,” says OX engineer Kristiana Hamilton. “It just wasn’t intuitive. There wasn’t any obvious place where things were stored. In Onshape, everything is stored in the same document. If you create a document that has the overarching assembly, you can have sub-assemblies within that.”

Hamilton also noted that her team was frustrated by the way traditional file-based PDM workflows slowed down the design process.

“One of the main issues was when you've got multiple engineers working on the same area and someone's checked out a part that you need to look at,” she recalls. “It just delays everything because you can't see it. You can't change the things that you need to change.”

“Whereas now in Onshape, because we can all work on the same document, it allows us to work efficiently,” Hamilton adds. “No one is blocked from doing their work. Onshape helps us stay running at a pace that is needed for a startup, whereas I think we would potentially run into a lot of problems doing that in a traditional software.”

Improved CAD Collaboration and Multi-Part Design

While the core OX product design team is based in the UK, they also have engineers on the ground in Rwanda. Being able to instantly share design changes and feedback between globally dispersed teams was another key motivation for the company to use cloud-native CAD and PDM.

“The anticipation is for our Rwanda team to grow and to employ local engineers,” Hamilton says. “We also can share our designs with local mechanics. So, if there are drawings that they need to see, they can just open Onshape rather than having to print out pages and pages. If we need them to fix something or to make something for us, we can easily just pop a laptop up and say, ‘This is what we would like.’”

“It's really important that we don't limit ourselves to being just within the UK because we want that diversity and we want to make sure that we're hearing voices from everywhere,” she adds. “That’s particularly important in engineering when the people you're designing for should have their input into design.”

Instead of the traditional CAD collaboration method of sending files back and forth through email or cloud storage sites, Onshape users can instantly see the latest design changes made by their colleagues. A comprehensive Edit History tracks who made which change and when, allowing users to revert to any prior stage of the design if desired.

Hamilton notes that her team also values Onshape’s Part Studios, which enables CAD users to simultaneously work on multiple parts in relation to one another versus having to model parts in individual files. As with all aspects of Onshape, the shared workspace also allows multiple engineers to concurrently work together on the same assemblies.

“Part Studios makes it so easy to visualize and see all of the different components that will be interacting with one another further down the line,” she says. “In our old CAD system, you had to make a part on its own. You could make it in some form of context, but it's never as intuitive as seeing it in the Part Studio.”

Embracing Agile Product Design

OX Delivers has a companywide commitment to Agile Product Design, a methodology to build products faster and with more innovation – strongly emphasizing rapid iteration, tight communication between a geographically diverse team, and an openness to embracing change.

The idea of Agile Development has already been widely adopted with great success in the software world and is now being adopted further in the automotive industry. Favoring “responding to change over following a plan,” the approach breaks down software development into short review cycles or “sprints,” with incremental product improvements being delivered at the end. Agile Development is a collaborative process, using customer feedback to determine the next set of tasks.

OX works in sprints, delivering incremental product improvements at the end of each cycle.

“Because we work in an iterative design process, Agile really lines up and helps with that. So going forward, the truck design will be continuously refined as we learn from the data collected in service,” Hamilton says. “And the idea is that OX parts are backwards and forwards compatible as well. So, we’re working in a modular structure within Onshape so that we can pull things off and update them as we go.”

Hamilton credits Onshape’s Technical Support team for helping OX maintain its fast-paced sprints.

“If you send in a support ticket, someone from Onshape will get back to you very quickly,” she says. “If your request is already in their backlog of things to update, they’ll let you know about it, and they’ll also let you know when things get changed. The team is very responsive.”

Expanding OX’s Global Vision

OX Delivers has developed a business model and transport solution that will be relevant across the Global South, and indeed many rural areas of the Global North. It will first expand its electric fleet in Rwanda to grow learnings and draw on current experience in the most efficient way, but ultimately, there will be few limits to OX Delivers' growth potential.

“Working for OX has really impacted my life,” says Hamilton. “I have a strong emotional connection to our mission, and it makes me want to work even harder.”