2:40

Safety regulations and requirements are stringent in the automotive, aerospace, defense, and medical device sectors. Nearly every company within these industries must furnish industry-standard reports, including inspection documents like AS91002 or PPAP forms.

Notably, while many CAD users are actively generating First Article Inspections (FAI), inspection reports, or ballooned drawings, a relatively small number have embraced software solutions to streamline these processes.

In this Tech Tip, learn how to initiate FAIs and other related reports using Onshape’s intuitive tools.

First Article Inspection and Dimensional Layout Reports

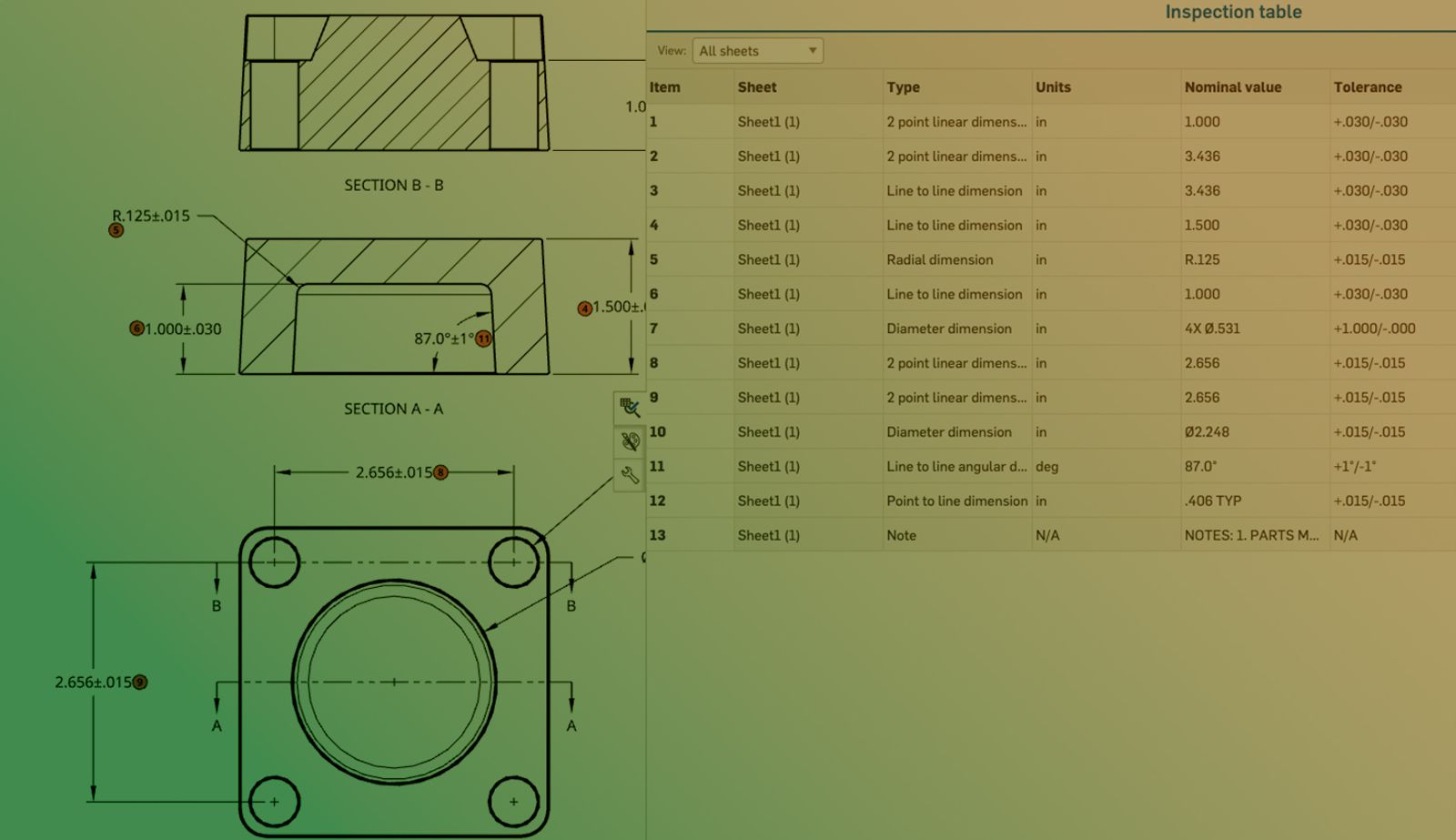

Onshape's built-in Inspection Item feature enables the First Article Inspection (FAI), significantly simplifying and automating ballooned inspection drawings and reports.

Unlike other CAD software packages, Onshape provides inspection item functionality without the need for any add-ons. By referencing the Inspection Item table, you can easily understand the inspection callouts defined on the Drawing. Engineers and designers can download these inspection tables into a spreadsheet for further use in manufacturing and quality processes.

Dimensional Layout Reports are lists that contain detailed information about a product's specifications, characteristics, and the results of its measurements. These reports also include an assessment that indicates whether each dimension has either “passed” or “failed” its specified criteria.

Inspection Items offer a versatile way to create reports with drawing annotations such as dimensions, GD&T frames, hole callouts, surface finishes, and more. Additionally, they can be applied to specific lines within tolerances or dimensions.

Apply Inspection Items to Drawings

In a Drawing, select Inspection Item on the toolbar to use the Inspection Item feature. This action triggers an interface that provides the next sequential number, text height, border shape, and size.

To attach an Inspection Item, hover your mouse over the annotation or callout to which you would like it associated, then click to activate it, and place it where needed. This links the Inspection Item effectively, allowing it to move as a group.

For individual item edits, right-click on the item and select Edit. This opens an interface that is specifically related to that item.

If you wish to adjust the default display settings for the entire Drawing or the Drawing template, you can make those changes by editing the inspection options in the Drawing properties.

Create the Dimensional Layout Report

The Inspection Item table provides a comprehensive view of assigned and unassigned dimensions in the Drawing. It has columns for sheets, types, units, and various values.

You can filter the view by displaying values across all sheets or focusing solely on the sheet you are currently viewing. As you assign inspection numbers to dimensions, you will notice they automatically arrange themselves in sequential order in the table.

Lastly, the Inspection table offers the convenience of exporting data to a CSV file. Notably, this export only includes assigned item numbers, even if unassigned dimensions are in both your Drawing and table view.

You can export the Inspection Item list as a CSV file that inspectors can use. This CSV file includes item numbers, annotation types, nominal values, units, and upper and lower limits.

Take a look at these tips in action by watching the video below:

Interested in learning more Onshape Tech Tips? You can review the most recent technical blogs here.

The Onshape Learning Center

Take self-paced courses, get technical briefings, or sign up for an instructor-led training session.

Latest Content

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more