1:56

If you are a designer, you should be familiar with the rules for creating fillets:

- Create structural fillets before finish fillets

- Create shell features after fillets

- Create draft features before fillets

- Create big radius fillets before small ones

But what types are available in Onshape? How do you know which type to use?

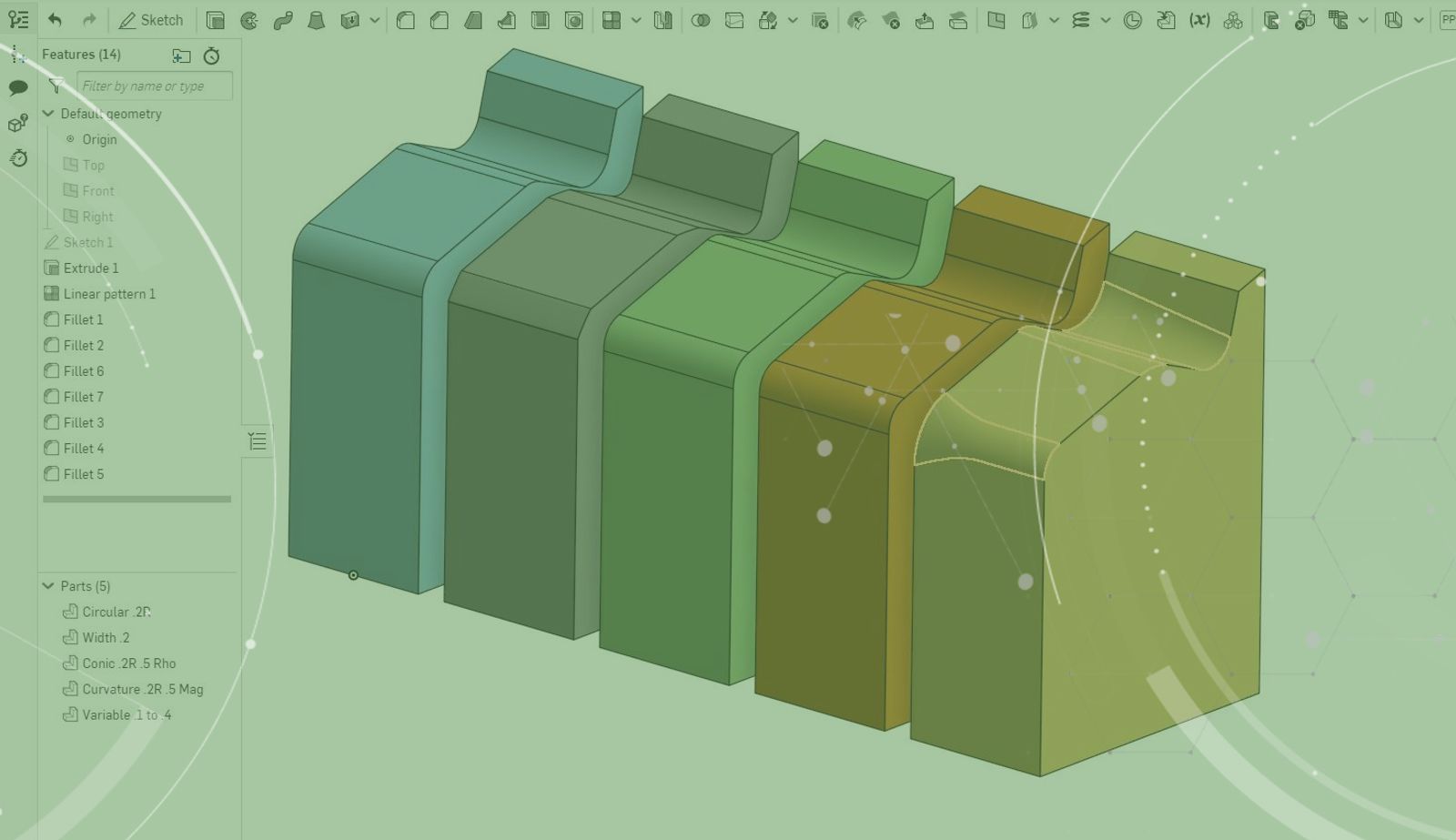

Constant Radius Fillet

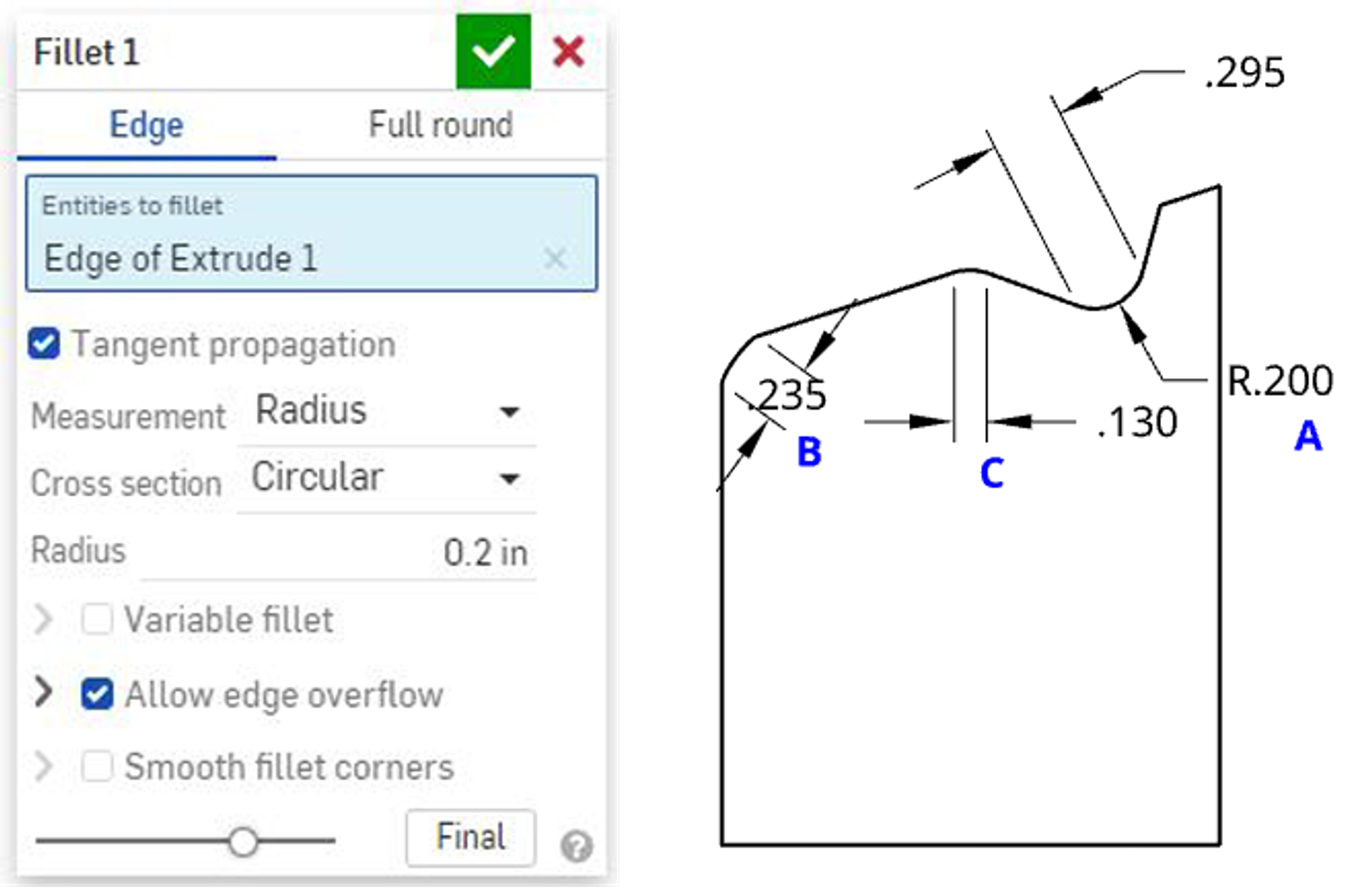

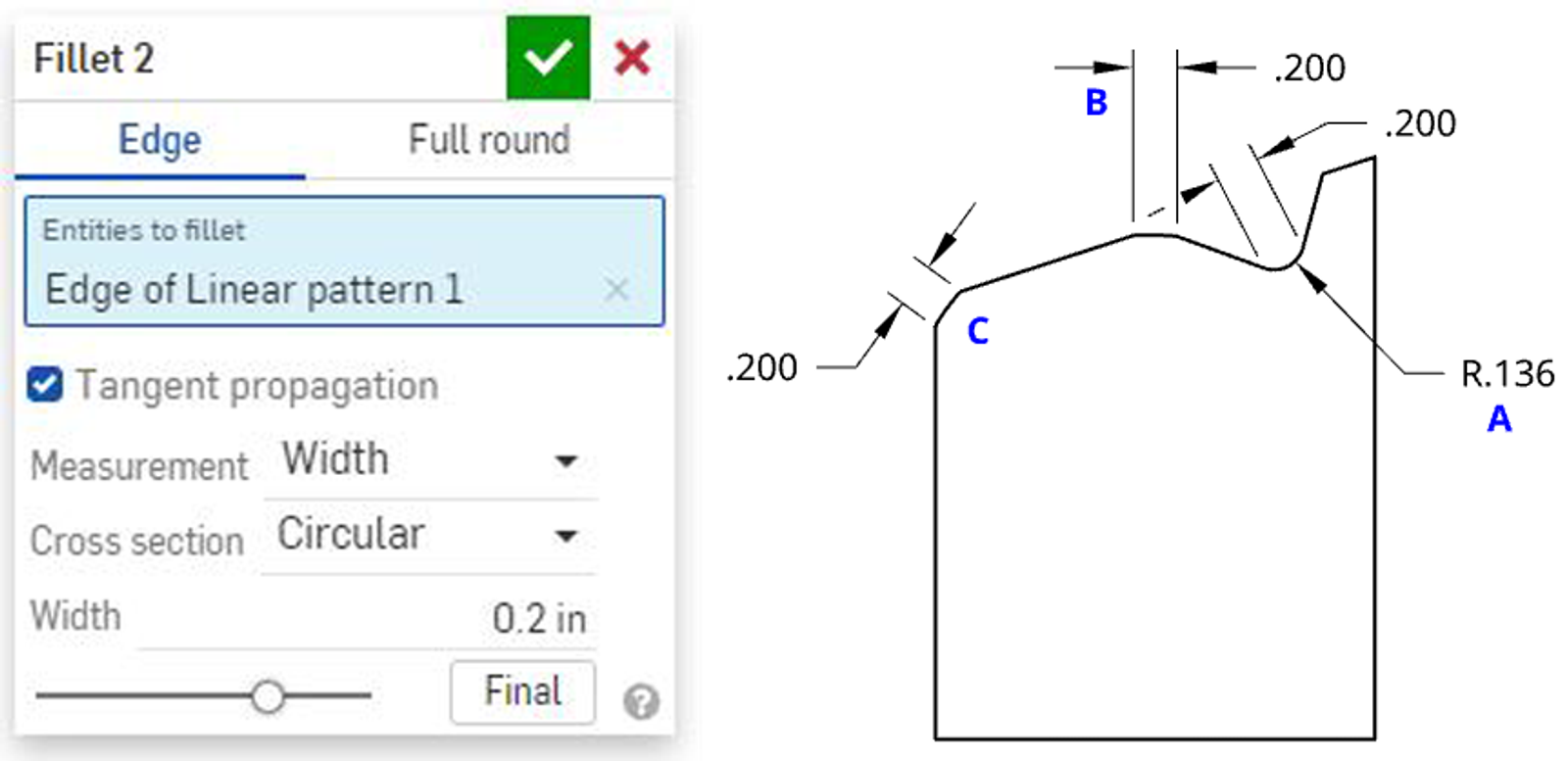

When using a radius measurement type fillet you input the radius of the fillet you are creating. You can then choose the shape of the fillet profile.

Circular (A) – The radius is an arc that can be dimensioned on a drawing.

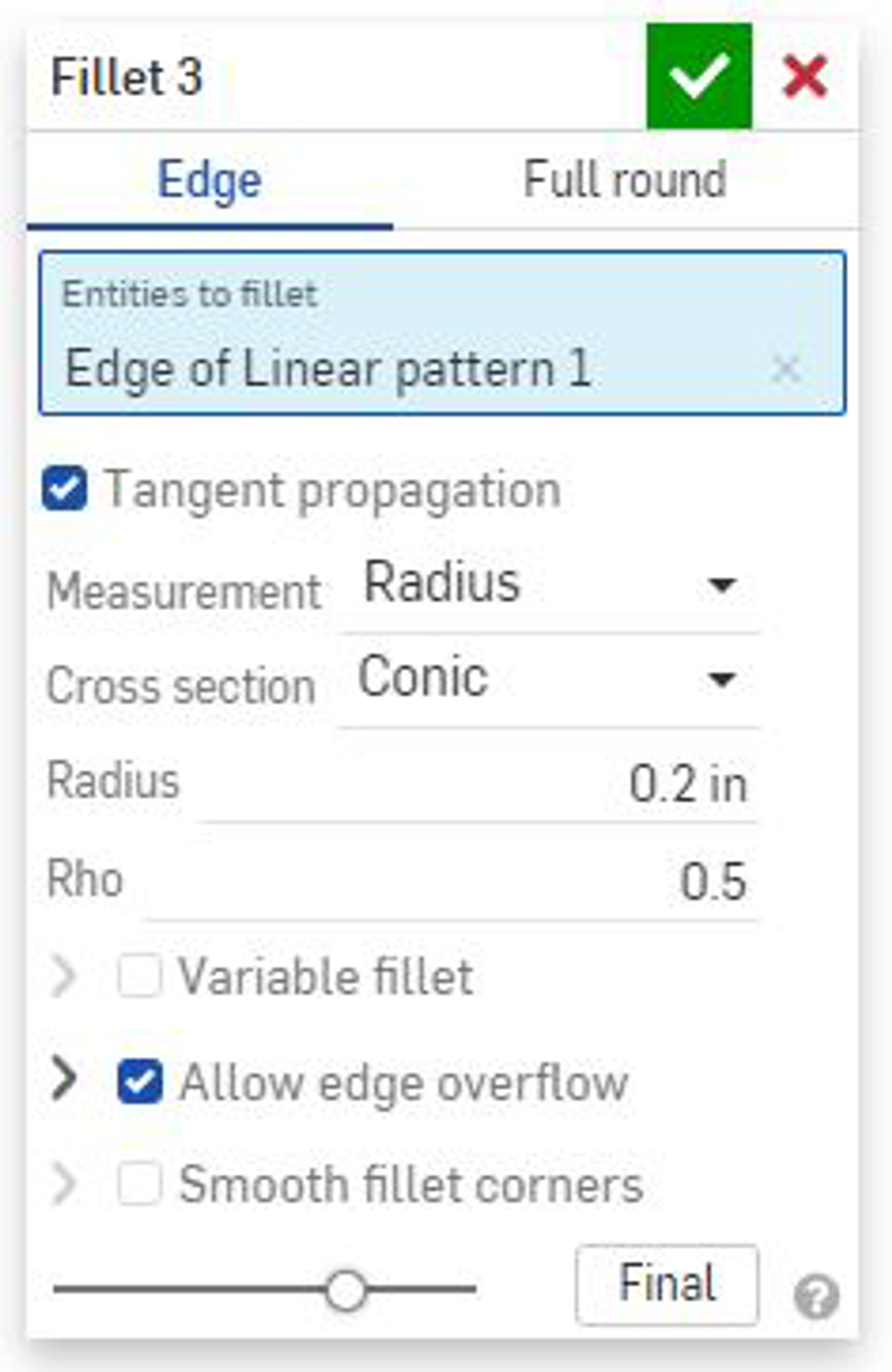

Conic Fillet (B) – The radius is a radial measurement and a Rho value is used to determine the shape of the curve, elliptical (Rho < 0.5), parabolic Rho = 0.5) or hyperbolic Rho > 0.5).

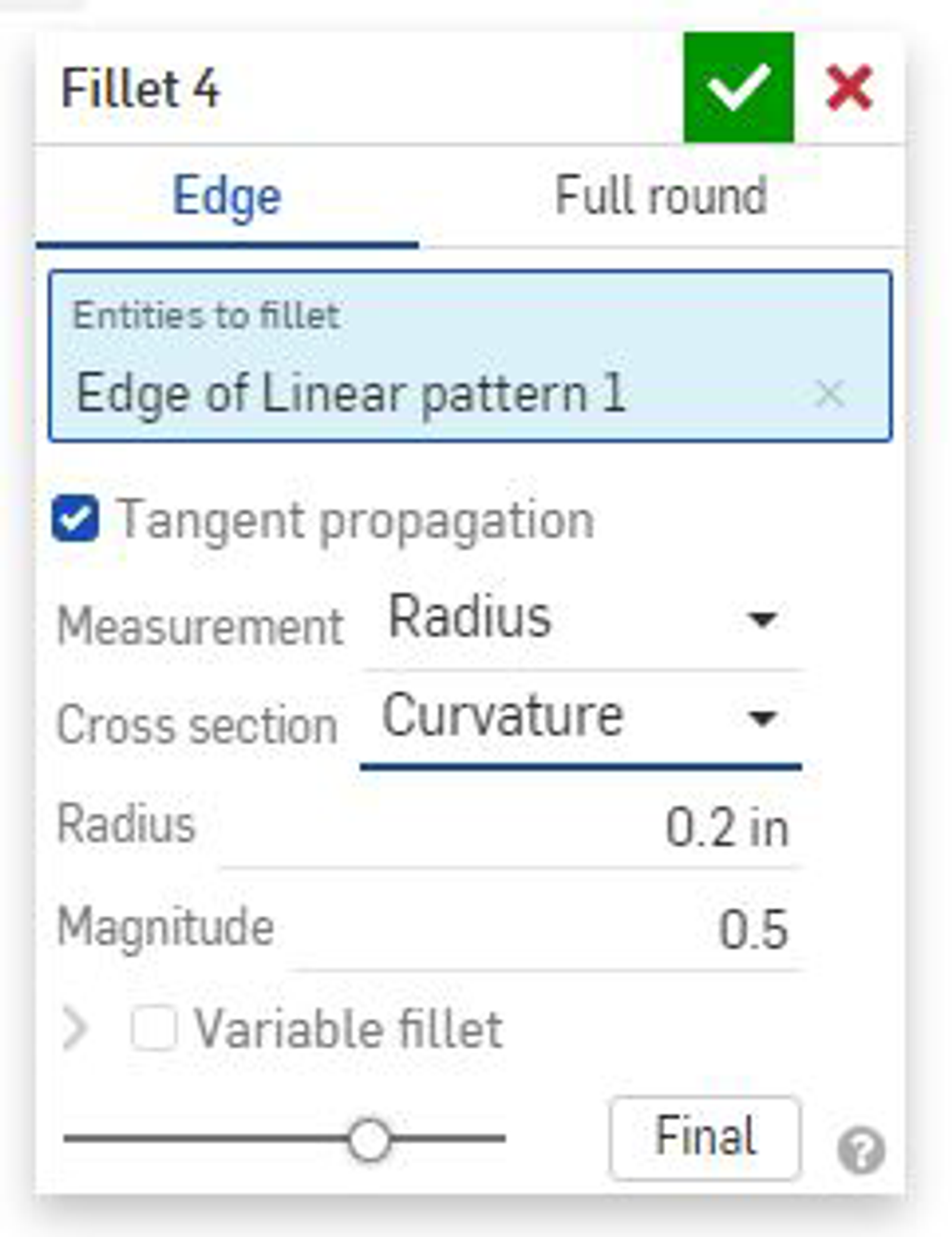

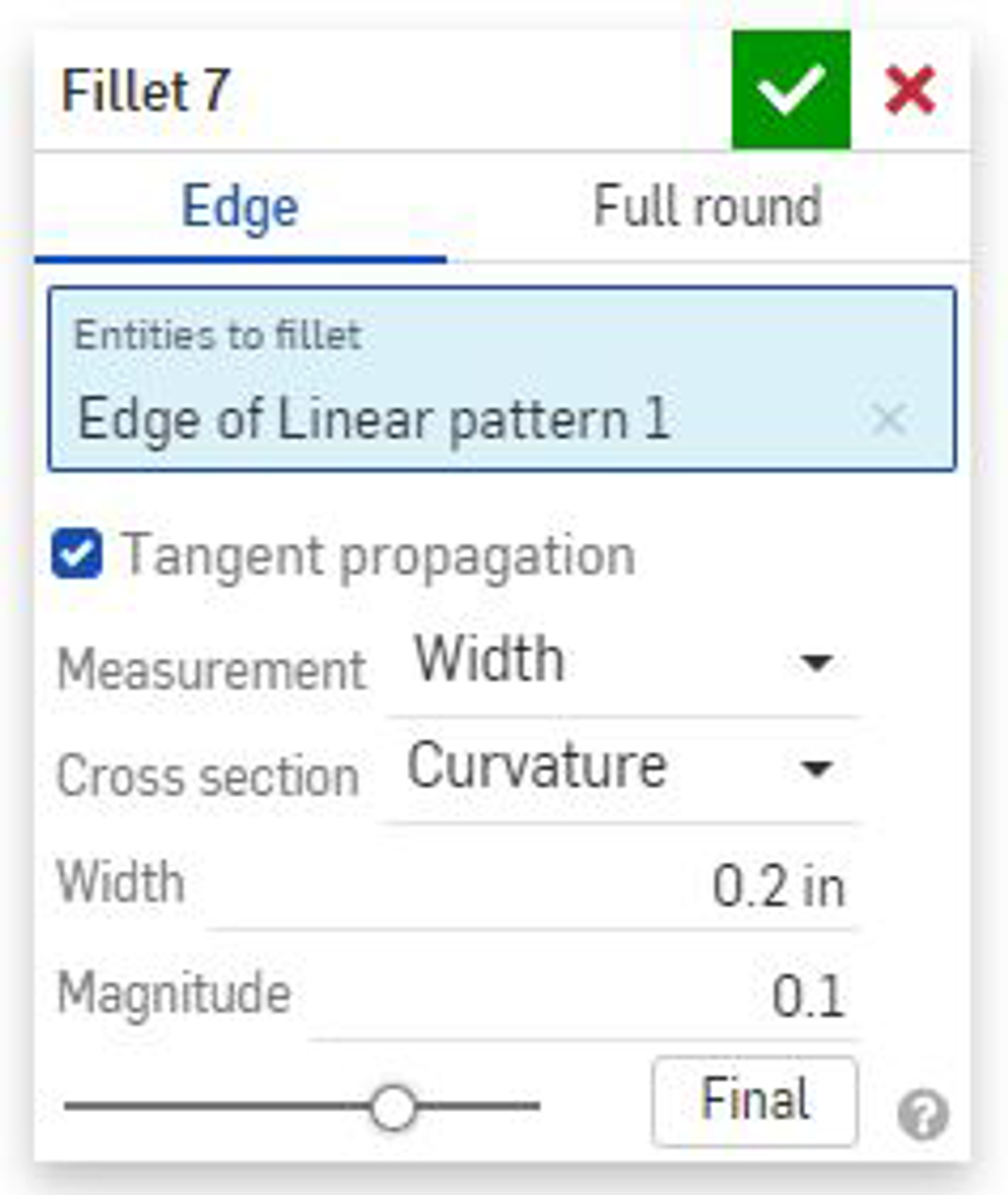

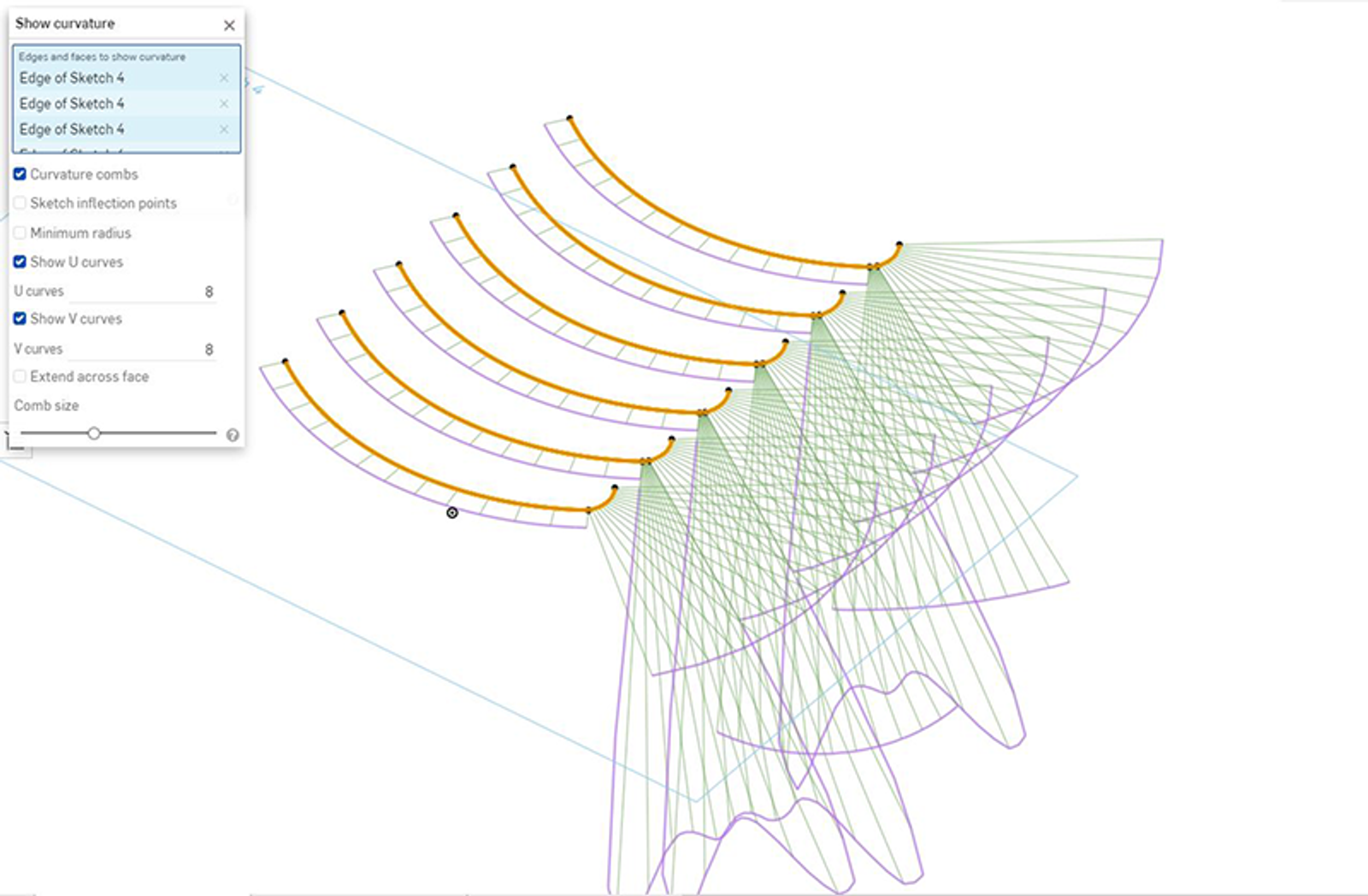

Curvature Cross Section (C) – The radius is a radial measurement used to match the curvature of the surrounding edges with a magnitude value to adjust the tangency.

With curvature and conic fillets the resulting geometry is a spline, not an arc.

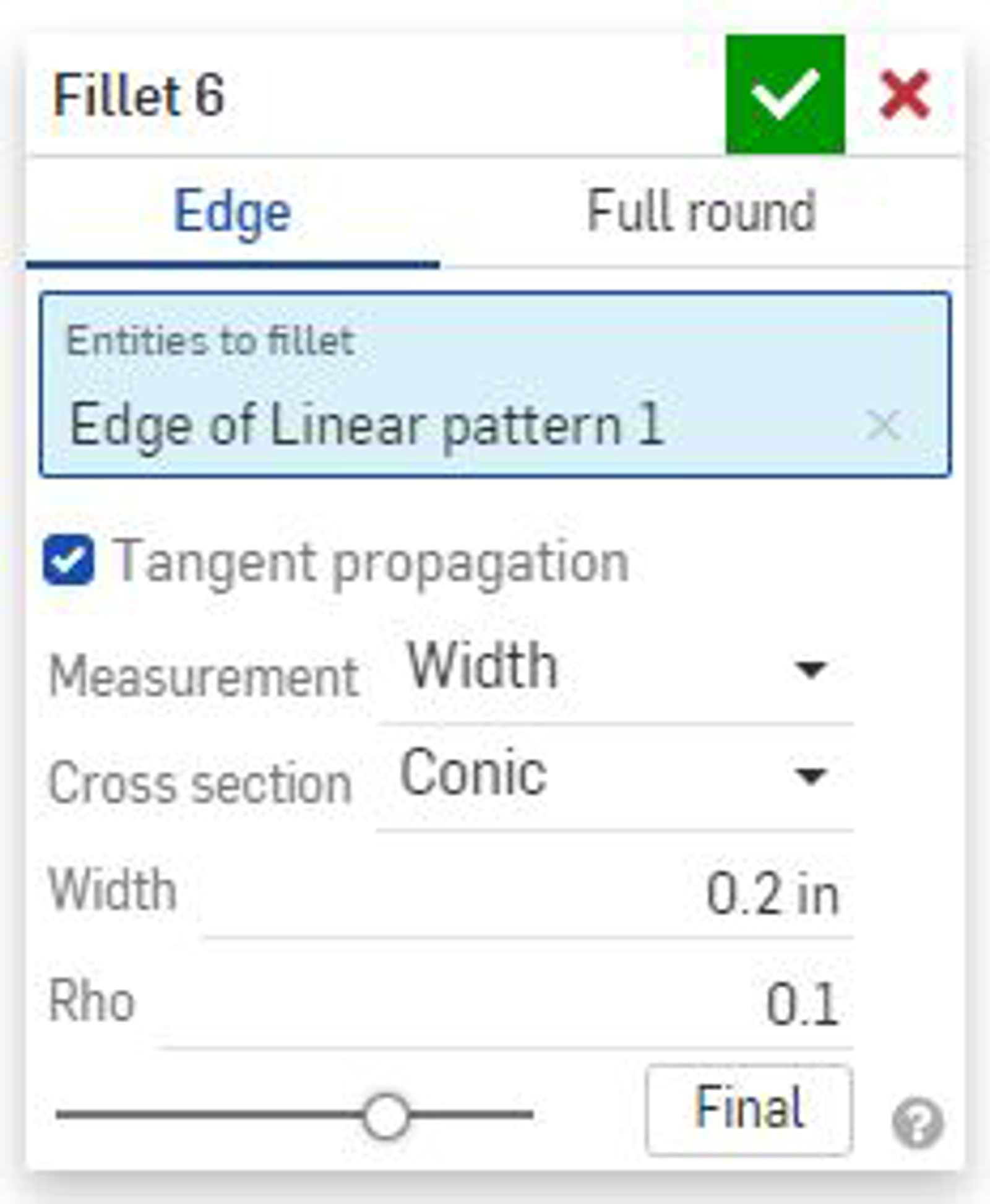

Constant Width Fillet

Width fillets behave in the same way, only you are setting the width dimension across the fillet and the arc dimension is dependent on the geometry. You can’t select multiple edges on one part on a feature with a width fillet unless the edges are continuous.

Circular (A)

Conic Fillet (B) – The width is the distance between the two ends of the fillet and a Rho value is used to determine the shape of the curve, elliptical (Rho < 0.5), parabolic (Rho = 0.5) or hyberbolic (Rho > 0.5)

Curvature Cross Section (C)

Which Fillet Type to Use

Which fillet type depends on the type of parts. Consumer goods typically want the surfaces to blend together with no discernible edges so curvature-based fillets are used more.

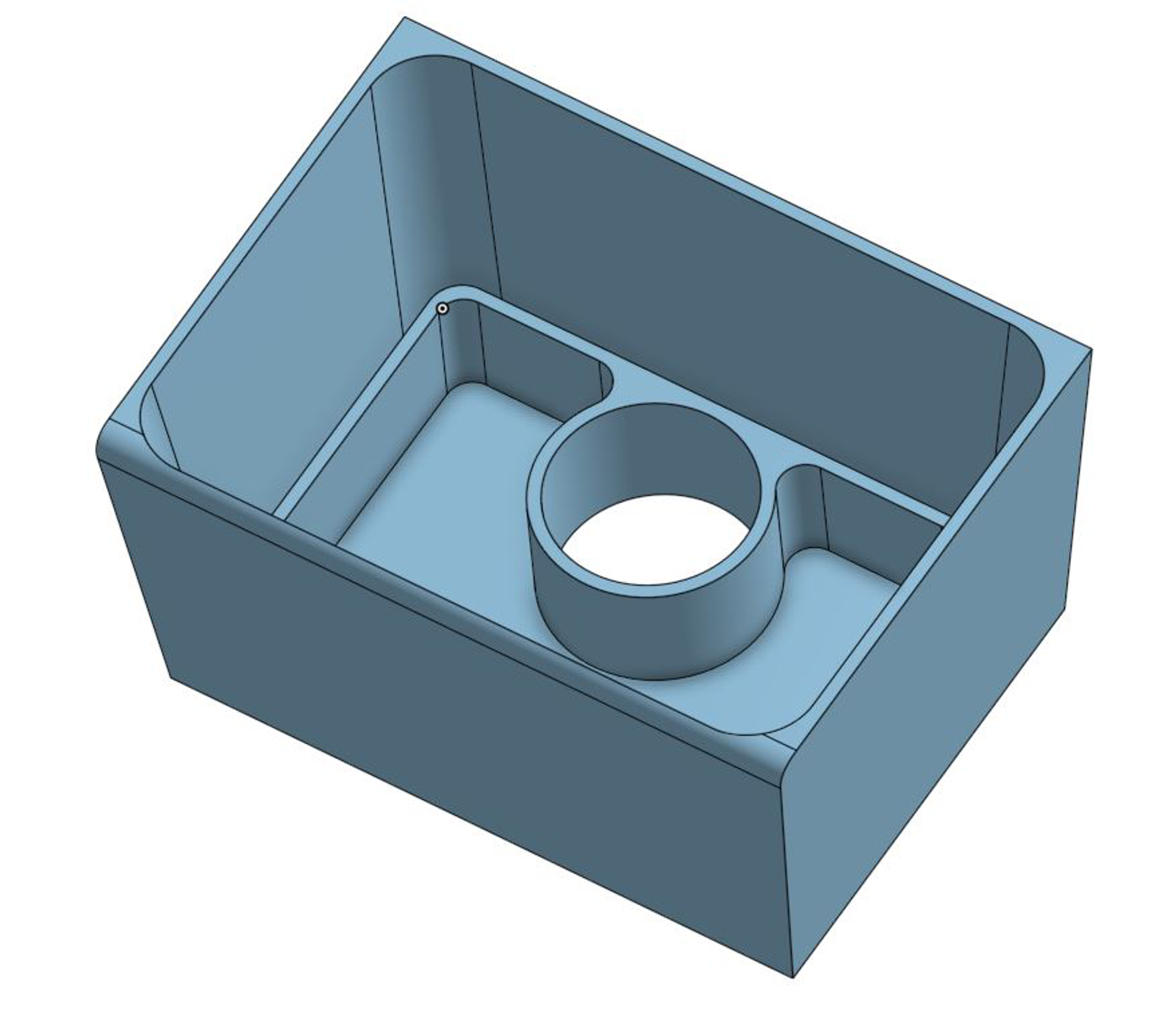

Parts that are machined need fillets with a fixed radius to allow a specific tool to be used in machining. Fillets are used in internal corners to prevent stress concentrations, but otherwise can be a costly addition to a part. Just because they look nice does not mean every corner needs them.

Learn more by watching the video below:

Interested in learning more Onshape Tech Tips? You can review the most recent technical blogs here.

Latest Content

- Blog

- Evaluating Onshape

- Simulation

- Rendering

- Surfacing

- Consumer Products

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 learn more

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more