2:43

When it comes to Sheet Metal design in Onshape, mastering bend calculations is a key skill that can significantly impact the accuracy and manufacturability of your designs.

In this Tech Tip, you will explore the various options available: K Factor, bend allowance, and bend deduction, with guidance on when each should be used.

Defining Bend Calculation

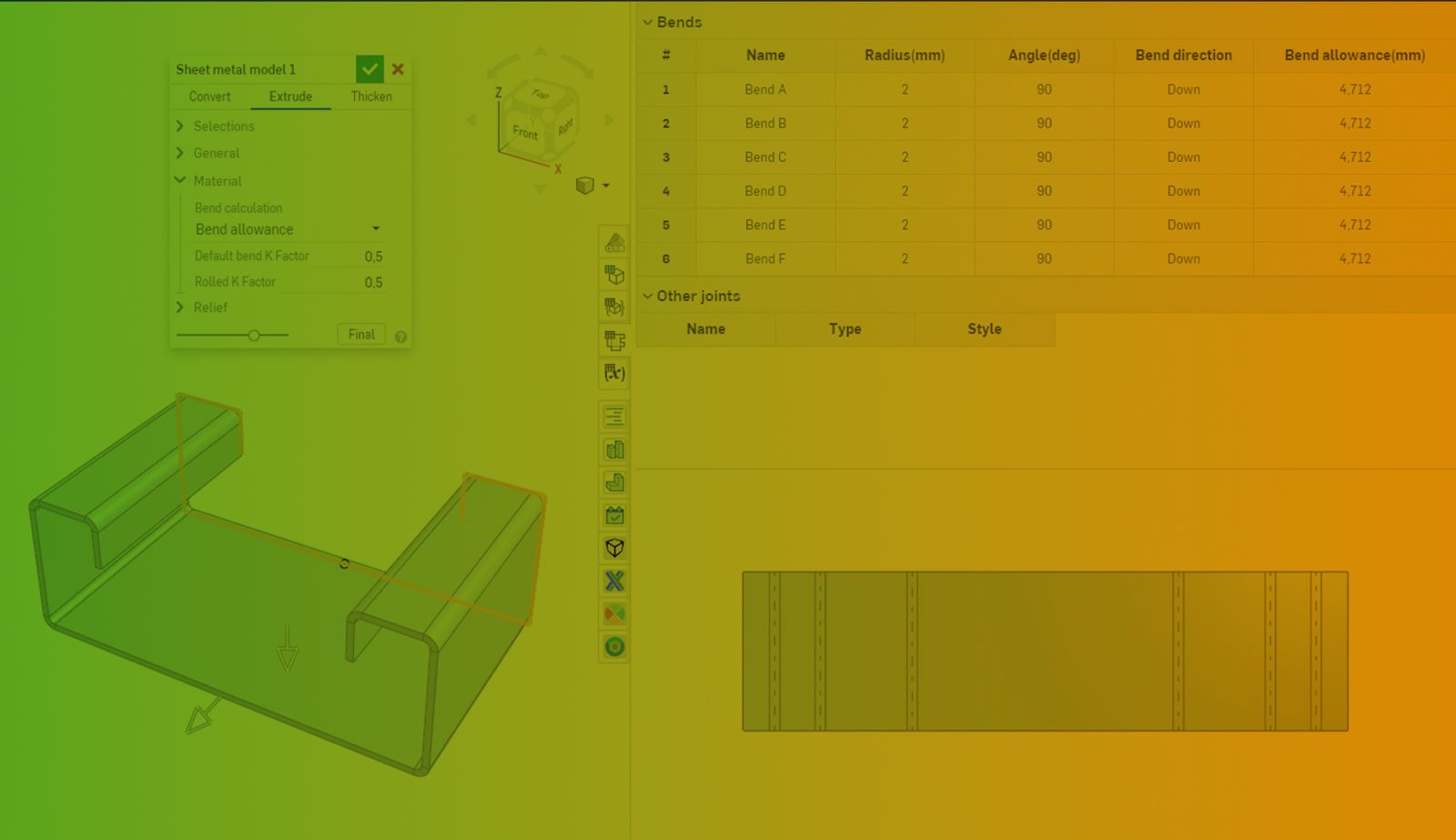

When designing sheet metal with the Sheet Metal model feature, locate the Material > Bend Calculation option in the dialog. The dropdown options are:

- K Factor: A dimensionless factor representing the ratio of the neutral axis length to the material thickness during bending. It is a common choice for many sheet metal designers. Onshape allows you to input a specific K Factor or select from predefined values based on industry standards. Opt for the K Factor when you want a reliable and widely accepted method for calculating bends.

- Bend Allowance: A measurement that accounts for the physical stretching or lengthening of the material on the outside of a bend during the bending process. It is typically used in calculating the flat pattern (developed length) of a sheet metal part before bending. Bend allowance is useful when you need high precision in the final dimensions of your bent part, especially when dealing with materials with known properties and consistent behavior during bending.

- Bend Deduction: The difference between the initial length of the sheet metal and the length along the neutral axis after bending. It is particularly useful for accurately predicting the inside radius of a bend. If precision in the inside bend radius is a critical requirement, bend deduction might be the right choice.

Choosing the Right Option

The selection between K Factor, bend allowance, or bend deduction depends on the specific requirements of your design and manufacturing process.

For standard bends in common materials, K Factor is often a safe and widely used choice. However, for more complex geometries or specific manufacturing processes, bend allowance or bend deduction can be more suitable.

Defining Bend Calculations for Each Bend

Onshape enables users to customize bend calculations for each specific bend in their design. Depending on the chosen bend calculation option, a dedicated column appears in the Sheet Metal table.

This allows users to use the table to specify different bend allowances, K Factors, or bend deductions for individual bends. This high level of customization ensures that sheet metal designs are adapted to the unique characteristics of each bend, optimizing accuracy and manufacturability.

Understanding Bend Allowance, K Factor, Bend Deduction

Mastering bend calculations in Onshape is a powerful skill that enhances the accuracy and efficiency of your sheet metal designs.

By understanding the nuances of bend allowance, K Factor, and bend deduction as well as leveraging Onshape's capabilities to customize calculations for each bend, you can ensure that your designs are not only precise but also adaptable to various manufacturing scenarios.

Watch the video below for more about bend calculations in Onshape.

This Tech Tip helped you to better understand the different bend calculation options for sheet metal design in Onshape. For additional learning materials, explore our training courses/videos on sheet metal available in the Onshape Learning Center and Help menu.

Interested in learning more Onshape Tech Tips? You can review the most recent technical blogs here.

The Onshape Learning Center

Take self-paced courses, get technical briefings, or sign up for an instructor-led training session.

Latest Content

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more