1:32

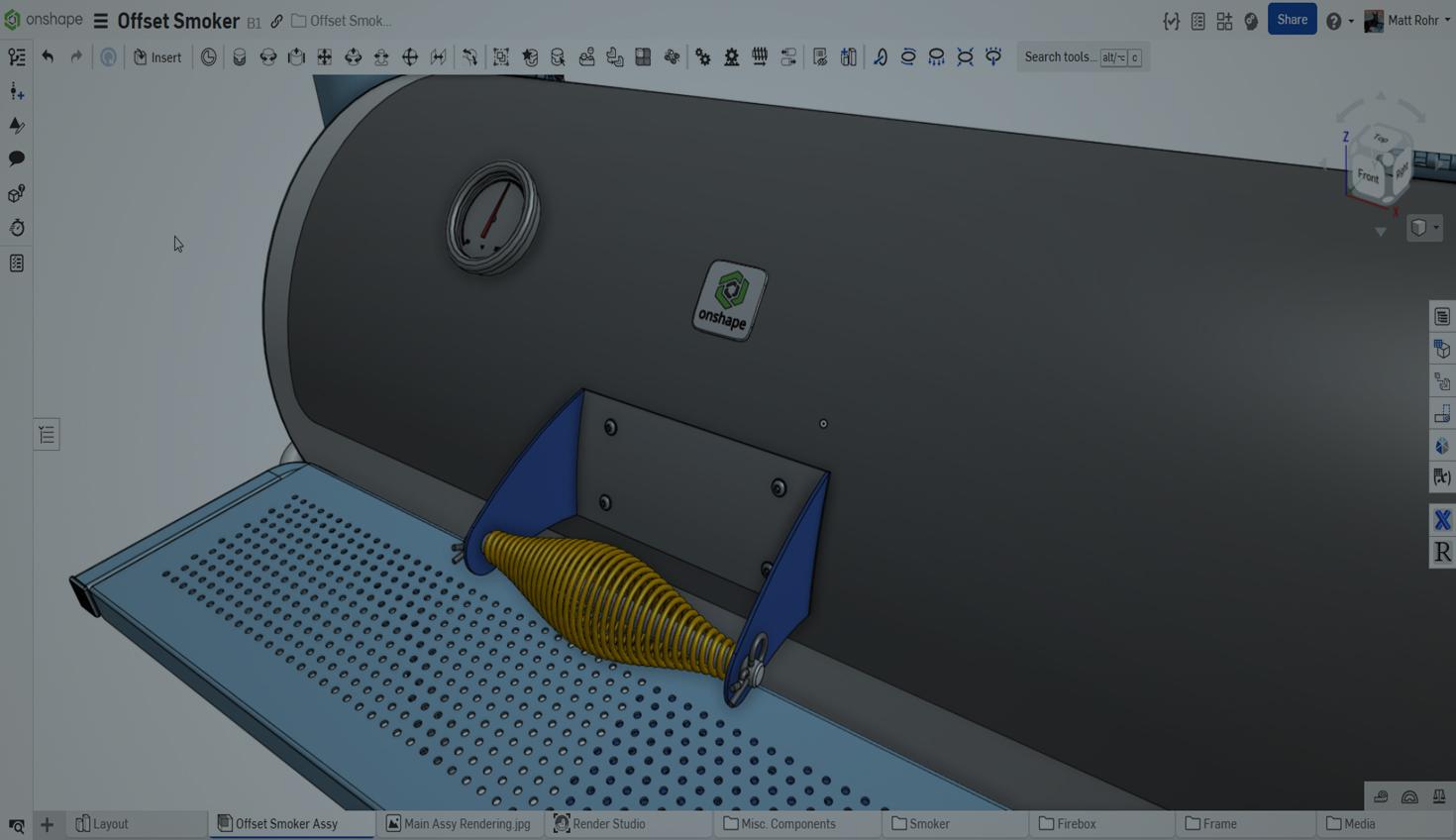

Modeling a constant diameter compression spring is a straightforward application of Onshape's Helix and Sweep features. However, some designs call for varying diameters, such as convex or barrel-shaped springs.

This Tech Tip demonstrates a robust and efficient approach for modeling the spring handle for a wood stove or barbecue.

Using Surfaces to Model a Barrel Spring in 8 Steps

Step 1

Add a new Sketch to a Part Studio. Sketch a side profile of the spring handle and revolve a solid. Defining the profile with a spline creates a single smooth face and produces optimal results. Name this part “Tool.”

Step 2

Create a cylindrical surface and use the Helix feature to create a helix. The diameter is arbitrary but should be slightly larger than the extents of the “Tool.”

Step 3

Sketch a line perpendicular to the cylindrical surface and coincident with the helix. Ensure the line slightly interferes with the minimum diameter of the “Tool.”

Step 4

Use a Sweep feature to sweep the sketch using the helix as the path, creating a helical surface.

Step 5

Add a Boolean feature and subtract the Tool from the helical surface.

PRO TIP: Offset the Boolean by half the wire diameter to maintain the design intent of the initial sketch.

Step 6

Create the profile sketch referencing a vertex of the helical surface.

Step 7

Use a Sweep feature to sweep the profile using the helical edge as the path to complete the part.

Step 8

Defining an explicit Mate Connector can streamline assembly workflows. You can also optionally use the Delete part feature to clean up the construction geometry.

Applying multi-part techniques using solid and surface geometry combinations is an excellent way to solve tricky modeling problems.

Interested in learning more Onshape Tech Tips? You can review the most recent technical blogs here.

The Onshape Learning Center

Take self-paced courses, get technical briefings, or sign up for an instructor-led training session.

Latest Content

- Blog

- News from Onshape @ PTC

Onshape at CES 2026: Where Innovation Meets the Show Floor

01.05.2026 learn more

- Blog

- News from Onshape @ PTC

Onshape’s Top 10 Best and Newest CAD Design Software Features of 2025

12.23.2025 learn more