1:27

Today’s Tech Tip will focus on using offsets when using the Extrude feature. Onshape features are designed to consolidate many different functions all within the same tool. Offsets are used either to offset from the face/sketch region to extrude, or as part of the end condition.

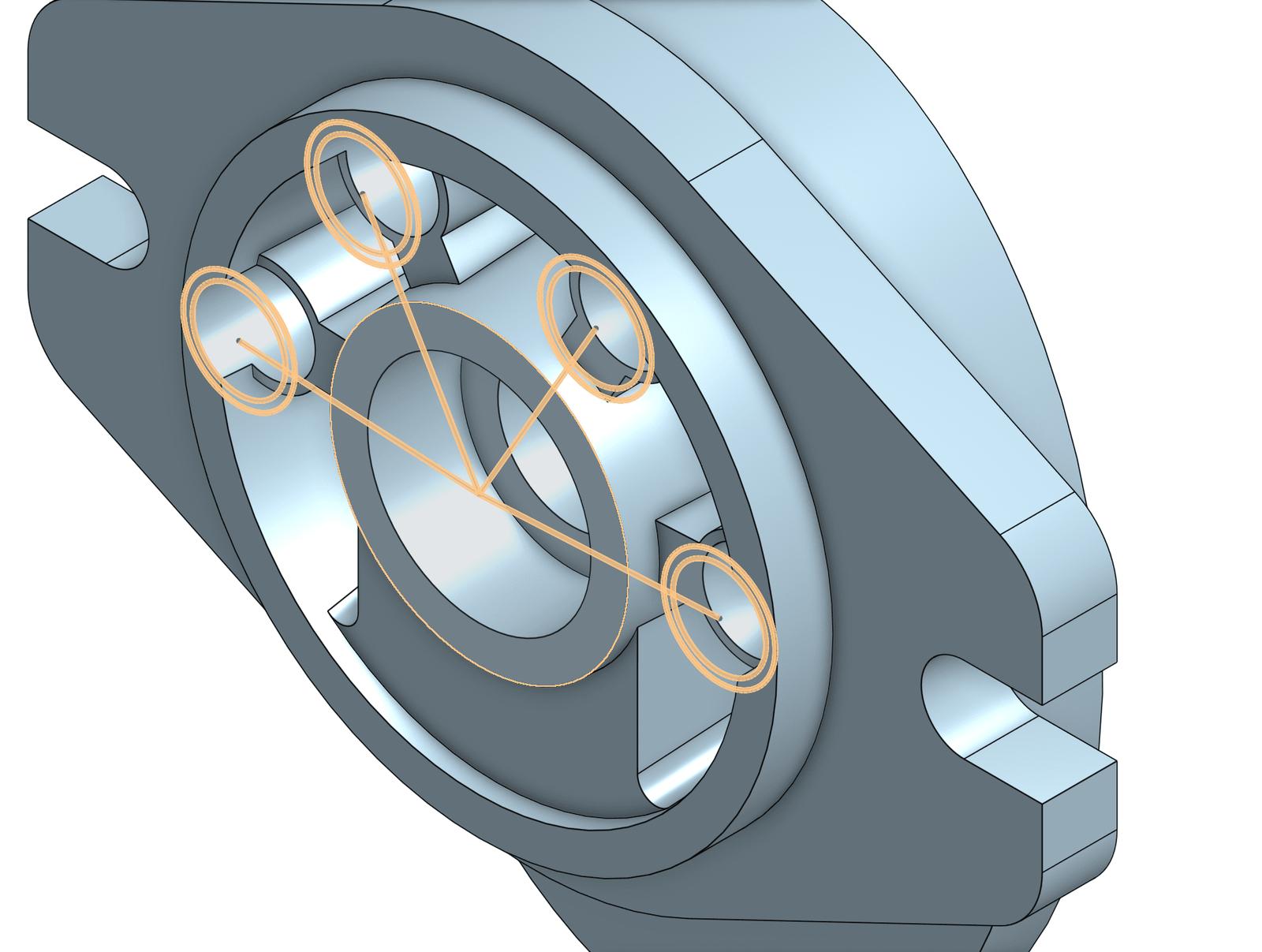

In the hydraulic steering pump model below, there is a master sketch to define the bolt circle. The boss needs to be offset from the original sketch, while the hole will be extruded directly from the sketch. Without the ability to offset, you would need to separate them into two different sketches.

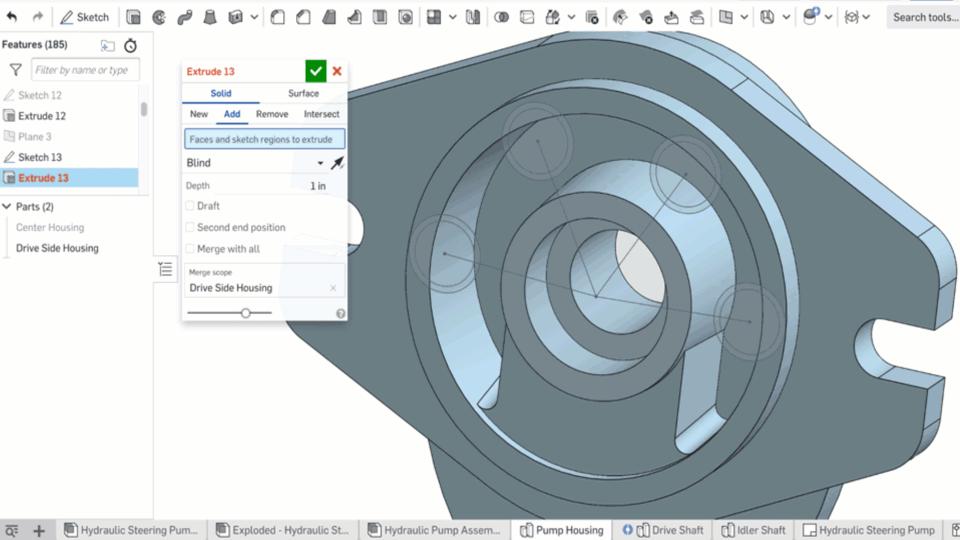

Begin an Extrude, select an end condition, and the regions to extrude. If you choose “Blind,” enter the overall depth (including the offset). The feature will show it extruding from the source sketch. To offset it, select the option for a second direction. Make sure it is pointing in the same direction as the first, and set the depth to what you would like the offset to be.

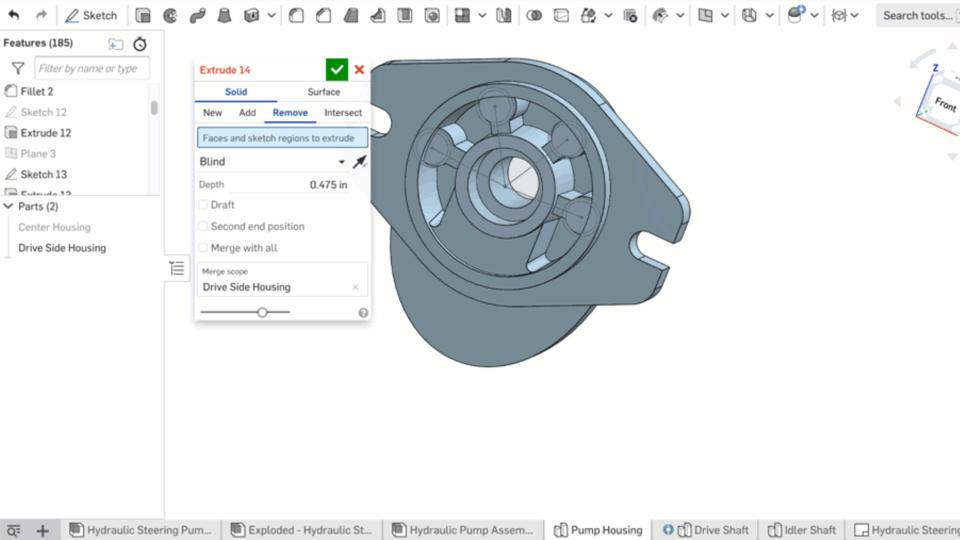

Now, the boss needs a hole added for the bolt. The hole will start at the sketch, but will be a specific offset from the bottom. Select the regions to extrude and choose the end condition “Up to face.” This enables an input for “Offset distance.” Next, choose the face to offset from and put in a distance.

The offset input is available for up to next, face, part and vertex end conditions.

Now you can use offsets in the start and end conditions for an extrude feature. This will reduce the number of features and sketches you will need to complete new parts.

Interested in learning more Onshape Tech Tips? You can review the most recent technical blogs here.

Latest Content

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more