02:01

With complex design ideation, it can be useful to use various math functions to control geometry. To this end, Onshape has numeric fields built in directly to dialog boxes. The following table summarizes these functions and operators:

Functions | ||

Name | Syntax | Examples |

Absolute Value | abs(x) | abs(-3) = 3 |

Ceiling | ceil(x) | ceil(4.75) = 5 |

Clamp | clamp(x, min, max) | clamp(x,1,10) will allow for x to vary between 1 and 10 freely but never go above or below. |

Exponential Function | exp(x) | exp(2) = 7.389 |

Floor | floor(x) | floor(4.75) = 4 |

Hypotenuse | hypot(x,y) | hypot(3,4) = 5 |

Logarithm - Natural (ln) | log(x) | log(10) = 2.303 |

Logarithm - Common | log10(x) | log10(10) = 1 |

Minimum | min(x,y) | min(2,5) = 2 |

Maximum | max(x,y) | max(2,5) = 5 |

Round | round(x) | round(3.50002) = 4 |

Square Root | sqrt(x) | sqrt(4) = 2 sqrt(100) = 10 |

Functions

Name

Syntax

Examples

Absolute Value

abs(x)

abs(-3) = 3

Ceiling

ceil(x)

ceil(4.75) = 5

Clamp

clamp(x, min, max)

clamp(x,1,10) will allow for x to vary between 1 and 10 freely but never go above or below.

Exponential Function

exp(x)

exp(2) = 7.389

Floor

floor(x)

floor(4.75) = 4

Hypotenuse

hypot(x,y)

hypot(3,4) = 5

Logarithm - Natural (ln)

log(x)

log(10) = 2.303

Logarithm - Common

log10(x)

log10(10) = 1

Minimum

min(x,y)

min(2,5) = 2

Maximum

max(x,y)

max(2,5) = 5

Round

round(x)

round(3.50002) = 4

Square Root

sqrt(x)

sqrt(4) = 2

sqrt(100) = 10

Trigonometric Functions | ||

Name | Syntax | Examples |

Sine | sin(x) | sin(30) = 0.5 |

Hyperbolic Sine | sinh(x) | sinh(1) = 1.175 |

Arcsine | asin(x) | asin(1) = 90 deg (must be used in appropriate field) |

Hyperbolic Arcsine | asinh(x) | asinh(1) = 0.881 |

Cosine | cos(x) | cos(30) = 0.866 |

Hyperbolic Cosine | cosh(x) | cosh(1) = 1.543 |

Arccosine | acos(x) | acos(1) = 0 |

Hyperbolic Arccosine | acosh(x) | acosh(2) = 1.317 |

Tangent | tan(x) | tan(30) = 0.577 |

Hyperbolic Tangent | tanh(x) | tanh(1) = 0.762 |

Arctangent & Arctangent2 | atan(x) atan2(x,y) | atan(1) = 45 deg atan2(1,2) = 26.565 deg |

Trigonometric Functions

Name

Syntax

Examples

Sine

sin(x)

sin(30) = 0.5

Hyperbolic Sine

sinh(x)

sinh(1) = 1.175

Arcsine

asin(x)

asin(1) = 90 deg (must be used in appropriate field)

Hyperbolic Arcsine

asinh(x)

asinh(1) = 0.881

Cosine

cos(x)

cos(30) = 0.866

Hyperbolic Cosine

cosh(x)

cosh(1) = 1.543

Arccosine

acos(x)

acos(1) = 0

Hyperbolic Arccosine

acosh(x)

acosh(2) = 1.317

Tangent

tan(x)

tan(30) = 0.577

Hyperbolic Tangent

tanh(x)

tanh(1) = 0.762

Arctangent & Arctangent2

atan(x)

atan2(x,y)

atan(1) = 45 deg

atan2(1,2) = 26.565 deg

Misc/Operations | ||

Modulo Operator | x%y | 6%2 = 0 6%4 = 2 6%5 = 1 |

Array | [0,1,2,3,4][n] | [1,4,7,8,23,7][0] = 1 [1,4,7,8,23,7][3] = 8 |

Misc/Operations

Modulo Operator

x%y

6%2 = 0

6%4 = 2

6%5 = 1

Array

[0,1,2,3,4][n]

[1,4,7,8,23,7][0] = 1

[1,4,7,8,23,7][3] = 8

Numeric fields are powerful by themselves. However, their true power comes from how creatively a Part Studio or Onshape Document can be architected to automate some of the math that is inevitably a part of design. A quick example would be to combine variables and configurations with numeric fields.

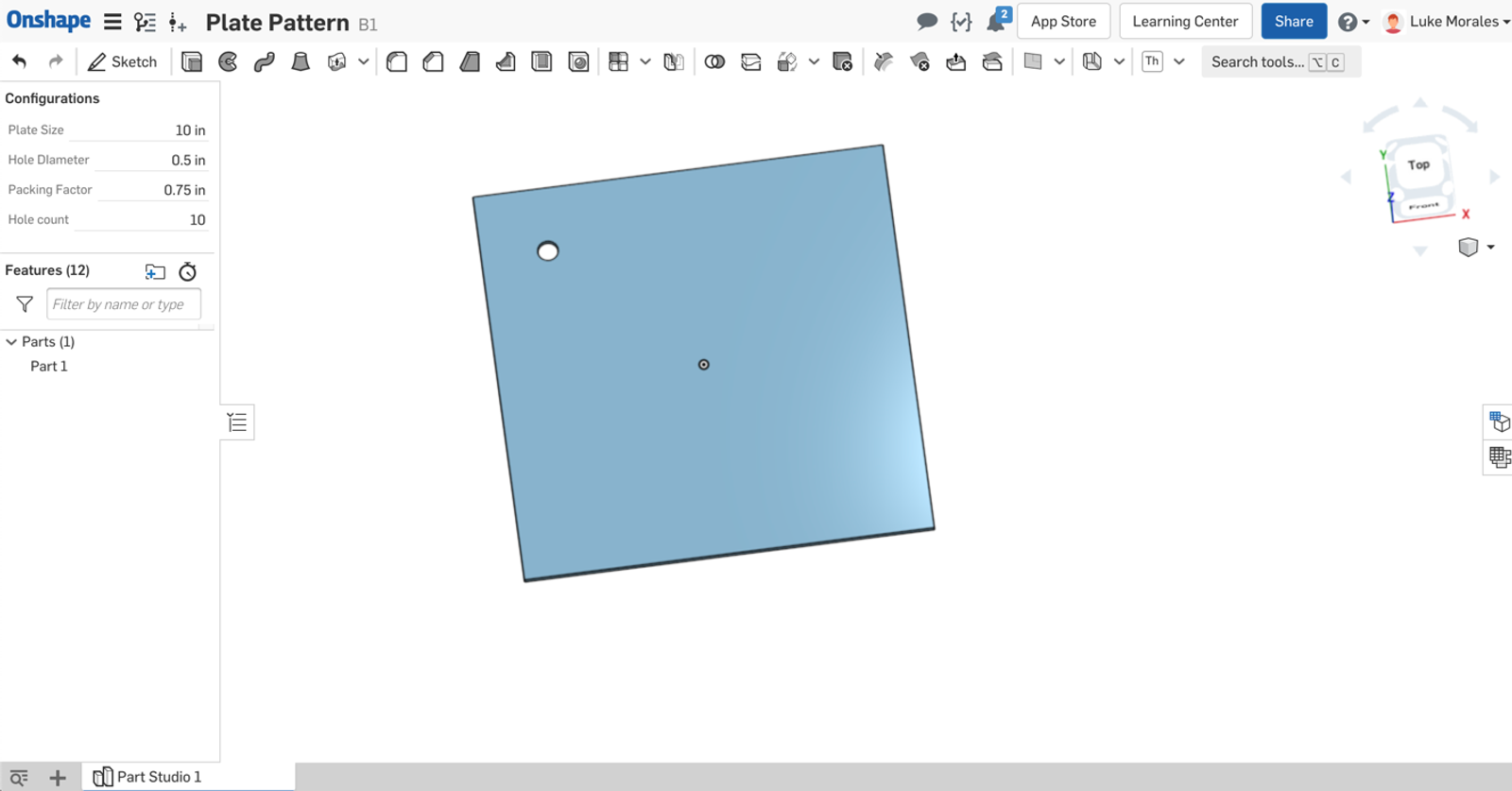

For this example, I’ll use the Clamp function to show how to use equations to generate a bounding box for a variable. To start, I’ve created a sheet metal plate with a single hole:

I have a combination of configuration variables and parametric variables in this Part Studio. The configuration variables will control the plate size (#Size), hole diameter (#Hole_Diameter), distance between holes (#Packing_Factor), and number of holes per row (#Hole_count).

I want to create a pattern of this hole that changes based on these configurations. However, linear patterns are not “smart” in so far as the scope of patterning “up to” a certain point. Thus, the following method is used.

First, I create two parametric variables: #HoleClamp and #Edge. #Edge is just the calculation of the space on either end of the row using #Hole_count and #Packing_Factor. The real magic happens with the #HoleClamp variable; its definition is as follows:

clamp(#Hole_count,2,floor(((#Hole_Diameter-#Size)/(-#Packing_Factor))))

This is then set as the instance count for a linear pattern of the hole. As the #Hole_Count configuration variable is changed, the clamp ensures that the pattern never exceeds the carrying capacity of the plate given the other dimensions specified by configurations.

This is a good way to leverage the accessibility of the configuration variable while adding a minimum and maximum that are governed by variable equations.

Following the same logic, two more parametric variables are created: #HoleClamp2 and #Edge2 which are driven by a new configuration variable, #Row_Count. The final product behaves like this:

This is one example of how to combine numeric fields with other design drivers with Onshape. Of course, all of the functions and operators listed above can be used together to drive complex shapes.

For more Onshape Tech Tips, you can review the most recent technical blogs here.

Latest Content

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more