1:41

Onshape’s Group and Fasten features seem very similar on the surface. They both prevent components from moving or changing orientation with respect to each other. Where they differ is their impact on assembly performance and parametric design.

Group is not solved like a true mate. It records all of the positions of the parts with respect to each other, but does not solve for degrees of freedom as a mate would. It is especially convenient when parts in an assembly are already in the correct positions and do not need to move with respect to each other. Group overrides changes to position caused by Part Studios or subassemblies that are a part of the group. Suppress the Group and the positioning updates. Unsuppress it, and it will lock in the new positions.

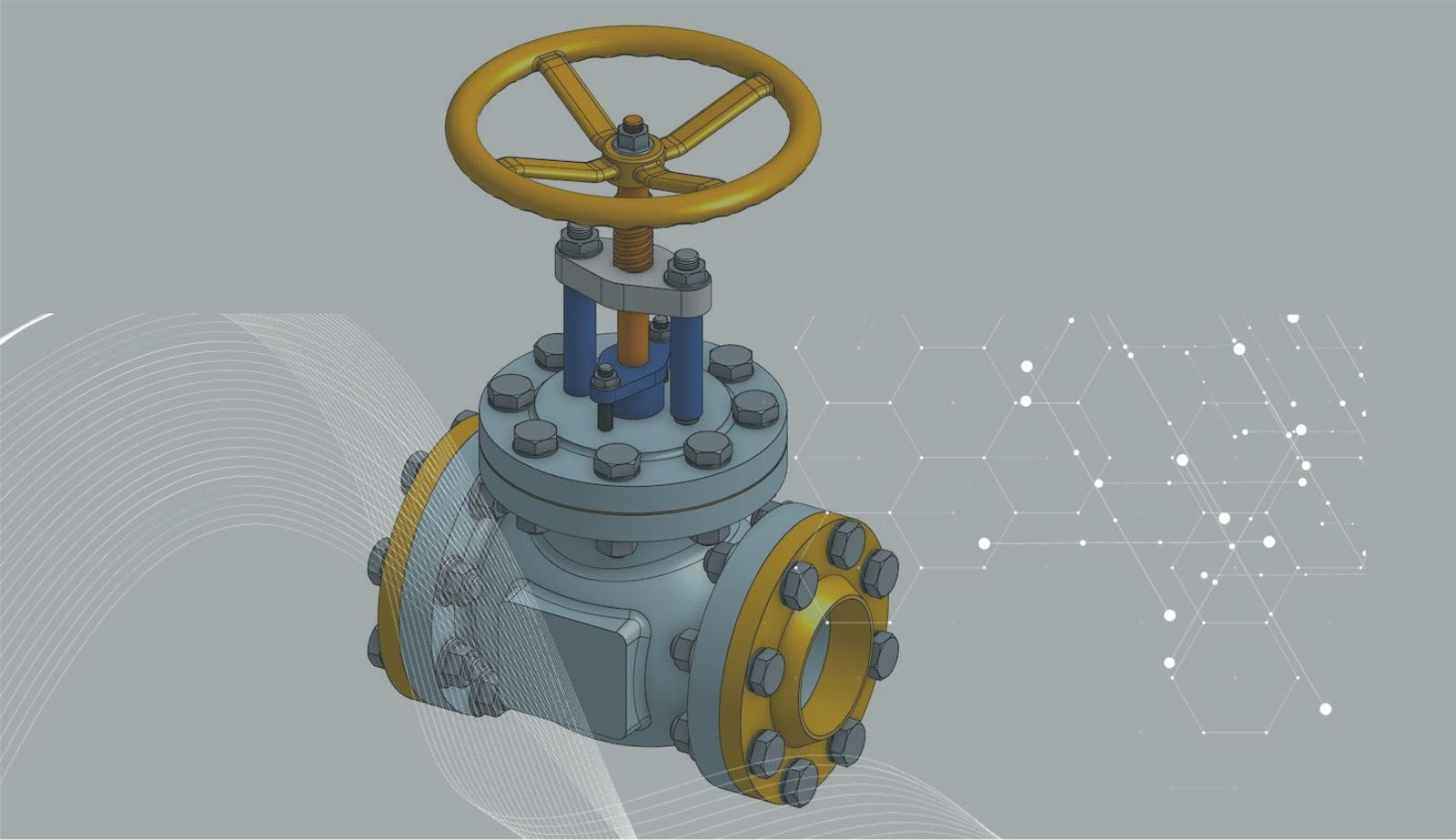

The globe valve model below is a good example of this behavior. In the top-level assembly, all mates are suppressed and replaced with a Group. The lower-body subassembly has everything defined with fastened mates. The Part Studio is updated to a new valve length. In the subassembly, the flanges and bolts move appropriately to match the new geometry. In the top-level assembly, the Group takes precedence and they stay in their previous location. Suppressing and then unsuppressing the Group updates the top-level assembly with the new positions.

Fasten may seem similar to Group, but it is defined like a traditional mate. It locks all six degrees of freedom with respect to the other component in the mate. It is useful for assemblies that have movement or contain components that can change dimensionally.

Performance isn’t impacted significantly in smaller assemblies, but larger assemblies can perform slower with a large number of mates. If you are having issues with performance in a rigid assembly with a lot (~250+) of fastened mates, you should consider suppressing the fastened mates and adding the parts to a Group.

For other tips on making your assembly more robust and efficient, check out the Technical Briefing on Creating High Performing Assemblies.

Latest Content

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more