1:45

Dimensional accuracy is critical when it comes to manufacturing sheet metal components. When parts are not sized correctly, they may interfere with other components of the assembly, or leave gaps or clearances that compromise the design.

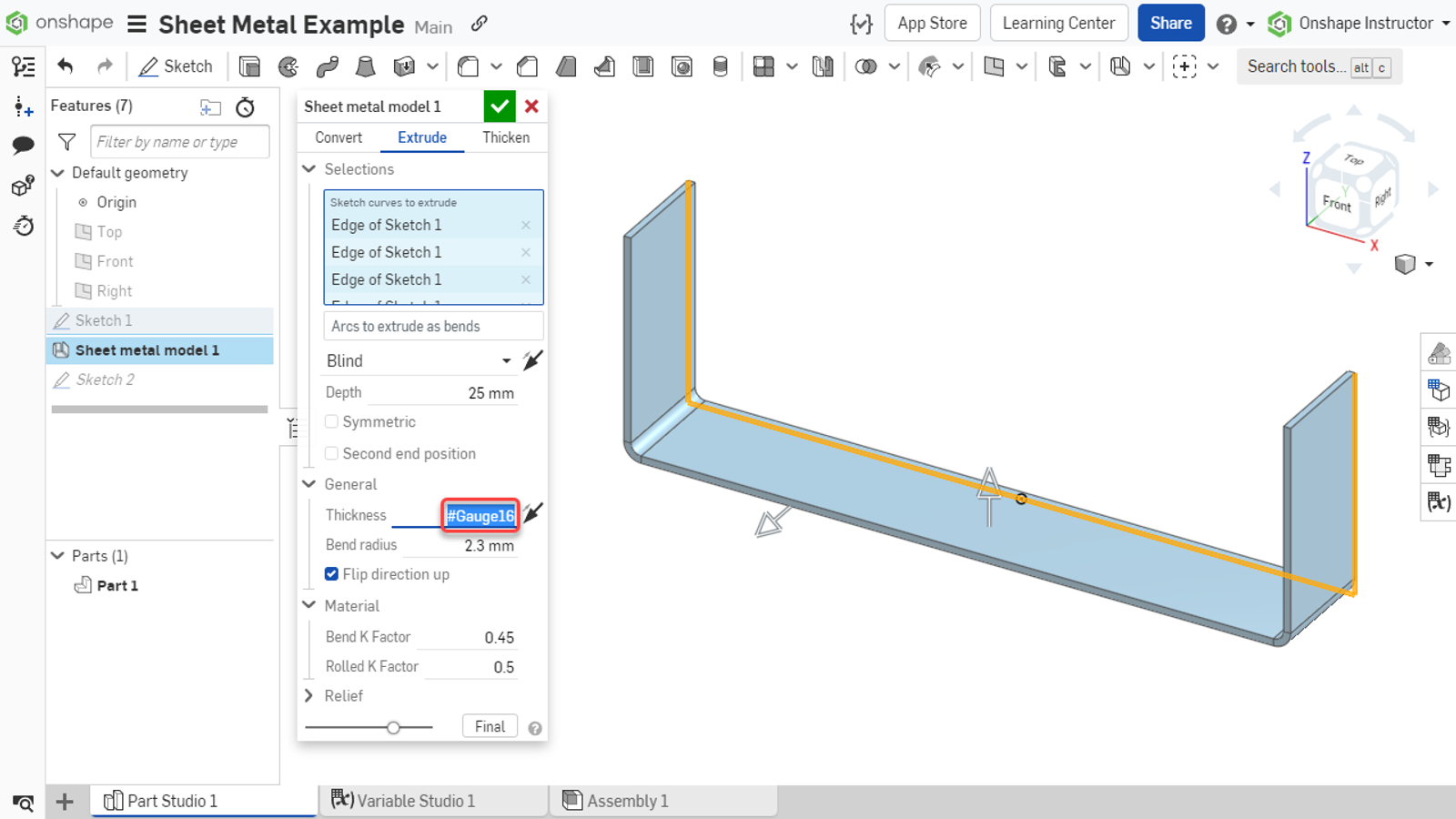

In this Tech Tip, you will learn how to utilize Onshape’s Variable Studios to drive key sheet metal parameters and ensure that your designs are accurate.

What Is a K-Factor?

When manufacturing bent sheet metal parts, the dimensional accuracy is driven by the flat pattern. When metal bends, it stretches. If the flat pattern is not cut to the correct dimensions, the final bent parts will never match the intended design.

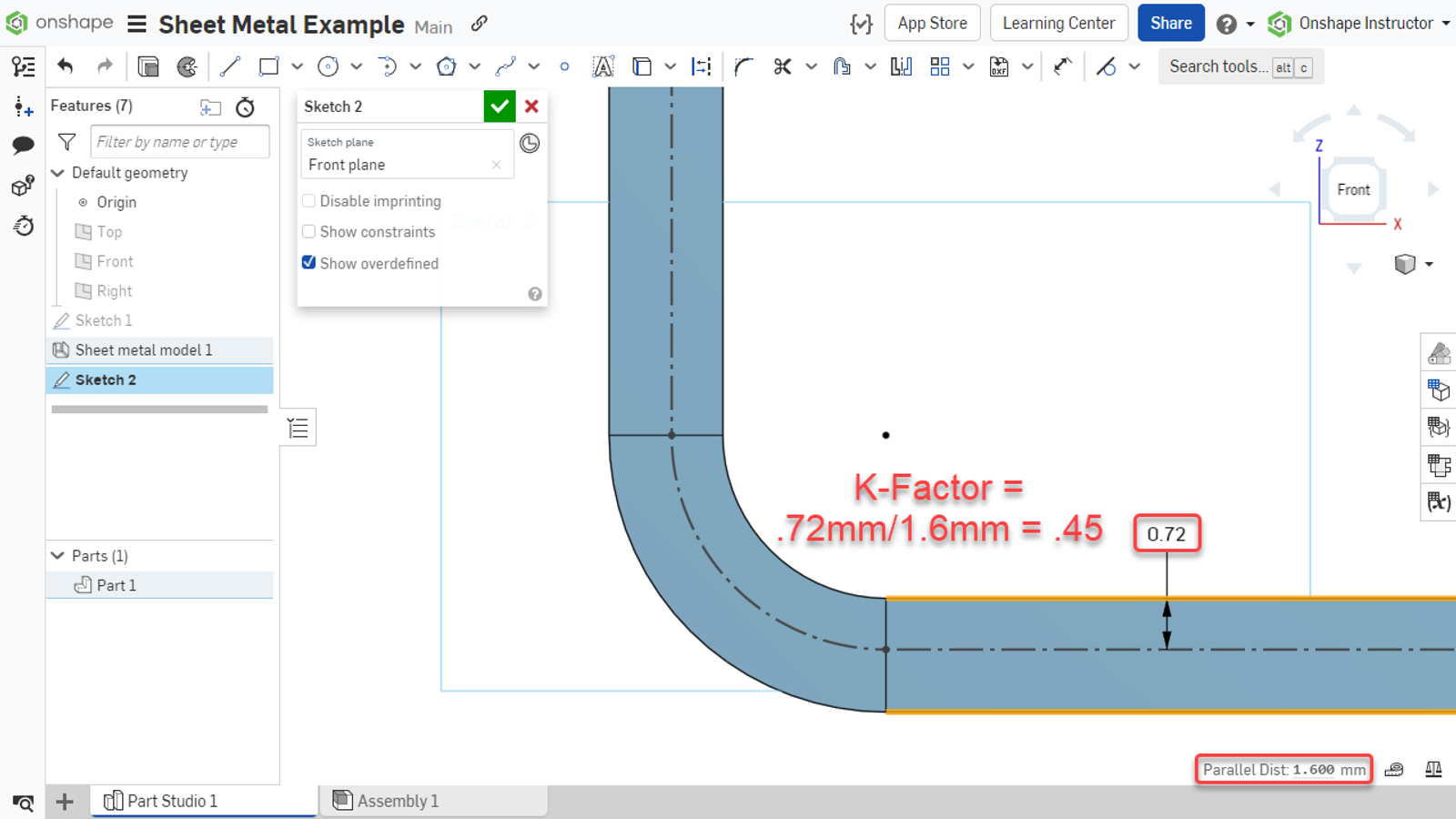

Sheet metal designers account for this stretching by gathering data and applying a known bend allowance, bend deduction, or K-factor to each bend. The K-factor is the ratio between the distance across the thickness to the neutral axis (where no stretching or compression occurs), and the overall thickness of the sheet.

This K-factor can change based on the sheet metal material, thickness, bend radius, and bend angle.

Additionally, sheet metal is available in multiple materials, and in multiple thicknesses for each material. There are also multiple radii available for each material and thickness, depending on the tooling on hand.

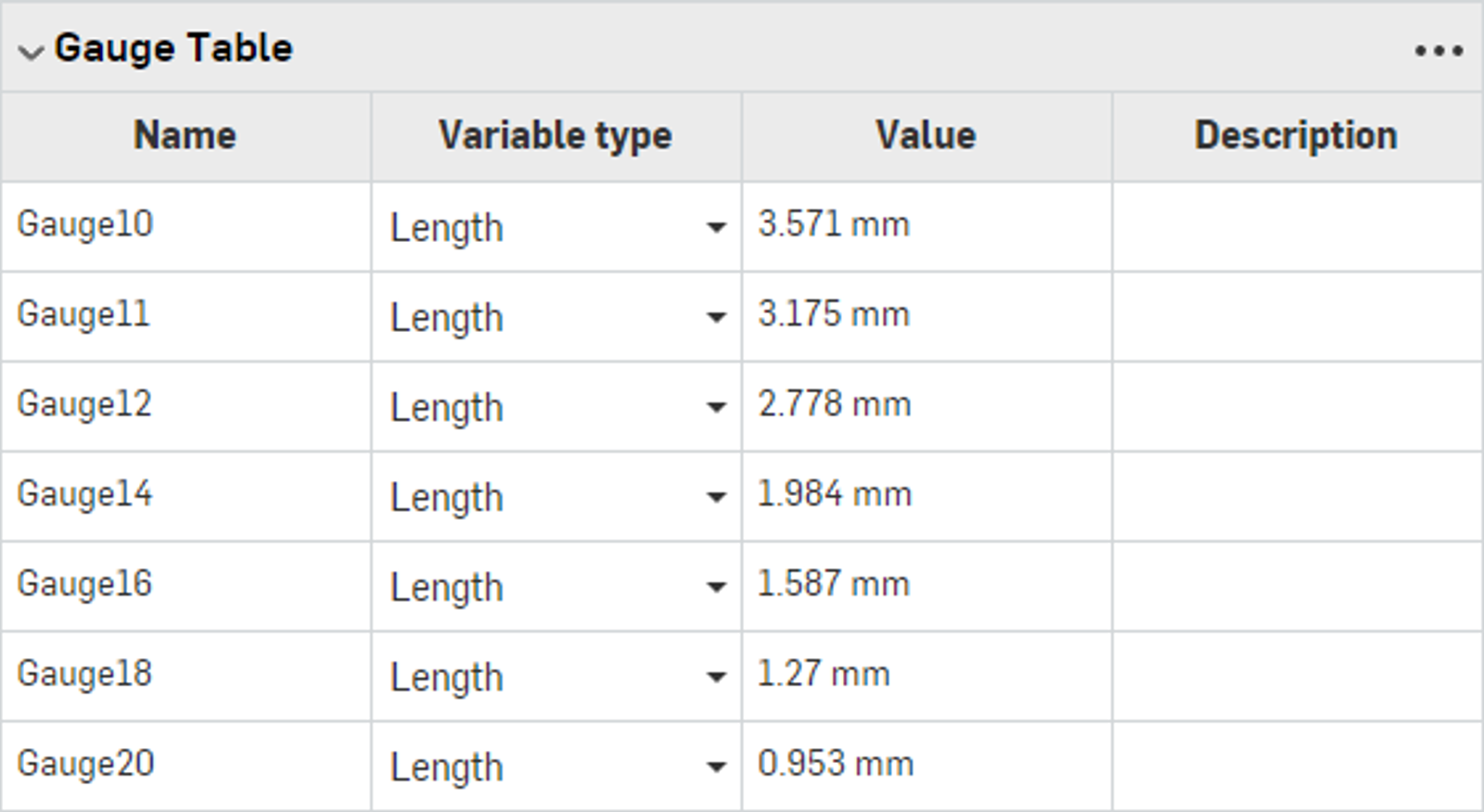

This thickness and bend data is typically tracked in a gauge table and bend table.

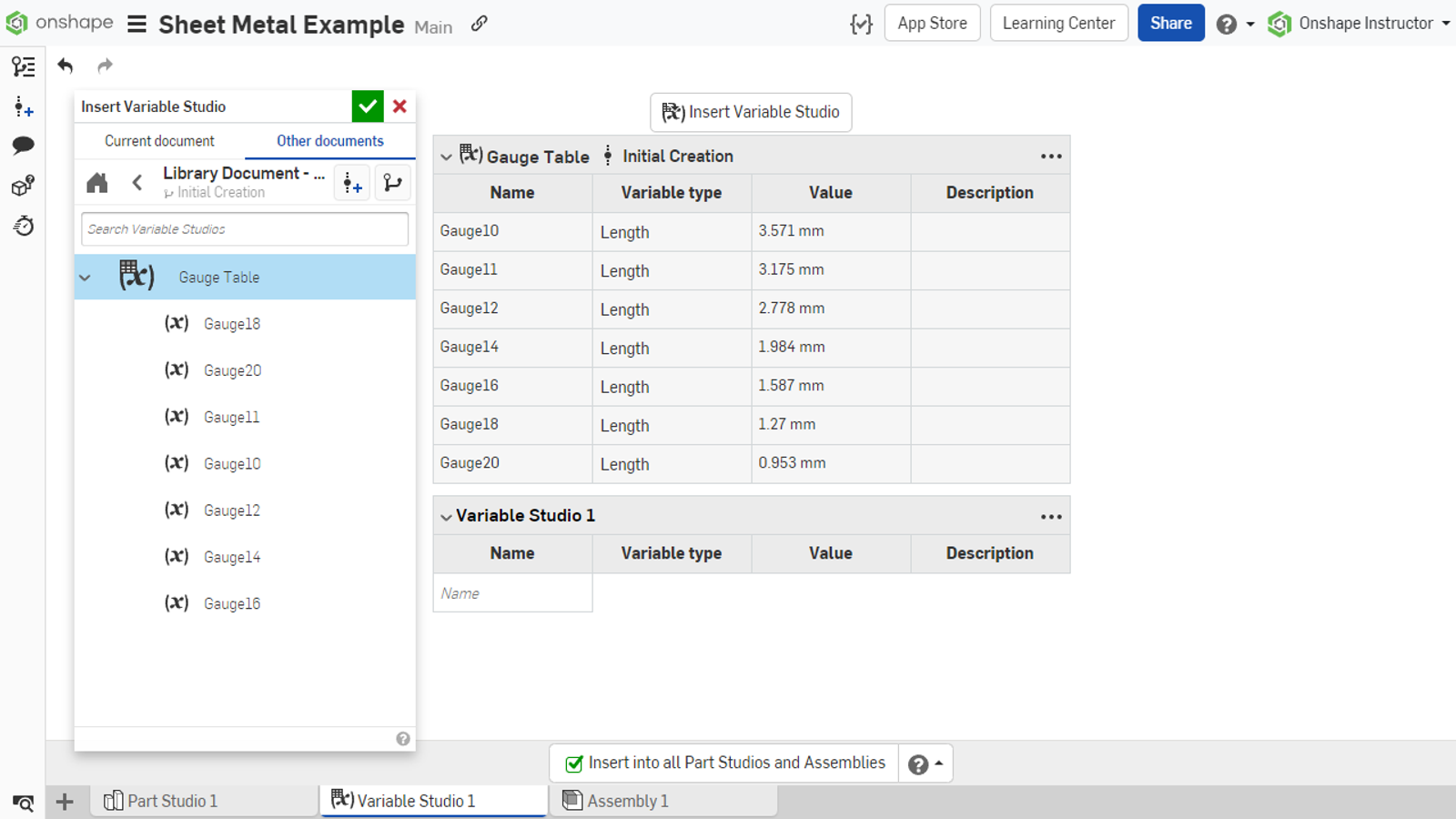

Mapping this data to global variables within Variable Studios allows them to be stored in a library document, and inserted into other documents to drive sheet metal parameters.

Once inserted, the variables are used within the sheet metal feature parameters.

By linking this data to Variable Studios within a library document, the sheet metal data may be updated as needed. Any designs going forward use the updated data, and any old designs are updated to reflect the new values.

Learn More About Sheet Metal Design in Onshape

Do you need to design sheet metal parts in Onshape? Check out our self-paced course, Simultaneous Sheet Metal, in the Onshape Learning Center.

Interested in learning more Onshape Tech Tips? You can review the most recent technical blogs here.

The Onshape Learning Center

Take self-paced courses, get technical briefings, or sign up for an instructor-led training session.

Latest Content

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more