6:40

3D printed houses? Food? How about a human ear?

The future is here, as predicted in 2017 by Onshape co-founder John McEleney.

For some time, 3D printing designs weren’t thought of as a solution to the many problems facing us today for a number of reasons: lack of the right material, irregular consistency, and a small knowledge pool.

But as more and more companies begin to use 3D printing throughout the product development process, the problems of a newfound technology are becoming smaller and easier to mitigate.

What is 3D Printing?

3D printing as we know it now has been around since at least the 80s. Since then, makers and hobbyists around the world have taken advantage of this technology to create solutions for everyday problems, like organizing pens or holding keys, as well as for fun, like creating dragon figurines.

It’s only grown since then as larger companies are integrating 3D printing designs into their workflows and processes. But what is it exactly?

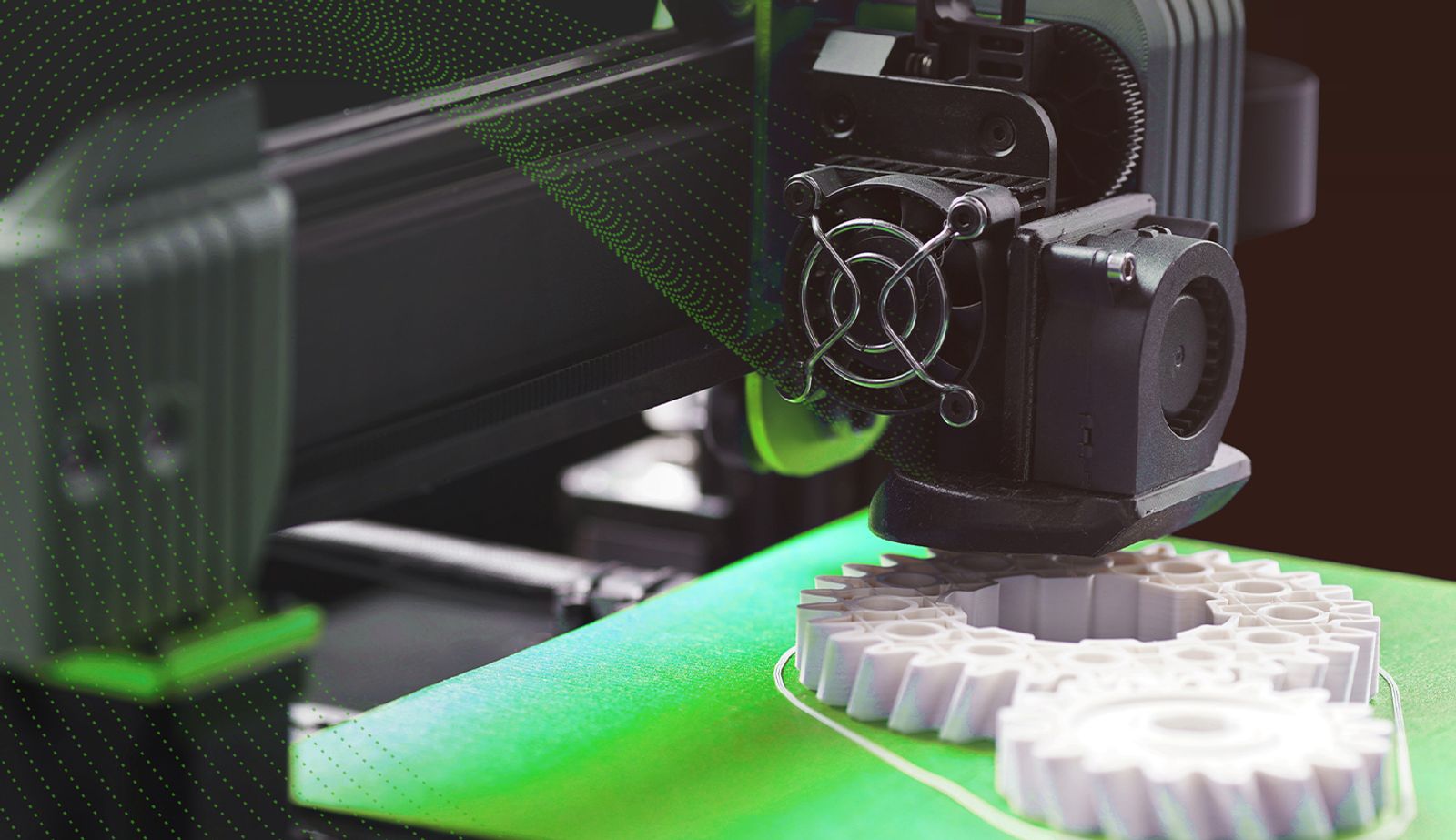

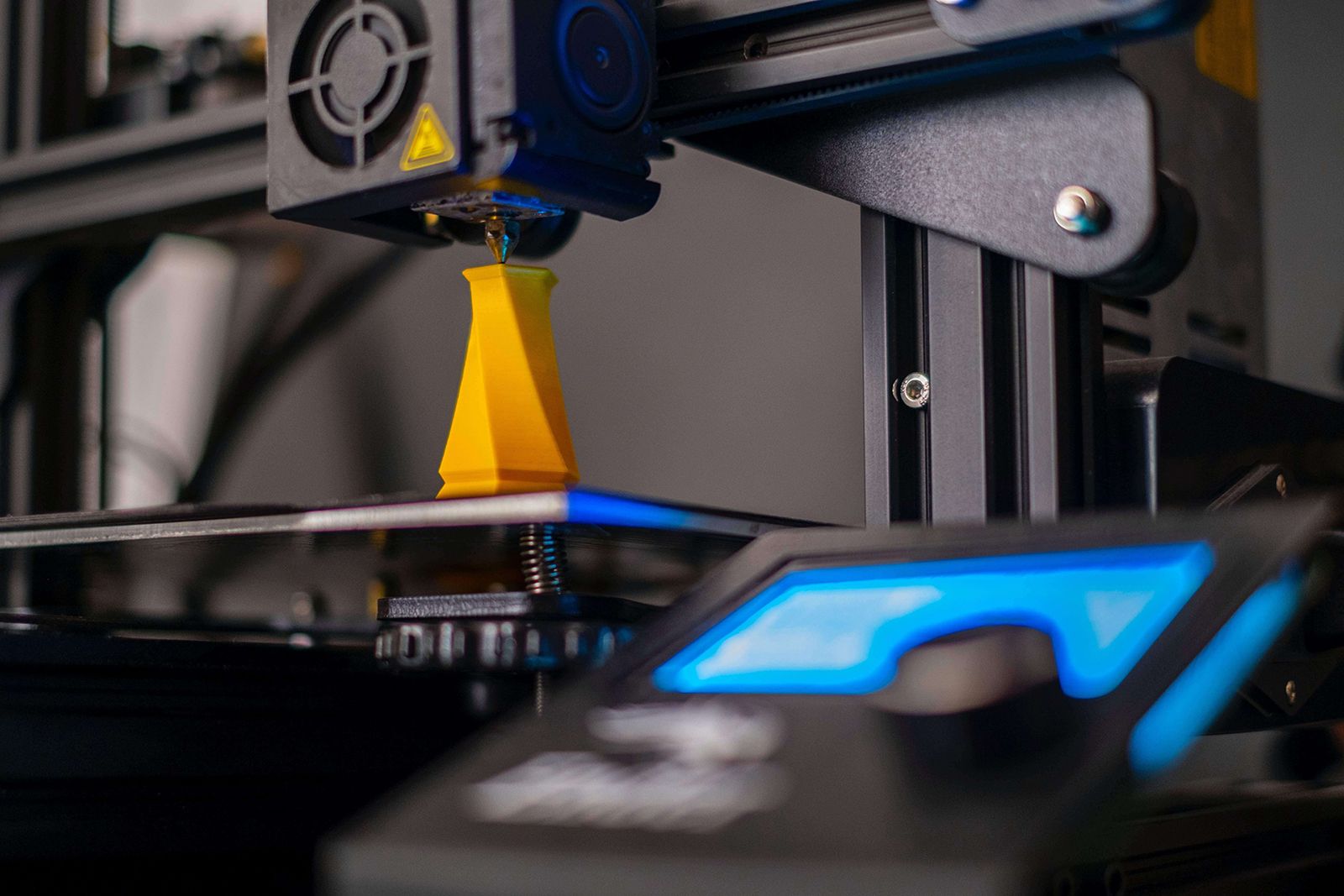

3D printing is a technique that adds layers of material to build an item that was designed using CAD software. Since this technique adds material, it is also called additive manufacturing.

3D printing differs from the older, more traditional way of building items. Typically, items would be made by a subtractive process, much like sculpting clay. But because you’re taking away material, this process is usually more expensive than an additive process that uses a set amount of plastic, metal, etc.

TECH TIP: Your Guide to Successful 3D Printing.

A 3D printer in use. Osman Talha Dikya/Unsplash

Quick Tips on Using CAD Software for 3D Printing

To create an easily printable object, there are five key design rules to keep in mind:

- Design to Avoid Supports: Supports are extra material that act as “scaffolding” to hold a design in place if there is nothing beneath it to build on. Although supports are sometimes necessary, there are a lot of benefits to designing in a way that avoids them altogether. This includes saving time and money, lowering the probability of printing errors, and creating a smoother surface finish.

- Design for Printing Tolerances: A 3D printer can only successfully reproduce a certain amount of detail, so you need to take these physical limits into account when creating intricate designs.

- Prevent Overheating & Warping: Prints with narrow parts can often get overheated during printing and warp the design. To prevent overheating in one place, you need to disperse the heat and allow the hot end of the extruder to move away from your object to give it time to “cool off”.

- Design for your Material: Depending on the intended use of your printed piece, your choice of material can affect certain aspects of your design, and needs to be taken into account for the best results.

- Choose Your STL Export Settings: If you’re designing for an FDM printer, you’ll most likely be exporting your design as an .STL file which creates a representation of your design in triangles. High poly counts create more detail in the print but can create file sizes that are difficult for your slicing program and 3D printer to handle.

While 3D printing has been embraced by hobbyists and small companies, the technology is now being adapted for larger, industrial-level applications.

3D Printing as an Industrial-Level Solution

Now, 3D printing is proving to have a vital and permanent role in product development by accelerating and improving the design, speeding up time-to-market, and reducing reliance on the global supply chain. It has spurred the use of rapid prototyping, which allows companies to create physical prototypes of a new product earlier in the design process. The technologies and materials available now can produce a close replica of the final product. This way, teams can fail fast as the feedback loop is shortened and improvements can be made quickly.

Beyond rapid prototyping, product development teams can 3D-print end-use parts that are high-precision and functional in a fraction of the time and cost. Because of these benefits, governments around the world are turning to additive manufacturing to relieve the stress on the global supply chain and update the aging manufacturing sector.

For example, Germany and Sweden have invested money and created programs to spur the adoption of additive manufacturing and 3D printing.

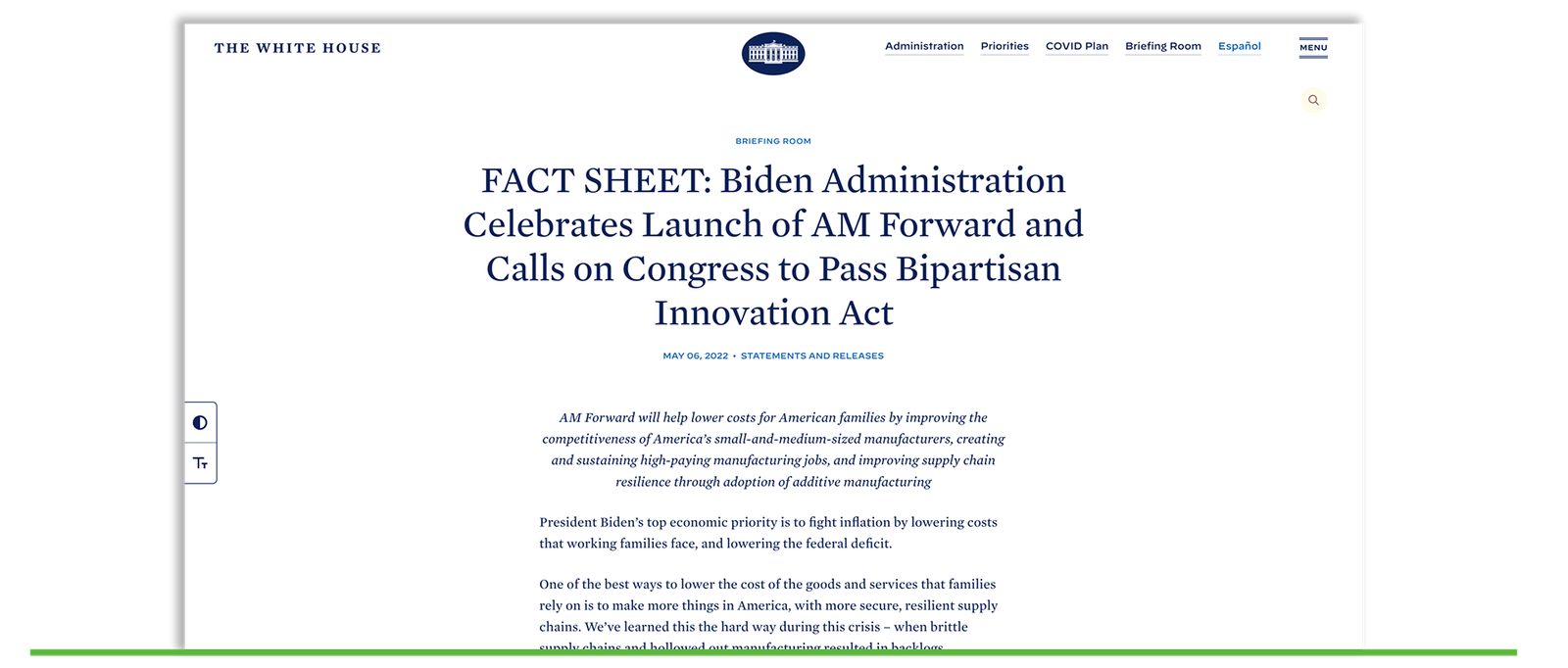

In the U.S., the Additive Manufacturing (AM) Forward program was formed in May 2022. The initiative is to encourage a tighter partnership between original equipment manufacturers (OEMs) and SME suppliers. AM Forward aims to help companies invest in new additive machines, train workers, and help standardize 3D printing, a major pain point preventing the industry from scaling up.

Latest Trends in 3D Printing

The 3D printing industry is continuously evolving, with several key trends shaping its future according to reports from 3D Printing Industry and Protolabs:

Market Growth: The 3D printing market is expected to grow significantly, with projections reaching $57.1 billion by 2028. This growth is driven by increased adoption across various industries, including medical, aerospace, and consumer goods.

Innovative Applications: The applications of 3D printing are growing in both type and scale, with advancements in micro printing and large-format applications. This includes the use of 3D printing for end-use parts and rapid prototyping.

Investment in Additive Manufacturing: Significant investment continues to be made in additive manufacturing solutions and materials. This includes the development of new materials and the integration of AI (artificial intelligence) into 3D printing processes.

Support 3D Printing Designs with Agile CAD Software

Since the 3D printing design process frequently includes numerous iterations for quick prototyping, more additive manufacturers are opting for cloud-native CAD software for 3D printing, like PTC’s Onshape.

Several businesses are taking advantage of 3D printing and cloud-native CAD to speed up their design processes and cut down on time-to-market.

For example, Quebec-based Omnirobotic relies on both Onshape and additive manufacturing to improve their automation system robot. Additive manufacturing is used to speed up rapid prototyping on the housing components for Omnirobotic’s robotic cameras.

Every automation system is a one-of-a-kind creation based on the manufacturer's specific requirements. The components in the camera units may change as the system's parameters change, necessitating camera housing modifications. To keep up with rapid iteration, Omnirobotic engineers use CAD for 3D printing to create 3D-printed prototypes to test the customized system before the final product is machined in aluminum.

Omnirobotic’s technology allows robotic cells to “see” and respond to an individual part.

Cloud-native CAD allows designers to quickly generate and store numerous versions of a design and lets users easily blend the best elements from several models into a completely new one.

Engineers with Informal, a freelance network of engineers, use additive manufacturing to print several prototypes to adjust the fit and positioning of the Neurosity Crown, “the world's first wearable brain computer.”

By being able to hold and look at the quick plastic 3D prints, the team is able to speed up the prototyping process compared to the traditional method. The Informal team not only saves time in the prototyping process but in communicating with clients as well with the power of Onshape’s collaboration tools.

Because cloud-native CAD’s streamlined tools are available throughout the development process, Onshape makes sense for designers and engineers who want to iterate quickly, save money, and effectively use 3D printing technology.

eBOOK: See if your CAD software is the best choice for 3D printing

Cloud-Native CAD, 3D Printing, Endless Possibilities

3D printing, or additive manufacturing, has evolved from a hobbyist’s tool to an essential component in industrial-level product development. By leveraging CAD software for 3D printing, companies can accelerate their design processes, reduce costs, and bring products to market faster.

The integration of cloud-native CAD software for additive manufacturing further enhances the efficiency and collaboration within teams, making it a valuable asset in today's competitive landscape. As governments and industries continue to invest in and standardize 3D printing technologies, the future of manufacturing looks promising, with endless possibilities for innovation and growth.

Try Onshape Today

Head to our sign-up page to choose the right CAD plan for you and your team.

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Evaluating Onshape

- Simulation

- Rendering

- Surfacing

- Consumer Products

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 learn more

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more