08:07

Who is TALON 540?

TALON 540 Robotics, a FIRST FRC team, hails from Mills E. Godwin High School in Henrico, Virginia. The team annually supports between 50 and 70 students who participate in local robotics competitions, STEM advocacy, and community outreach. The goal is to provide students with a fun environment where they learn modern skills to take into college and careers.

In past years, ineffective project management practices spawned design and build processes that led to incomplete robots with little to no autonomous capabilities when competition season arrived. Students found themselves stressed out during build season and demoralized at competitions as the team struggled to get a functioning robot onto the competition field.

During the fall semester, the FRC preseason, the students dedicated themselves to improving various aspects of the team. TALON 540 developed an Agile project management system, restructured the team’s leadership, and adopted Onshape as its sole CAD platform to overcome the challenges the team faced in previous years.

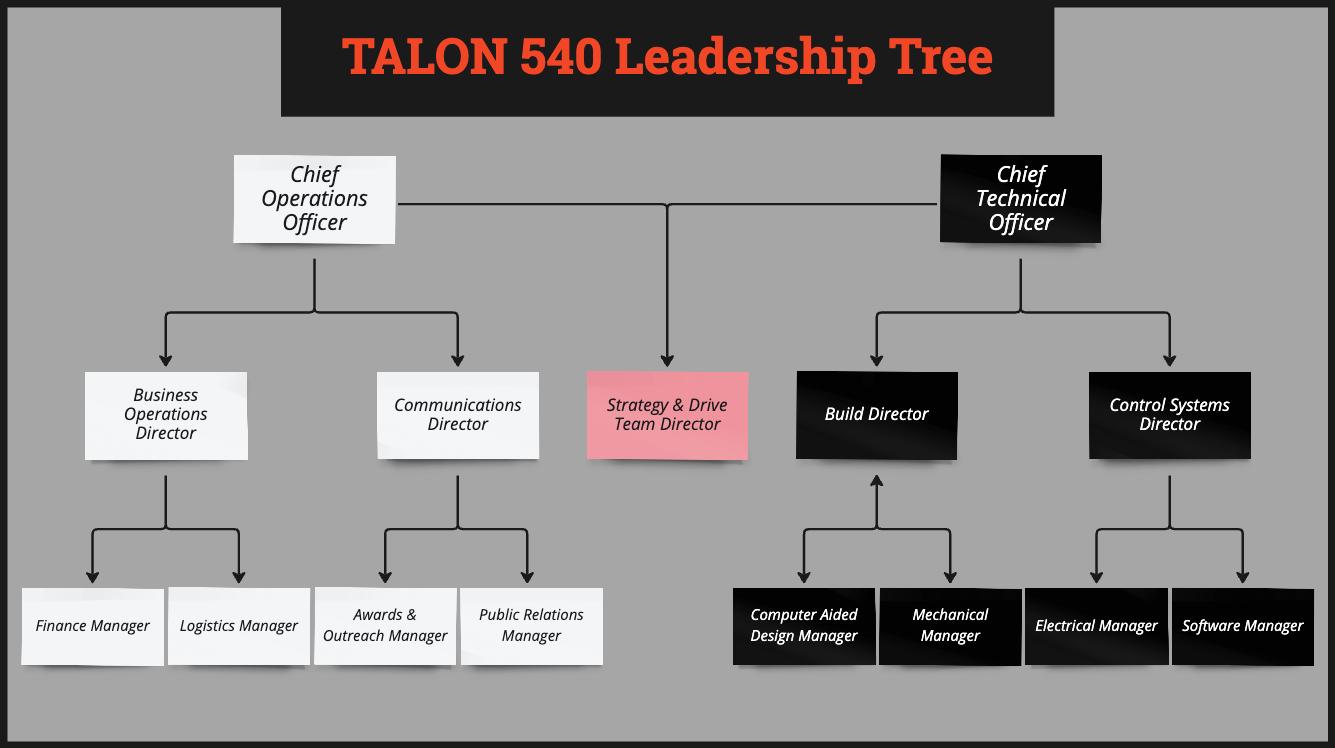

Leadership Structure

From top to bottom, a corporate team hierarchy typically includes a Vice President, Directors, Managers, and Team Members. The VP will typically work with Directors to determine goals and directions of the team, then Directors will work with Managers to determine strategies for achieving the goals. In reverse, Team Members will work with Managers on the details of their projects, and Managers can escalate issues to Directors or the VP for support.

TALON 540 applied a corporate structure to their team to facilitate better communication, efficient and informed decision-making, and increase the contributions of each team member. Similar to corporate structures, they split the team in two. The Technical Officer in charge of all things robot-related leads the Tech Team, and the Operations Officer in charge of business operations, events, communications, and advocacy/outreach leads the Operations Team.

The new leadership structure put decision-making power in the hands of a smaller number of people, making for a more agile and efficient decision-making process while leveraging everyone’s voice through one-on-one meetings, group meetings, and reflection surveys to help inform decisions.

Adopting an Agile Style of Project Management

The team decided to embrace the agile methodology for the build season this year, specifically the Scrum framework, which divides the project into smaller builds called sprints. They thought of Scrum as a formalized set of meetings repeated during each sprint – in order, they are planning, check-ins, review, and reflection. A product manager, a student role, curates the content for each meeting, and the scrum master, an adult mentor, runs the meeting to ensure efficiency. The team used Monday.com to track all tasks throughout the project.

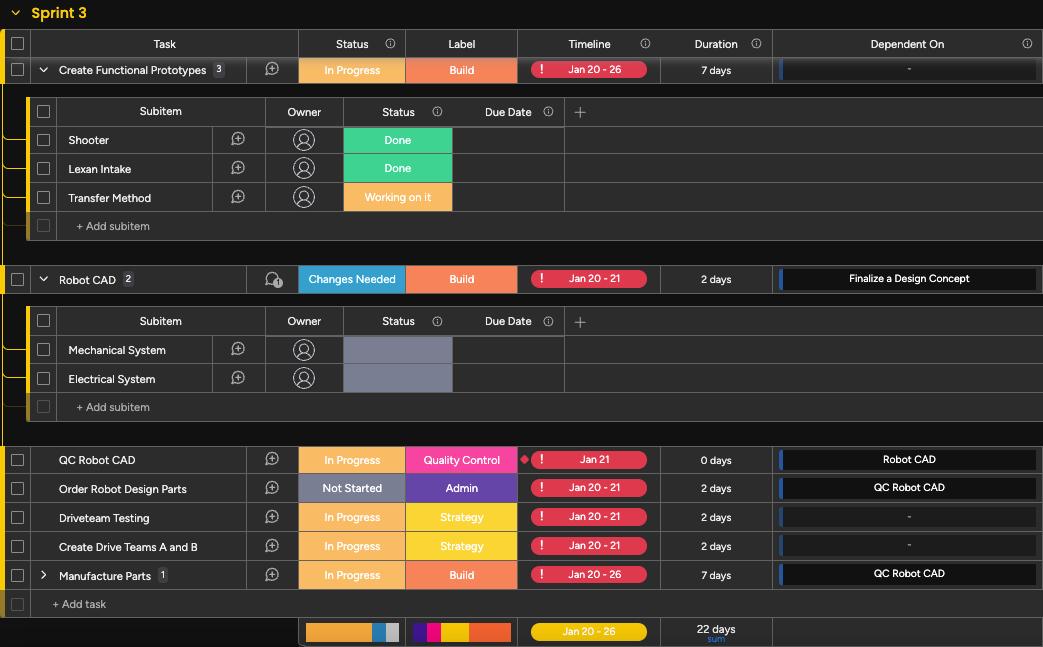

The Product and Sprint Backlogs

The product is whatever it needs to be. For the building season, the robot is the tech product, and awards are an example of products from the operations side. The backlog is a list of major tasks and subtasks required to build and maintain the product. The backlogs are ordered by priority or necessity, assigned to a person or group, and then have their statuses tracked along with dependencies between tasks and roadblocks preventing the completion of current and future tasks.

A Sprint backlog is a separate list of tasks curated from the Product Backlog. The product manager adds all tasks that should be completed during the upcoming sprint to the Sprint Backlog. Large tasks are broken down into component subtasks and assigned to individuals or small groups. Each task is tracked similarly to the Product Backlog. At the end of the sprint, the product manager rolls over all uncompleted tasks to the next Sprint Backlog and then adds new tasks from the Product Backlog.

A Typical Build Season Sprint

During Build Season, TALON 540 used 1-week Sprints to maximize flexibility during those 8 weeks. Each sprint started Saturday morning with a Leadership (high-level) Planning Meeting and ended Friday afternoon with a Leadership Review Meeting and submitting the reflection form.

- Saturday 8 a.m. – Leadership Planning meeting led by Officers, with Directors and Managers – Ops Team and Tech Team

- Saturday 9 a.m. – Group (low-level) Planning Meetings led by Directors, with Managers and Group Members – BizOps Group, Communications Group, Build Group, Controls Group

- Saturday midday – Group Check-ins followed by Leadership Check-ins

- Monday 4 p.m. – Group check-ins followed by Leadership Check-ins

- Thursday or Friday, during school or at the end of a team meeting, if one occurs – Leadership Review Meeting

In between meetings, leaders and team members worked assigned tasks while the Officers steered the ship.

Regular planning meetings led to fluid communication across the team, reducing rumors, misunderstandings, and confusion. Regular meetings became an opportunity for built-in conflict resolution. Failed tasks became opportunities to discuss what went wrong and how to fix the issue instead of assigning blame. Effective planning led to efficient use of materials, people, and time – the robot was mechanically and electrically complete in 5.5 weeks instead of the usual 8-plus weeks.

Thinking of Agile as an iterative approach to managing projects that focuses on continuous releases and incorporating customer feedback with every iteration, how does Onshape work for TALON 540 as a tool to facilitate this approach?

Implementing Onshape with an Agile Team

When TALON 540 adopted Onshape last year, the Technical Team used Learning Center courses to learn the fundamentals of Onshape to train new and veteran members on the basics of using Onshape, including the Fundamentals and Basics modules.

They took full advantage of Onshape’s cloud-based collaborative document structure. Multiple students worked on the main document simultaneously and asynchronously. The district-provided laptops had no problem running Onshape since no installation was required, and local resources were required to run Onshape. With file management a thing of the past, students focused more of their time on design and honing their skills.

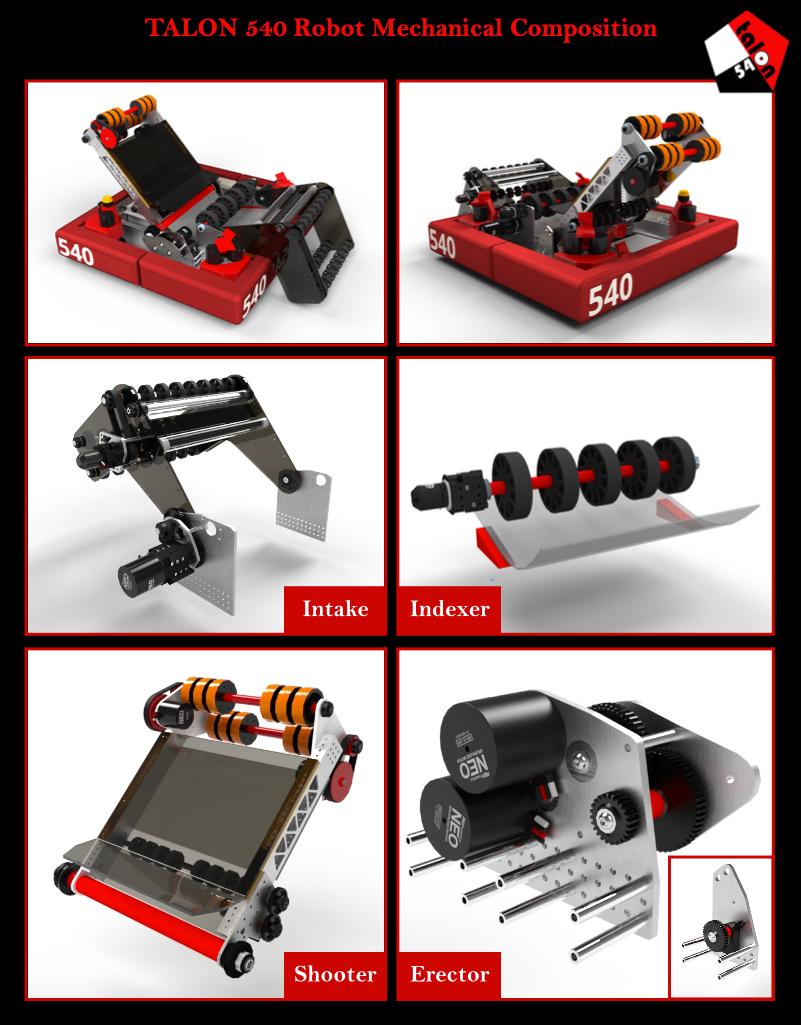

This year, the team significantly expanded their use of available resources and features and began experimenting with new techniques to maximize Onshape’s capabilities. Additionally, as part of their design process, the team implemented an iterative design approach, incorporating Onshape as part of the design feedback loop. The team took further advantage of collaboration concepts within Onshape to allow multiple groups to design each mechanical sub-assembly, electrical system, and sensors in Onshape simultaneously, instead of waiting for completed design files to be delivered. Finally, they added extensive Quality Control to their design process, where Onshape played a central role in design. All told, TALON 540 saved 3 weeks of time from previous years.

In preseason, training new members in CAD became a lot easier to facilitate and monitor asynchronously with the release of Classes & Assignments. The CAD group used Classes & Assignments to assign new CADders exercises from Intro to CAD and CAD for Robotics Competitions, as well as custom assignments. Their student leaders take on the responsibilities of teaching new members the basics, so mentors gave the CAD Manager Educator privileges for a class so they could run and monitor new member training throughout the preseason.

Additionally, CADders used the CAD Challenges app for extra CAD practice. The Onshape Learning Center became their source for veteran members to learn advanced topics in the use of Part Studios, Assemblies, and FeatureScript.

Designing the Robot

Based on past precedent, TALON 540 set up their build season calendar to include one week of CAD, three weeks of build, one week of electrical, and three weeks of sensors and programming. In the past, the mechanical group took several weeks to design and build the robot, while the CAD group copied what the mechanical group built. The Electrical group took the remaining time to lay out and assemble the electrical components and complete the wiring. Programming would get the robot in the pits as mechanical and electrical continued to iterate, problem-solve, and build.

This year, prototyping and CAD worked together to design and QC the robot over three weeks. With a fully specced robot, the build team just had to put the robot together. The Build Group completed building the mechanical aspects of the robot 4.5 weeks into the season. The Electrical group completed their work one week later, giving the programming and drive groups 2.5 weeks to bring the robot to life and practice driving, something unprecedented in the team’s history. Their agile approach allowed them to pivot to this unforeseen timetable.

The Team’s Plans for the Future

This past year, the team only applied Agile to the build season. Next year, they plan to implement Sprints, Product Backlogs, and Scrum meetings throughout the school year to help organize training, events, and postseason. They hope to be more disciplined in preparing for and conducting each meeting throughout the year. The results of applying an Agile design workflow for the mechanical and electrical aspects of the robot exceeded expectations.

Follow TALON 540 Robotics' progress on their website.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

(Ryan Mosse works for PTC Education as a Data Systems Engineer. He was a high school teacher for 10 years, leading students through engineering, computer science, math, and music classes. He continues his involvement in education by supporting educators and students with PTC Education and Onshape and mentoring TALON 540 Robotics.)

Latest Content

- Case Study

- Automotive & Transportation

Zero Crashes, Limitless Collaboration, One Connected Workflow With Cloud-Native Onshape

12.04.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more