1:25

You might not know exactly what removable carbon brush holders or shaft grounding systems do, but you definitely depend on them every day. They are critical equipment for electric power plants – whether the generators are nuclear, coal, wind, hydroelectric or natural gas.

Based in Ferndale, Washington, Cutsforth Inc. designs and manufactures this equipment for some of the world’s largest power companies and corporations, including National Grid, Pacific Gas and Electric, ExxonMobil, Shell and General Electric.

The high stakes of keeping the lights on means that Cutsforth has very little room for error. Depending on the size of the power plant, a delay of only 10 to 24 hours can cost hundreds of thousands of dollars.

What can cause one of those delays? Well for starters, Cutsforth’s old CAD system was very susceptible to crashes. Their design team also says they used to devote way too much time to managing their PDM system, which housed more than 15,000 legacy files accumulated over 10-12 years.

As Cutsforth CEO Rob Cutsforth puts it, “We’re product development people, we’re not in the IT business.”

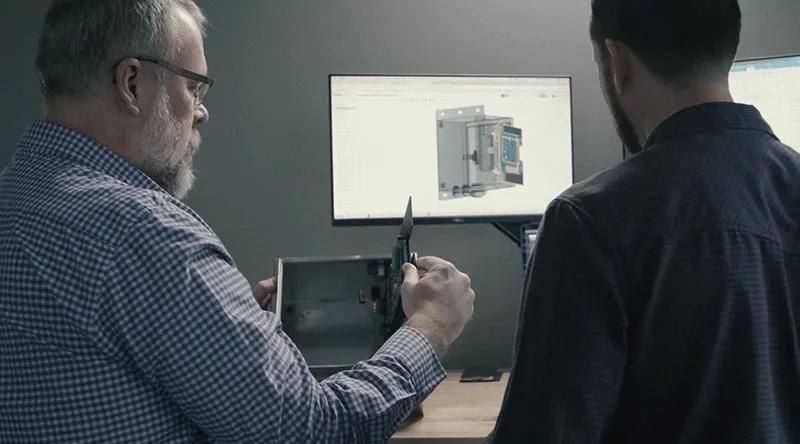

Cutsforth CEO Rob Cutsforth (on left): “If you don’t like change, you’re not going to be happy here.”

The lure of Onshape’s built-in design data management was strong, but switching from SOLIDWORKS® to Onshape wasn’t a sudden decision. First, the company designated one of its R&D engineers as the staff “guinea pig,” and had him design only in Onshape for a few months.

At the end of the experiment, their guinea pig didn’t ever want to go back.

Watch this video to see how Cutsforth is streamlining their entire design and manufacturing process with modern CAD!

The CAD Migration Station

Find everything you need to know about transitioning from SOLIDWORKS to Onshape.

Latest Content

- Case Study

- Industrial Equipment & Machine Design

Reframe Systems: Transforming Homebuilding with Digital Automation and Cloud-Native Onshape

09.25.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more