Manufacturing engineers need to determine the most efficient way to manufacture each part of a design. Whether that be by machining, casting, molding, sheet metal, fabrication, or rapid prototyping, input from the manufacturing floor early on can reduce the number of redesigns later.

However, manufacturing engineers typically have not had access to traditional 3D CAD because the high cost of licenses and hardware couldn’t be justified. Jig and fixture designers don’t use CAD anywhere near as frequently as the core design team. So they’ve usually had to trek to another department for the nearest computer installed with CAD software.

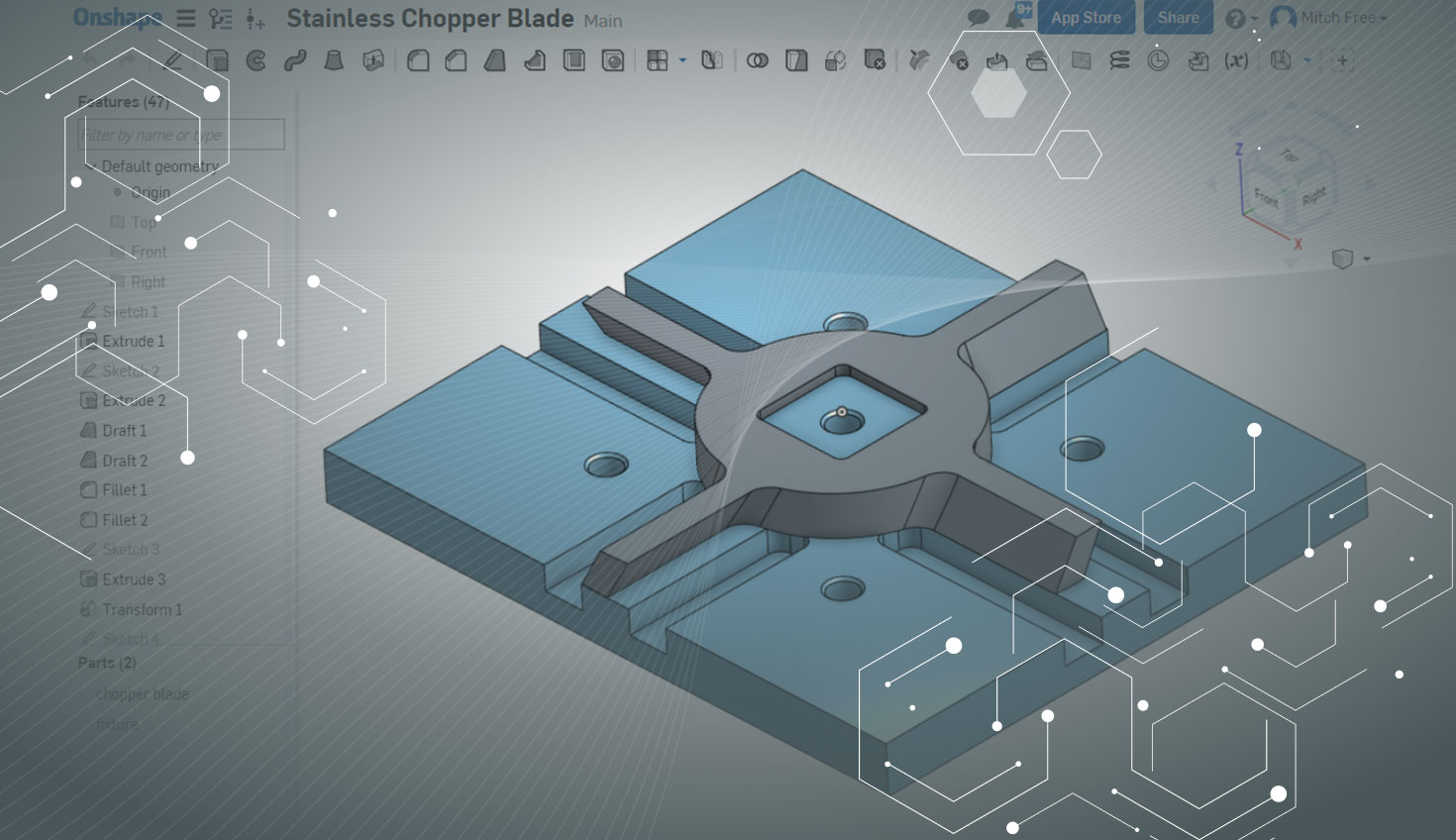

But there’s a faster way. As part of modernizing your shop floor, your team can now design fixtures and jigs in Onshape online right at their workstations. Since full-cloud CAD runs on tablets and even inexpensive Chromebooks, it’s instantly accessible to anyone who needs it. Regardless of which CAD system you’re using for core product design, fixturing lends itself nicely to a multi-CAD environment because you don’t want the fixturing person to edit the actual product. You just want him or her to build around it.

How much time can be saved by making full-cloud CAD available everywhere on your shop floor? ZYCI, a high-end CNC machining and additive manufacturing company, credits Onshape for saving its team at least a day in production on every manufacturing job.

“Regardless of which part we are manufacturing on short notice, Onshape helps us streamline the process and be more agile on the shop floor,” ZYCI CEO Mitch Free says. “It’s a difference that doesn’t go unnoticed by our customers.”

“Sometimes we save a little more time and sometimes it’s a little less, but it makes no sense to return to the days of one person designing all the fixtures and creating a bottleneck,” he adds.

Can your company use an extra day or two this month?

Because the cost of traditional desktop-installed CAD has been prohibitive ($5,000+ for a license and $1,295+ in annual maintenance fees), it’s understandable why 3D tools have been out of reach for most professionals outside the core product design team.

However, the affordability of Onshape ($125/month billed annually) allows companies to take advantage of full-cloud CAD throughout their organizations. Beyond speeding up jig and fixture design, here are some other ways that Onshape can improve the way you do business:

- Accelerating Sales Results – Engineers teamed with sales reps can make requested design changes on the spot as impressed prospects follow along on their phones. In addition, Onshape Documents can efficiently aggregate 3D design information with existing customer data for better sales intelligence.

- Enriching Customer Engagement & Support – Using Follow Mode and Onshape Comments, you can visually communicate with customers from within your design models and better respond to their needs.

- Enhancing Marketing Collateral – The constant need for quality product images shouldn’t be the engineering department’s burden. 3D models and rendered images make press releases, trade show banners and other promotional materials shine.

- Improving Communication With Suppliers – Instantly and securely sharing your designs with suppliers helps you quickly source the best components. There are never any software compatibility problems because all Onshape users are always on the same version of CAD – the latest one.

- Improving Accuracy in Order Fulfillment & Inventory Management – Warehouse workers can quickly verify the contents of shipments by matching 3D models to their corresponding parts – all with the click of a hyperlink. Every Onshape Document, Part Studio, Assembly, Drawing, and Version has its own unique URL address that can be pasted into any database.

Interesting in learning more? You can fully explore each of the above strategies in the eBook, “Extending CAD’s Business Value Beyond Core Design.” Download your free copy today!