03:58

Manufacturing companies are searching for solutions to organize a seamless and effortless data handover between different processes in the organization.

Traditionally R&D activities and procurement activities belong to different departments and live in different information silos. It creates an enormous amount of inefficiency; the information is lost, wrong data is used, and the communication between engineers and purchasing departments is disparate.

The outcome is an extra cost, mistakes, and, as a result, delays and quality issues.

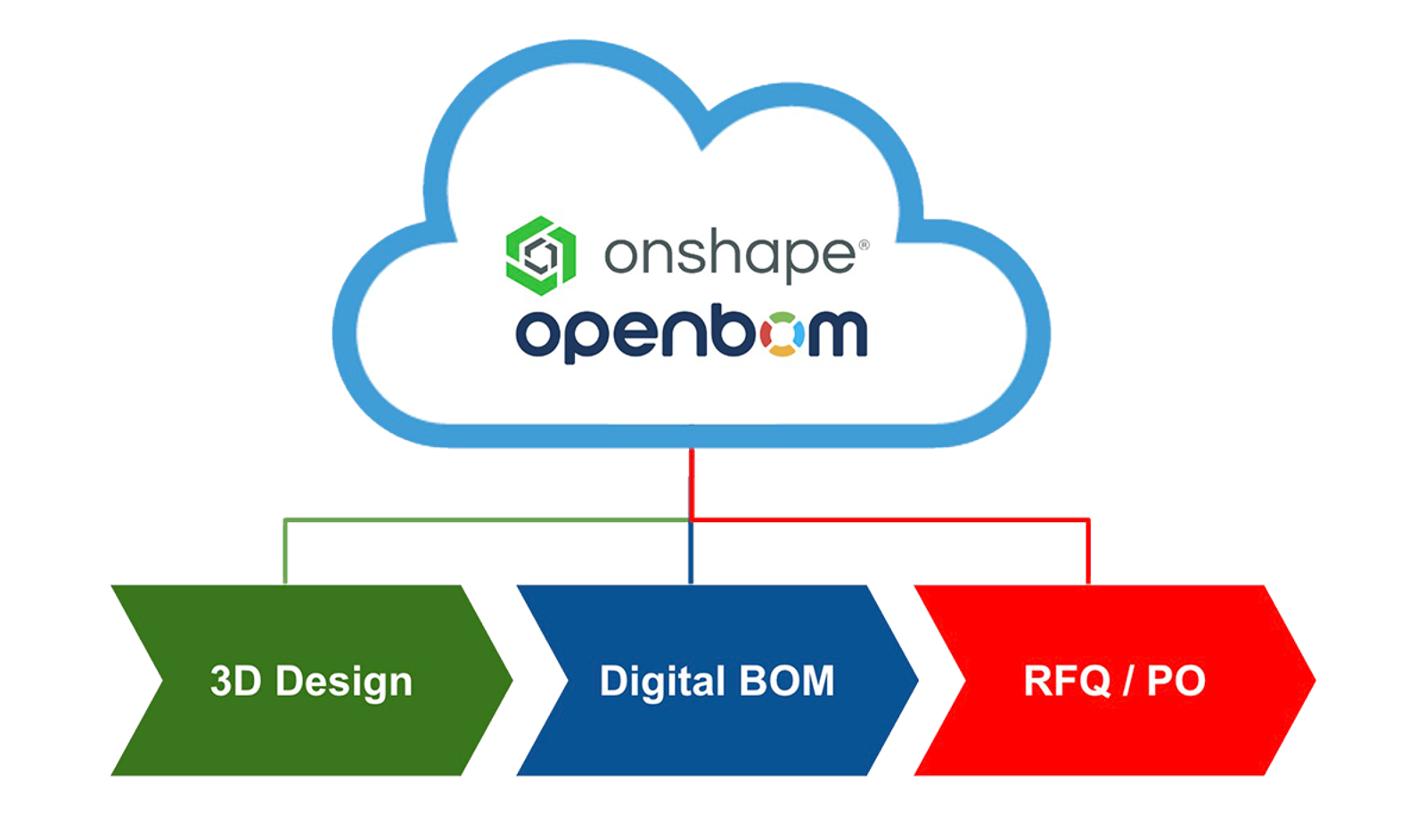

Tight integration between product design tools breaks down those siloes, creating a single source of truth about the product and purchasing information and, as a result, increasing efficiency and saving money.

At Xtend Robotics, teams are able to seamlessly work together with the use of cloud-native tools.

‘A Magic Duo’ of Product Development Tools

Xtend Robotics is literally making the service robots of the future! Their robots can and will be assisting doctors and nurses in hospital and care facilities, providing telemedicine to those in remote facilities, and taking orders and delivering dinner right to the table at a restaurant near you.

Xtend Robotics was founded in 2020 by CEO Harry Fox and a team of forward-thinking technology and business veterans who understand the role robots are to serve.

David Rubli joined the U.S. and Israel-based company in 2021 as the Senior Mechanical Engineer and is responsible for not only what the company designs but how they design as well.

“I came to Xtend Robotics with a proven set of tools that delivered productivity immediately,” David told us. He brings a “magic duo” of tools: OpenBOM and Onshape.

“What I like the most about Onshape and OpenBOM is the ability to model and plan for all aspects of our robots, and not just those items confined to traditional CAD.”

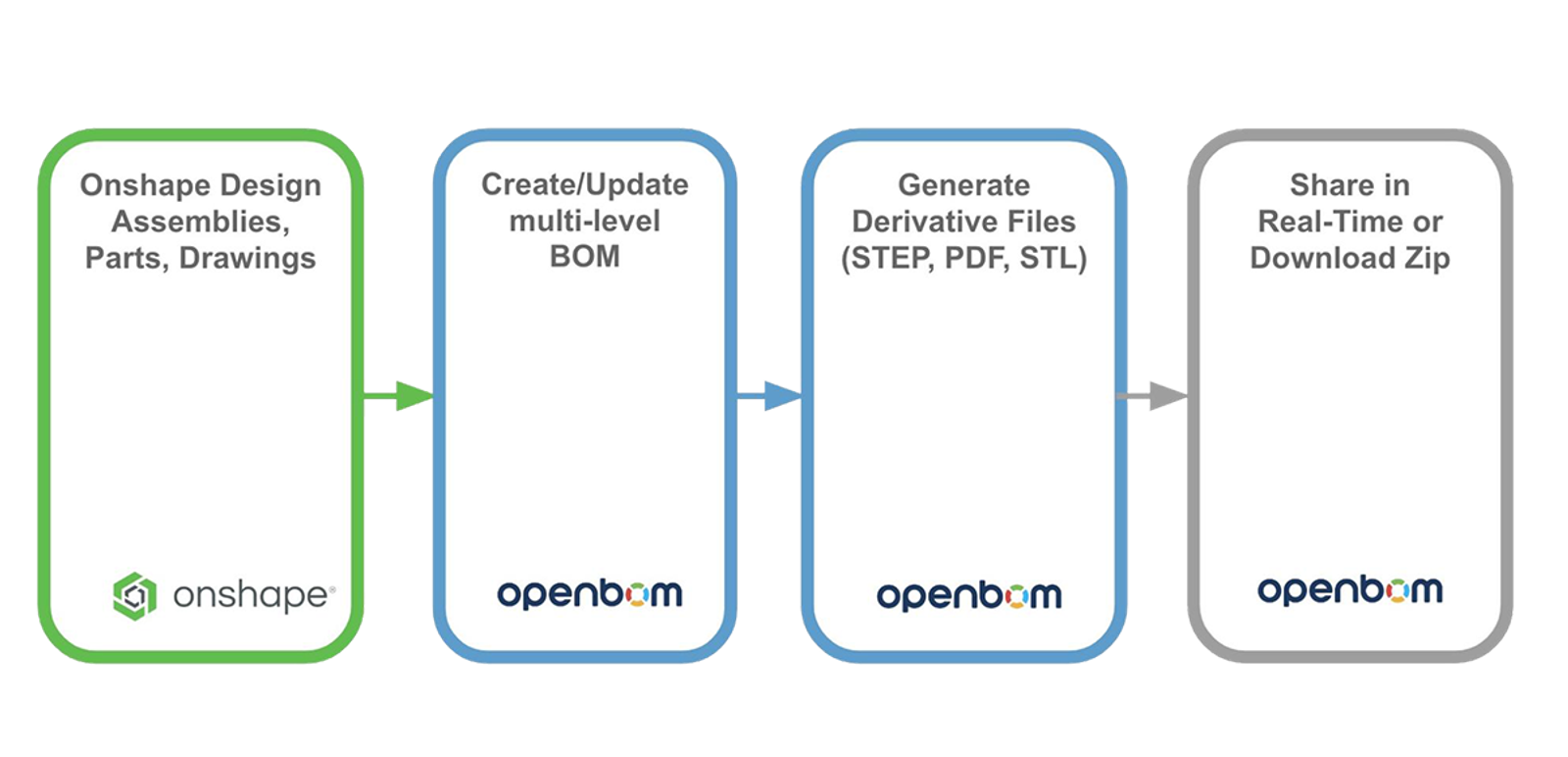

“Our wire harness and PCBs are all designed separately and then brought together in OpenBOM to form a complete multidisciplinary BOM of our entire buy-level product,” David explains. “We can manage non-modeled items like adhesive or labor easily in OpenBOM, create a new purchased BOM and manipulate options and variations.”

“As our company and products mature, we are managing inventory and creating external and internal POs to drive manufacturing. All with one item master definition and never any duplicates!”

The impact on the business is important to the company leadership and engineering team.

“Reducing disparate tools speeds processes. We can go into manufacturing with confidence,” he says. In the past, component and supplier RFQs were done by hand and were a burden to the team.

“OpenBOM and Onshape combined to reduce the RFQ and PO process by 75% while greatly increasing the quality of the overall activity,” David says. “The individual RFQ was significantly more accurate and well understood by everyone involved.”

What’s New with OpenBOM

If you’ve been following Onshape news, you may have already heard of OpenBOM and considered adding it to your repertoire of powerful tools.

The latest enhancements to OpenBOM should make the decision even easier for you.

The automation of one of the most painful engineering tasks on the team, the creation of the derivative files needed for manufacturing.

Let’s take a closer look at how OpenBOM can improve your workflows and increase your productivity. In particular, let’s check how OpenBOM's new features allow you to create PDF, STL, and STEP files, and automatically attached to OpenBOM Items and BOMs.The enhancement closes the digital loop between the design process and the creation of digital BOM, which is not only a list of components but a comprehensive representation of product information, with all dependencies and relationships including cost, vendor, product spec sheets, drawings, STEP files, etc.

Digital Tools and Connected Processes

A digital thread is an uninterrupted flow of data and information that can be accessed by authorized users. It helps connect software-as-a-service (SaaS) tools and processes, making it possible for everyone to have the most up-to-date information regardless of location.

This level of interconnectivity allows businesses to operate more efficiently and effectively, which is why we recommend creating a digital thread for your business. By connecting SaaS tools, you can create a digital backbone that will support your company now and into the future.

Through a seamless connection of cloud-native SaaS tools, such as OpenBOM and Onshape, companies can benefit from improved process and data organization, which streamline processes, eliminate mistakes and increase the speed of operation.

The Onshape App Store

Extend the power of Onshape with integrated cloud partner apps for PLM and more.

(Oleg Shilovitsky is a co-founder and CEO at OpenBOM.)

Information from the OpenBOM website was repurposed for this blog.

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more