1:19

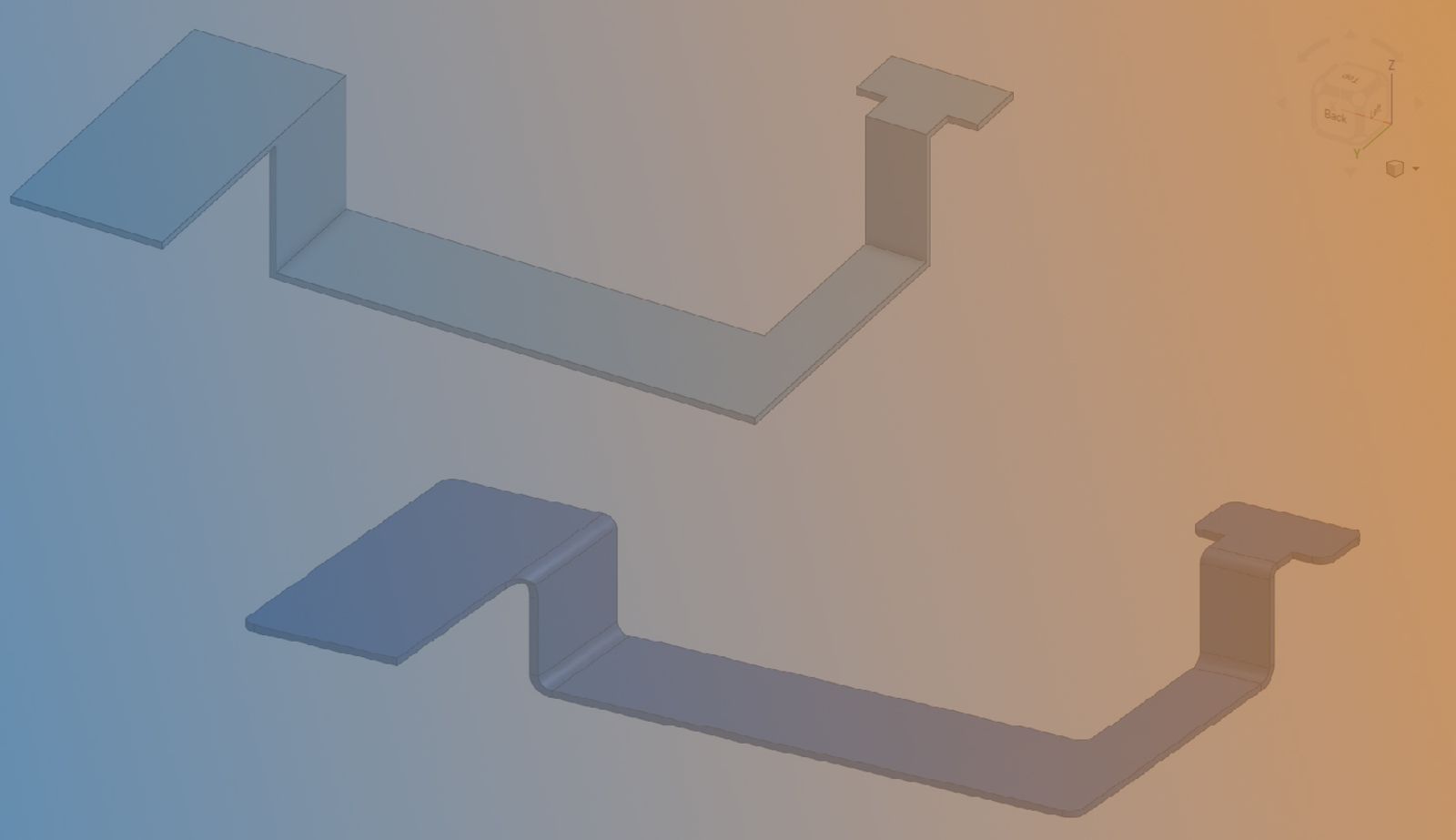

When you convert sheet metal components from legacy systems you often need different sheet metal bend geometry. Onshape uses a unique approach to bent and flattened states of a component that allows you to modify the design in both states.

Modeling Using Standard Features

If you want a sheet metal component, you can use standard modeling practices to create the geometry and then use Onshape’s Sheet Metal model feature to convert the model to sheet metal.

Once the model is converted, the bends and corners may not meet your specifications, or you may be using the Sheet Metal tools in Onshape to mimic other bending applications like flexible printed circuits or paperboard boxes.

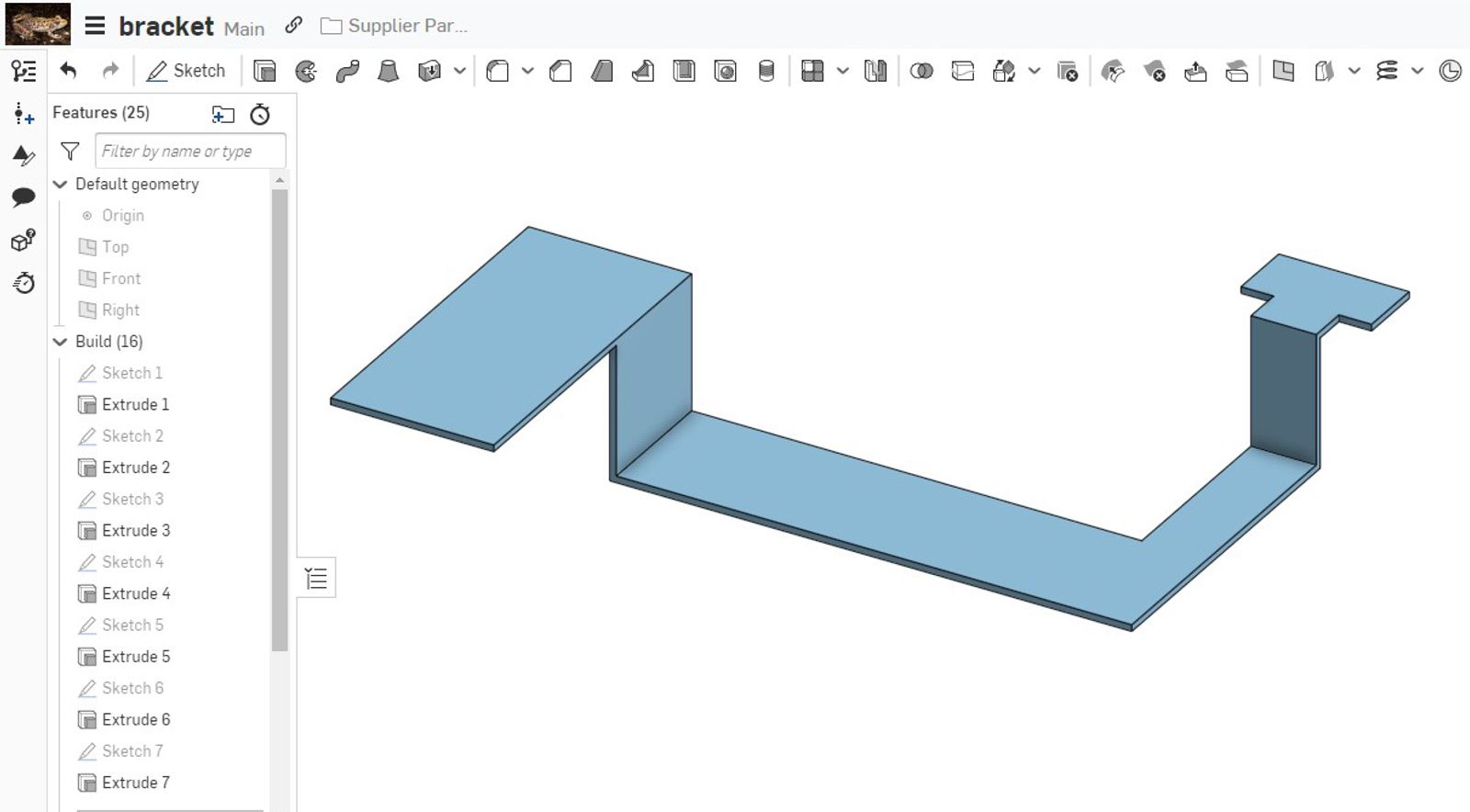

Modifying the 3D and Flat Pattern

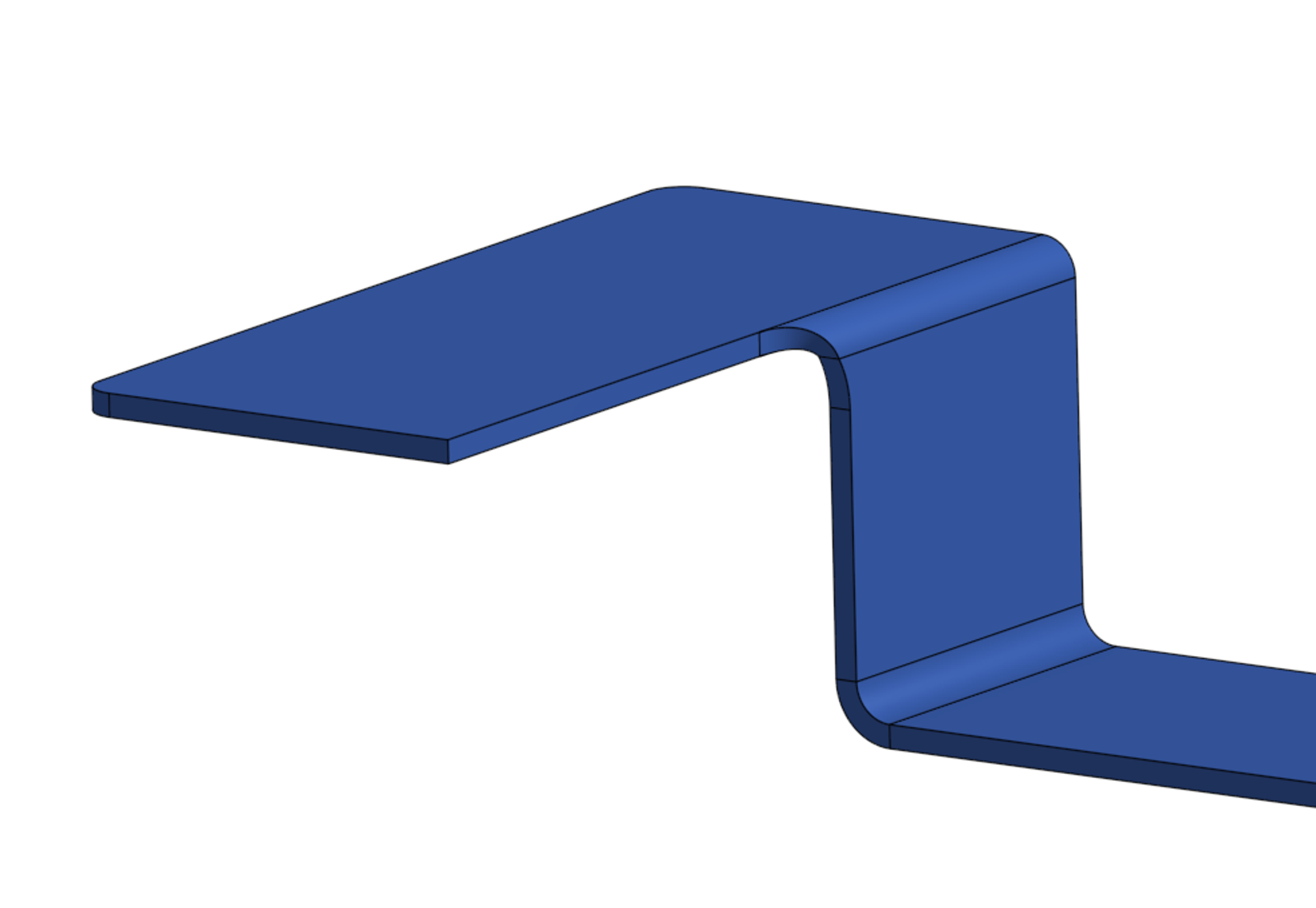

In the following example, we have a sheet metal model that requires bend and corner alterations. Using the power of Onshape's features, these modifications are easily made in just a few steps.

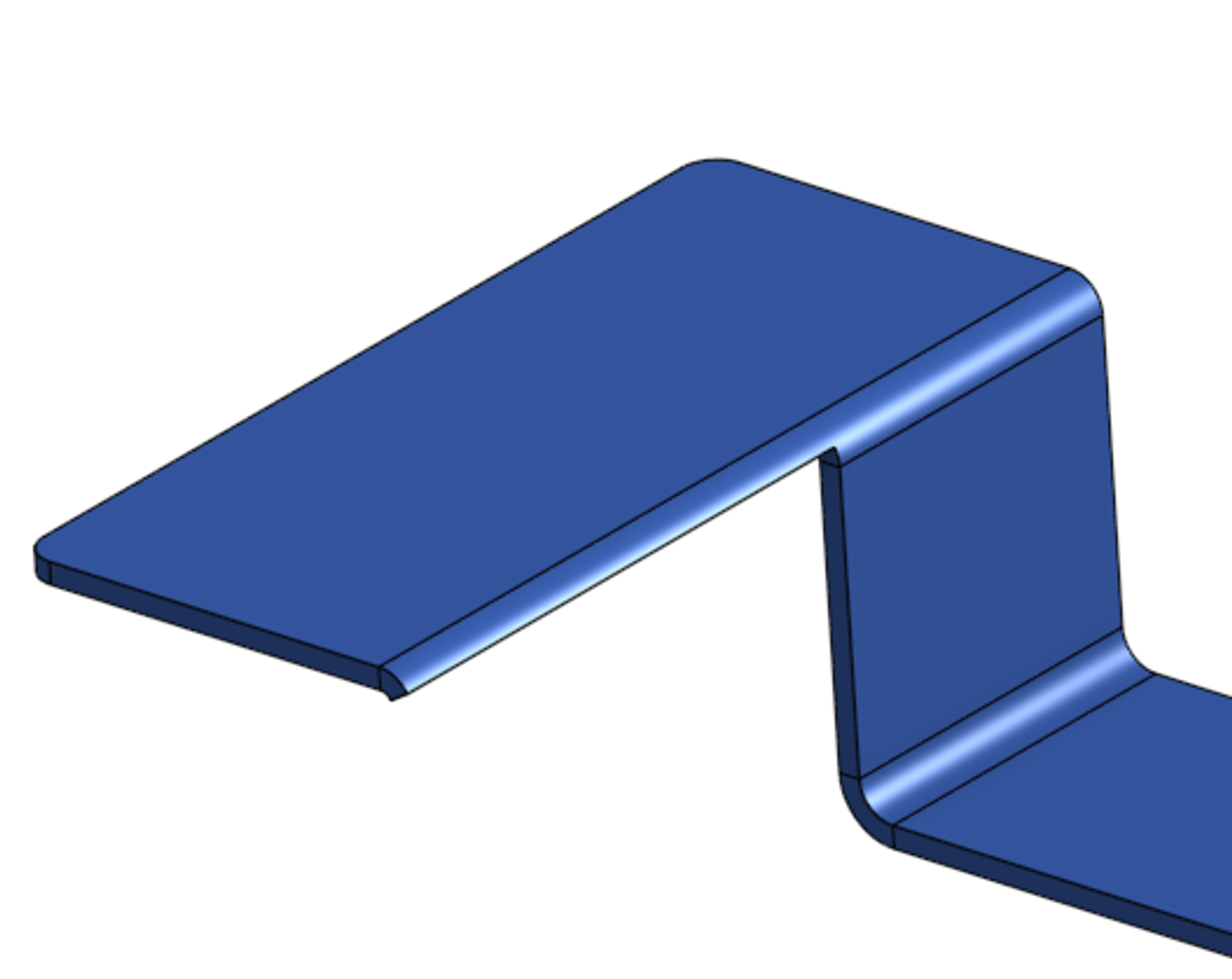

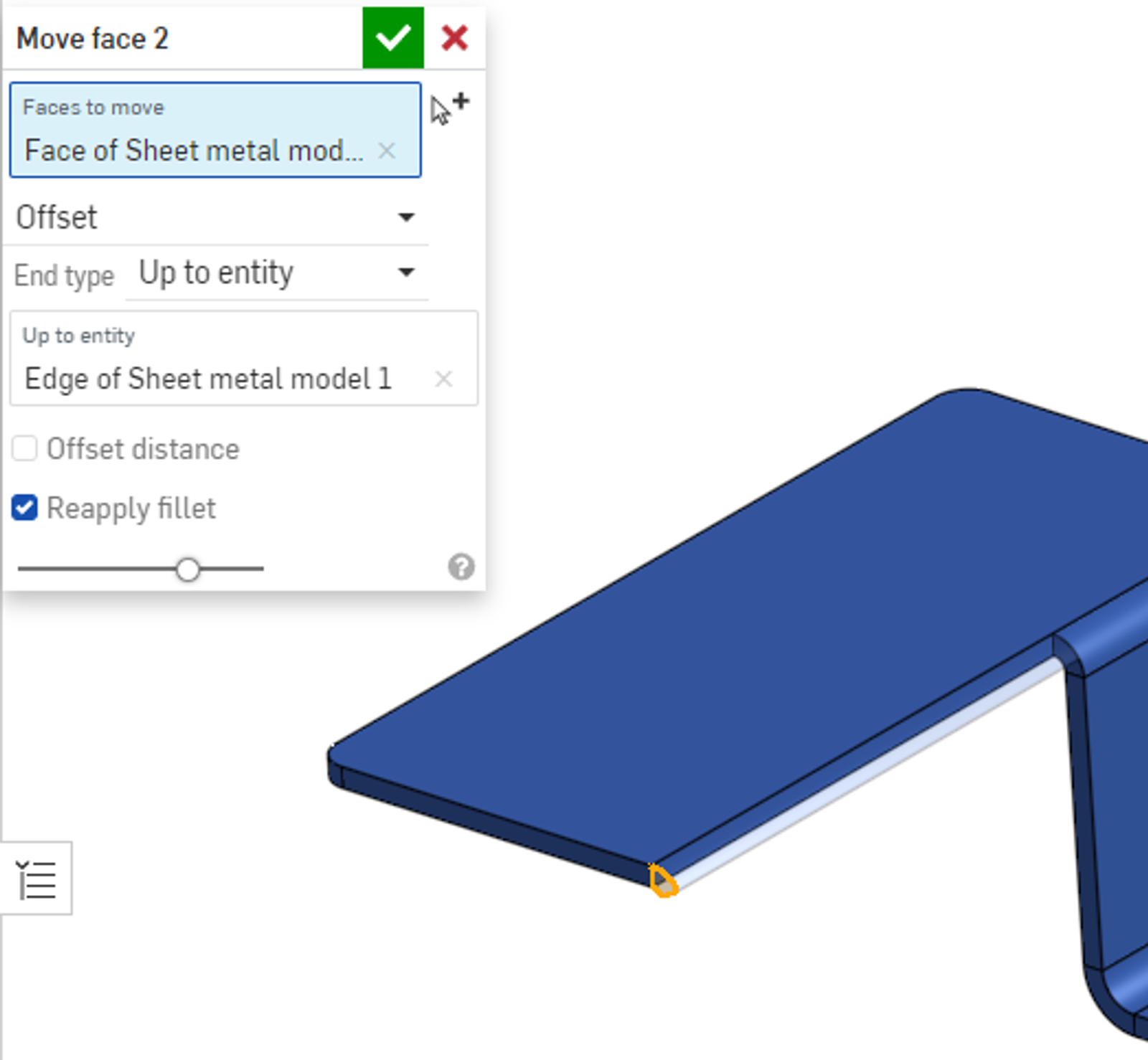

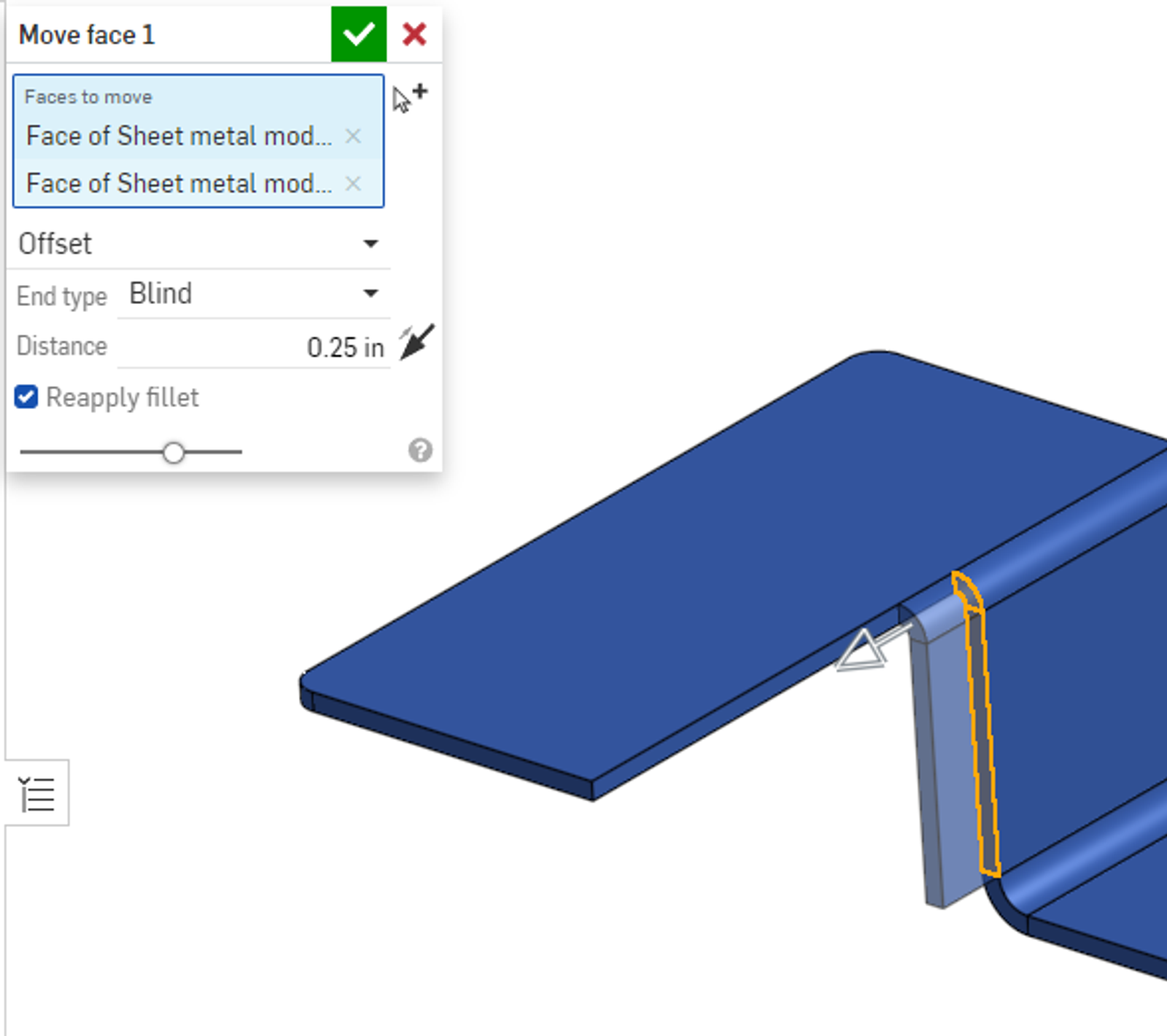

1. Modify the converted part with the Move Face feature. This removes unwanted material.

2. The Move Face feature also allows you to add extra material.

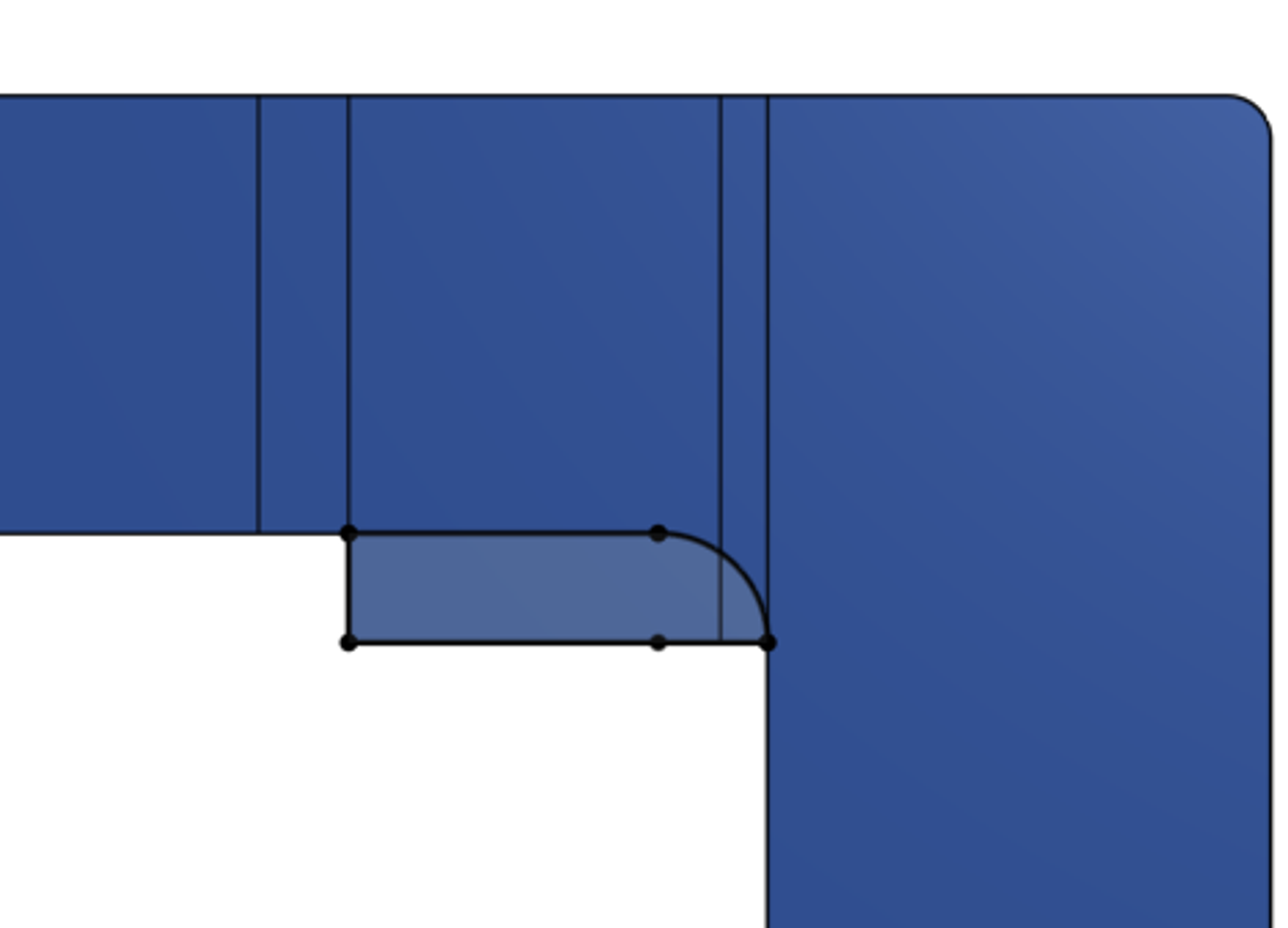

3. Modify the model to have the specified geometry in the Flat View.

4. The 3D model updates at the same time.

This Tech Tip helped you learn how to modify Sheet Metal models to achieve the desired geometry. Watch the video below to see this tip in action.

For more information on removing holes in sheet metal models, see our Tech Tip on how to easily remove holes in sheet metal parts. In addition, check out the Tech Tip on Partial Flanges.

The Onshape Learning Center

Take self-paced courses, get technical briefings, or sign up for an instructor-led training session.

Latest Content

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more