4:30

Accelerating time to market is a critical consideration in the product development process. Unfortunately, a longstanding challenge faced by teams is a system for CAD version control.

For designers and engineers seeking to share their design concepts with one another, and also ensure timely review and approval by managers, the simple attempt of getting (and keeping) everyone on the same page is inordinately difficult.

Thus, version control for CAD becomes imperative.

What’s Version Control?

Version control systems track changes made to product data over time. With an effective version control workflow, you can:

- View a comprehensive revision history of who changed what and when

- Easily revert back to previous versions of a file if needed

- Merge contributions and feedback from multiple users into a single updated version

- Create parallel branches to test out ideas without altering the main version

Having a reliable version control system is essential for critical product design data like 3D CAD models that undergo multiple cycles of changes and approvals. Poor version control can lead to lost work, accidental overwriting of changes, and general chaos when trying to consolidate input.

File-Based CAD’s Version Control Woes

Most traditional CAD tools still rely on the same fundamental file-based approach that originated decades ago. This approach essentially only digitized the existing processes of the original pencil and vellum design process.

In those early days, a user would make their edits to the master file, which was then protected tightly under lock and key in a file drawer. Following this same approach, file-based CAD software requires users to make all edits to one file.

For instance, to share a project with a colleague, a file-based CAD user must first make a copy of their design file and then distribute that file – often through email or a file-sharing service such as Dropbox – to one or more collaborators. After receiving their copy, the colleague must find a way to share their edits or suggestions with the file owner, again via email or Dropbox.

This back-and-forth process is cumbersome and inefficient. As one can imagine, reviewing, consolidating, and synthesizing feedback from multiple stakeholders can create an enormous administrative challenge. This tedious process often results in version control issues where key ideas can be missed or critical design elements can be lost or overwritten by accident.

To address version control woes, many companies implement PDM (Product Data Management) systems on top of their file-based CAD tools.

However, these solutions simply put filters and processes around the same fundamental file-based approach.

PDM Not Quite the Version Control Solution

Perhaps the greatest challenge posed by the PDM vault is tied to the approach of their underlying technology. In serving as a gatekeeper to data, to the exclusion of user needs, the technology inevitably creates downtime. Users must bide their time, waiting for coworkers to finish their work on a design file and return it to the system, before they can be granted access.

This outdated approach to data management is representative of an earlier era in technology. The forced serial editing process is more akin to the traditional waterfall-based product development methodology than today’s widely sought-after agile approach to product development.

For file-based CAD users, the extra wait time is more than an annoying inconvenience. The PDM vault creates inefficient check-in/check-out processes that hold up team members while they wait for files. The rigid data management also hampers design iteration and free exploration of ideas.

EXPLORE: 6 Ways Onshape's Cloud-Native PDM System is Advancing Data Management

Single Source of Truth: Cloud-Native CAD with Built-in PDM

In contrast, cloud-native CAD platforms, like PTC’s Onshape, resolve versioning headaches by utilizing a cloud-native data architecture that provides a true “single source of truth.”

With a cloud-native CAD system like Onshape, you get:

Real-Time Collaboration on the Same Design

- No more dealing with multiple copied versions of the same file

- Multiple CAD users can access and edit the 3D model simultaneously

- All teammates can see each other's changes happening in real time as work progresses

Comprehensive Edit History and Version Tracking

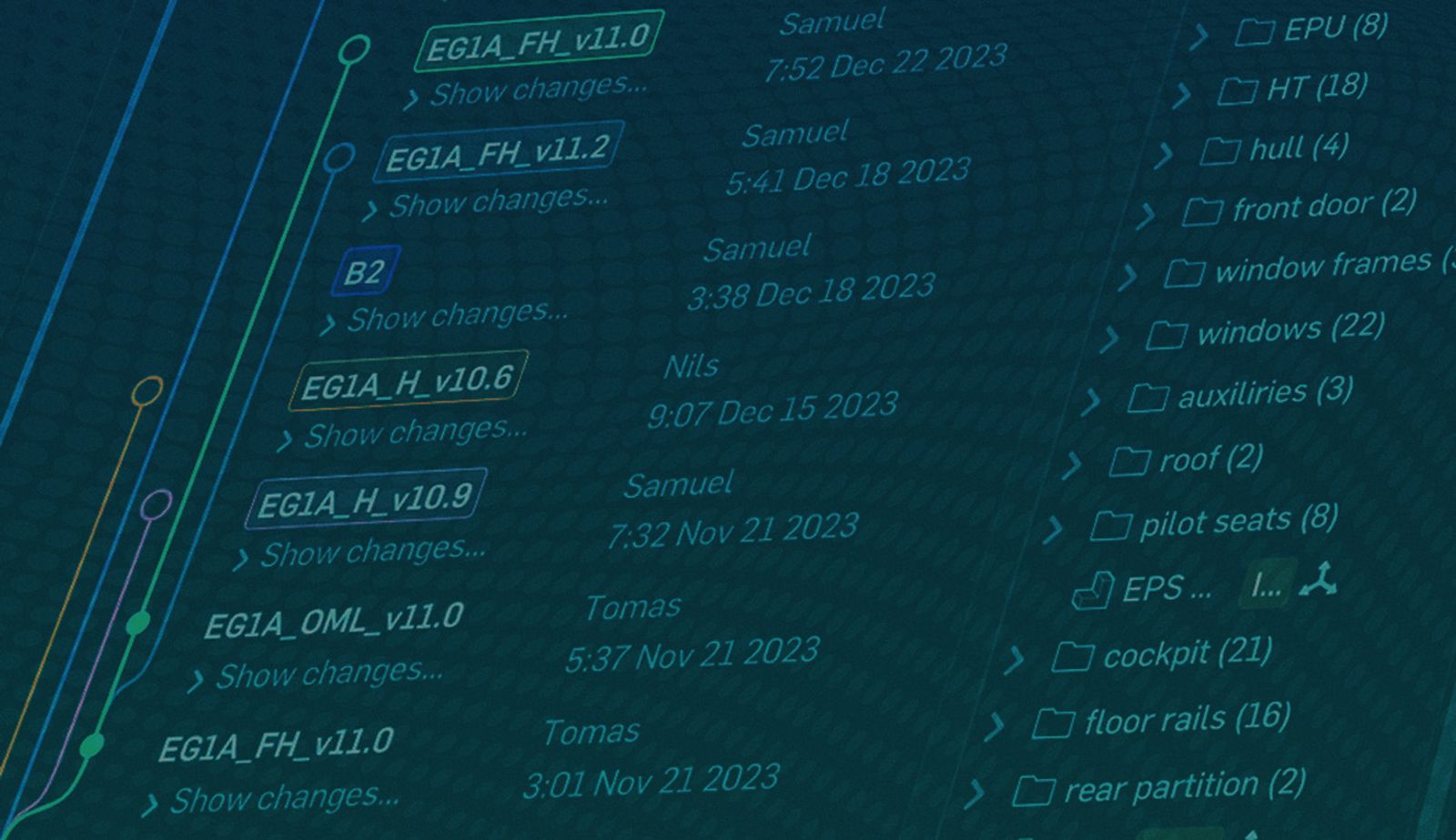

- Every single revision is automatically tracked – who changed what, when, and why

- Visually review a timeline of the editing process with 3D version comparisons

- Quickly revert to any previous version with just one click if needed

Flexible Branching and Merging of Designs

- Create parallel branches to explore "what-if" alternatives without altering the main design

- When ready, selectively merge branches to combine the best ideas into the main model

- Test out concepts freely knowing you can simply unmerge branches later

Streamlined Reviewing and Approval Process

- No more emailing copies for feedback – share a web link to the latest version

- All reviewers automatically see changes as they happen and merge feedback inline

- Mention teammates, collaborate in real-time, or lock designs pre-release

Rather than getting bogged down managing files, cloud-native version control frees your team to focus on designing, iterating, and collaborating – not CAD data administration.

Onshape: CAD Version Control You've Been Waiting For

Onshape is the leading cloud-native CAD platform purpose-built to eliminate version control headaches.

Don't settle for product teams being held hostage by clunky version control patch jobs. Try Onshape today to experience the power of built-in, cloud-native version control. With powerful branching, merging, and edit history capabilities core to the platform, you can empower your engineers to design better products faster and with more confidence than ever before.

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more