5:47

Product data management (PDM) systems play a pivotal role in managing and organizing the complex interdependencies inherent in 3D computer-aided design (CAD) software. Before delving into the specifics of data management, let’s explore how these dependencies are created and the problems that can arise.

Why does CAD need PDM?

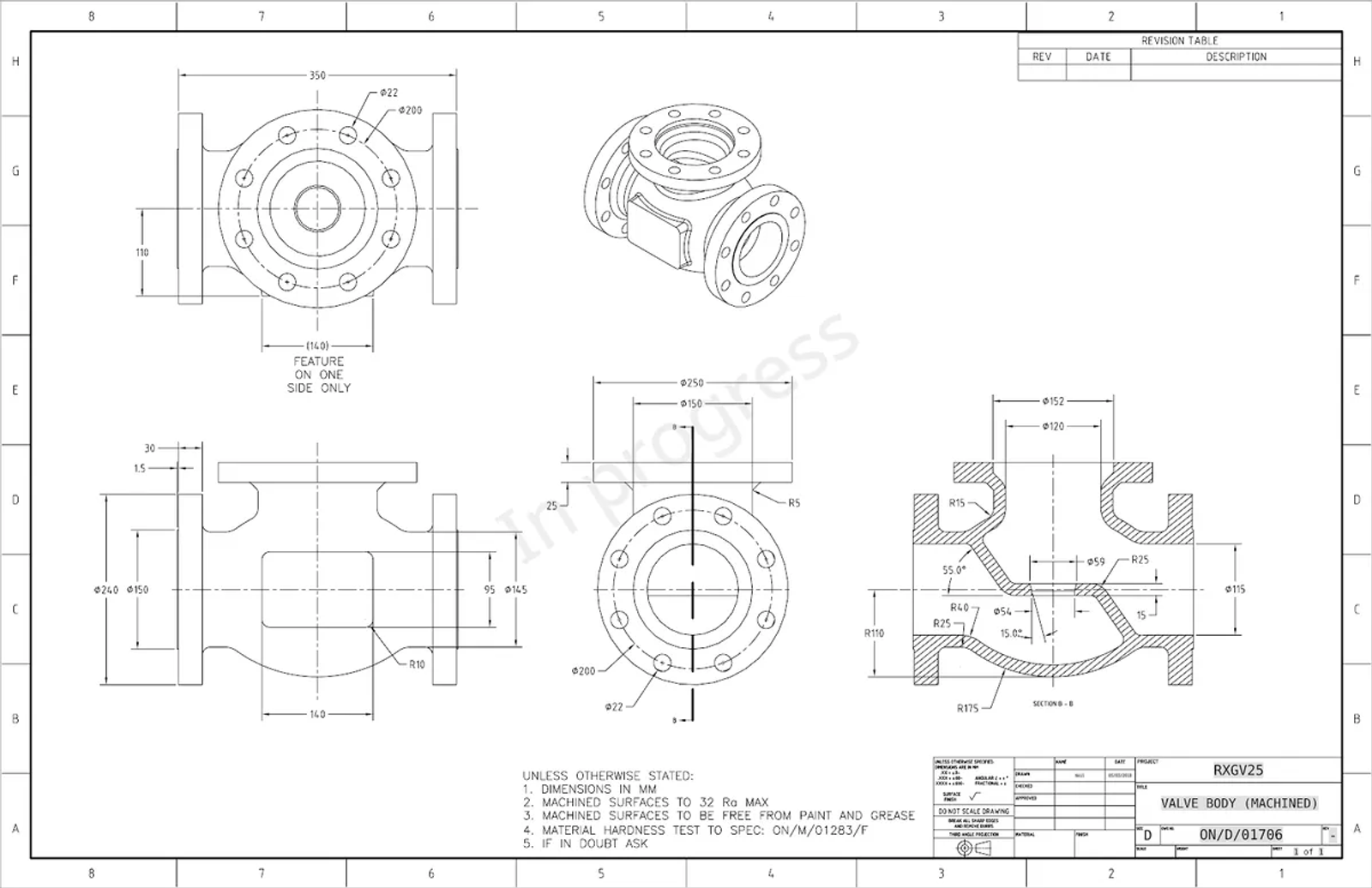

A typical CAD file contains either a part, an assembly, or a drawing. The part file contains the geometry, the assembly file positions the parts relative to each other, and the drawing file displays the views, dimensions, and annotations for manufacture.

This dependency chain all starts with the part file. If the part file is corrupt or missing, the assembly and drawing files are useless. Some systems cache display data to overcome this, but without access to the latest up-to-date part files, assembly, and drawing files are like a paper copy – unreliable and probably out-of-date.

Like a printed manufacturing drawing, a drawing file can be out-of-date the moment it is created.

It is impossible to effectively manage all these dependencies without data management software. PDM systems, often supplied by CAD vendors, understand the data structures within each file and know which files are dependent on others.

What is a PDM System?

When a design is checked into a PDM vault, each file is opened in turn, and metadata such as name, description, material, part number, and other file dependencies are extracted, recorded in the database and a copy of the file is stored on a separate server. With all this information safely stored away, finding what you need is easy.

A file record in a PDM database is like a library card. If you want information about a file, everything you need is there without having to get the file itself. If you then want to check-out the file, the transaction is recorded on the library card. While it’s checked-out, nobody else can have it, but they can still see the metadata on the library card so they know what it is and who is working on it. When the file is checked back in, the library card is updated and the file is then available for the next person who needs it. This creates a secure, but very serial workflow.

This process works well if you are using your CAD vendor’s PDM system. Even then, the annual CAD update often forces a change to the PDM database, so you can’t upgrade PDM until all your CAD files have been upgraded and you can’t manage those upgraded files until you have upgraded PDM. It’s a mess. Third-party PDM systems lag behind even further due to their need to reverse-engineer the encrypted CAD file formats every year.

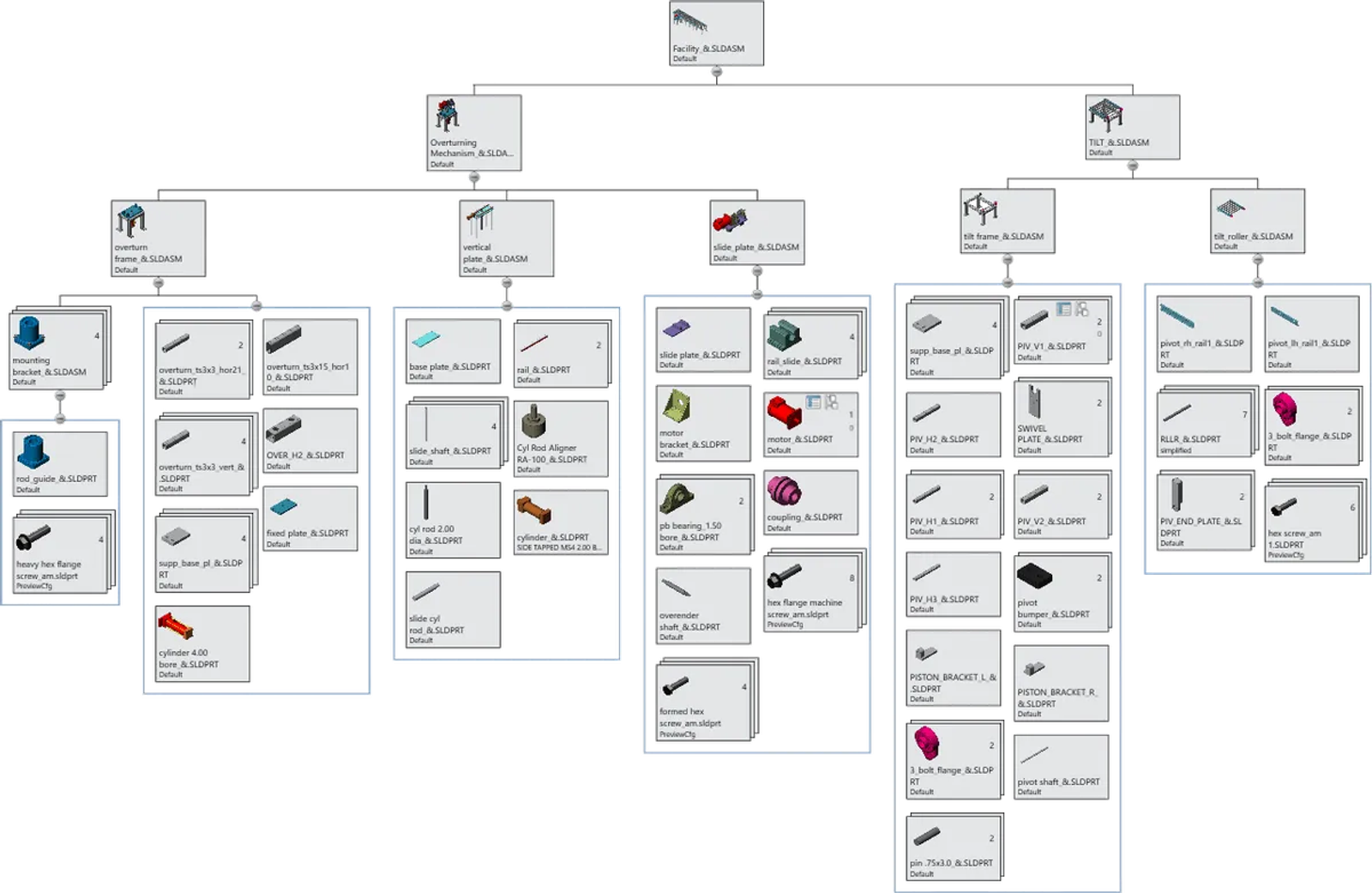

An example of file-based assembly structure.

The Essentials of a PDM System

Implementing a PDM strategy is a significant endeavor that impacts project managers and stakeholders across the board. Instead of focusing solely on checking off PDM capabilities, it's crucial to understand how a specific PDM solution aligns with your business processes. Let's delve into the minimum requirements you should consider when selecting a PDM system:

1. Installation, Setup, and Maintenance

Smoother installation and maintenance processes favor companies with dedicated IT resources, while smaller firms may face challenges. Installing the PDM software is relatively straightforward, but provisioning servers and configuring SQL databases can be time-consuming. To ensure a seamless transition during annual updates, creating sandbox environments matching the production setup is essential. For multi-site collaboration, assess data replication options and the associated network bandwidth and server costs. Explore flexible licensing and remote access for suppliers and other occasional users.

2. Security

Security is paramount when adopting a PDM system. Robust authentication mechanisms like unique usernames and passwords, Single Sign-On (SSO) and 2-Factor Authentication (2FA) are a must. Check granular data access control by user, group, role, team, and project with detailed audit trails for easy forensic examination. Plan to secure servers, network drives, and USB ports while maintaining physical server room security.

3. Engineering Document Control

Ensure smooth check-in and check-out processes, considering network transfer times between different sites. Manage non-CAD files like PDFs, images, and documents within the product release process. Centralize standard parts and supplier components to prevent duplication across projects, teams, and locations.

4. Search

Effective search capabilities are vital for quick data retrieval. Assess the system's indexing capacity and granularity of search criteria. Check if you can search based on metadata and combine multiple criteria. Consider searching checked-out and new files.

5. Version Control

Version control is crucial to the document design progress. It provides a snapshot of designs at specific milestones. Ensure versions are easily searchable, immutable, and provide a history of changes. Tracking design modifications is essential between versions or check-in/check-out actions.

6. Revision Control and Approval Workflows

Streamline revision control with preconfigured approval workflows. Assess if the system replicates your existing revision schemes or if process adjustments are needed. Workflow design tools should enable process automation, including document routing, approval, and exception handling. An API for customization should be available.

7. Automatic Part Numbering

Ensure the system supports unique part numbering and customization. Check ERP integrations for automated part code generation.

8. "Where Used" Reports

"Where used" reports aid in standardizing and reusing parts, reducing costs. Assess the system's ability to provide detailed usage information for better inventory management and design traceability.

9. Effective Collaboration

Easy data sharing and controlled access ensure frictionless collaboration between internal and external teams. Test the end-to-end design process including all stakeholder input and investigate file-locking bottlenecks and conflict resolution.

10. Engineering Change Orders (ECOs)

Ensure workflows and permissions handle ECO processes effectively. Check for support of parallel ECOs to avoid design bottlenecks.

11. Bill of Materials (BOM)

The BOM should reflect the exact product configuration and be accessible to all and easily editable by users with permissions.

12. Integration with ERP

Integrate PDM with ERP to automate production BOMs, reduce manual rework, and synchronize the design process with your business processes.

13. Real-Time Analytics

Uncover process inefficiencies and reduce costs with transparent reporting and role-based custom dashboards for evidence-based decision-making.

14. Automated Backups and Disaster Recovery

Ensure automated backups are performed daily, replicated, and integrity-tested. Store copies securely offsite to minimize data loss in case of system failures, corruption, or unforeseen disasters.

Choosing the Right PDM System

A well-implemented PDM system will help product development teams address the critical issue of data management while providing a robust framework for streamlining design processes and collaboration.

As you embark on the journey of selecting the right PDM solution for your organization, it's crucial to focus on the specific needs and processes that align with your business goals. The list of requirements we've explored here serves as a guide to ensure that your PDM system enhances your design and engineering workflows, ultimately leading to more efficient and effective product development.

With the right PDM system in place, you can confidently embrace a future of innovation and productivity.

Why Onshape?

Accelerate product development with the power of cloud computing, real-time collaboration tools, and a built-in PDM system – all for the same price as CAD.

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more