6:46

For years, we have been hearing from users about the pain and hassle of old file-based, installed CAD and PDM systems. Prospects often come to us suffering from a malady we call “design gridlock.” Customers with design gridlock often can be overheard saying things like:

- “Are you sure you have the right file?”

- “The part is checked out, so I’m dead in the water.”

- “We were both working on different versions of the same file. What now?”

- “This old, obsolete version keeps rearing up and biting us.”

- “Hold off on that for now. We’re cutting a revision next week, and it gets confusing.”

- “We’ve terminated XYZ Corp as a fabricator. Get all our files back from them.”

- “Did you see my email with feedback on those changes?”

- “The BOM doesn’t match what I see in the assembly.”

Engineers have told us that significant portions of their daily work time are consumed with design gridlock chaos and nonsense like searching for files, comparing files, copying files, sending/receiving files, waiting on files, fixing blown-up assemblies, and so on.

That’s on a good day when the PDM server isn’t down, and they can get access to a floating license. This is time spent by the most valuable design engineers that could have gone into innovation instead of IT. Untreated design gridlock is chronic: it diverts precious engineering energy into useless overhead day after day, year after year.

So what’s the cure?

Finding a Gridlock Solution for PDM

Teams suffering from chronic design gridlock often experiment with simple remedies like Dropbox enhanced with memorized ad hoc procedures and conventions (e.g., “remember to save the latest file here and name it...”, “use the one called ‘really_final_this_time’”, etc.).

They quickly discover that this approach fails to scale as their team grows and as their projects become more numerous and complex. They also rediscover the frailty of human memory. Folk remedies do not cure design gridlock. They just briefly postpone the inevitable slide into chronic inefficiency.

Teams with thicker wallets – often hundreds of thousands thicker – sometimes turn to costly therapies like old-school PDM systems that claim to comprehensively cure design gridlock. But they don’t. They just mask the symptoms. Unmanaged copies of files are littered below the surface of every PDM shop: on workstation hard drives, on USB sticks, in emails, and across multiple vaults across globally distributed networks. Managing copies of files is a problem, and PDM systems are just high-volume copy machines.

Another thing that the PDM practitioners fail to mention is that old PDM has nasty side effects that hinder your team’s productivity and creativity. In their attempt to impose order on design gridlock chaos, PDM introduces rigid processes that suck the life out of creative teams and slow innovation to a crawl. I’m talking about the serialized check-out/locking/check-in madness, vault synchronization errors, VPN connectivity errors, and other side effects users have suffered for so long.

I’ve heard engineers say, “Oh yeah, we’re not using PDM on this project because we need to go fast.”

I’ve never ever heard a customer say, “We got our project done faster because we checked out files,” or, “We were more innovative because we were waiting for someone else to check-in their files.”

Think about that for a minute. PDM = slow with illusory control. No PDM = faster but chaotic. Which do you choose? The right answer is neither.

Root Cause of Old PDM’s Gridlock: Files

One of the key insights we had when we started Onshape was that the root cause of PDM design gridlock is files. Storing design data in files is an old, obsolete idea. Files are often hard to find and search for because they are stored across many places. Files are hard to control because they can be copied, and every copy is a source of new copies. Files are hard to keep synchronized between many locations, creating confusion about versions. Files that reference each other are inherently brittle because file paths are always changing (I’m looking at you, old CAD assemblies).

What’s Different About Cloud-Native PDM?

Back when we built SOLIDWORKS 30 (!) years ago, we didn’t know any better than to store data in files all over the place. The “database” we used for SOLIDWORKS was “C:\”. That would be funny, except that it’s true. Mea culpa. But we know now. So we created a radically different approach that marks a new era in the way engineers manage design data. What’s different about cloud-native PDM? Here are the foundational principles that make it so special:

A Database, Not Files

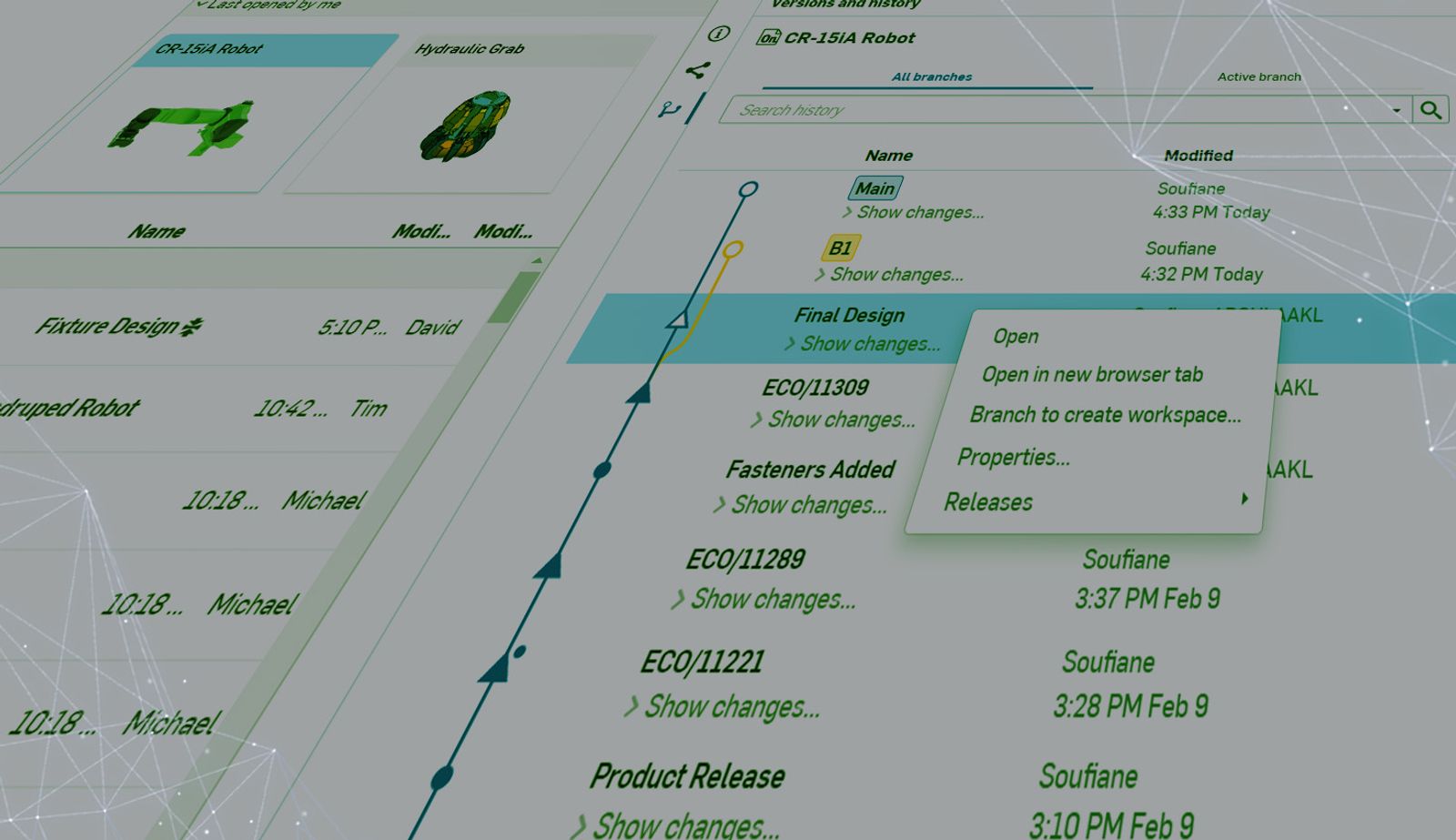

We store design data in a cloud-native database that presents data to users as virtual documents that show all design history. We log all actions by all users at the level of each individual edit and allow you to go back to any previous state of your model – forever. It is always clear what is the latest version, who has access to it, and who did what. And by the way, you never lose work, and you very seldom crash.

Secure Cloud Workspace, Not Scattered Copies

We store design data in a secure cloud workspace accessible by authorized users from anywhere where humans normally work. Administrators can prevent users from making local copies or exporting sensitive data. When a user no longer needs access, administrators can revoke access without worrying that there are copies floating around.

Parallel, Not Serial

Our unique database architecture allows engineers to explore multiple design directions in separate branches and then merge desirable changes into the main branch. This allows engineers the freedom to explore design directions in parallel instead of forcing formal handoffs and waiting. The result is faster, better innovation.

Instant Collaboration, Not Meetings

We provide robust tools for sharing designs with other engineers or stakeholders, offering and receiving comments on designs, and comparing and accepting changes – all in a single cloud workspace without making copies. This allows teams and extended groups of stakeholders to stay in sync, instantly see what each other is doing, work together, and keep work flowing without the friction, confusion, and time-sucking meetings that plague old CAD collaboration techniques that rely on endless copying and exchanging files.

Design Data in One Place, Not Many

We put the PDM experience right in the design experience instead of forcing the user to switch between their modeling tool and their PDM system. This theme of deep integration and putting the right interface in front of the user at the right time is something our User Experience (UX) team has championed since day one, and our production customers seem to love it.

Zero IT

We set out to deliver a system that would never require dedicated IT, installation of servers, or installation and upgrading of desktop software. For those of you who have been forced to master these tasks, you are getting your life back.

This is the PDM experience thousands of companies get to enjoy in production with Onshape every day. Now we are taking it to a whole new level.

Learn From the Past, But Don’t Live in It

I’ve been building CAD and PDM systems all my life, and I’ve learned a lot. But I don’t live in the past. Too many CAD and PDM vendors are still living in the past, and as a result, too many engineering teams are also stuck there. Although the limitations of old CAD modeling approaches and old PDM systems have been painfully clear for a long time, many teams just assume that’s the way it has to be and that there’s no alternative. But now there is an alternative.

There’s a new breed of modern design teams with modern ideas who demand modern engineering technology. These teams want to jump ahead of their competition, and they know that old technology won’t get them there. These are the professionals who are embracing cloud-native CAD and PDM. They are starting to recover the time previously lost to old, obsolete CAD and PDM technology platforms. And they are seeing incredible business results, right now. Modern teams. Modern CAD and PDM. Finally.

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more