3:28

When you are an engineering leader seeking to purchase a Product Data Management (PDM) system, it’s natural to want to try out the software right away – versus waiting weeks for the opportunity.

Dealing with a delayed sales timeframe created a frustrating shopping experience for Benoit Tucoulat, Head of Mechanics and Applied Science for Withings, a Paris-based manufacturer of hybrid fitness watches.

Hassles and Hidden Costs of ‘Old’ PDM

“I spent more than two months talking with ‘old’ PDM providers,” Tucoulat recalls. “We organized several face-to-face meetings to understand how their software worked, what kind of licenses we needed, and how we could integrate their software. But I couldn’t test their software during these two months as they were unwilling to provide licenses for beta testing.”

“They explained that we would need to purchase servers to host our data and that it would take 4 to 6 months to set up and fully deploy their solution,” he adds.

Withings is the pioneer company that invented the world’s first hybrid smartwatch, a wrist piece that looks like a traditional analog watch, but with added health sensors that relay real-time critical health information (ECG, heart rate, SpO2, activity tracking, sleep patterns) to a mobile app.

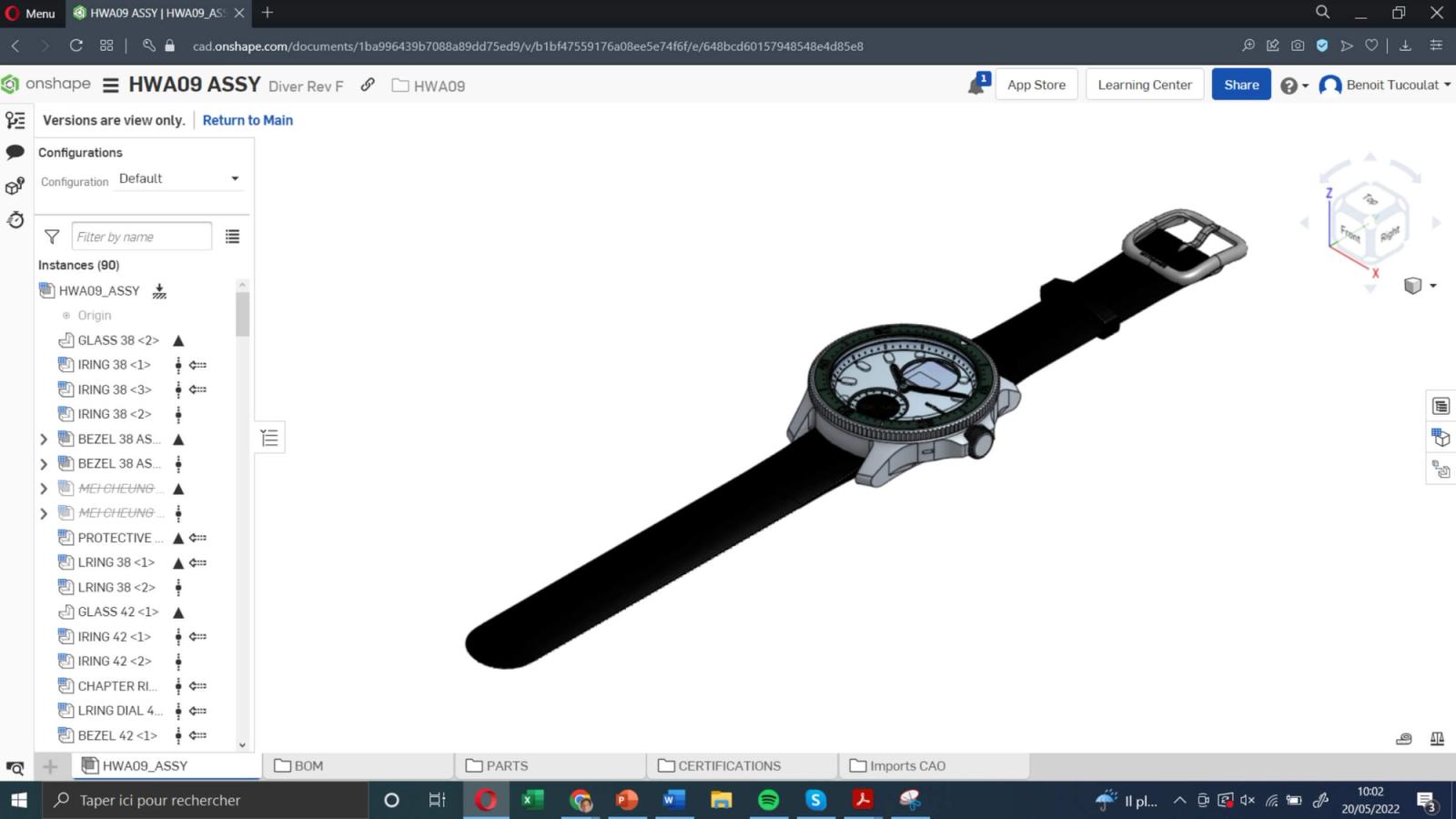

To design and manufacture its ScanWatch Horizon, Withings uses cloud-native Onshape to streamline collaboration between its product development teams in France, Hong Kong and China.

The growing company, which markets smartwatches and other health-tracking devices in more than 40 countries, had an urgent need to replace its inefficient version control processes (manually naming files) with a PDM system in 2019.

Frustrated with the overall buying process of file-based, add-on PDM systems – which require purchasing from third-party resellers instead of dealing directly with the software vendor – Tucoulat researched cloud-native Onshape, which includes CAD and data management costs for the same price of buying CAD alone.

“In contrast, when I went on the Onshape website and talked to their bot, I got a conference call with the Onshape sales team an hour later,” he says. “The next day I was testing their solution without any need for a license. After two weeks of beta testing, our team was up and running.”

The Cost Benefits of Integrated PDM

According to Tucoulat, cloud-native Onshape’s built-in PDM saved Withings $65K USD (€62K EUR) in its first year and $50K USD (€48K EUR) annually in subsequent years compared to file-based, add-on PDM systems they evaluated. Sticker prices aside, Tucoulat says he was surprised by an extra $28K USD (€27K EUR) in hidden training and installation costs of file-based PDM.

(To learn more about the invisible costs of traditional on-premise CAD and PDM, see this “Sticker Shock” infographic.)

The Withings product development team chose cloud-native Onshape for its primary design platform, seeking to resolve some of the version control issues they were experiencing with file-based CAD.

The time savings realized from adopting Onshape magnifies the company’s PDM savings even further, asserts engineer Manon Navellou, Withings Mechanical Team Leader.

“To make our products stand out in the market, the most important thing is for us to iterate every day,” she says. “We design something, prototype it, test it, make modifications and then start the loop all over again. It’s such a huge benefit that our engineers no longer have to waste time worrying about data management and can spend more of their time focusing on design.”

In addition to the built-in version control, Withings also credits two unique Onshape collaboration tools – Branching and Merging, and Multi-Part Part Studios – for helping to accelerate their design process. Multiple Withings engineers can now simultaneously branch off the main design and explore alternative designs independently, later coming back to merge the best ideas into a final design. Onshape’s modeling environment also allows engineers to design multiple related parts at the same time in the same space versus bouncing back and forth between individual part files. This process mimics the way the brain works for creating assemblies.

(To learn more about how Withings and other companies leverage cloud-native PDM to improve their design and manufacturing processes, visit the Onshape Customer Case Study page.)

Leveraging Cloud-Native PDM

Learn how Withings improves their design and manufacturing processes using Onshape.

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more