Bill of Materials (BOM)

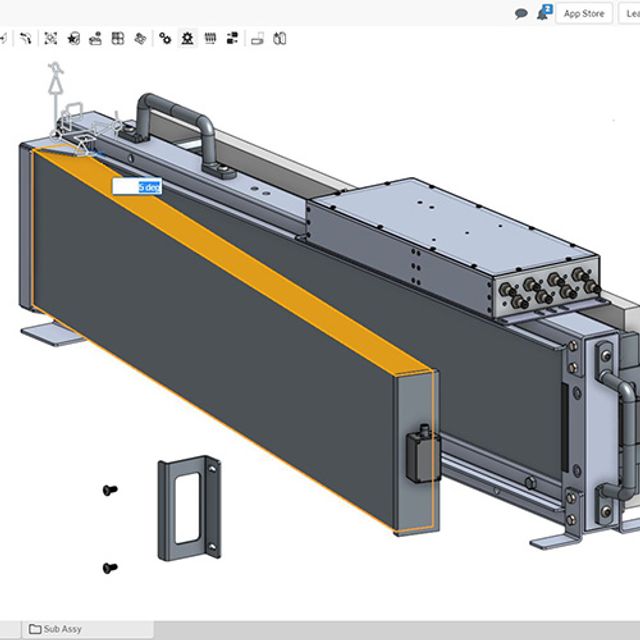

Streamline Assembly Management with Onshape's Real-Time Bill of Materials.

Streamline Assembly Management with Onshape's Real-Time Bill of Materials.

What makes BOM’s integral to mechanical design?

BOMs are essential in mechanical design for tracking components, estimating costs, managing the supply chain, and facilitating collaboration. They help with the quality control process, streamline production planning, assist in documentation for compliance, and are pivotal in product lifecycle management, making them indispensable for efficient project execution.

Key Features

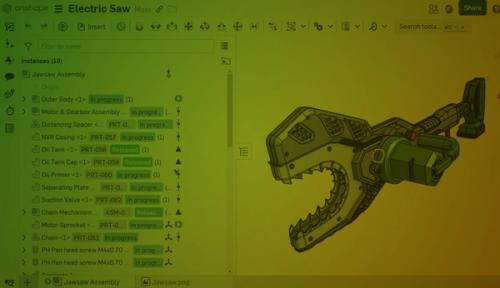

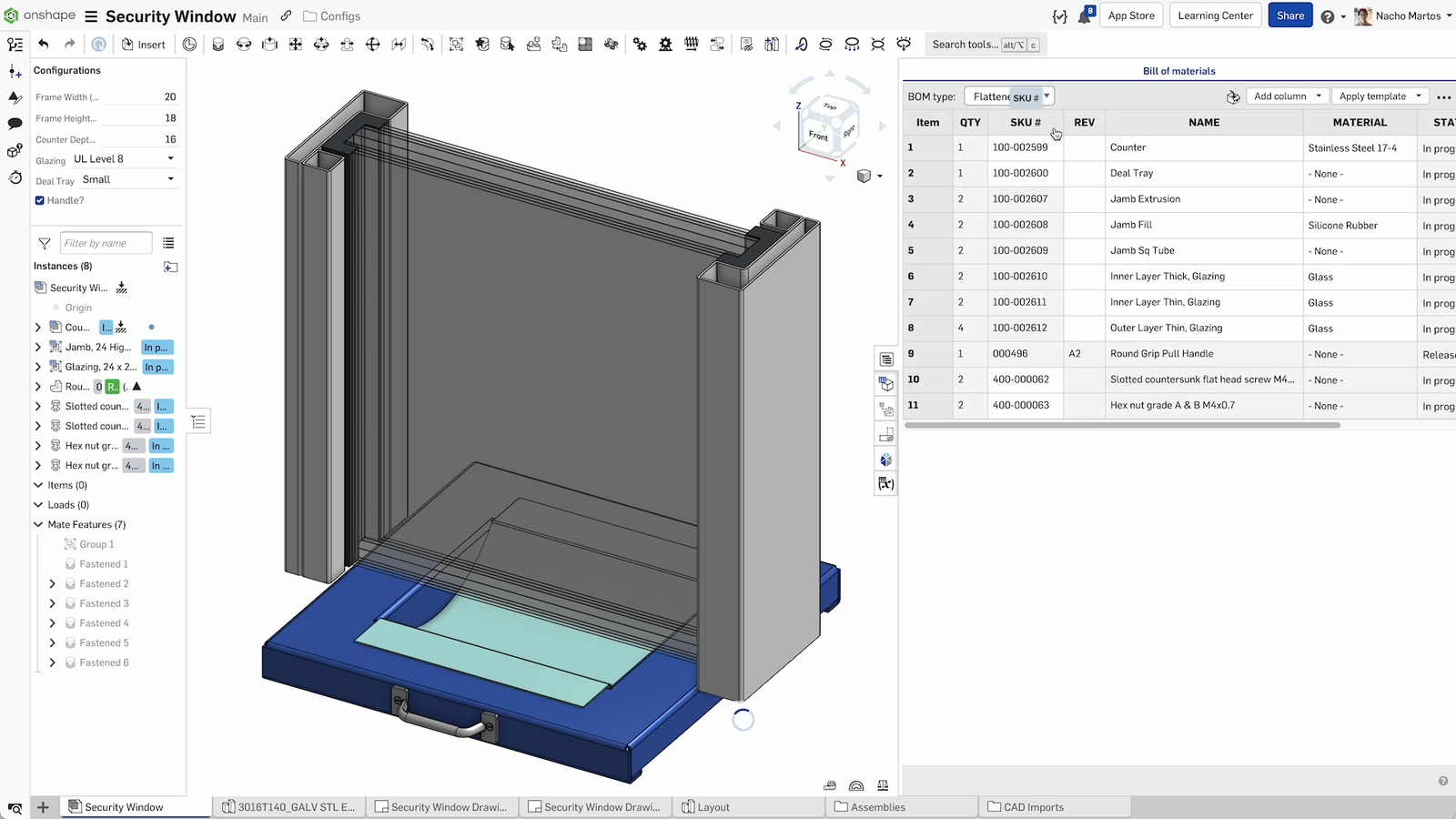

Real-Time Updates to Your CAD Bill of Materials

Onshape's BOM integration allows the data to be edited within the Assembly model, ensuring real-time updates between the model and BOM tables. Its cloud-native architecture ensures all stakeholders –from purchasing to assembly techs– have accurate design and BOM data on their devices. This guarantees details are up-to-date, avoiding inaccuracies and mistakes.

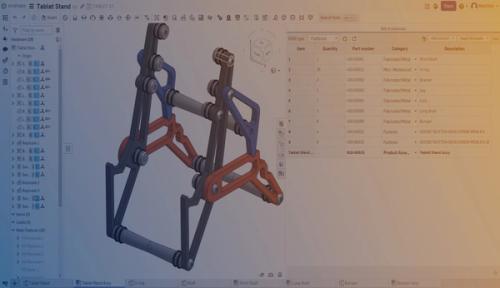

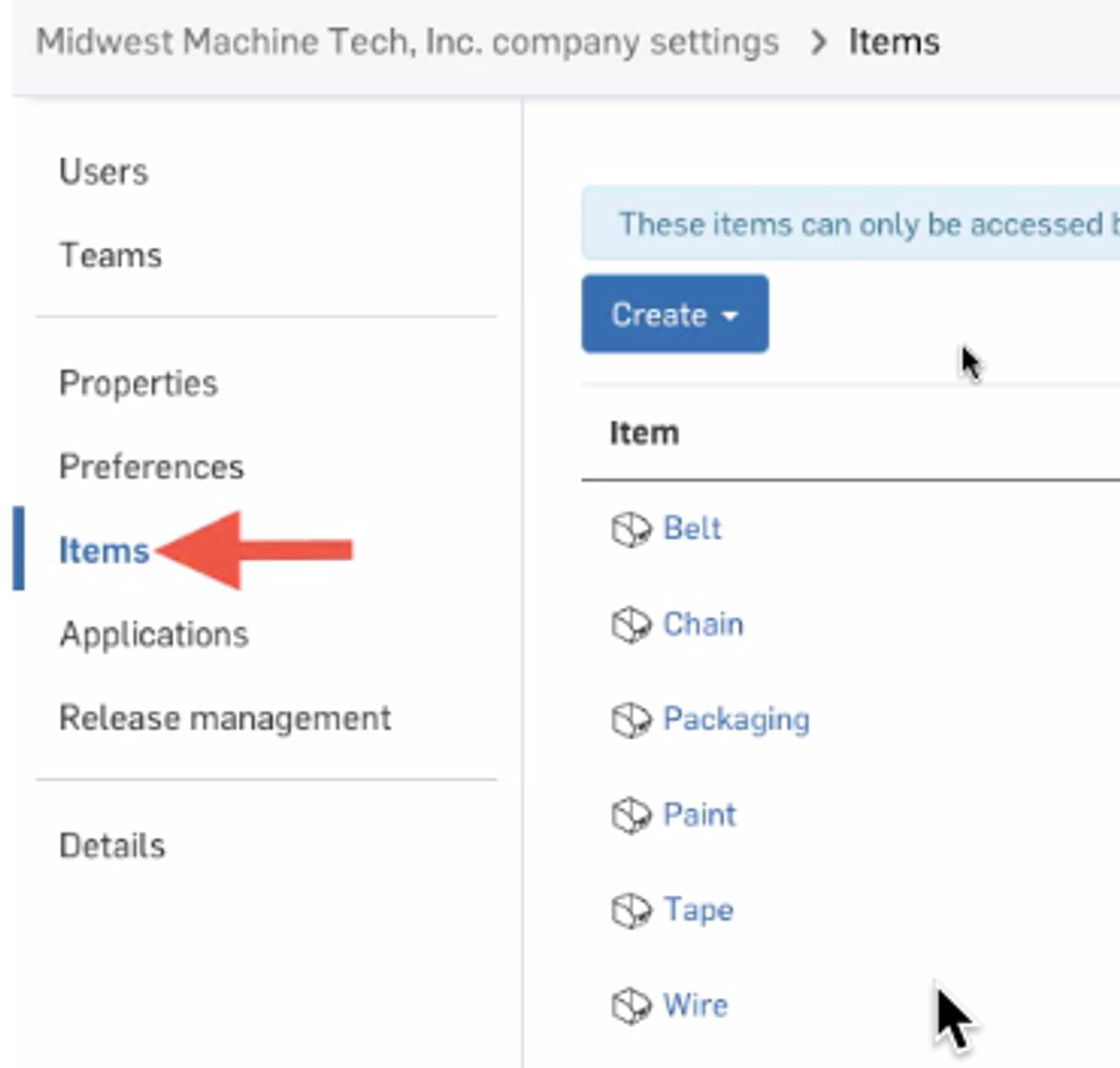

Include Non-Geometry “Items”

Incorporate essential non-geometric items like adhesives, lubricants, and paint into the BOM directly from a predefined company inventory. Define bulk items with details such as quantity, units, and application parts. Enrich your 3D model by adding diverse elements to reflect design intent and enhance realism.

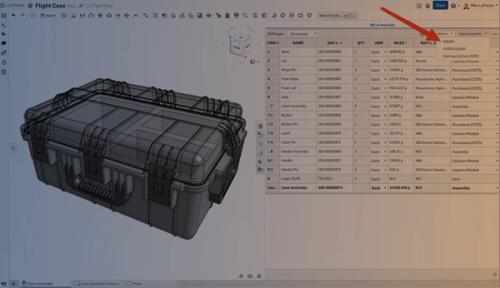

Custom Views for Your CAD Bill of Materials

Manage BOM data the way you want, with options for hierarchical or flattened views. Customize tables by adding or removing columns to show any component property, with in-place editing for efficient data entry. Tailor BOM views by highlighting or erasing specific rows and columns to suit viewer preferences. Save custom views with the assembly, enabling unique data column sets for each project, ensuring flexibility and precision in data presentation.

BOM API’s for Advanced Customization

Onshape offers a BOM API for clients with complex, multi-discipline needs, allowing the creation of custom apps to utilize BOM table data. This enables the export of data directly to ERP systems via the BOM API, catering to advanced customization and efficiency in managing BOM data.

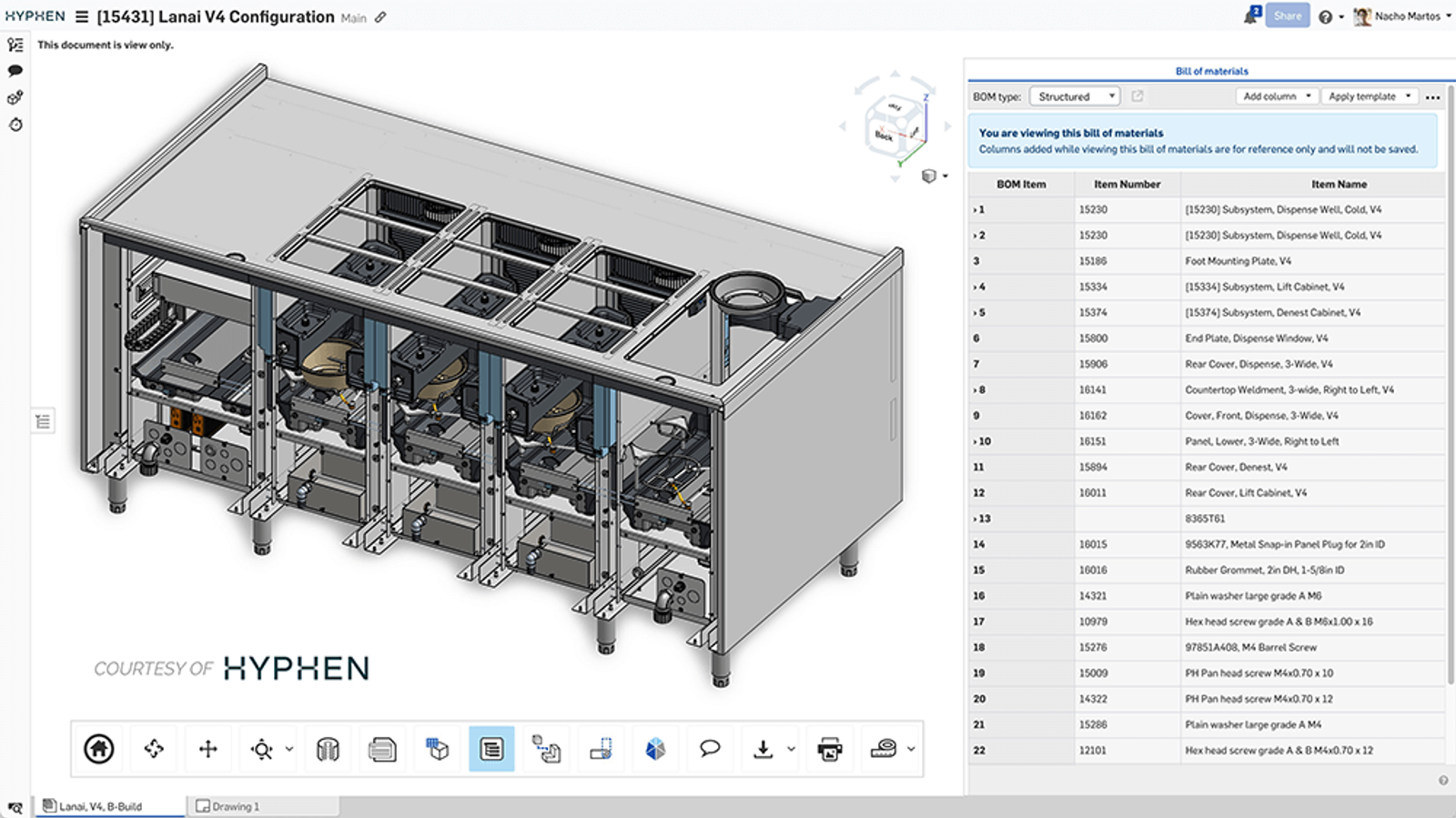

Bill of Materials on the Cloud

Collaboration is at the heart of what Onshape delivers, and this extends to BOM management. Cloud-native CAD collaboration and built-in PDM accelerate time to market, facilitate teamwork, and encourage product innovation. Real-time updates to parts in your design reflect immediately in both the model and CAD BOM for all authorized users, ensuring seamless coordination and instant access to the latest design changes.

Explore More

Kickstart your BOM management skills with this handpicked collection of Tech Tips and instructional videos.

Tech Tip: How to Assign Part Numbers for Referenced Parts in an Onshape Assembly

01.07.2025

Learn how to assign part numbers for referenced parts or assemblies in Onshape. This saves time by eliminating unnecessary steps.

Read Tech Tip

Tech Tip: Set Structured or Flattened BOM Views by Default in Onshape

05.12.2025

Set default BOM views in Onshape to streamline engineering and purchasing workflows. Ensure consistency with saved templates and company-wide settings.

Read Tech Tip

Tech Tip: Using Tables in Drawings

07.23.2024

Discover how to seamlessly transfer tables from Configurations or external spreadsheets into Onshape Drawings in this Tech Tip.

Read Tech Tip

Tech Tip: Use the Onshape BOM to Assign and Sync Metadata with Arena PLM

07.16.2024

Quickly assign categories and part numbers to assembly parts and subassemblies using the BOM table in Onshape. Learn this efficient method for managing parts and – for Enterprise users – syncing to Arena PLM.

Read Tech Tip

Master BOM creation with guidance from the Learning Center and Documentation

Got Questions?

What is a BOM, and where is it used?

What display types can I use when creating my BOM table?

Can I share my BOM template with my team?

Can I export my BOM to Excel or other formats?

Can Onshape automatically generate part numbers?

Onshape allows us to keep everything much more organized without needing a PDM system. Onshape probably cuts our design time in half because we’re designing our parts together in one place versus flipping back and forth between files. We can make changes without worrying about breaking the assembly.’’