4:12

Farming is not for the faint of heart. Neither is machine design.

For Glen and Lucas Kuhns, farming is not only a livelihood but an opportunity to find solutions for the entire industry by improving agriculture equipment.

It started with their father Kenny, who founded Ohio-based Norden Mfg in 2005 after developing the Accumulator, which speeds up the process of hay baling. With this powerful machine, one person could make 1,500 bales in a day.

“This Accumulator was actually really needed on the market. It's a very simple design. It's all mechanical. There's no hydraulics electronics on it,” Glen says. “The reliability of the machine was really what the market needed.”

Now, Norden Mfg manufacturers a wide range of agricultural equipment. Glen is the vice president and Lucas is a manufacturing engineer.

Part of their success can be attributed to overcoming the challenges that come with machine design and learning how to use CAD software to solve those problems.

What is the Machine Design Process?

Machine design improves the tools and equipment used for industries as wide-ranging as grocery fulfillment centers to bicycle manufacturers. Each improvement can increase efficiency, safety and productivity for workers and businesses.

Just as Kenny worked on a machine to exponentially speed up the hay baling, engineers are continually looking for better ways to sustain product development and support supply chains.

“Looking for better ways” is the machine design process, which involves a high level of collaboration with stakeholders and demands fast iterations for prototypes. To achieve this, engineers and product designers need to use the right tools to stay transparent and organized.

Product Data Management & Machine Design

Glen and Lucas Kuhns

When the team at Norden Mfg began designing their products using SOLIDWORKS, they realized they needed something more than CAD to keep files organized.

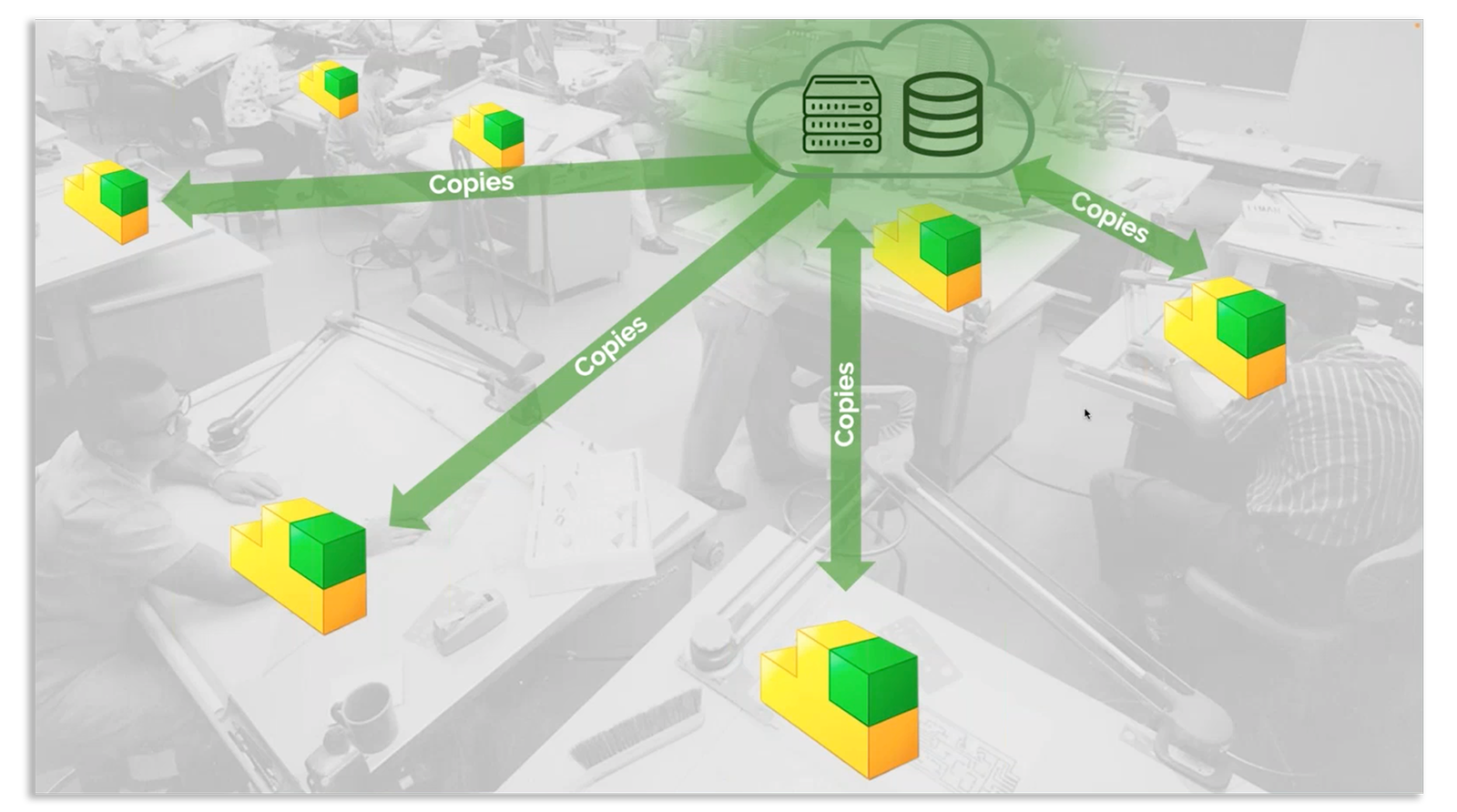

As a solution, Glen recalls installing Dropbox on every device to back up files and make models quickly accessible, but at the cost of mudding up version control.

“The problem is that the files aren't locked out,” he explained. “We had hundreds of conflicting copies.”

Relying on file-based CAD, plus Dropbox for Product Data Management (PDM) processes, was a “nightmare” for the team.

The overwhelming challenge of sifting through old files made Onshape an attractive option for its integrated design management system.

With Onshape’s cloud-native platform, Glen said, “the data is there at your fingertips. It's easy to get at. And it's structured correctly. And it just makes the process much easier to manage.”

“Something like renaming is pretty seamless in Onshape. It's a whole process to do in SOLIDWORKS,” Lucas added.

Utilizing Configurations

Norden Mfg takes advantage of Onshape Configurations to manufacture different sizes of the Accumulator, Grabbers (which grab the hale bales), and other products.

“There’s all these different sizes and use configurations pretty heavily,” Lucas said. “Not only do we have the different sizes of frames, but we also have different brackets.”

Configurations allow the Norden Mfg team to easily produce machines that fit the needs of their clients. With a simple variable in the configuration table, Lucas or Glen can go into the Onshape Document to set the parameters of the machine that is requested. For instance, different widths or fewer hooks for grabbing can be easily set in one place – not in a complex, external spreadsheet.

The Kuhns gave a demo of how they used configurations and other Onshape tools during the webinar, How Norden Mfg Built a Faster, More Efficient Machine Design Process, which can be watched on-demand.

Version Control & Machine Design

The machine design process requires an interactive process, preferably with quick feedback loops. This way, prototypes can be quickly tested and the time to market is shortened.

Testing various parts of a design can be scary if there is no backup and there’s only one file to work with. What if you make the wrong decision? What if you want to go back to a design from a month ago to pursue a different design path?

Onshape’s version control allows you to do just that.

“The analogy I use for this is we're laying a train track while driving the train. Anywhere along the line, you can decide to put a depot station in,” Lucas said, explaining that the depot station is like a saved version of a design. “So it's very easy to go back to depot station. But anywhere between the depot stations, there's a full record of everything in between.”

A Tool for the Machine Design Process

As the supply chain continues to strain under pressure, improving machines and their development is increasingly becoming a number one priority across industries.

For the Kuhns, they turned to Onshape for easy access to CAD tools, quick collaboration, a better way for product data management, configurations and much more.

“That's why I'm so happy with Onshape, because it is so data-centric. That everything is just there. It's so solid. And we're really, really happy with that,” Glen said.

Are you ready to experience the power of Onshape?

Try Onshape Today

Head to our sign-up page to choose the right CAD plan for you and your team.

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more