11:14

FIRST Robotics Team 4522, Team SCREAM, went into the 2024 CRESCENDO season with a lofty goal: make it to Einstein, the highest level of competition in FRC.

To do this, they must qualify for the World Championship and then win their Championship division. Of the more than 3,400 teams that compete in the FIRST Robotics Competition each season, only 32 teams will make it to Einstein, and only one alliance of four teams will leave a champion.

Team SCREAM was one of the victorious four.

Who is Team SCREAM?

Founded in 2011, Team SCREAM – Smith-Cotton Robotics, Engineering, and Mathematics – is located in Sedalia, Missouri, roughly between Kansas City and Columbia. The team operates out of Smith-Cotton High School’s Robotics Operations Center and is composed of around 50 active students and 12 mentors.

Team SCREAM began competing as Team 4522 in the 2013 FIRST Robotics Competition season. The program has grown substantially since then, and when COVID caused the cancellation of the 2020 and 2021 seasons, the team divided into four smaller groups and built robots for an intramural competition. The extra hands-on opportunities that building more competition robots enabled ultimately led to the creation of Team SCREAM Jr., which has competed as Team 4766 since 2022.

Team 4522 started strong by earning the Rookie All-Star award in their first appearance at the Greater Kansas City Regional and has not slowed down since – they have won each of the six judged engineering awards at least once and have won 12 blue banners. While each award and event win is an important part of each team’s story, their 12th blue banner may be their biggest accomplishment yet: Winners of the 2024 FIRST Championship!

Choosing the Right CAD Software for FIRST Robotics

Designing an FRC robot takes time, effort, and talent. Each team must also choose the best hardware and software tools that fit the situation. Team SCREAM leadership decided to switch to Onshape before the 2024 competition season. According to Jameison, the engineering sub-team leader in charge of integration, and Nolan, the engineering lead for the drivetrain, they had plenty of reasons to change CAD systems.

For example, they said, “We had so many issues with our file management system. If two people have the same part open and one person saves it, you’re now out of sync and dealing with issues.”

Many have dealt with on-premise CAD and PDM software, which requires careful planning of who will open which files so no work gets lost. Onshape removes this headache and lets teams focus on what matters – designing the best robot possible.

Accessibility is also a huge factor, according to the team.

“Onshape being cloud-based is very nice for robotics teams. The teamwork, the collaboration, the accessibility, you don’t need licenses and can run it off of a Chromebook,” said Jamieson.

The ability to open the model on the devices students already have ensures that anyone who wants to contribute to the model can do so.

Embracing Top-Down Design Techniques

One of Onshape’s biggest strengths as a product development platform is the ease of implementing top-down design practices. Designing FRC robots parallels designing a real product, and Team SCREAM said as much.

“Take the time to learn and understand top-down modeling,” Nolan advised, “because having all of your parts referenced together properly can save you time when making changes.”

The team also addressed another key component of top-down modeling in Onshape: “Part Studios are the best thing about Onshape. Ensuring parts fit together the first time ends up saving so much time over the build season.”

Once you start using part studios to design your parts in place, it’s hard to go back to any other design style.

If you’re unfamiliar with top-down design or how your team can implement it, don’t worry – the Onshape Learning Center has a great learning pathway that will get you up to speed.

Team SCREAM’s Experience with Onshape

One quote from the team leadership sums up their experience: “We could have never done what we did if we were still running our old CAD software.”

Beyond the previously-mentioned advantages of Onshape, the team enjoyed how simple it was to publicly share their robot model so teams worldwide could follow along.

As members of the Open Alliance, Team SCREAM and SCREAM Jr. posted frequent updates about their prototypes and development process to inspire other teams. By making their model public, interested teams could access the Document, take measurements, and study different mechanisms.

CAD MODEL: Check out the Open Alliance Build Thread here!

The team also used the Learning Center to get new students up to speed. With various intro-level tutorials, step-by-step instructions, and self-checks, it’s easy for teams to let new members learn the product at their own pace.

Once students were familiar with the basics, Team SCREAM guided them through designing simple frames, drivetrains, and spur gearboxes. The ability to hop in and out of Documents and utilize features, such as Follow Mode, makes it easy to check how each member is doing on a given lesson.

Team SCREAM’s 2024 Robot: AXL

To reach their goal of playing at Einstein, Team 4522’s strategic design committee determined early in the build season that their robot would need to be able to complete all major game tasks.

They ultimately designed and manufactured AXL, an incredibly effective scoring machine that scored in every field element and could play any role that a competition alliance needed.

CAD MODEL: AXL’s public Onshape model!

If you want to learn more about the 2024 CRESCENDO season and what each team needed to accomplish, watch this video.

Additionally, Jaimeson and Nolan provided us with an in-depth writeup of their World Championship-winning robot-read on to see the level of detail in this robot in their own words!

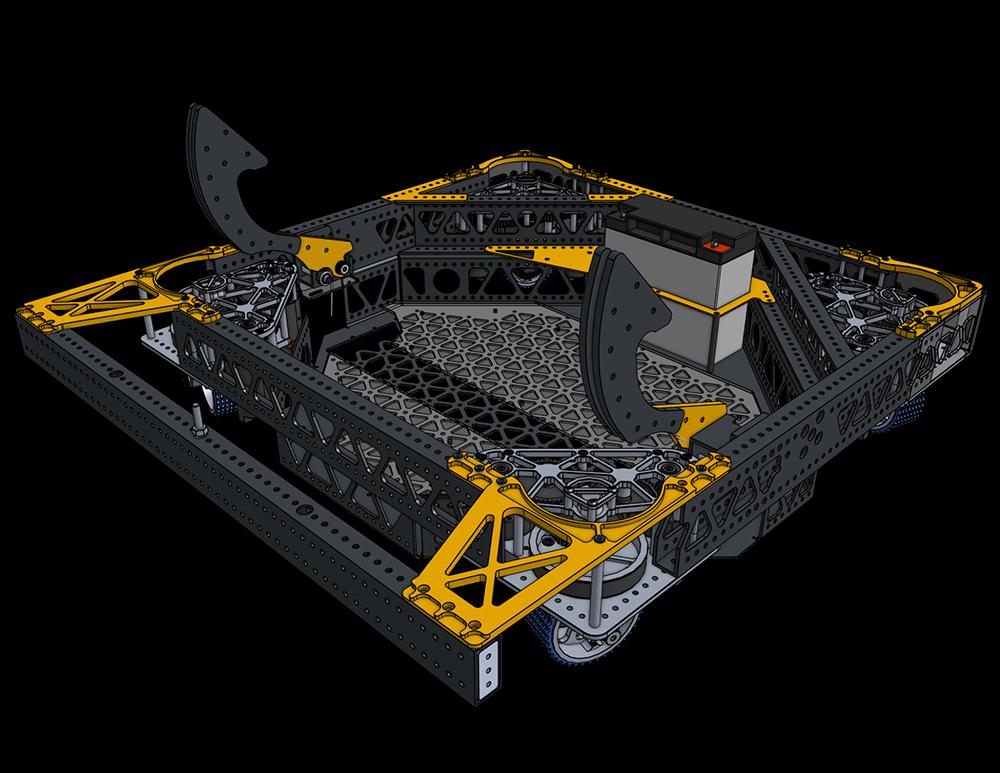

Chassis

AXL’s swerve chassis is constructed differently than most typical FRC chassis. This year, we opted for a chassis utilizing 3”x1” tubing instead of the more common 2”x1”. This was done to create a completely flat building surface over the MK4i swerve modules so they wouldn't stick above the building surface. This also stops debris from getting into the modules. The frame also features tubes at a 45° angle acting as a corner brace to help hot swapping swerve modules, ensuring the chassis does not deform when the swerve module is unbolted. This extra stability also gave us the confidence to utilize a non-load-bearing belly pan shaped more like a bucket.

This “bucket” pan is one large piece of sheet aluminum bent a total of 14 times to give AXL a floor that sits a little less than 1⁄4'' off the ground. With all of the main electronics and wire pathways so low to the floor, we had room to lower the elevator and any other subsystem we desired, giving us a low center of gravity for this contact-heavy game. The chassis also has frequent triangular and isogrid hole patterns to remove about 10 pounds, allowing a larger weight budget for other mechanisms.

Shooter Box

The “shooter box” was the subsystem that allowed us to score in each field element. It consists of three main parts: the flywheels, the conveyor, and the trap rollers.

The flywheels used for shooting are positioned on the top and the bottom of the note. The top and bottom axles are separately powered, each belted to a Falcon 500 with a 1:1 ratio. Two different types of wheels – ThriftyBot Urethane on the left and Andymark Stealth on the right – create spin while shooting the note to improve accuracy on our shots.

The conveyor used a mix of 2” and 1.625” compliant wheels to manipulate the note. The conveyor is powered by a Falcon 500 with a 4:1 belted reduction. The conveyor also has standoffs with passive rollers to guide the note when transferring it into the flywheels. There are multiple beam break sensors to detect when AXL acquires a note and to position the note in the same place reliably.

In order to score notes in the Trap, we added a set of rollers on top of the conveyor. These rollers are powered by the same Falcon 500 that powers the conveyor system. We used a single-powered roller and the top side of our intake to hold onto a note. We added a passive roller behind this to help prop the note vertical to reduce contact that the note has with the trap door.

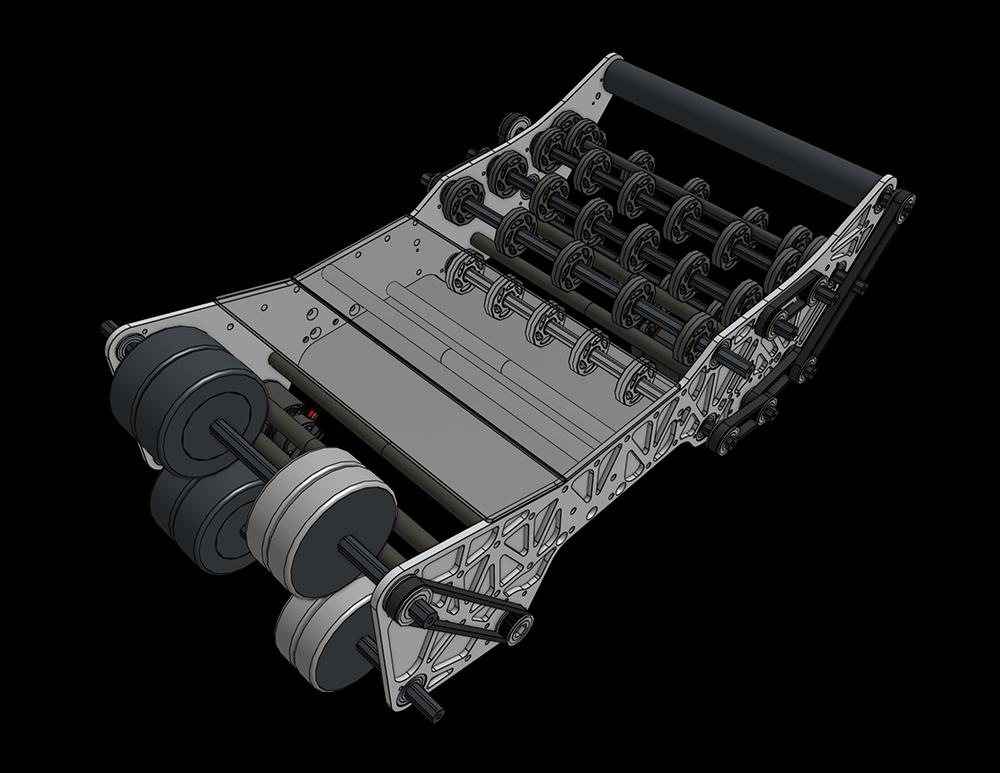

Intake

AXL’s intake is different compared to what Team SCREAM has built during previous seasons. Our design style typically utilizes an over-the-bumper intake to acquire game pieces, but this year, we decided to go with an under-the-bumper intake. At the beginning of our team’s game analysis process, we identified that the auto period would have heavy contact at the centerline. To preserve reliability, we opted for this different (but not unwelcome) design. The intake consists of 3 rollers made of 2” and 1.625” compliance wheels, which pick notes off of the floor and pass them into the conveyor system of the shooter box. Due to how wide the intake is, we used ⅜” standoffs, which we call “fangs,” located a few inches off each side of the intake to simply and reliably center the note.

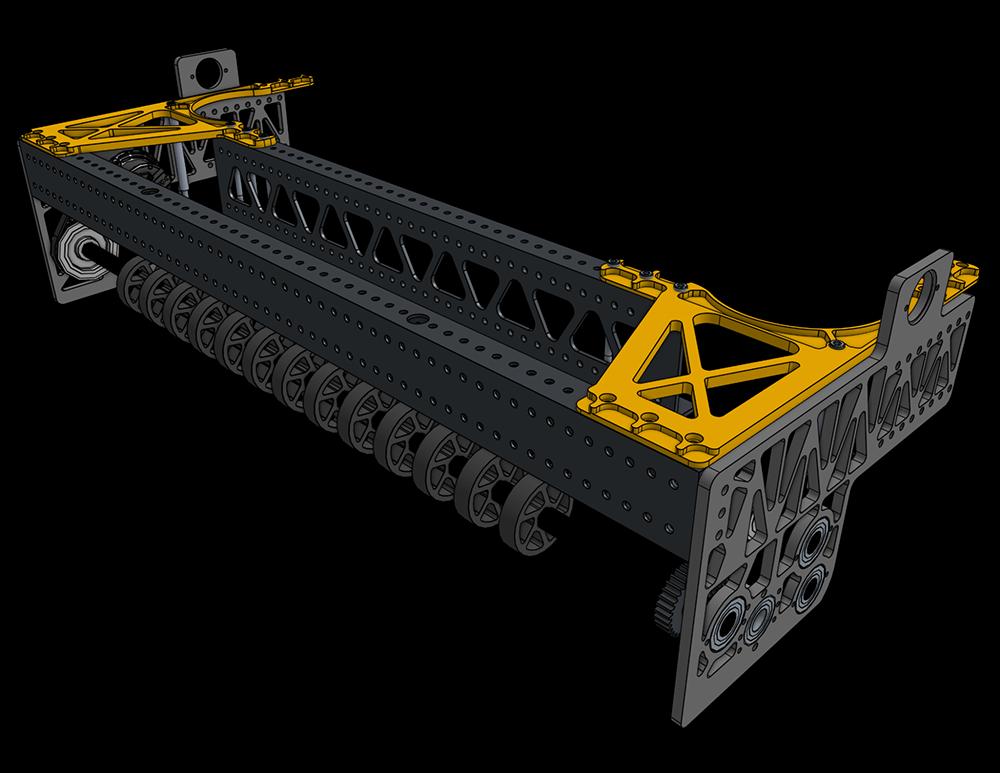

Elevator

The elevator subsystem enables AXL to climb and score. By putting the shooter box on the elevator, we determined we could accomplish all of the different game tasks while ensuring all systems would be packaged nicely.

During the offseason, we took inspiration from Team 4414’s (HighTide) elevator and reverse-engineered it as an Onshape training project. This design is a two-stage continuous elevator that uses steel-lined 5mm HTD belts to power the extension and retraction motions. A two-motor gearbox drives two timing pulleys, which, in turn, drive the belt that runs over a series of idlers to tie everything together. The shooter box is mounted to the elevator on a high-reduction pivot–A Falcon 500 through a 409:1 overall reduction aims the shooter box system at the speaker, amp, and trap, depending on where we’re trying to score.

The elevator is a critical part of AXL, so throughout the season, we designed and implemented many improvements. After winning the Central Missouri Regional, we determined we would need to speed up our trap scoring sequence, which would require climbing with new hooks on the elevator. To make this happen, we:

- Changed the elevator drive motors from two Falcon 500s to two Kraken X60s for extra power.

- Changed from a 7:1 gearbox to a 14:1 gearbox to increase the elevator’s lifting capacity.

- Changed the spur gears in the gearbox from aluminum to steel to handle the higher loads.

- Added .09 aluminum tracks for the bearings to ride on to be better supported and would not derail from the elevator extrusions.

- Added more supporting plates at the bottom corners of the fixed elevator uprights and welded the structure to prevent flexing/racking that would cause the elevator to derail.

Looking Back on a Season of Success

So, how did Team SCREAM and AXL end up competing in Einstein and becoming World Champions?

Going into the World Championship, Team SCREAM knew when AXL was at peak performance, it could keep up with the best of the best in the Daly division. This proved true as they ranked fourth after qualifications and were invited to join the third-seeded alliance captained by Team 1690, Orbit, from Tel Aviv, Israel. They then invited teams 9432, Team 8-Bit, and 321, RoboLancers, and their elimination alliance was set.

Smart strategy and great execution propelled their alliance into the Daly finals. This is where the gravity of the situation started to set in – they were two wins away from their season goal of reaching Einstein. Two tense finals matches later, they had done it: Team 4522 had gone undefeated in eliminations to win the Daly Division.

Once the excitement of winning their division had settled, the real reward began, as it was time to take to the Einstein fields and battle against the other seven division winners in front of a crowd of 30,000 people. Nolan and Jaimeson described this as a “moment of tranquility” for them, as they had no expectations past this point and wanted to enjoy the energy and atmosphere.

To say they had fun would be an understatement. Their strategy of 2 offensive and 1 defensive was executed perfectly; slowing down opponents at choke points, stealing game pieces, and maximizing the value of each scored note was too much for their opponents to overcome. They eventually battled all the way to the Einstein Finals, where they faced down one of the most powerful alliances in recent memory – Team 254, Team 1323, and Team 29, all previous Championship winners with high-powered scoring machines. It took two incredibly tense back-and-forth finals matches, but when the score for Finals 2 lit up the jumbotron and the confetti flew, Team 4522 flew into a frenzy: they had just won the 2024 FIRST Robotics Competition World Championship.

It’s hard to describe how impactful a win is for the students, the mentors, the school, and the community. Talking with Team SCREAM, it’s clear how much passion every member of the team has for robotics and STEM. Knowing that Onshape was an important tool in their process is extremely gratifying, and the entire Onshape team is proud to support teams like 4522 as they chase their dreams of winning it all.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Automotive & Transportation

Zero Crashes, Limitless Collaboration, One Connected Workflow With Cloud-Native Onshape

12.04.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more