3:35

For specialty engineering manager Jack Hudson, communication between him and his core design team has always been as critical as the product designs themselves.

“Having the ability to look at a project that we have in progress and share that information is paramount to moving swiftly and maintaining agile development,” said Hudson, of Syzygy Plasmonics, a deep decarbonization company that uses light to power all-electric chemical reactors.

He noted that outside of the design team, his company’s intellectual property lawyer also benefits from quick access to 3D models to select images for patent applications.

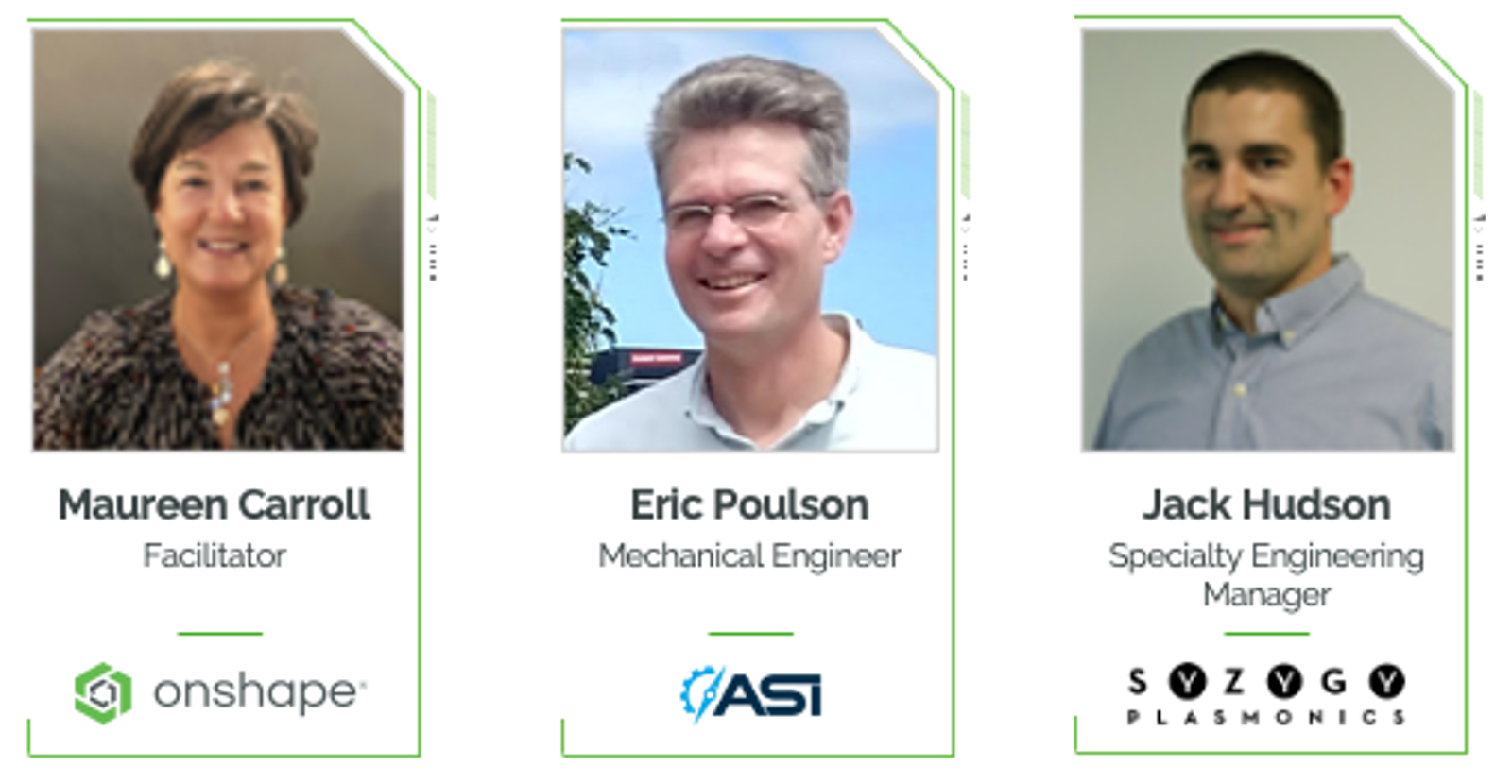

Hudson was one of three panelists for the “Reimagining Your Processes with Agile Development” discussion during the Onshape Live ’23 conference.

Agile Product Development is an iterative and collaborative approach to creating products that have long been widely used in the software world. It’s now becoming a popular alternative methodology to traditional waterfall and phased-gate approaches in the hardware development world as well.

At the conference, the panelists shared how using Onshape’s cloud-native CAD and built-in PDM facilitates more agile workflows and better collaboration at their companies – representing the diverse industries of alternative energy, telecommunications, and vehicle automation.

CAD Collaboration Tools Enable Agile Product Development

Hudson stressed that Syzygy Plasmonics scientists also can’t afford to lose time seeking CAD access when they need the information to create grant applications for projects.

“We are a technology startup,” he said. “The ability to quickly access information without having to reach out to the rest of the design team (for permissions) has proven to be a huge advantage.”

Syzygy Plasmonics developed a zero-emissions manufacturing process to produce sustainable hydrogen fuel from ammonia. The company credits Agile Product Development methodologies for accelerating its time-to-market.

Fellow panelist Eric Poulson, a mechanical engineer and product architect at Autonomous Solutions, Inc., also credited Agile Product Development processes for achieving significant efficiency gains.

His company — which develops driverless vehicle solutions for farming, industrial, and military applications — recently started a new approval and review process using Onshape’s Branching and Merging feature.

“In the past, we did more of a workflow where approvals had to happen sequentially by multiple people,” Poulson said. “If it got rejected anywhere in the process, then we had to go back and fix it and start that process all over again.”

Whenever an engineer starts a branch to explore a new design idea, Onshape’s live Comment tools enable everyone involved in the project to leave feedback in the CAD model itself, he noted.

Once feedback is addressed, a design can “sail through” the release workflow, usually in two-week sprints, Poulson said. “The old way, it was often difficult to get things done in the sprint.”

Poulson added that with collaboration now being seamless at Autonomous Solutions, Inc., employees are more eager to pitch in — and that’s especially handy for last-minute reviews and approvals when it’s all-hands-on-deck.

“We can have more people have the Document open at the same time as we work on it together in a Teams chat or just in a phone call,” he said.

Before Onshape, Poulson recalled that he and his colleagues were inclined to “go work on our little task and get that done and not ask for help. But Onshape changed that and made us work together better.”

Agile Design Processes Made Possible with Zero-IT Footprint

Enabling better Agile Product Development processes wasn’t the only Onshape benefit cited by the panelists.

Onshape’s zero-IT footprint has allowed companies to no longer worry about continued purchases of terabytes of cloud data or the exorbitant cost of power consumption from running racks of their own data center servers.

Syzygy’s Hudson added that Onshape has also made it easier to collaborate with outside suppliers.

“The more pieces of software that need to be involved with each other, the more complicated it typically gets, and that was a major source of difficulty for us,” he said. “No one wants to have to do manual data entry. But you can export data directly from Onshape into an Excel file, and then share that with almost any other software.”

How Onshape Can Deliver More Agility to Your Company

To learn more about how Syzygy Plasmonics and Autonomous Solutions Incorporated adopted more agile design processes with Onshape, watch the video on demand.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Evaluating Onshape

- Simulation

- Rendering

- Surfacing

- Consumer Products

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 learn more

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more