07:21

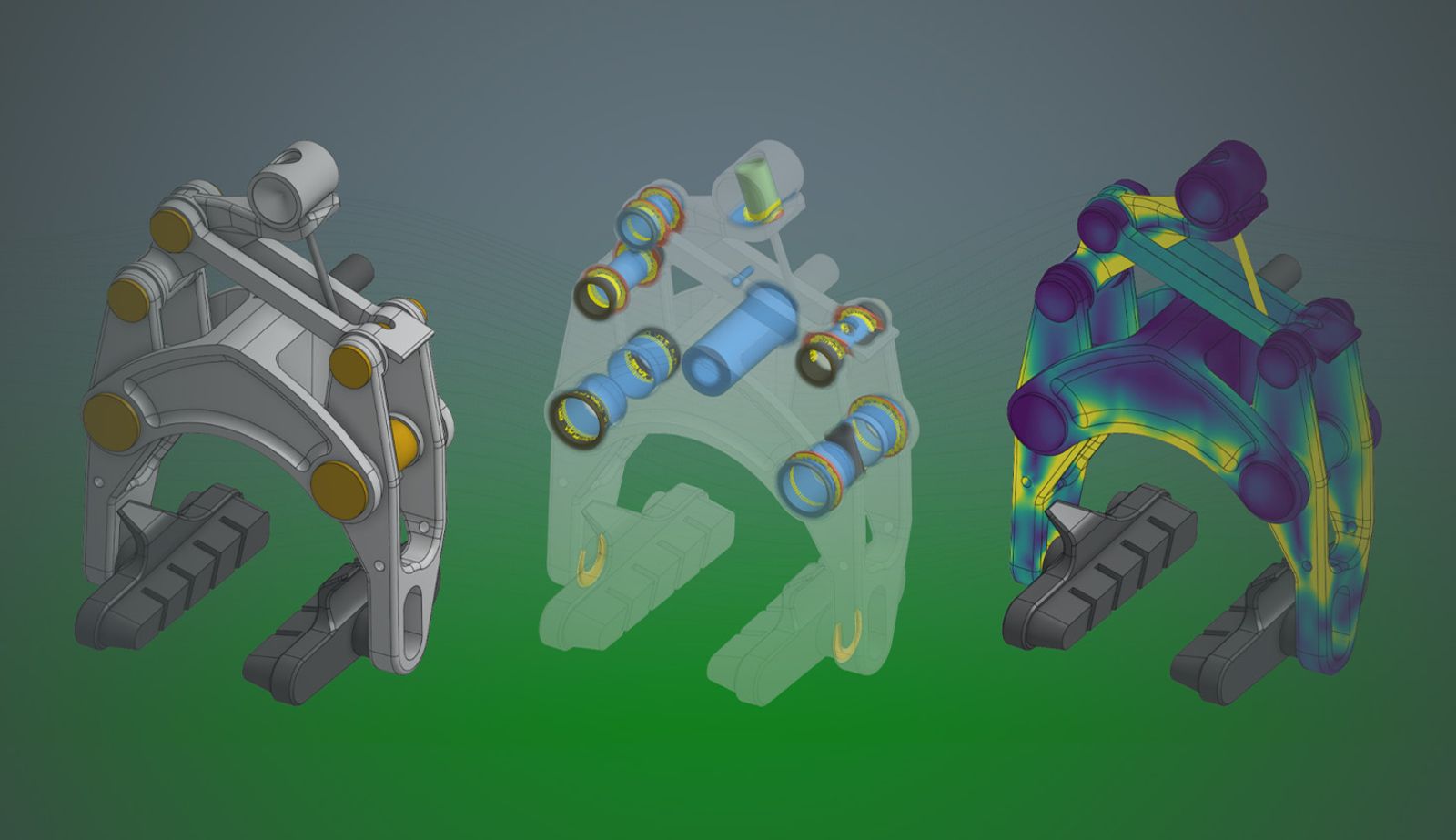

Onshape Simulation is the fastest and easiest FEA simulation software environment for CAD designers to get meaningful and timely decision support on the behavior of their designs under load.

With this cloud-native FEA analysis software, product designers can now be more agile and can more quickly identify the best- and worst-performing aspects of their models earlier in the design process. Furthermore, there are no steep learning curves required to benefit from this new finite element analysis software – if you know how to use Onshape, you already know how to use Onshape Simulation!

Onshape Simulation is available to Enterprise and Professional customers.

The Evolution of FEA Simulation Software

Before we go any further, it’s important to stress (pun intended) that Onshape didn’t invent simulation. In fact, ever since the earliest days of modern computing (let’s say the 1950s), modeling and simulation have been areas of intense focus in our industry. What we are doing is impacting when, where, and how FEA simulation is used – and influencing who uses it – resulting in design requirements being met sooner, preventing costly redesigns down the road, and creating more opportunities for innovative, new concepts.

Interwoven right into Onshape’s cloud architecture, you access always-on simulation results from your assembly environment. Providing both linear static analysis (the most widely needed kind of finite element analysis) and modal analysis for vibration and frequency studies, Onshape Simulation empowers you to make better-informed decisions by seeing animated stresses, displacements, natural frequencies, and safety factors that update as you model.

Historically, CAD designers needed to consult expert FEA analysis software specialists for these kinds of actionable insights – and they had to do it later on in the design process when the cost of making changes starts to rise dramatically. Traditional FEA software also requires complex workarounds like artificial constraints for unconstrained systems, but Onshape Simulation includes advanced capabilities like inertial relief that automatically handle these challenging scenarios.

Breaking Down Traditional FEA Software Barriers

In addition, as you might expect from Onshape, the extraordinary hardware costs and IT requirements for traditional finite element analysis software are no longer a barrier. Having to buy high-performance workstations just to run the software is a thing of the past.

Our cloud-based FEA solution runs with no drivers, downloads or installs – just like Onshape itself – and requires only a supported web browser. Again, no special hardware is needed – anyone with a PC, Mac, Chromebook or Linux device can immediately enjoy the benefits of professional-grade FEA simulation software.

Why Modern FEA Analysis Software Must Be Fast, Easy, and Accurate

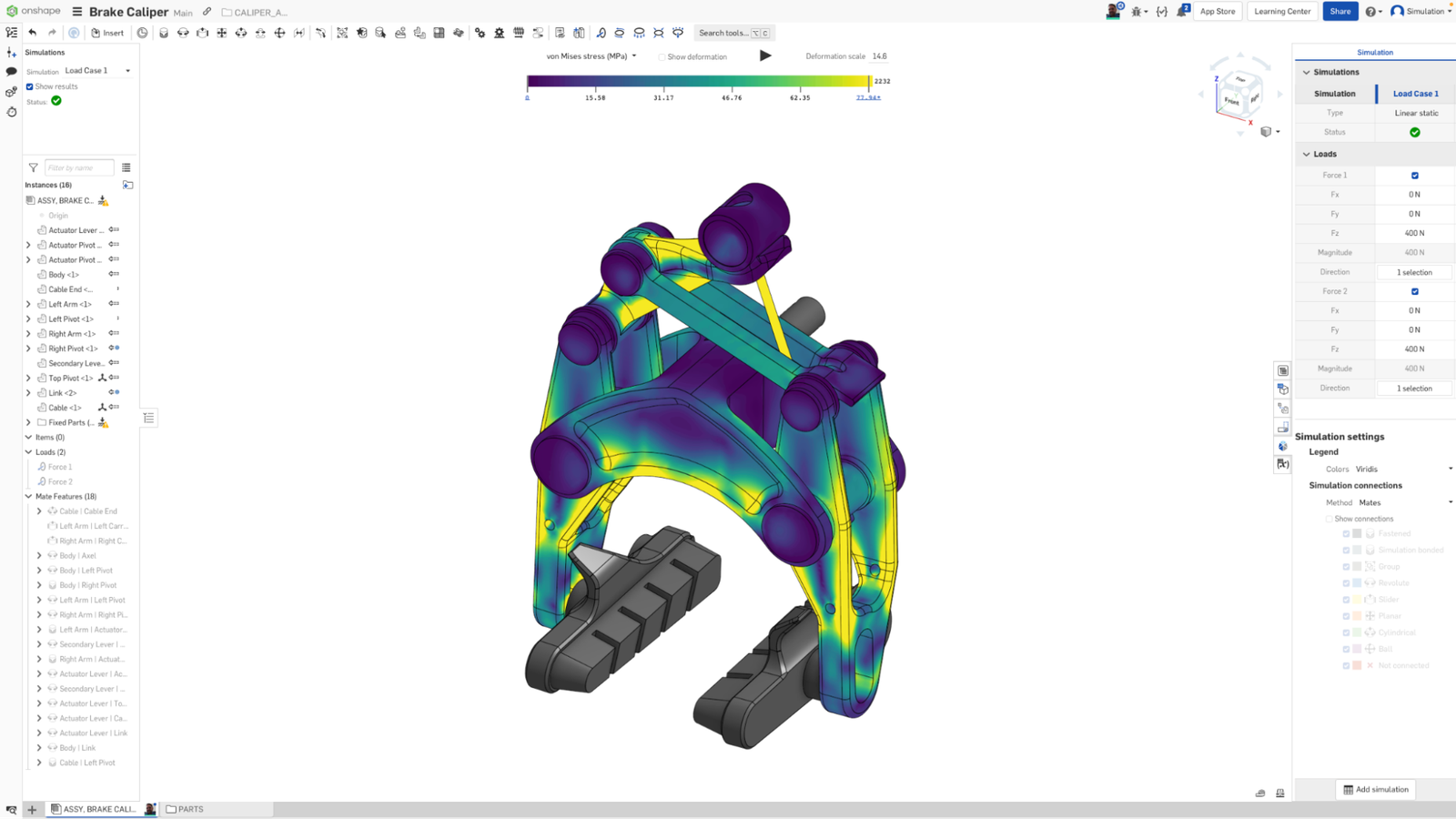

Finite Element Analysis (FEA) is built into the Onshape design environment. It is part of your Onshape Document and accessible in the Assembly tab.

The whole notion of giving designers tools to make better decisions during their design process – versus after the fact – has been something the industry has been seeking for a long time.

Indeed, it was how I personally came into the industry in the first place. I was an early adopter and advocate of RASNA Applied/Mechanica, which incidentally became part of PTC through acquisition and pretty much gave rise to the “designer simulation” movement. There have been many attempts at designer-focused FEA simulation software over the past three decades by multiple vendors, and honestly speaking, most have only been partially successful.

Overall, there hasn’t been a finite element analysis software solution yet that fully gives designers meaningful and interactive analysis where and when they are designing. If we put a fun, ambitious spin on the FEA acronym – and say it ideally should stand for Fast, Easy and Accurate – the best FEA analysis software efforts to date have only been able to deliver two of those three criteria.

So far, most FEA simulation software has been either:

- Fast and Easy, but not Accurate.

- Easy and Accurate, but not Fast.

- Fast and Accurate, but not Easy.

The Future of Cloud-Native FEA Analysis Software

In order to be truly useful, FEA simulation needs to be fast enough to keep up with your pace of thinking and your pace of design. And it has to be accurate enough to support informed decisions – it’s always more expensive to make design changes late in the process than it is to make them early on.

Despite previous efforts to get finite element analysis in the hands of more designers, it generally is still too difficult for them to learn how to put loads onto a model, and how to constrain it – that is, how to hold the model so it accurately represents what is happening in the physical, real world. But just making the tools easier doesn’t necessarily make them better, or more useful. In my experience over the years with many different designer simulation tools from various vendors, I’ve found that “easier to use” really means “easier to do bad simulations.”

Onshape Simulation meets all three objectives – Fast, Easy and Accurate. It eliminates much of the time-intensive workflows of traditional FEA analysis software, which often require hours of tweaking your simulation model to match your CAD model. Worse still, designers are required to re-enter information that they had already painstakingly defined in their CAD model – because the simulation environment, its features and approach, are fundamentally different and separate.

In Onshape, you can be looking at structural simulation results within minutes, right from inside the assembly environment, leaving no possibility of mismatches between the simulation and CAD model. Why? Because the CAD data, including assembly connections, is the same data that the FEA simulation uses.

Seamless CAD FEA Integration: Using Onshape Simulation is Just Like Using Onshape

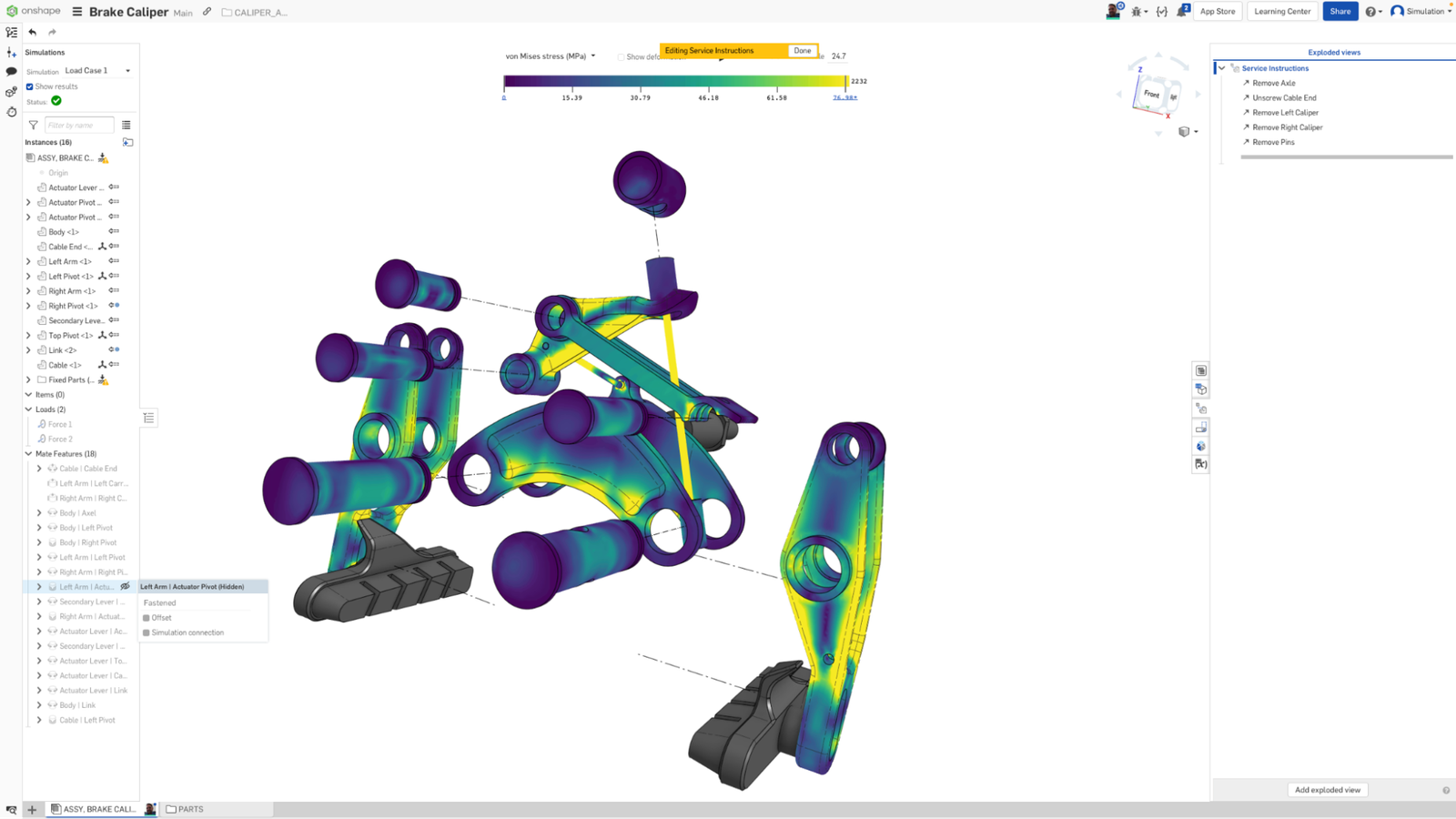

Onshape Simulation results visualized in Exploded View mode.

All you need to know to use Onshape’s FEA simulation software is to know how to use Onshape. Period.

TECH TIP: How to Simulate a Standalone Part in Onshape

We don’t expect you to feel like you are going into the cockpit of a 787 and have to know which knobs, dials and levers you need to use to get the right results. We want you to just be able to focus more on improving your products with powerful finite element analysis capabilities.

The same tools and techniques that make Onshape Assemblies so efficient and easy to work with are already understood by Onshape Simulation, so users just need to add loads and get on with their designing using our integrated cloud-based FEA platform.

I like to say that “Onshape Simulation is Onshape!” Because that absolutely describes how it was built and how it works as a unified FEA analysis software solution.

Real-Time FEA Simulation That Adapts to Your Design Process

After you’ve built an assembly, mated it together, and made the exploded views and configurations, you won’t have to do it twice because Onshape’s finite element analysis software is going to use what you did the first time to calculate results.

The FEA simulation definitions stay with your model, no matter what you are doing with it. If you start a new branch or configuration, and you're still looking at the stress results, they will be automatically recalculated. Whether you're analyzing fully constrained systems or free-floating assemblies using inertial relief, Onshape Simulation adapts seamlessly to your design changes. In the same way that CAD users don't have to remind themselves to refresh the shaded graphics or to recalculate the hidden line view, Onshape Simulation knows what needs to be done and it does it for you.

Cloud FEA simulation is now a regular part of building CAD models in Onshape. You don't need to switch back and forth in a separate tab or another browser window. Finite element analysis guidance is always there, giving you interactive, meaningful information on a design's rigidity and strength.

TECH TIP: How to Make Static Analysis More Agile with Branching and Merging in Onshape

Why This Breakthrough in FEA Analysis Software Matters

Now every CAD designer can benefit from early insight and decision support using professional-grade FEA simulation software, creating a domino effect for better product development outcomes down the line.

With the addition of its always-on cloud-based FEA simulation tools, only Onshape enables you to simultaneously design and analyze CAD models in the cloud with a unified CAD, PDM, and finite element analysis platform. From structural stress analysis to modal analysis for understanding vibrational behavior, we can't wait to see how Onshape’s FEA analysis software helps your team improve its product development process!

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more