Simulation

Rapidly analyze stress, deformation, and natural frequencies of parts and assemblies leveraging the power of cloud computing with Onshape.

Rapidly analyze stress, deformation, and natural frequencies of parts and assemblies leveraging the power of cloud computing with Onshape.

Simulation

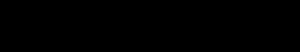

Onshape Simulation is the easiest and fastest way to examine meaningful structural analysis results such as stress, displacement and natural frequencies, as you create and iterate in the Onshape design environment.

With simulation built into Onshape’s cloud-native architecture, you can build better quality products faster with mechanical feedback that stays in sync with your assembly throughout the product development process.

Webinar: Introducing Onshape Simulation

Learn more about Onshape’s built-in, interactive and intuitive simulation capabilities.

Key Features

Accurate Solver, Expert Guidance

Onshape Simulation supports linear static and modal analyses - the most fundamental tools in a structural analyst's toolbox. Expert mechanical guidance is now available for you to use early and often in the design process.

Design better products faster as you interactively visualize stress, deformation, and natural frequencies to ensure designs meet their factors of safety and avoid mechanical resonance.

Easier to Get Started

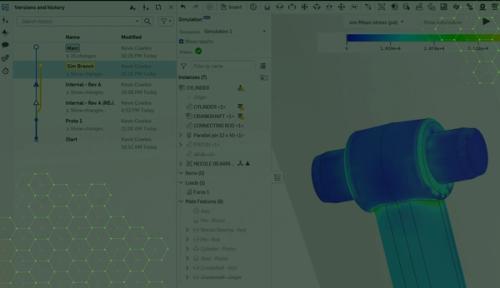

Onshape delivers simulation in the assembly environment, so you can easily simulate full assemblies, not just parts. Assembly mates – such as fastened, revolute, slider and more – automatically translate into simulation kinematics, dramatically simplifying your FEA analysis while ensuring an accurate physical representation of your assembly.

Onshape Simulation is easy and efficient for full assembly analysis and does not require defeaturing or meshing. You can apply loads and constraints directly to either full parts or individual part faces.

Faster Results, Faster Decisions

Be agile and get to a final design faster, change your assembly configuration, modify a part or update a global variable and without any additional effort simulation results refresh automatically.

Seamlessly switch between visualizing stress analysis results and editing your part in the context of your CAD assembly allowing you to iterate quickly with informed mechanical guidance.

Unified Experience

Simulation is built into the familiar Onshape Assembly environment and directly uses the full assembly's parts, materials and mates offering a unified and efficient FEA experience.

As part of your Onshape Document, simulations are version controlled with built-in product data management (PDM) and can be securely shared instantly with other users for better collaboration and better decisions.

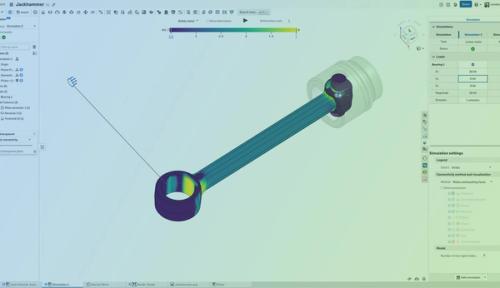

Cloud-Native Simulation

Onshape Simulation is a unique, proprietary, and cloud-native approach to finite element analysis (FEA), offering designers the ability to perform and share structural analysis from any web browser, anytime and anywhere.

Simulations are part of your Onshape Document, making it easy to leverage high-performance cloud computing for fast and interactive FEA – without leaving your design environment or requiring any specialized hardware.

The State of Product Development & Hardware Design 2023-2024

Engineering and manufacturing leaders reveal their top challenges, strategies for success, and experiences adopting newer technologies.

Explore More

When it comes to agile product development, only Onshape has the technology and tools to support rapid simulation for interactive and iterative assembly design. Simulation works with configurations, branching and merging, and Onshape’s built-in PDM. Explore these Tech Tips to learn more about Onshape’s unique assembly-focused design environment.

Tech Tip: How to Make Static Analysis More Agile with Branching and Merging in Onshape

02.13.2024

In this Tech Tip, see how using Branches for Simulation can make Static Analysis more agile in Onshape.

Read Tech Tip

Tech Tip: Linear Static Analyses with Bearing Loads

03.18.2025

Learn how to perform linear static analyses with bearing loads in Onshape with this step-by-step Tech Tip.

Read Tech Tip

How to Assess Your Models for Structural Weakness with Onshape

07.03.2025

Cloud-native CAD integrated with structural analysis or Finite Element Analysis (FEA) empowers engineers to design better products, faster.

Read Blog

Learn how fast, easy and accurate Onshape Simulations are

Got Questions?

For more answers or to ask a question yourself head over to the Onshape Forum.

What type of analysis can Onshape Simulation perform?

What type of guidance for designers does Onshape Simulation provide?

Does Onshape Simulation do Finite Element Analysis (FEA)?

How does Onshape Simulation work?

What technology powers Onshape Simulation?

Using Onshape Simulation made design decisions easier and our whole development process more efficient. Simulation results refreshed quickly with every design change giving us guidance on dimensions, materials and hole locations. We were able to reduce the number of physical prototypes we needed and were able to identify where we could reduce material weight and cost faster. With Onshape Simulation we were able to start production faster.’’