05:54

Situated within the heart of Paris, CentraleSupélec University stands as a distinguished institution renowned for its academic excellence in engineering and technology. With roots tracing back to 1829, and now part of the Paris-Saclay campus, the university has consistently produced top-tier engineering professionals, shaping the landscape of innovation and industry.

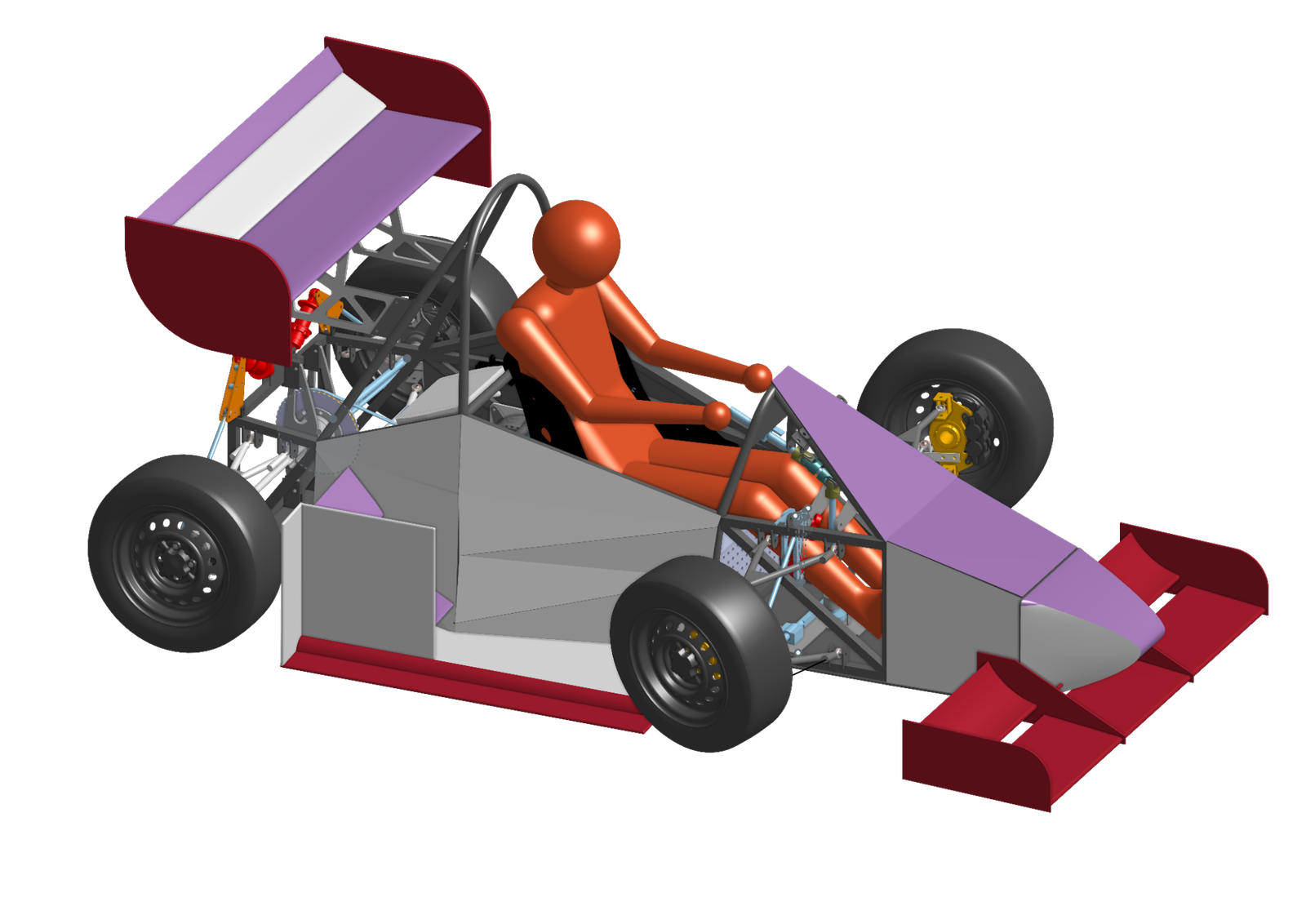

In 2022, a group of students from the university formed the APECS team with a clear objective in mind: to apply their engineering and design skills, build a Formula Racing car, and participate in the Formula Student competition.

Formula Student is an international engineering competition that challenges university students to design, build, and race a single-seat formula-style race car. While the first event took place in the United Kingdom as a Formula SAE competition, it has since branched out as an independent event, held in numerous countries around the world, including the United States, France, and Germany.

Onshape Supports Students’ Drive for Excellence

I met the APECS team, represented by Ulysse Lemoine, Thomas Gamelin, Simone de Rinaldis, Grégoire Genouville, and Antoine Vallade, as part of their effort to leverage Onshape’s Collegiate Teams Sponsorship Program.

The Onshape Education team is committed to ensuring a successful season for student competition teams and is proud to sponsor and support teams by providing access to software and resources. At the moment of writing this article, Onshape is delighted to announce that the APECS Association has joined our list of sponsored university teams, and we are looking forward to seeing them participate in Formula Student events in Europe and around the globe.

This month, April 2024, the students and I had an online rendezvous to discuss their project and their progress in Onshape more. We decided I would interview the team members to promote the association’s continuous aim for extracurricular excellence and their endeavor to apply their theoretical knowledge on the international competition stage.

Their main ambition is to participate with an electric vehicle in the Formula Student competitions in France and Germany in 2025. As part of the trials set out by the competition, their team must pass a series of various static and dynamic events that test the students’ engineering, design, and business acumen. They plan to launch a viable prototype car by the end of 2024.

Collaboration is Key

For the past six months, the team has been using Onshape to design their car.

“We needed to choose a 3D CAD software once we started working on the chassis, and we settled on Onshape for its collaboration features,” the students said.

As soon as they started modeling, the team found that Onshape made it easier for them to work together on large assemblies without the hassle of file transfers or version control issues. By avoiding traditional file-based workflows, Onshape has offered the team a seamless avenue for real-time collaboration, becoming a game-changer for the team and allowing them to focus more on design and less on logistics. The team also mentioned that assembling all parts of the chassis together was a difficult and complex process made easier by the fact that they were all able to work simultaneously on the same documents.

The students stated that they had discovered Onshape through their studies since their university, CentraleSupélec, acquired an Onshape teaching license at the beginning of the university year 2023.

When asked what has changed since transitioning to Onshape, they said that in comparison to traditional CAD software, Onshape is “more intuitive and easier to understand, but the most important difference between Onshape and other CAD software is the built-in collaboration features.”

When talking about collaboration, Onshape’s competitive edge lies in its cloud-native architecture, which facilitates remote access and modification of designs, enabling team members to synchronize efforts regardless of geographical constraints. The possibility of working remotely was yet another factor that made them choose Onshape.

“I was even able to work in Onshape and enable authorizations for my colleagues from my smartphone app while I was on vacation, with limited access to an internet connection,” said Ulysse Lemoine, the president of the APECS association.

Optimizing Design Workflow

While working on the chassis of the car, the APECS team encountered issues in the design process. Onshape was able to help them pass these hurdles through its intuitive Mate Connector interface, designed to ensure that there is a constant feedback chain between the individual contributor, the team, and the software.

They said the most challenging part of designing a car is working with large, part-heavy assemblies. That’s where Onshape comes into play.

“Some members of the team can fix parts together, while others can work on the overall assembly. There are always at least 10 people working in an assembly at the same time, but it always works well,” said one of the team members.

The car chassis is such an example of a complex structure that needs to be worked on, vetted, modified, and tested with every design change and deviation. A single mistake can cost the team hours or even days’ worth of work, but the team has leveraged Onshape’s Release and Version Management system to its advantage.

“Whenever someone makes a mistake, we can always roll back to a previous version by using the version control – it makes error handling much easier,” the team said.

However, in cases of working with large assemblies, a best practice of the APECS team, as stated by the students, is leveraging Onshape’s configuration tools to suppress redundant or unnecessary parts. The team has found that not getting overwhelmed by the large number of parts and assemblies is key when designing ambitious projects.

A Word of Advice

During our interview, I asked them what advice they would give to other students designing a Formula Racing car in Onshape.

They said it’s important to have a “good structure of Documents and folders and to understand the differences between composite parts and standard parts in assemblies” to import and collaborate efficiently. They also stressed the importance of adaptability and cross-software knowledge.

As testified by the team, advanced users of conventional CAD software will find Onshape to have a steep, yet easy, learning curve and that “you should not be afraid to change your software if it doesn’t meet your expectations – we had to try three different solutions until we found the right one.”

The APECS team's adoption of Onshape has streamlined their Formula Student car design process and has made it possible to overcome the complex design challenges they were facing. As they continue their journey, Onshape will provide a fast-paced environment for accelerating their progress towards their Formula Student goals.

You can find out more about the APECS Team by visiting their website or their LinkedIn profile page.

Are you on a collegiate team or club that uses CAD?

Learn about Onshape sponsorship opportunities!

(Kirian Lavoisard, Customer Success Specialist, PTC Education)

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more