The Challenge

Based in Minnesota, Command Tooling Systems designs and manufactures precision toolholders for CNC machines, with a special focus on the requirements of the aerospace and medical device industries. The company’s product development team was frustrated with its growing time and financial commitments to CAD software maintenance, keeping up with new hardware demands, and other IT overhead associated with file-based platforms. After 13 years using SOLIDWORKS, Command Tooling Systems switched to cloud-native Onshape in 2021.

Results

- Command Tooling Systems credits cloud-native Onshape for a 50% efficiency gain when working on custom manufacturing projects.

- The company now saves approximately 25% in annual CAD software costs with Onshape after eliminating maintenance fees from SOLIDWORKS.

- Using Onshape’s Render Studio, the team now produces photorealistic images from CAD models in less than 2 minutes compared to requiring hours per image with their previous file-based program.

- Cloud-native Onshape’s zero-IT footprint means that Command Tooling Systems’ top engineers can focus on more business-critical tasks instead of managing software upgrades and installation.

The rendering tools we used to use with SOLIDWORKS, even on a high-powered computer, would take a few hours to output a quality image. With Onshape, we’re doing 20, 30, 40-megapixel renders, and they’re done in two minutes or less!’’

Just like with carpentry hand tools, a CNC cutting tool is only as effective and accurate as the holder behind it.

Based in Minnesota, Command Tooling Systems specializes in precision toolholders for milling machines, with a special focus on the requirements of the aerospace and medical device companies headquartered in the Greater Minneapolis area.

“Sometimes our products get overlooked as manufacturers are more focused on what kind of cutters they need for specific materials,” says Chuck Berg, Director of Engineering and Technology for Command Tooling Systems. “But the accuracy, extension and rigidity of the toolholder is an extremely important part of the solution, too. As you can imagine, there’s a whole variety of characteristics that are important when choosing how you’re going to hold your cutter in a machine.”

A subsidiary of the global EWS Group – headquartered in Germany with facilities globally – the company has a reputation for delivering custom tooling solutions with a quick turnaround time. About half of its revenue comes from manufacturers throughout the U.S. Midwest.

“In the machining industry, typically everyone is trying to reduce setup time,” says Berg. “Every additional minute of setup time on the machine means you’re not cutting metal; if you’re not making parts, you're not making money. Everything that you can do to reduce your setup is important.”

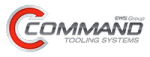

To help reduce setup time for their customers, Command Tooling developed its benchtop Gemini tool fixture – kind of a toolholder for toolholders – that allows machine operators to quickly and securely change out cutters.

“Everything is about speed nowadays,” says Berg. “We manufactured a basic product in the past, similar to what our competitors offered, using a lockdown screw to retain the holder. It took a little more time to use and could get a bit fussy.”

“We redesigned the product for improved ease of use; positioning the holder in a way that’s more accessible than the typical designs. The Gemini is a product that's simple in nature, but quite a bit different than what's out in the market right now,” he adds.

The ROI of Cloud-Native CAD and PDM

From 2008 to 2021, when Command Tooling Systems used file-based SOLIDWORKS as its primary product development software, Berg says the end of each year came with unpleasant surprises for him and his top two engineers – who doubled as the company’s CAD administrators by default.

“In general, the annual software upgrades would start out halfway decent. But our problems usually came with hardware compatibility,” he says. “There were always little gotchas that you may not expect. We have some workstations that are three or four years old. They have different types of memory. They each have different graphics cards and displays. Typically, we would lose a computer or two to compatibility issues.”

“For large companies that may have an IT specialist maintaining the engineering department, that’s fine. But Command is a small company and we just don’t have the IT resources to keep track of this stuff.”

When deciding to explore cloud-native Onshape as an alternative design platform, Berg found that not only were installs, upgrades and hardware compatibility no longer an issue, but the company would save 25% in annual CAD costs when cutting out the annual SOLIDWORKS maintenance fees.

Because running Onshape does not require high-performance workstations – and works in a web browser on any computer, tablet or phone – Command Tooling also gains significant savings on hardware replacement costs.

However, Berg says he found that the most profound benefit of moving to the cloud was his team’s increased productivity when using Onshape’s built-in Product Data Management (PDM) system, which allows for simultaneous multi-user collaboration versus the one-engineer-at-a-time workflow of the past.

“For us, this is really huge. I’ve got a guy working on a drawing or updating the assembly, and at the same time, three or four people can be in the same part making corrections, and can apply those corrections immediately,” he says. “What is the strength of a PDM system if it works correctly? Well, it's how people can use it collaboratively, right? I think Onshape has done a great job of making this all very intuitive and easy to use.”

Berg estimates that Onshape’s worry-free data management and collaboration – and the fact that every Onshape user is always automatically on the same software version – has boosted his team’s efficiency by 50 percent when working on custom manufacturing projects.

Beyond CAD: Onshape’s Cloud-Native Simulation and Rendering

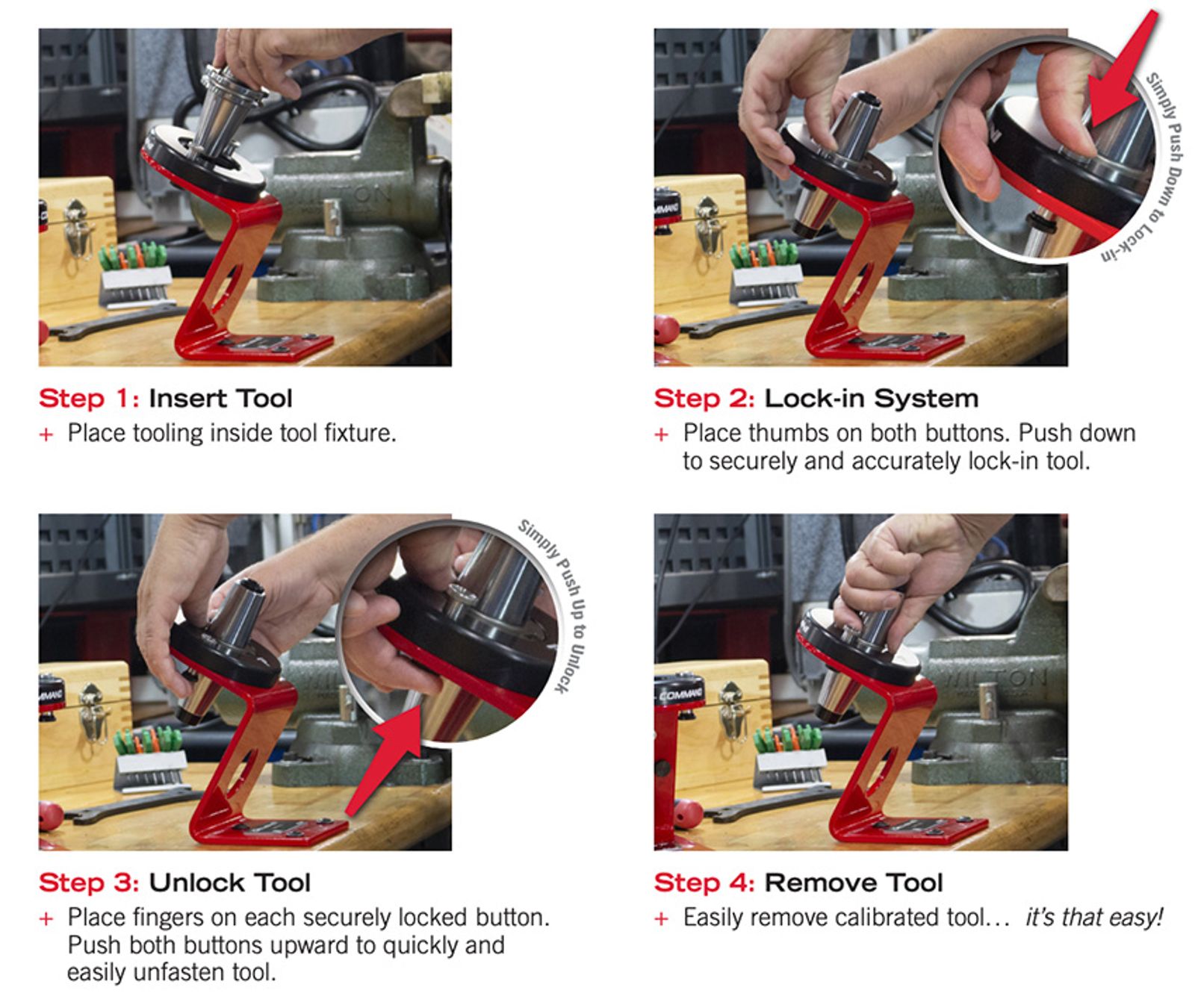

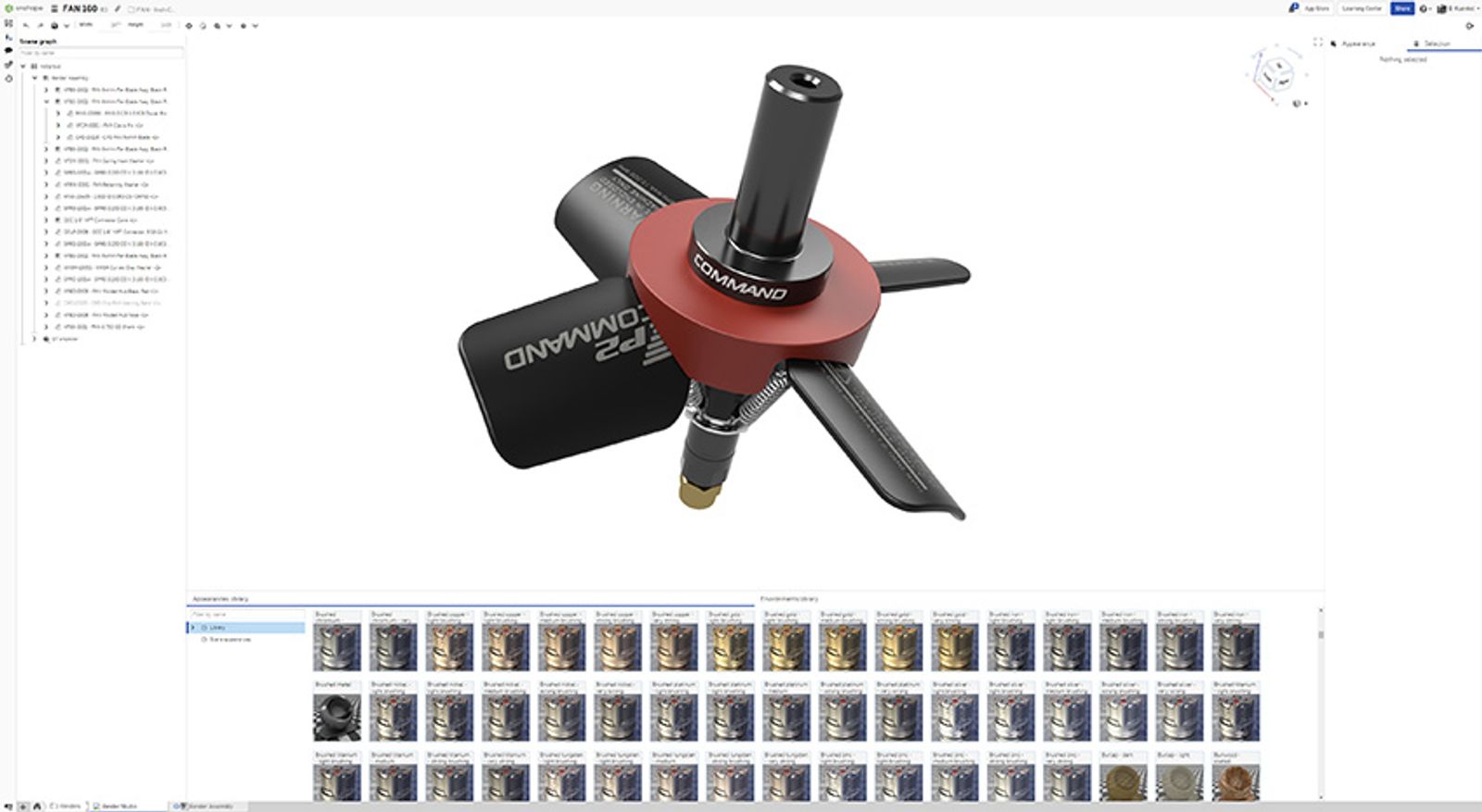

According to Berg, Command Tooling Systems is leveraging the full Onshape ecosystem beyond its core CAD and collaboration tools, particularly with cloud-native simulation and rendering offerings.

Using Onshape Simulation, product designers can now more quickly identify the best and worst performing aspects of their models earlier in the design process. The built-in, always-on FEA tool provides linear static analysis results that update as your model changes. Berg says he recently found the simulation tool helpful for measuring the durability of a CNC fan that blows chips away from the cutting surface.

“We're spinning plastic parts at high RPMs, so you can imagine there's some different loading concerns,” he says. “Plastic molds are very expensive. You could be buying a brand new 30 or 40-thousand-dollar mold in this case. Having stress analysis inside the CAD environment is extremely valuable and gives you a comfort factor before you make the real thing. I also like that I am right inside my assembly when I’m applying the loads. It’s not a glue-on or bandaid-type application. All the tools are right there.”

“Another huge productivity bonus we’re experiencing with Onshape is in the rendering area,” Berg adds. “The rendering tools we used to use with SOLIDWORKS, even on a high-powered computer, would take a few hours to do a good-quality image. With Onshape, we’re doing 20, 30, 40-megapixel renders, and they’re done in two minutes or less!”

As a cloud-native service, Onshape Render Studio does not require expensive, hard-to-obtain, high-end GPUs. It runs in any desktop web browser on any device that currently supports Onshape (e.g. Chromebooks, MacBooks, Windows laptops, etc.).

It also has a quick learning curve. Berg says one of Command Tooling’s graphic designers is using Onshape to create images for a new product catalog even though they have no CAD background. In the past, the company had to devote the resources of a manufacturing engineer to do the same job.

College Interns Embrace Onshape’s Quick Learning Curve

Onshape’s quick learning curve also helps Command Tooling Systems jumpstart a new college internship program every summer.

“The program with our interns is very symbiotic,” says Berg. “It’s a huge benefit for the students and it’s a huge benefit for us because we’re accomplishing significant things with them. They’re producing production drawings. They’re producing production models. We don’t just give the students ‘busy work.’”

Berg has high-praise for the online Onshape Learning Center, which offers both self-paced virtual courses, and live “Bootcamp” training led by Onshape technical professionals.

“I've used every CAD package under the sun in my career, and I have to give the Onshape team a lot of kudos for their training materials,” he says. “All of our engineers and the students have gone through the Bootcamp and then they’re just ready to go. If you want to do more advanced things, there's also a lot of separate little training modules.”

“What I really like about the Onshape Learning Center is the interactive nature of it,” Berg adds. “No one has to go anywhere – they can learn it right here at our facility. It is very, very impressive.”