4:41

Starting a business for the first time can be like learning how to ride a bike – without training wheels.

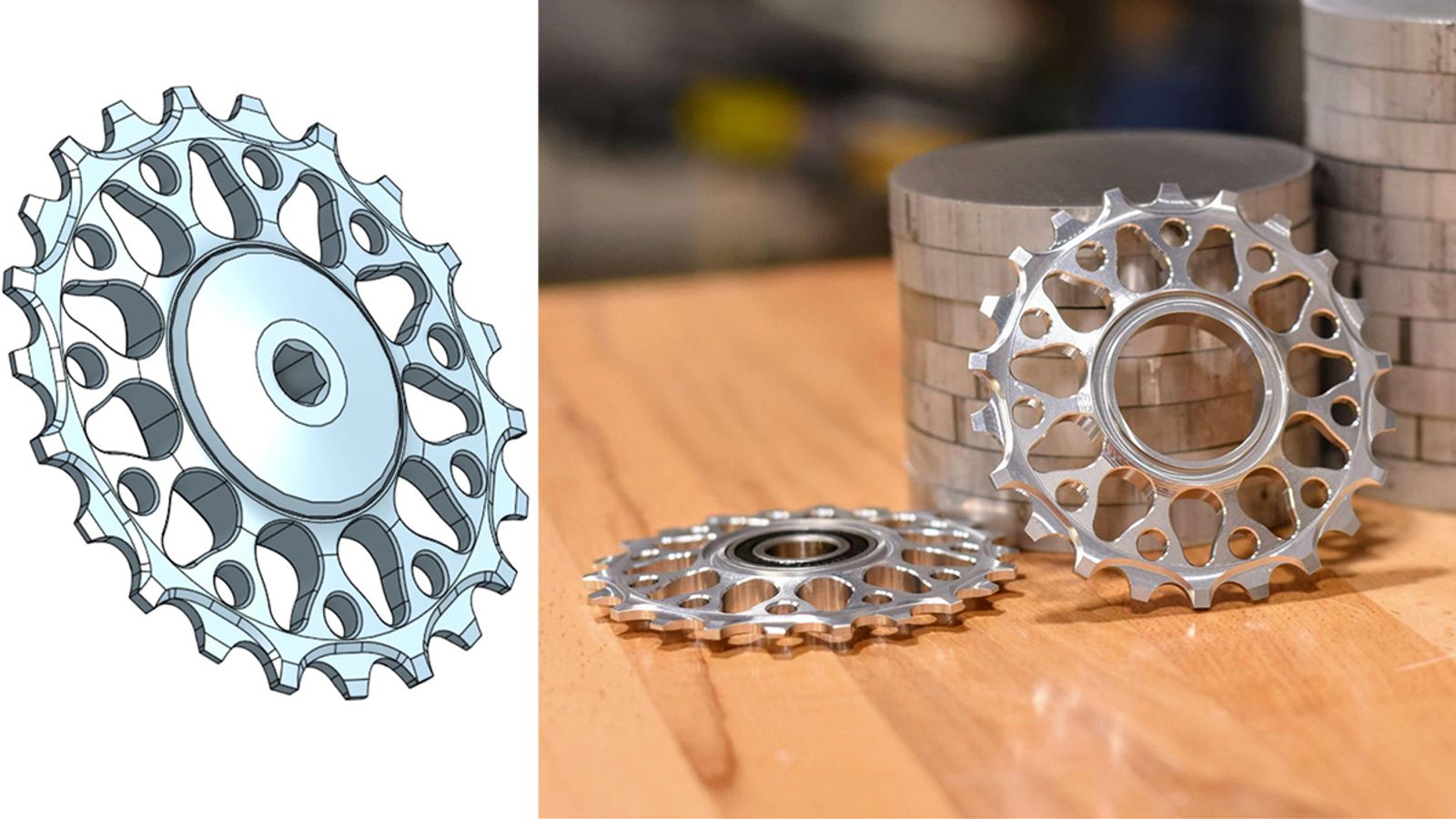

Cedric Eveleigh doesn’t seem to mind the thrill ride; he just doesn’t want the drivetrain to break. And that’s just what his startup is all about: Giving bicyclists repair-free rides with a no-fuss, no-muss gearing system. As any bicyclist can attest, when the gears stop working, it doesn’t matter if you’re riding a $15,000 racing bike or a cheap hand-me-down. It’s no longer a joy ride.

His company, Lal Bikes, aims to create a drivetrain that‘s reliable and lets riders ride. (The name is in honor of Pierre Lallement, who was credited for inventing the bicycle with a pedal crank.)

“The goal at Lal is to make the Supre Drive as durable, affordable, and high-performing as possible. To us, the holy grail is a derailleur and chain tensioner that outlast the bike that they’re on.”

An Idea Takes Hold on a Bike Ride

Eveleigh took to the off-road terrain of his hometown, Chelsea, Quebec, at a young age and has been cycling ever since. He started to think about changing the mechanics of bikes when he worked as a teenager in bicycle shops. There had to be a way to reduce, if not eliminate, a bike’s technical problems.

After studying engineering at McMaster University, Eveleigh focused on improving a mountain bike’s derailleur.

Taking a breather during a ride in 2019, he had his “ah-ha” moment. Taking the idea to his parents’ basement, he built a benchtop prototype drivetrain. It was then he believed he could deliver the durability and efficiency that bikers like him had long sought. And it was the moment he founded Lal Bikes.

Three years of development and testing in the basement followed. In 2022, he moved his company to British Columbia to take advantage of year-round biking weather and to be close to a vibrant mountain biking scene. But before leaving Quebec, he went public with his invention, announcing the Supre Drive derailleur online.

Eveleigh recently recalled that big moment: “It generated a lot of excitement because it solves a big problem for mountain bikers, which is their derailers breaking and bending,” he said. “So there’s been a lot of excitement about it.”

Excitement went to another level when Lal Bikes started a collaboration with the German bike company Nicolai.

“The founder of Nicolai reached out and said he’d like to develop a frame that's equipped with our drivetrain. And I was just like, ‘Heck, yeah. Let's do it.’”

The partnership led to the Nicolai Nucleon 16 Supre, a travel enduro bike designed to excel in rough conditions without the pesky drivetrain issues that sent Eveleigh to the drawing board years ago.

Getting Over Some Learning Curves

With Eveleigh’s parents’ basement a thing of the past, Lal Bikes now has a large workspace with all sorts of metalworking equipment. It’s been exciting to work at a bigger scale, but Eveleigh is occasionally reminded of the challenges of manufacturing.

Last year, he ran up against a 3D printing snafu.

“Some of our drivetrain parts are 3D-printed out of carbon-filled nylon, which is a really great material, but we made a bit of a mistake with the printing process,” he recalled. “The printed parts were brittle and weak, so we built a pendulum hammer for testing. That enabled iterating toward a solution.”

Another memorable moment came when Eveleigh bought a used CNC milling machine from another company. With the costs of professional movers too high, Eveleigh and a colleague borrowed a diesel truck, trailer, and forklifts to bring it back to their facility on the Sunshine Coast near Vancouver.

The move and the learning curve of operating the CNC eventually paid off.

“We’re operational now with his machine. We can make some of our drivetrain parts ourselves with it. I’m happy we got over that learning curve.”

Enjoying Easy-to-Use CAD Software to Design Parts

It’s certainly a challenge dealing with the many aspects of running a startup while also ensuring the product itself meets the high standard promised to customers. Eveleigh is happy that while he has been balancing those demands, he hasn’t had to worry about CAD software to design the bike part.

Lal Bikes qualified for the Onshape Startup Program, an initiative that gives qualifying hardware startups access to Onshape Professional, a fully cloud-native CAD and PDM package with integrated simulation and rendering tools. And, for Eveleigh, the bike design software of choice.

Eveleigh likes how he can collaborate with Nicolai and others on Onshape. The user experience has felt truly intuitive, unlike some other software. He added: “I appreciate the mobile app and the rendering tool. Also, I’m a big fan of the built-in version control.”

Also, Onshape’s take on Mate Connectors has improved his workflow, so much so that he recommended it as a key function to a mountain bike company that’s considering using Onshape. And although some users of cloud-based software might take updates for granted, Eveleigh doesn’t. Onshape’s continual updates are impressive, he said, not just for the frequency but also for the “seriously awesome improvements.”

Most of all, Eveleigh appreciates that he qualified for the Onshape Startup Program.

“The startup program is awesome because we’re a young company,” he said. “We're definitely not off the ground yet financially. We’re trying to survive, as almost any startup does, and the startup program has been incredibly helpful. We really appreciate that support.”

The Onshape Startup Program

Equip your team with full-featured CAD, built-in PDM, and real-time collaboration in one system.

Latest Content

- Case Study

- Consumer Products

How K2 Skis Accelerated Product Development by 25% with PTC’s Onshape

01.14.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more