4:59

Christina Perla and Manny Mota are designers at heart. After studying industrial design at Pratt Institute, where they met, they moved right into the field, taking on freelance clients and hoping to fulfill their career dreams.

But they soon discovered dreams can change. The owner of the 3D printing service that Perla and Mota used for their freelance business had a proposal: He wanted them to take over his company. He was moving to China and thought they could best carry on the business. Perla, who always had an “entrepreneurial bug,” and Mota warmed to the idea.

“We initially thought it was going to be a cash-cow business that would support our freelancing design work,” Perla said. “And we thought that by bringing it in-house we could reduce our 3D printing costs.”

That’s how Makelab started, but it’s not how it evolved. After a year of juggling industrial design and 3D printing work, they chose to focus on Makelab full-time.

“Makelab took most of our time, and we enjoyed the process of building a business,” Perla said. “It was something that was working organically and relatively easily. We felt like the universe was pushing us toward Makelab.”

Their universe, set in New York City, hasn’t veered away from design. But rather than designing things themselves, Perla and Mota – co-owners of Makelab and now a married couple – make the dreams of other designers come true, which makes them feel they haven’t really left the space.

“We’ve really enjoyed this aspect,” she said.

Finding the Right Software for Manufacturing

When Makelab started in 2017, it immediately had to stand out among other 3D printing services. But some of those competitors eventually folded, and Perla thinks she knows why Makelab was able to grow within a B2B space.

“There’s something about being able to talk to a human and ask a question. It’s an emphasis on customer experience that we offered and a lot of others didn’t,” she said. “You would think adding good customer service wouldn’t be scalable, but it enables you to retain customers longer. Most of our orders, I think something like 60 to 75 percent, are from repeat customers.”

And those customers have, in turn, referred Makelab to others, she said.

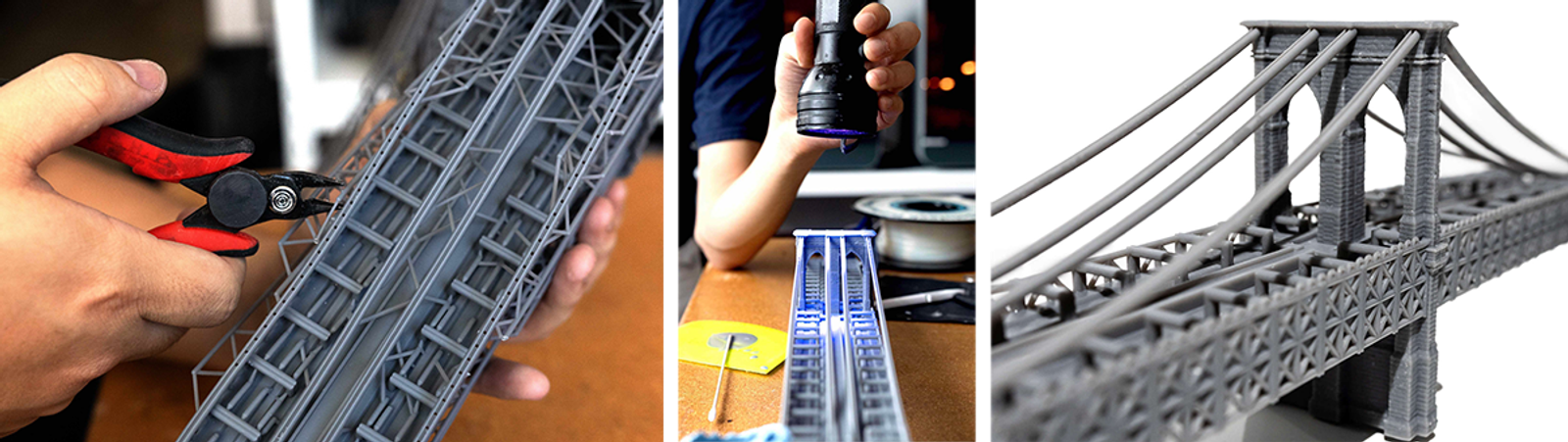

The company makes parts and prototypes for manufacturers in beauty, fashion, toys, hardware, robotics, medical devices, and other industries. They can make materials such as polymers, epoxies, and elastics either tough, high-precision, or flexible.

It's a line of work that can see customers’ needs and tastes change. That’s why Makelab needed consistency from CAD software for 3D printing. Perla “grew up,” so to speak, on SOLIDWORKS as a budding designer, but she found “it is pretty inaccessible” for her professionally.

Thankfully, Perla and Mota didn’t have to look far. Makelab qualified for the Onshape Startup Program, an initiative that gives qualifying hardware startups access to Onshape Professional, a fully cloud-native CAD and PDM package with integrated simulation and rendering tools.

“I’m a Mac user, so the first thing that got me interested in Onshape is accessibility,” Perla said. “The second thing is it was pretty robust for being cloud-based. It shattered my biases on what to expect for browser-based CAD.”

Onshape Opens Doors with its Many CAD Features

Even though CAD isn’t the main driver of Makelab’s business, “it's the side thing that we offer to bring value,” Perla said. “We do CAD when it’s a blocker to 3D printing.”

Perla likes how she can turn to Onshape to design all kinds of mock-ups or create different packaging designs.

“Whenever there’s a client need and we need to mock something up to get ballpark pricing before a customer has a file, we're able to do so quickly using Onshape,” she said. “You can also share it externally and that is really helpful for our client base.”

She appreciates how Onshape allows her to easily share cloud-based designs with customers, especially when there’s a last-minute ask. For instance, she remembers Onshape coming to the rescue when a customer in the beauty products industry needed to make edits on a mold of a bath bomb.

“They were going to 3D-print it to test it, but it was eventually going to be made of metal and not with us. We did it quickly in Onshape,” she said. “I was able to share a link with the client and they were able to pull measurements themselves. There were a lot of technical details and spacing that needed to be addressed. It would have been difficult to just do screenshots with callouts. With the link, they rotated it in 3D in the Onshape CAD space and get those measurements, which was great.”

Onshape also helped a company with the development of a single molded shoe that aimed to be comfortable for people who are on their feet for long hours. Makelab advised the company based on their goals to 3D print the shoe prototype utilizing VCJ (vision-control jetting) technology and soft elastic material by Inkbit. Makelab was able to successfully support the team in advancing their typical prototyping and testing process to reduce weeks off their production cycle and a result that could ultimately be field tested immediately. If you are interested in experimenting with VCJ technology (soft elastic, tough epoxy) for your next project, Makelab is the exclusive on-demand printing partner for Inkbit.

“And that was just very cool because having access to that material really opened up a wider realm of possibilities of what we can do with prototyping,” Perla said.

It was also a reminder of the many doors that Onshape could open for Makelab.

“There is a lot of customer overlap,” Perla said. “A lot of folks that use Onshape are most likely going to be 3D printing. So it does align with our long-term goal of being set up in many locations to enable true local manufacturing and prototyping. I think it’s a natural partnership, so I’m excited to be working together.”

The Onshape Startup Program

Equip your team with full-featured CAD, built-in PDM, and real-time collaboration in one system.

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more