6:08

Old MacDonald might have had a pig, duck, and other kinds of animals on his farm – but what he didn’t have was automated tools and granular data to manage the irrigation of crops.

Instead of an “E-I-E-I-O,” the old farmer probably would have appreciated having “V-E-R-D-I.” That’s Verdi, a technology platform that puts precision into the not-always-precise agriculture industry. Verdi sensors allow farmers to consider soil variability, differences in elevation, and other factors as they control water and fertilizer on a more accurate and granular scale, rather than the longstanding approach of irrigating all plants at the same time and with the same amount of water.

“If you have different types of soils across your farm, the result will be that your plants grow at different rates,” said Verdi CTO Roman Kozak, a co-founder. “What we do is help your plants grow all at the same rate so that you’re using less water and improving crop yield and crop quality.”

Verdi Helping to Improve Crop Irrigation & Save Water

Kozak and fellow Verdi co-founder Arthur Chen, who is CEO, started the company four years ago after recognizing a need for precision ag-tech while working on a Google-sponsored project as students at the University of British Columbia.

They recognized that many farms continued to operate as they always have, relying on the uniform, manual irrigation systems that deliver the same amount of water to every tree and every vine. But irrigation needs to be broken down into smaller zones, they say, because on a farm, soils can differ – sandy, clay-like – and topography can vary – flat, hilly, rocky. Farmers can preserve water and produce the crops their customers want by targeting areas, a process known as variable-rate irrigation.

The same technology Verdi has developed for variable-rate irrigation is also pioneering the way for widespread irrigation automation on farms. Verdi is the only company that can detect clogged or missing emitters and fully automate existing valves and pumps. In contrast, automation systems on the market today only focus on automating valves and pumps, which saves some labor, but workers still need to check for drip line or emitter leaks and breaks. Furthermore, new value is unlocked with the Verdi Software Platform, which allows automation based on prediction, data from field sensors, and remote imagery.

Plus, Kozak said, the preservation of water matters more than ever. Climate change has made weather unpredictable and drastic. Farmers face extreme storms that cause flooding and contend with long stretches of drought. They need the right tools and data to be resilient. That’s where Verdi’s variable-rate technology helps.

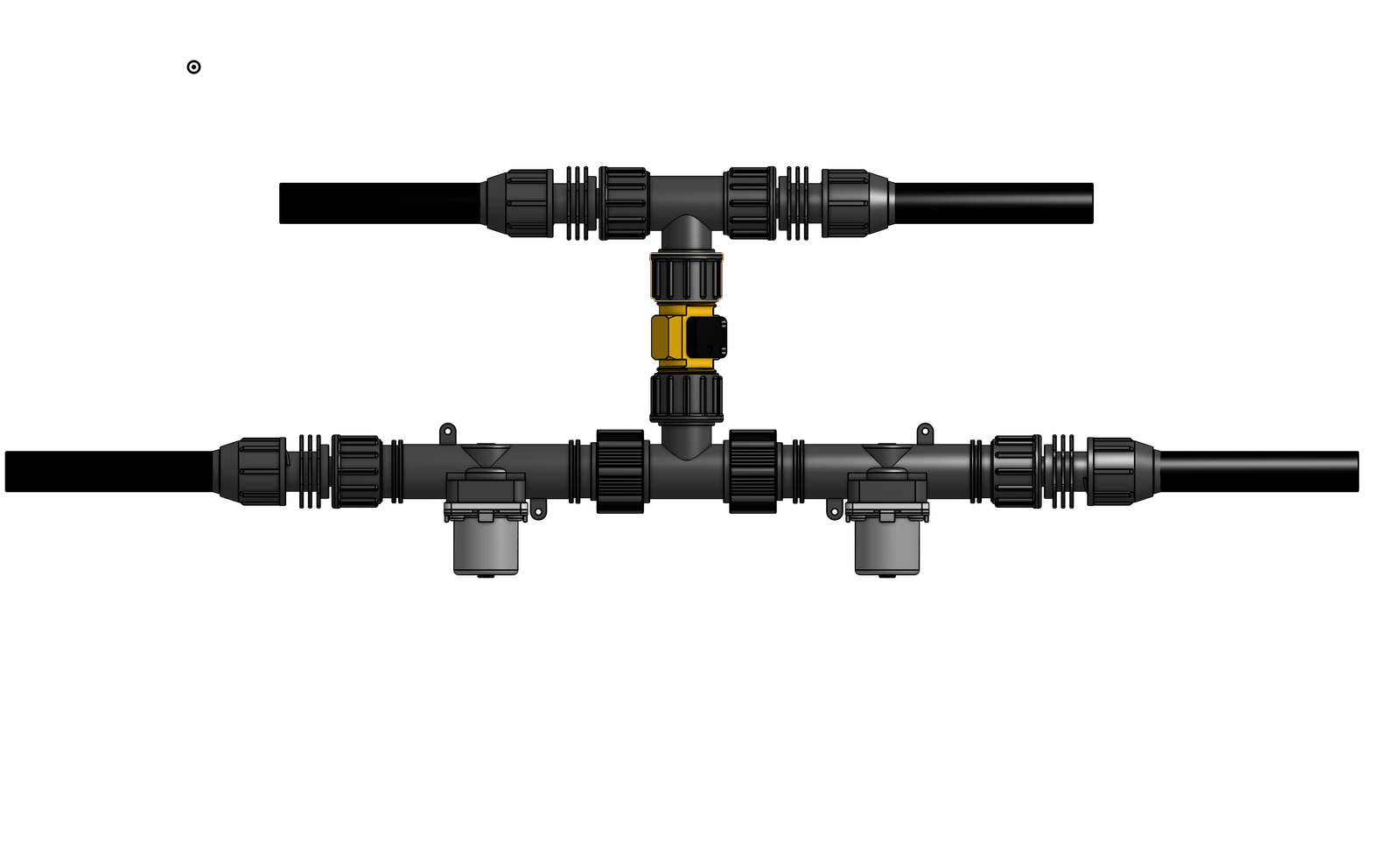

First, there’s the hardware. The underlying technology is based on a heavily integrated ultra-low-power design that enables simple installation and a significantly lower cost compared to existing automation systems today. The Verdi Micro-Block Controller is a smart device placed in each crop row to break the existing blocks into “micro-blocks” – determined by the company’s data-driven maps. Then, there is the Verdi Block Controller, another smart device used to bring a farm’s existing valves, pumps, and sensors online. Going digital allows growers to automate their most time-consuming tasks like creating data-driven schedules, looking for breaks, and keeping an accurate record of water. Farmers can make these decisions using Verdi’s software. The Verdi App streamlines and simplifies irrigation management from a laptop or mobile device. No more tedious, repetitive work that relies on instincts and handwritten notes.

Canada’s largest winery increased its per-acre revenue after turning to Verdi. Enhanced irrigation improved the quality of grapes, allowing the winery to increase the price of certain bottles, Kozak said. Also, instead of having to harvest a section of its vineyard in two passes, as it did in 2021, the winery harvested the section in only one pass the following year with Verdi automating irrigation.

“We helped them reduce their water use in problem areas by 60 percent,” he said. Over the past four years, Verdi has helped all of its clients save 30 million liters of water over 1,000 acres of land.

Verdi Collaborates and Designs on Onshape’s Digital Platforms

While farmers benefit from Verdi’s technology, Verdi receives support from Onshape, an affordable CAD software for startups and small businesses. The Vancouver-based startup qualified for the Onshape Startup Program, which provides qualifying hardware startups with access to Onshape Professional, a fully cloud-native CAD and PDM package with integrated simulation and rendering tools.

Verdi chose Onshape over SOLIDWORKS because of Onshape’s ease of use, how it is supported as CAD software for Mac, and the ease with which employees can collaborate. Using Onshape makes it an excellent CAD collaboration software.

“Bringing someone on board isn’t a huge problem,” Kozak said. “We can give them a username and password, and they can be online designing in a minute, compared with SOLIDWORKS where they might have to download something and then file and export – and all that stuff.”

Accessibility has come in handy when the startup needs to quickly create hardware that best suits a farm’s physical infrastructure.

“If we need something represented in CAD – like if we want to put together a system and need a part done up in CAD – we can give it to an engineer, give them an Onshape login, and just say, ‘Hey, can you, make this part and share it with us?’ Then we can easily add it to our assembly.”

Simon Fu, a Verdi mechanical engineer, also appreciates that Onshape is CAD software that runs natively on Linux, which also makes collaboration easy on his laptop, tablet, or phone.

“Before, when I was using SOLIDWORKS, it’d be the setup with SOLIDWORKS on your machine, and that took a lot of time depending on the operating system and the version of SOLIDWORKS,” he said. “You had to check a part out when you worked on it, and then remember to check it back in after you were done with it, or your changes wouldn't be saved.”

However, with Onshape’s CAD collaboration software, Simon can send a link to a colleague and request work on a design. He can also show a colleague or a customer what a particular design looks like.

“That is a huge time save,” he said. “And being able to run Onshape on my phone, if another machine isn’t handy, is incredible if I want to quickly pull up a CAD to show customers.”

Simon added: “With Onshape, we’re able to get a nice physical model that we’re able to play around with, and then once we have a design that we’re happy with…we can move onto representative prototypes of what the final product is going to be. But in that middle part, there's a lot of design and feedback. We will have a couple of different concepts and we can compare and evaluate them against each other in various ways. The ability to easily pull up and share designs during that stage is very important.”

Kozak couldn’t be happier that Onshape’s CAD software for startups is along for the ride as Verdi seeks to transform agriculture.

“Onshape is something I don't need to worry about, whether I'm on a laptop or desktop,” Kozak said. “I just know it’s going to work, and the things that Onshape does well are the things we need to do 95 percent of the time.”

The Onshape Startup Program

Equip your team with full-featured CAD, built-in PDM, and real-time collaboration in one system.

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Evaluating Onshape

- Simulation

- Rendering

- Surfacing

- Consumer Products

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 learn more

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more