The Challenge

Based in Bristol, UK, Open Bionics is the developer of the Hero Arm, an advanced, lightweight, 3D-printed bionic prosthetic for people with a below-elbow amputation. The Hero Arm costs 5X less than traditional bionic prosthetics, making the technology more accessible to people in need. In the early days of R&D, the product development team was using Blender, a 3D modeling tool better suited for animation and video games. Getting closer to production, the startup was seeking to switch to a professional CAD program that could facilitate better collaboration between its mechanical, electrical and firmware engineering teams.

Results

- Onshape Configurations reduces design time by more than 75% on prosthetic wrists and hands offered in multiple sizes, and in right-handed and left-handed versions.

- Branching and Merging tools empower the engineering team to rapidly explore more alternative design ideas, 3D print prototypes, and get faster feedback from bionic arm users.

- Onshape’s real-time Simultaneous Editing accelerates communication between hardware, electrical and firmware engineers.

- Cloud-native Onshape enables Open Bionics to run CAD and PDM without the need to purchase high-performance workstations.

A great thing about Onshape is that it enables us as an exec team to check our progress on our product roadmap. So we can check 3D models live as they're being edited, we can make suggestions, and we can get really good insights into where we are with R&D.’’

For the Open Bionics engineering team, psychology can be just as an important product development tool as mechanical design.

Based in Bristol, England, Open Bionics is the creator of the “Hero Arm,” a lightweight, 3D-printed advanced robotic limb with a multi-grip hand. Perhaps more immediately noticeable than the life-changing technology, is the device’s upbeat, decorative outer shell. The prosthetics have bright, colorful magnetic covers that pop off like changeable eyeglasses frames. Users can match their clothing, “personality and mood” to their robotic arms with over 50 designs, colors and textures – or they can choose licensed Marvel, Star Wars and Disney characters like Iron Man, R2D2, or Elsa from “Frozen.”

One of the company’s slogans is “Turning Disabilities Into Superpowers.”

“A generation ago, as a society, we really valued conformity. Everyone wanted to look the same. And that's why you saw a lot of prosthetic arms that tried to blend in – that tried to look human,” notes Open Bionics co-founder and COO Samantha Payne. “But as engineers, we couldn't quite get the look right. So it's really cool that as time moved on, we began to celebrate individualism and self-expression. And that’s exactly what the Hero Arm allows its users to do.”

“This insight came from the user workshops. So the users really wanted to wear a device that they found empowering to wear,” she adds. “And we're really proud to be pioneering in that aspect.”

Fashion aside, one of the founding goals of Open Bionics was to radically reduce the price of bionic arms to make them more accessible to the public. According to Payne, less than 1% of the adult amputee population can afford the high-end devices, which can cost up to $100,000 depending on the model. Open Bionics’ 3D-printed arms cost 5X less than traditional robotic prosthetics, the company says.

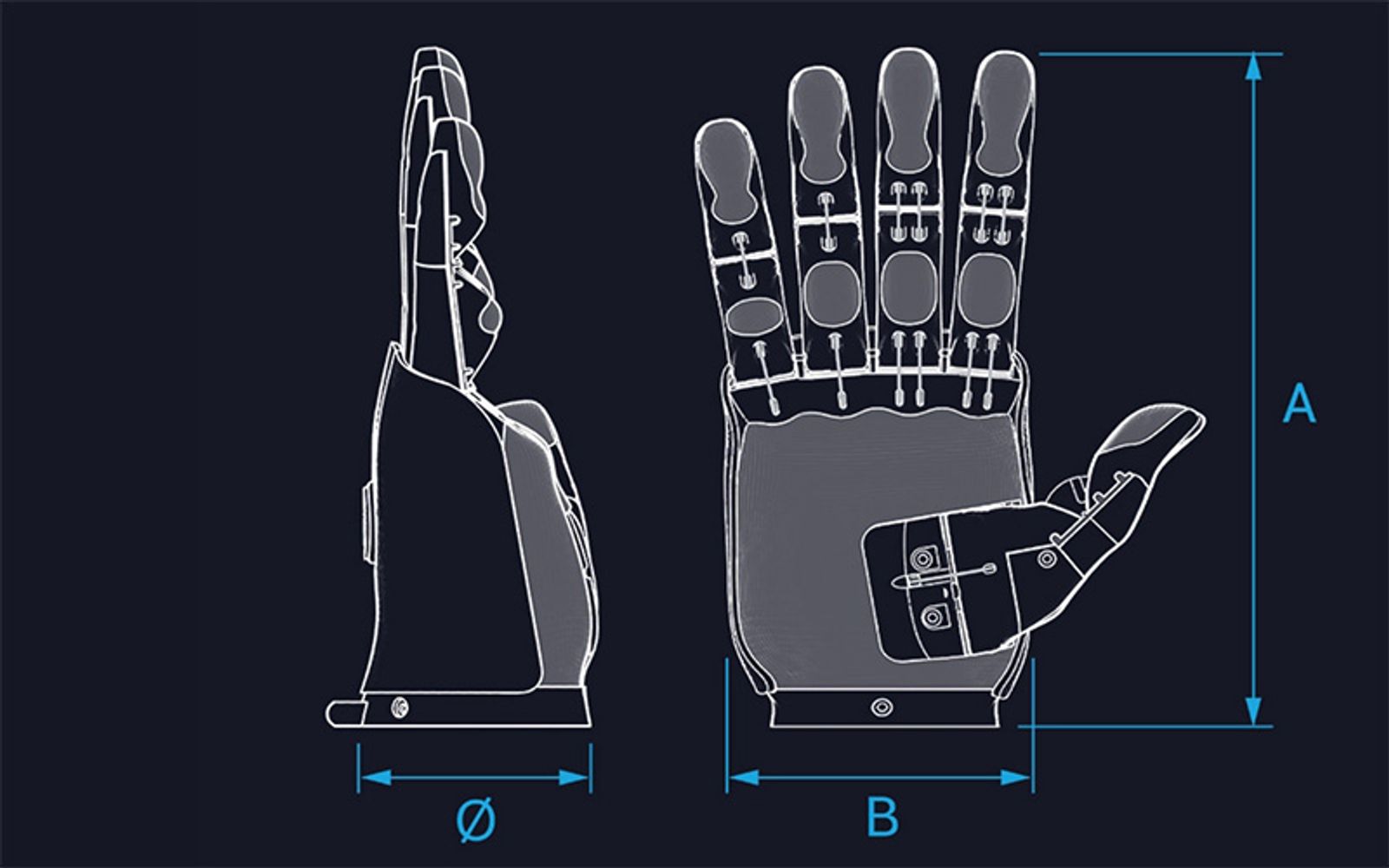

Every Hero Arm is custom fit for the user, with the wrists and hands being offered in multiple sizes. Children as young as 8-years-old are eligible to receive one. The device uses myoelectric sensors which detect underlying muscular contractions generated from specific muscle groups in the upper arm. The body’s electric signals are then amplified and converted into intuitive and proportional bionic hand movements.

Hero Arm user Kim Smith, of Buckinghamshire, UK, credits the 3D-printed prosthetic for helping her reclaim some of the independence she lost when she contracted sepsis in 2018 and needed to have all four limbs amputated to save her life. “It’s just amazing what I can do,” she says. “I can brush my own hair and teeth. I can use a fork to eat and operate the button on my electric wheelchair. I can even fist-bump my grandson, Oliver.”

Jonathan Raines, Research and Development Manager at Open Bionics, says it’s extremely gratifying to interact with Hero Arm users and see his engineering work directly impact people’s lives – a feeling he did not experience when he was designing jet engines earlier in his career.

“One of my favorite memories is when we were fitting one of the first arms to one of our ambassadors and we happened to have a stress ball on the desk. She just threw it up and caught it. The look of shock on her face when she realized she caught it with her robot hand was amazing," he recalls.

Cloud-Native Collaboration Tools Accelerate Design

Raines, the first mechanical engineer hired at Open Bionics in 2015, was initially using Blender – a 3D modeling tool better suited for animation and video games – for product design. Two years later, as the product development team grew, the startup was seeking to switch to a professional CAD program.

Raines recalls that he was initially attracted to Onshape – a cloud-native platform that combines CAD with built-in Product Data Management – because of its affordability to startups with tight budgets. The price of Onshape’s annual subscription, which includes regular software upgrades at no extra cost, was less than the competing vendor’s annual maintenance fee (on top of buying CAD).

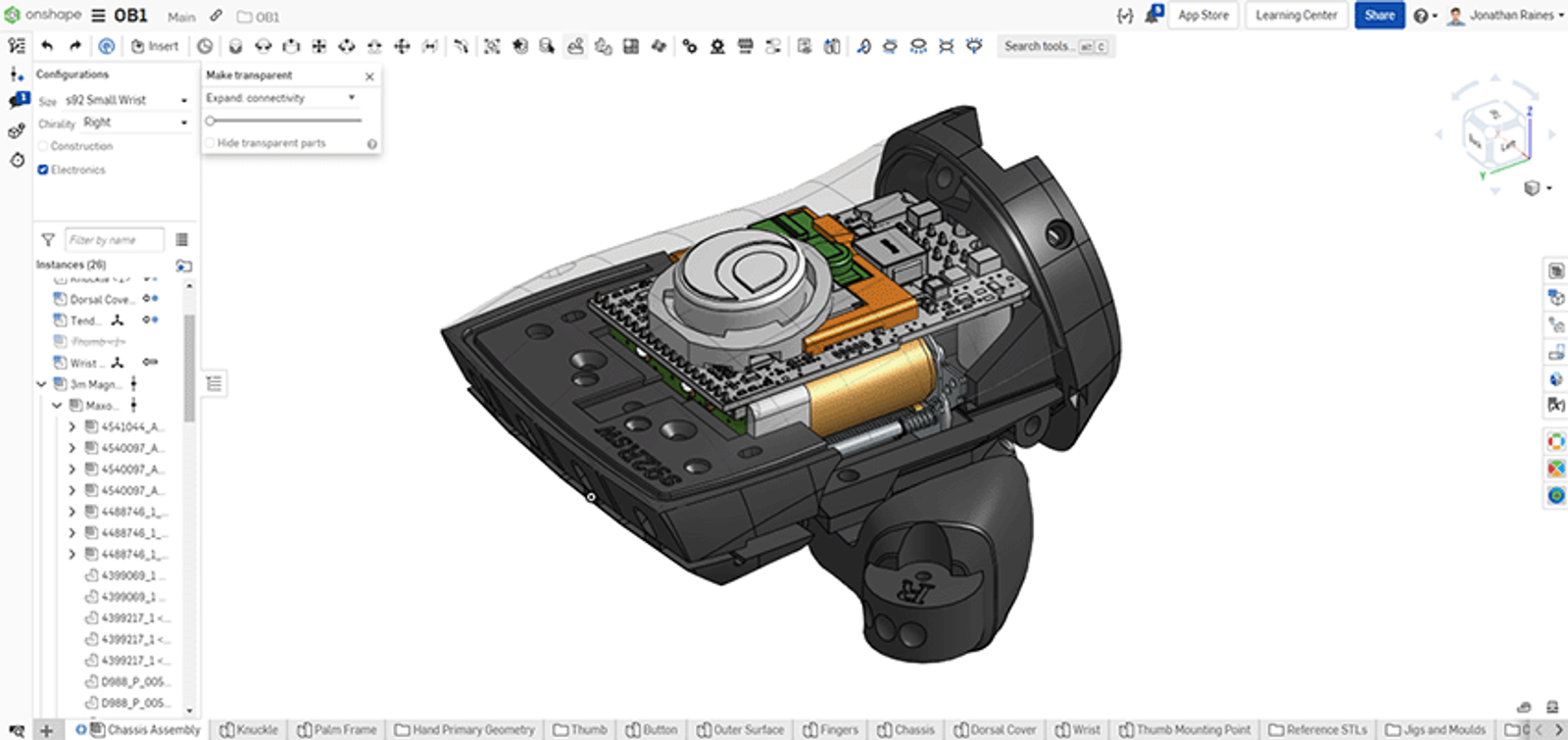

However, more importantly, it soon became apparent that Onshape’s real-time CAD collaboration tools could better streamline communication between the company’s mechanical, electrical and firmware engineers.

“When we had Blender, there were five people working on various bits,” recalls Raines. “And it was okay as long as we were working in different files – the finger in one file, the palm was in another, and the thumb was in another. As long as you divided up the work like that, it was great. But if two people needed to work on the palm, it was a disaster. That basically meant that they would both do their work, someone would save, and then the other person would have to sit and copy all their work into the same file.”

With Onshape’s Simultaneous Editing functionality, whenever one member of a team makes a design change, everyone else on the team instantly sees it. A comprehensive Edit History tracks who made which changes and when, allowing teams to revert to any earlier stage of design anytime if desired.

According to Payne, Onshape’s multi-user environment also gives 24/7 project visibility to internal company stakeholders without the need to wait for scheduled formal design reviews.

“A great thing about Onshape is that it enables us as an exec team to check our progress on our product roadmap,” she says. “So we can check 3D models live as they're being edited, we can make suggestions, and we can get really good insights into where we are with R&D.”

Payne adds that these same collaboration tools are perfectly suited for the R&D and manufacturing teams in the UK to share the latest bionic arm designs with their clinical teams locally and with their United States clinic in Denver, Colorado.

Onshape Configurations Saves Significant Design Time

The Hero Arm comes in two different wrist sizes, and three different hand sizes to accommodate most children ages 8 and older, and most adults. Onshape’s Configurations tool enables teams to plug in the measurements and automate hand designs in different sizes and the right-handed and left-handed versions.

Raines says Onshape cuts the design time for Hero Arm variations by more than 75% compared to his team’s previous need to create each new hand size from scratch.

“Configurations is a huge lifesaver,” he says. “We used to need to have a separate file for each one of those things, and then every time we made a change, I’d have to go make it five more times. So it's just a massive time saver.”

In addition, Raines credits Onshape’s Branching and Merging feature for enabling his team to fearlessly explore alternative design ideas without risk of impacting the original model. Engineers can experiment with their own “branches” off a core design, and then later merge the best elements from multiple designs together – having the assurance that they can instantly return to any prior stage if needed.

“We like to generate lots of concepts and print them out and then show them to users, show them to prosthetists, and ask, ‘What's good about this? What's bad?’ Then we take that feedback and make some adjustments,” he says.

“In Onshape, it’s easy to flip between the design branches and see what the differences are,” Raines adds. “You can see this is concept one, this is concept two, this is concept three. And you can make your changes without worrying about messing up anyone else's work.”

Bringing Advanced Robotic Prosthetics to the Masses

As of 2023, more than 450 Hero Arms have been matched with users in Australia, France, Ireland, Netherlands, New Zealand, the United States, and the United Kingdom. Open Bionics just completed a successful $1.87 million (£1.57 million) crowdfunding campaign to launch the Hero Arm in 10 new countries over the coming year.

“The campaign was really to superfuel what we’re doing already, but also to start work on the future of our R&D roadmap,” says Payne, explaining that the company is sticking to upper-limb prosthetics right now, but is open to exploring other bionic applications in the future.

As Open Bionics finds new markets for the Hero Arm, Payne adds she expects Onshape to play a key role in helping the company reach its goals.

“We are in the business of changing people's lives. And that means we have to stay laser-focused on new technologies, new services and new innovations so we can make our products accessible for everyone,” she says. ”Open Bionics is here to create products that enhance the human body, and we see Onshape as playing an integral role within R&D by being the platform of choice to design every standard part that is 3D printed.”