5:18

Jason Harwerth got hooked on fitness in eighth grade. The 26-year-old hasn’t lost his passion all these years later. But like many other gym rats, he suddenly had nowhere to turn when the COVID-19 pandemic shut down his local fitness club.

But faster than you could say “MacGyver,” Harwerth devised a makeshift gym in his parents’ basement. Investing only $50, he built a “rickety” personal workout space with resistance bands, a wooden plank, a lacrosse stick as a barbell, and a coffee table as the bench.

Not missing a beat in his exercise routine, Harwerth eventually realized he could modernize his invention and turn it into a commercial product. He could market it to exercise enthusiasts with varying strength-training goals by giving them something they’d all savor: a system they could put wherever they wanted.

They could tuck it in a basement, living room, or even in a hotel room while traveling. With just a quick flex of engineering and business muscles – and, eventually, with the help from the Onshape Startup Program, which provides professional-level CAD for startups at no cost – the company Alperian was born. Development of its first product, the Astro Rack, is now underway.

(Follow Alperian's Kickstarter page for more information on Astro Rack's development.)

“It delivers something for a huge market of people,” he said. “It'll be made from metal and plastic, so it's not like it's going to cost $4,000. It’s portable, so it's something you can set up on your own. You don't need someone to install it at your house.”

A Personal Gym for the Home and Other Gyms

Alperian looks to give people a gym experience without having to deal with the heavy weights and many different elements and storage racks that are part of a gym.

“If you replace all that with a system that weighs 50 pounds, obviously, the logistics are a lot easier,” Harwerth said. “If you’re not sacrificing any of the experiences they expect from a gym, then people will want to use it.”

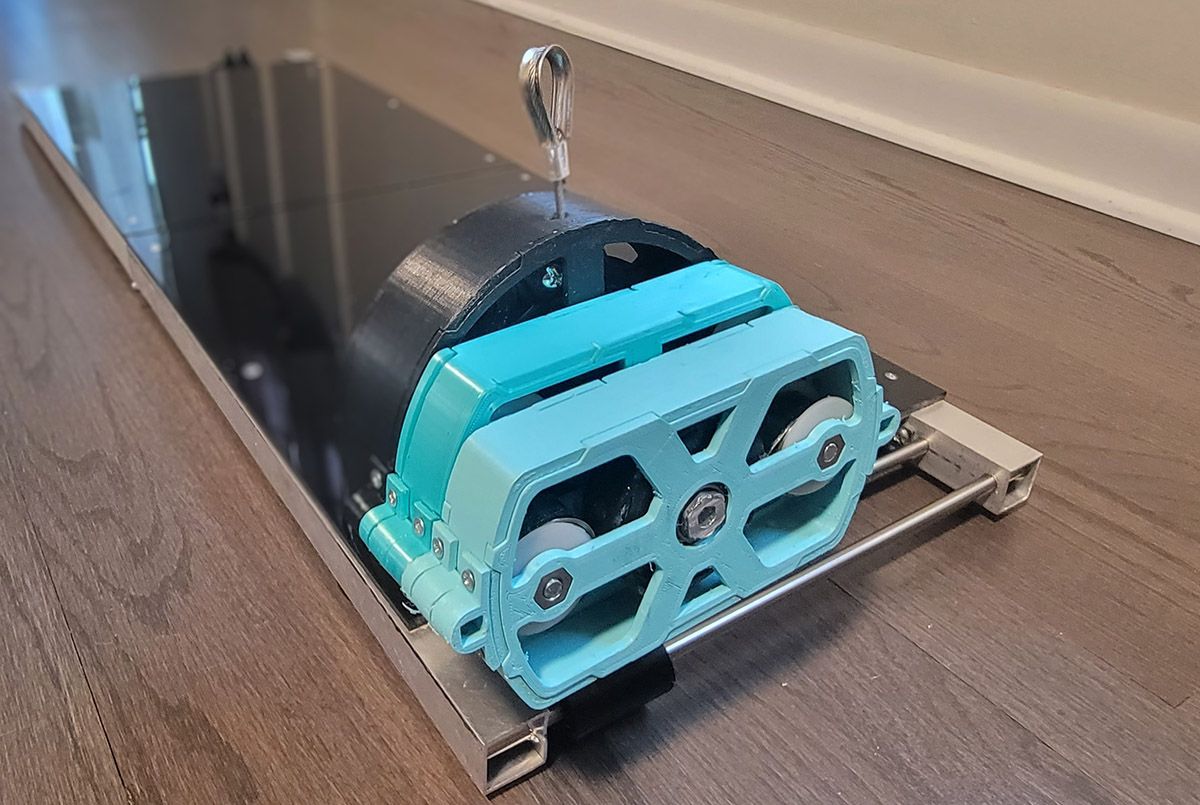

The patent on Astro Rack is still pending, and Harwerth and his three co-founders are still designing, tweaking, and testing its dimensions, materials, feel, and other basics. But essentially, the power rack will rely on lightweight mechanical resistance plates that can be used for various exercises to give users the oppositional push and pull that carves and defines muscles.

Used as a bench, platform, or overhead extension to cover the many different exercises for the chest, back, arms, legs, and shoulders, Astro Rack will provide up to 400 pounds of resistance, Harwerth says. It can be folded and placed or carried anywhere.

Aside from marketing it to individuals for use at home, Harwerth would also like to target rock climbing and mixed martial arts gyms, workout spots where members would want to pump iron on the side but can’t because those ventures don’t have the space for weights and racks. Sports teams could also take it to train during away events.

Testing Out CAD Software for Startups

Harwerth has a graduate degree in mechanical engineering and learned software engineering over the past few years. He’s quickly taken to the concept of agile engineering and “bringing in those different ideas and quickly developing things, but not having this big launch that may or may not fail. As one of the lead engineers at Alperian, I want to instill that in the company.”

He and his Alperian co-founders initially used SOLIDWORKS for CAD design, but they hit a roadblock when they tried to integrate Git, the open-source control system that tracks changes in computer files, launching the team on another software for startup search.

“It was a little bit messy,” Harwerth recalled. “It kind of worked, but it wasn't built in, and there's no support for compares or anything of different models. I wasn’t pleased with it.”

It was then that Eli Kohn, an Alperian co-founder and the company’s CTO, pointed Harwerth to the Onshape Startup Program. It has the design tools Alperian needed at no cost. The program provides Alperian and other qualifying hardware startups access to Onshape Professional, a fully cloud-native CAD and PDM package with integrated simulation and rendering tools.

“There’s a demo video on the Git tools and Onshape, and I was immediately sold at that point because it was exactly what I was looking for, a built-in Git into 3D modeling software,” Harwerth said. “It's everything that I had wanted, right in a browser.”

Onshape for Startups: Developing from a Position of Strength

Fast-forward nearly a year, Harwerth, Kohn, and the other co-founders are pleased with Onshape as a product development platform for startups and beyond. With Onshape, they can share and collaboratively tweak or make wholesale changes to design ideas for the Astro Rack – all thanks to the platform’s Branching and Merging features.

“Normally, in 3D modeling software, you have part files which contain an individual parametric solid, and then you would bring them all into an assembly and make the larger assembly out of those parts,” Harwerth said. “But the Part Studios in Onshape are very useful. Instead of developing one part in a file, you're developing multiple similar parts in a studio, so you can design things that are dependent on each other without having multiple files. It's all contained in that one studio, and it makes it easy for developing multiple different parts quickly.”

Those features are just what Harwerth and his team need as they consider the many big and small functions exercise enthusiasts will expect from Astro Rack.

“When you're making a workout machine, you have to take into account everything that weightlifters like,” he said. “Weightlifters love the feel of weights and the narrowing on the bar and having a little grittiness to it.”

With Onshape, creating that experience has been all easy lifting.

“As a startup, the biggest challenge really is making high-quality prototypes without having the thousands of dollars needed to make them,” he said. “With Onshape, it's just easy to make parts that mesh well together without having to put them all into assembly and then check to see if they work. I can see right there in the parts view that they do fit together, and then I can go print it, and usually it leads to fewer reprints and faster development time.”

The Onshape Startup Program

Equip your team with full-featured CAD, built-in PDM, and real-time collaboration in one system.

Latest Content

- Case Study

- Consumer Products

BOA Technology: Redefining Outdoor Fit Equipment with Cloud-Native Onshape

11.03.2025 learn more

- Blog

- Evaluating Onshape

Cloud-Native CAD 2025 Wins: Revenue Growth, Real-Time Collaboration, Unified CAD-CAM

12.17.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more