8:39

I’ve worked on many interesting projects over the years, mainly related to planes, trains and automobiles, and the machines that help build them. But something recently came along which was obviously very different, yet contained many of the same challenges typically faced in “mainstream” engineering.

Anouk Wipprecht is a Dutch designer, engineer, and innovator working in the emerging field of FashionTech, the melding of fashion and technology. I was first introduced to Anouk in 2021 when Onshape sponsored the Battlebots Team Ghost Raptor, of which she was a member.

She shared with us an idea for a unique project she wanted to design in Onshape and 3D print through HP’s new Jet Fusion 5420W 3D printing solution.

FashionTech Dress Reads the Wearer’s Mood

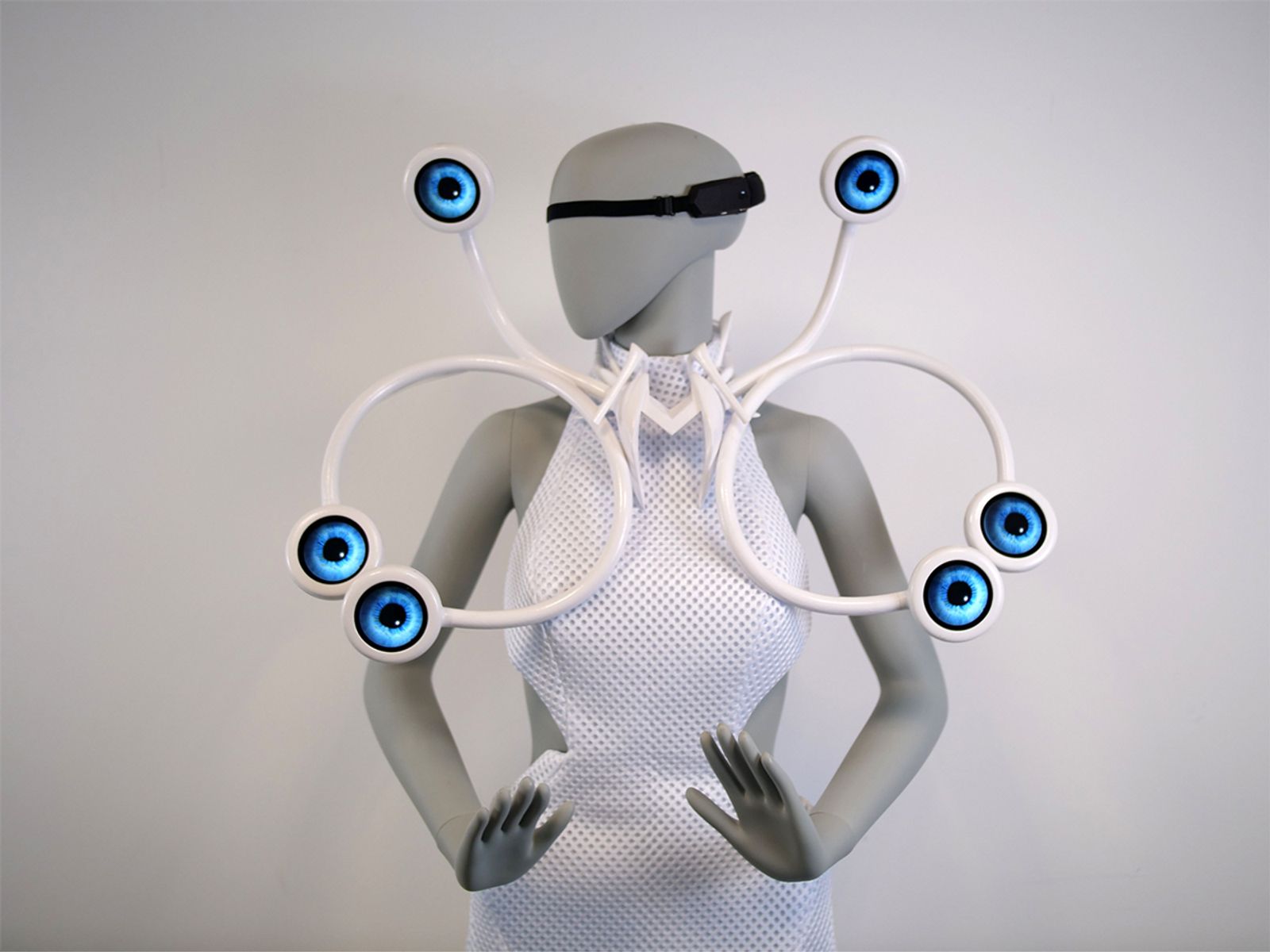

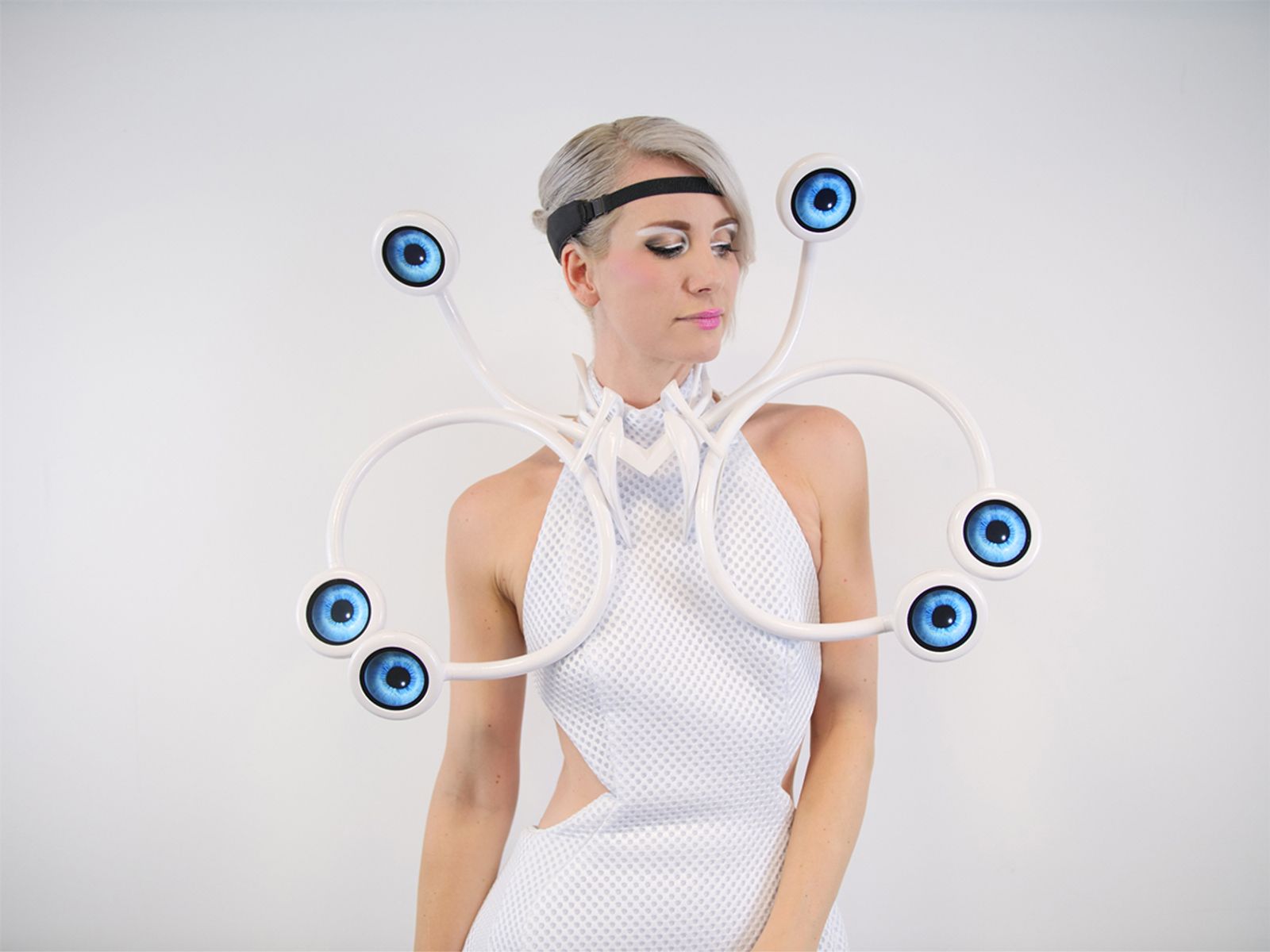

The finished product. (Courtesy images: Anouk Wipprecht)

The concept was a one-of-a-kind FashionTech dress containing a neck piece with six small round screens that branched out from the center. The dress would measure the person’s emotional data over electroencephalogram (EEG) and the screens would generate visualizations controlled by subconscious signals from the wearer’s brain.

These signals would be picked up using a new cutting-edge EEG sensor that forms a wearable brain-computer interface. The interface uses machine learning techniques to determine the mental workload of the wearer, which is then reflected in real-time on the six circular displays extending from the dress’s sculpted neckpiece. As the wearer’s mental workload increases, each display shows an iris and pupil dilating wider and wider.

The EEG sensor is a four-channel “Brain Computer Interface” (BCI) headset that Anouk and neurotech company g.tec developed together. The head-mounted brain interface needs to be trained for two minutes, allowing the machine-learning software to adapt to the wearer. After that, the person can walk around and do tasks that affect the signal load, and thus the visualizations. Not just FashionTech, but NeuroTech Fashion!

The design intended to create a technology-based dialogue between the body and the surroundings of the wearer using fashion as a new kind of interface. In this instance, not just a digital twin, but a digital first-person!

I had the pleasure of helping throughout the design process and wanted to share some of the experiences, design techniques, and unique Onshape features we utilized along the way.

Designing FashionTech with Cloud-Native CAD

As the only truly cloud-native and full-featured product design platform, Onshape is the perfect tool for innovators and designers to realize their creative projects. It’s the CAD for fashion design.

Here are six techniques used throughout the development process:

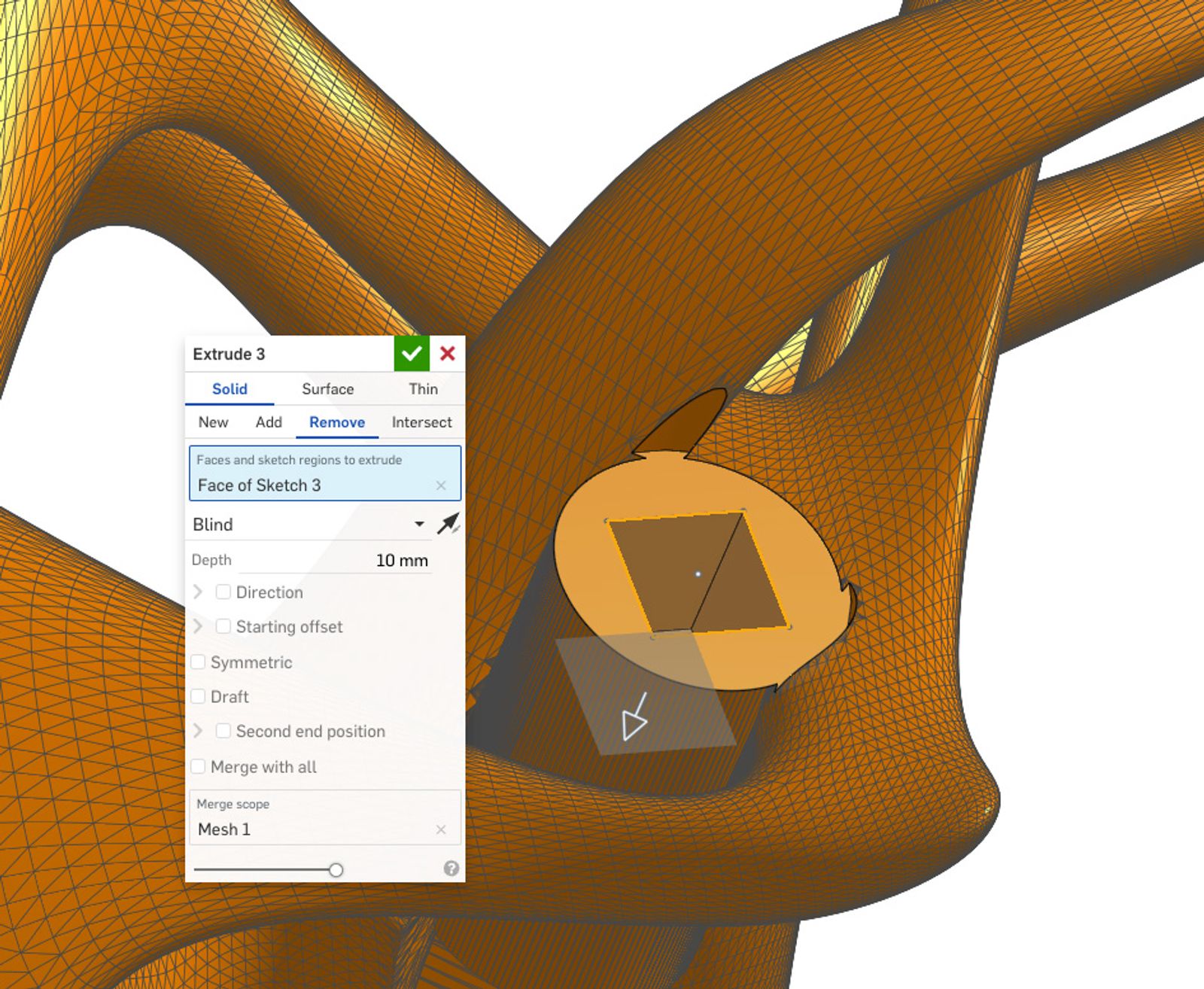

1. Mixed modeling was key when designing this piece. The project started with an existing mesh model that was imported as an OBJ file. Onshape recognizes these mesh parts just like any other part you might create natively. I was able to use the imported meshes in Part Studios, performing a multitude of regular feature-based editing operations like extrude, Boolean subtract, split part, and so on to turn the original design into something new. These highly modified parts could then be used in assemblies, drawings, renderings, simulations, and more.

A close-up of the mesh with some modifications for connection sockets being performed with an extrude feature.

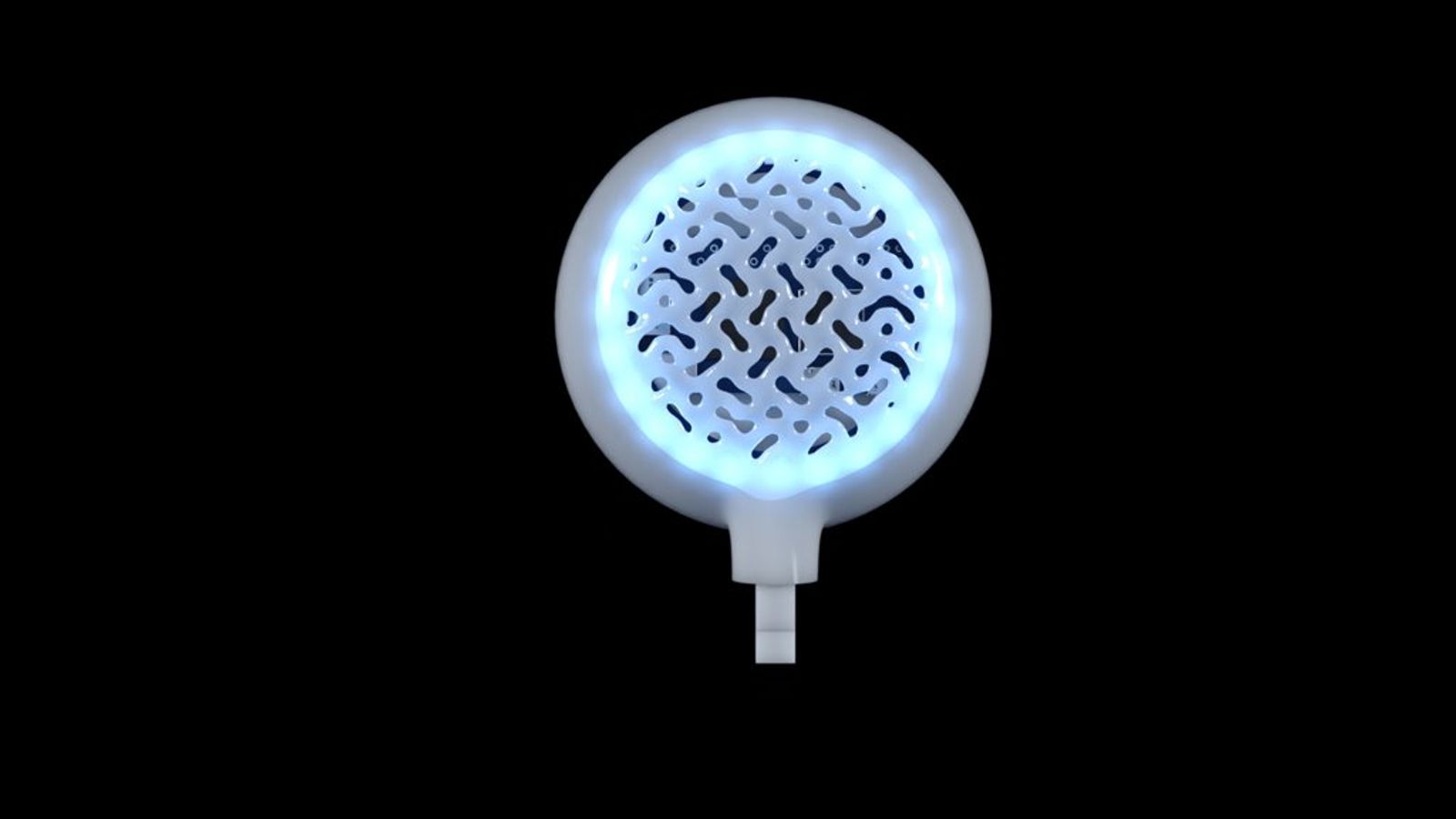

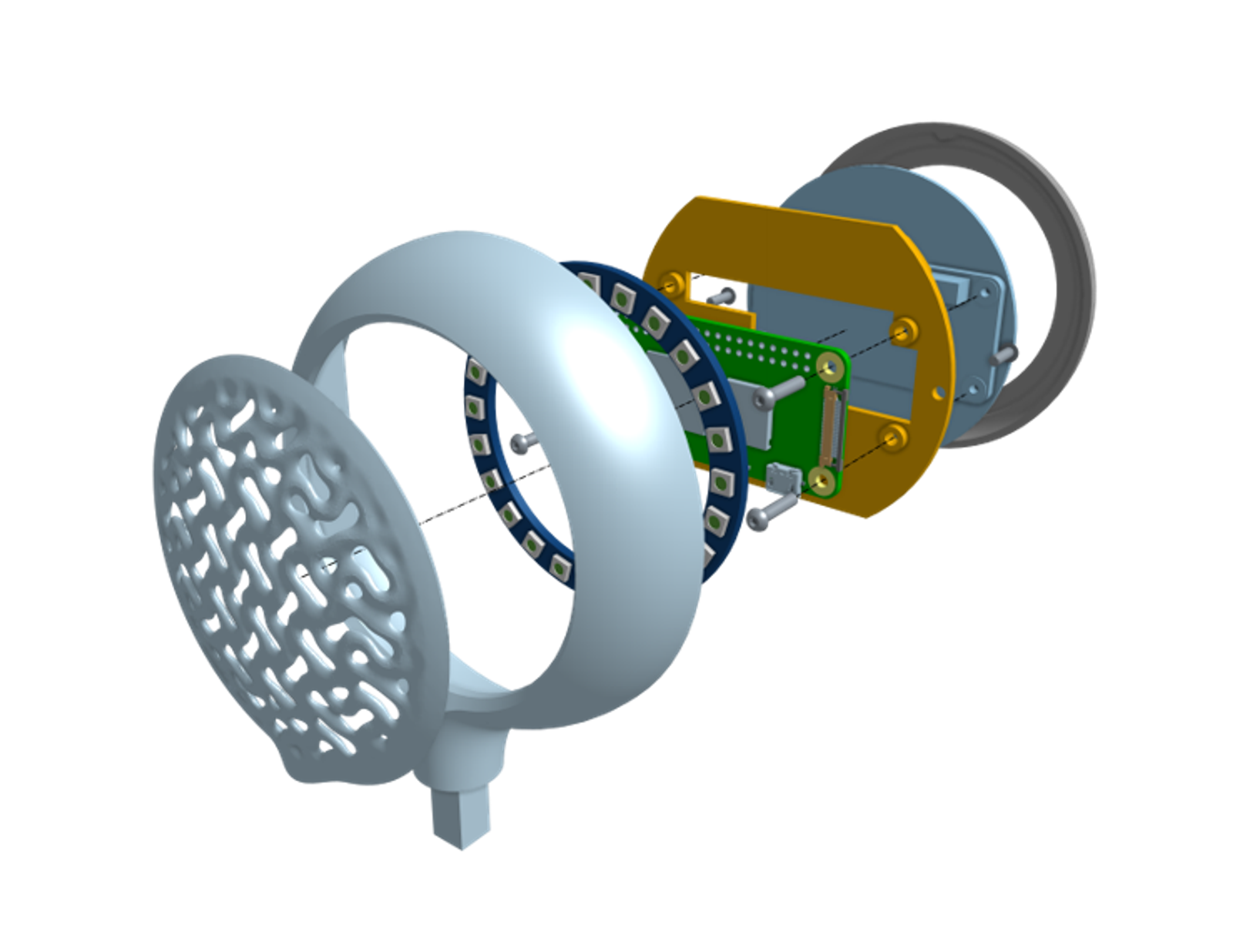

2. We also used our generative design proof of concept to redesign the back of the six screen-holders. After seeing mockups of the initial smooth design, we were inspired to add some additional detail, so we used a generative algorithm to create a unique pattern in the geometry. By illuminating the screen’s interior using a ring of LEDs mounted to the back of the PCB, the aim was to cast some unique shadows and highlights on the surroundings. A close-up of the screen holder is shown below.

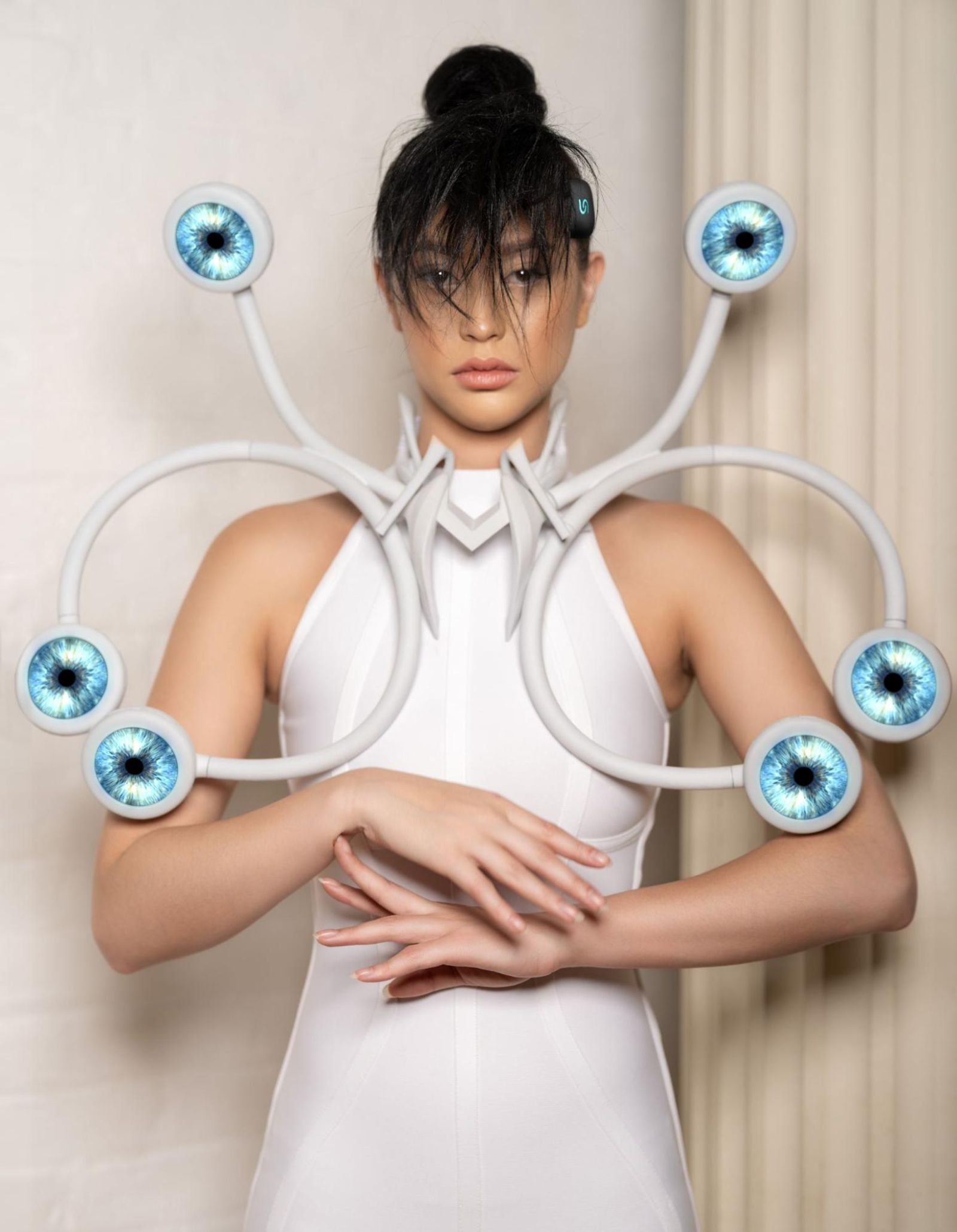

3. To test how the new generative pattern would look in a real environment, I rendered the assembly in Onshape’s Render Studio. In fact, I used realistic rendering capabilities as a design tool to better understand how the shadows would change, how the LED lights would look on a human, how different levels of translucency of the materials would look, and what the overall effect would be with different colors. Seeing the product in the virtual space helped us perfect and iterate the design.

“It was fun to play with the render capabilities in Onshape,” Anouk said about the render results, shown below. “It helped us understand the look and feel of possible embedded light/LED and the reflections back on the body and the space around it. It added more drama this way that we could investigate from the digital side before having to engineer it and explore it in real life.”

4. There were multiple Raspberry Pi Zero Ws, Hyperpixel screens, LED rings, and other commercial off-the-shelf components that needed to be integrated into the piece. We relied on in-context design to reference and build around the pieces. During the course of the project, Anouk decided to switch screens from her original specification of OLED screens to a bigger and brighter HyperPixel 2.1 screen, but fortunately, this type of late-stage design change was easily managed and incorporated. I have a name for this aspect of Onshape: “Fearless Design” — you are always ready to embrace changes, pivots, and new directions, without fear of losing work or stifling you or your team’s creativity.

5. Collaboration with globally distributed contributors was key in this design process. Anouk is very busy with multiple events every month in different locations around the world. No matter where she happened to be, Anouk and I could collaborate in Onshape in real-time to see and discuss different design approaches or to brainstorm new ideas.

“I was in Amsterdam when Greg showed me how he would approach the setup of the dress from the sketch and technical drawing I was working on, together with some 3D data that existed from a former draft of mine,” Anouk said. “From there on, we could fluently go back and forth on how the screens would fit around the body, and hold all the electronics, and wherever I was I could access Onshape on whatever device I had available.”

In addition, late in the process, we had some problems with securely connecting the individual pieces together and I asked for the assistance of a fellow engineer who was located a few states away from me, but who also used Onshape. Of course, he was able to instantly join our discussions and help solve the design challenges Anouk and I faced.

Another huge benefit of Onshape was highlighted when we were able to collaborate with HP for 3D printing prototypes and final designs. We could quickly create the necessary data for their print workflow, and securely share this in the Onshape Document with the HP team without relying on email attachments.

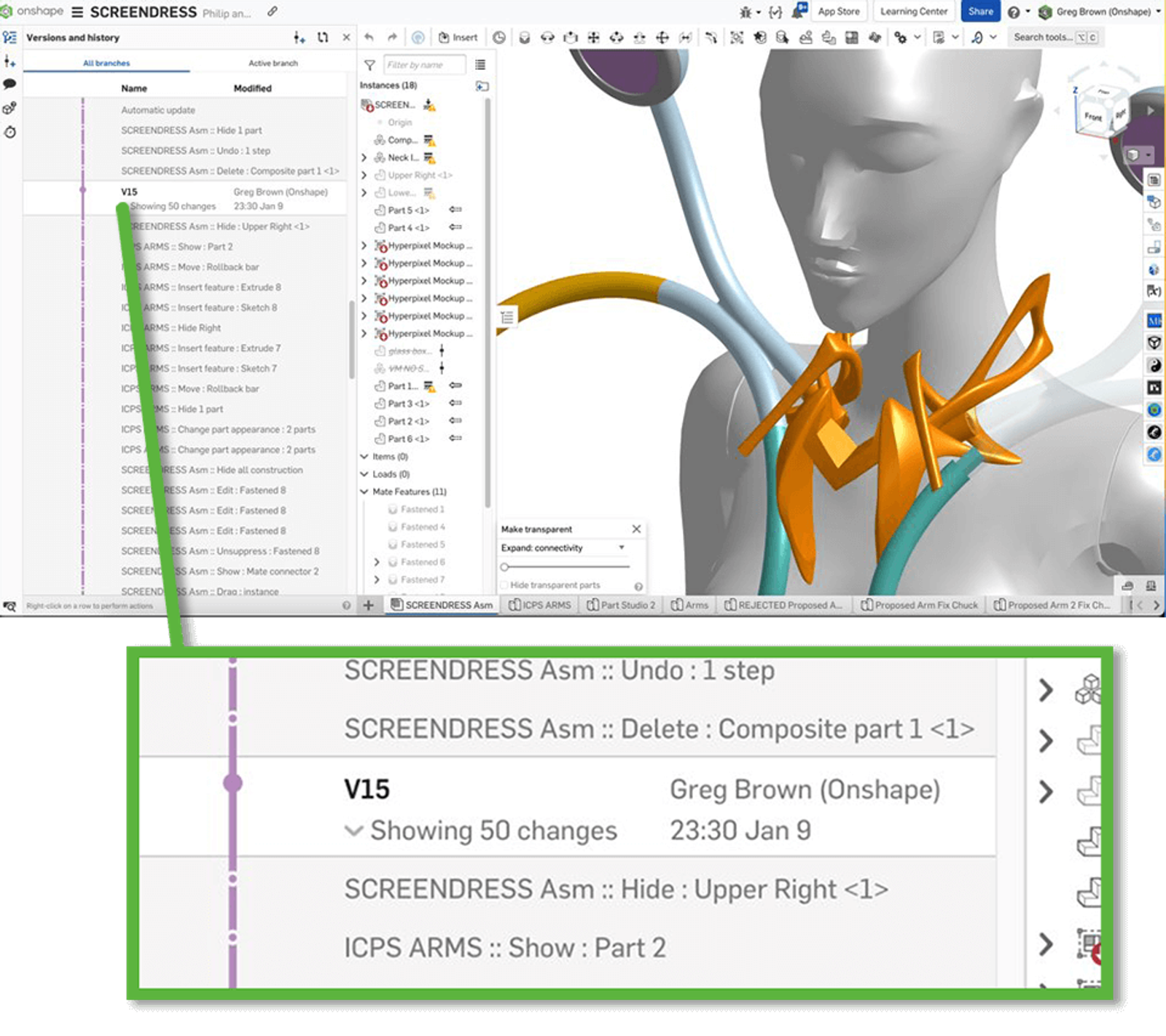

6. A key part of designing this intricate FashionTech dress was the ability to fearlessly explore various designs and approaches. We worked in real-time in multiple branches and executed complex selective merging in order to bring together the best ideas that we had. This was especially vital when we had to solve a last-minute and time-critical redesign issue. Of course, this type of collaboration has been at Onshape’s core since the beginning and it’s always a joy to experience first-hand!

Bringing the Dress to Life

After many iterations, the design phase was complete. Now it was up to HP Inc. to make the dress a reality.

The file was sent to the production department, and within a few days, Anouk received the design and was able to finish, paint, engineer, test, and embed the parts. HP printed the piece using the HP Multi Jet Fusion 5420W and the HP 3D High Reusability PA12 W. The new PA12 W, also known as nylon, is ideal for engineering-grade, white, quality functional production parts.

“The pieces were very light…like nothing I ever experienced before, and perfect for a piece like this, as you don't want to have heavy parts filled with technology being hoisted on your body,” Anouk said. “It was a perfect match of materiality and design.”

“The other cool thing about HP’s new PA12 W prints is their white parts stay white and don’t discolor over time like some other prints I’ve experienced,” she added. “They have an outstanding shelf-life stability; I experienced no changes in color or mechanical properties after testing. The prints stay white consistently and have a nice light refraction and a great strength.”

FashionTech Designer Gaining Global Attention

Anouk’s incredible designs typically draw attention from the media, and this piece was no different. Even prior to the dress’s launch, the prototype has been featured around the world in magazines and throughout the web.

For example, Bionic Pop Artist Viktoria Modesta wore the piece in a photoshoot during a documentary about artificial intelligence (AI) in Los Angeles. Miss Universe Thailand 2022 contestant Perpetua Smith also wore the piece on the cover of Pump Magazine.

In addition, the first prototype is on display at the Museum Beeld & Geluid, the Netherlands Institute for Sound and Vision, as “a wearable computer” in their media devices exhibit.

The Official Release and Future Plans

The dress debuted at ARS Electronica 2023 in Linz, Austria, where Anouk demonstrated the project. Following this exhibit, the piece will travel to BrainBar Budapest from September 21-22 for a showcase, and then finally land in New York City. when lol, you put dates only for Budapest but not the two others

Anouk enjoyed working on the project with Onshape and plans to continue expanding on her Onshape skills.

“I am planning on using Onshape more in the future,” Anouk said. “I started to design some new projects myself in Onshape, including a new version of the Spider Dress (version 3.0) to deal with some mechanical and design flaws that the second version had. I also plan on designing a new prosthetic leg for Viktoria Modesta with embedded mechatronics.”

She’s also interested in using Onshape Simulation to test “the movements that mechatronics and robotic parts can make.”

“It makes you explore the engineering side before you actually get your hands dirty on soldering and coding: It enables you to explore the degree of movement your robotic part can make in a simple and effective way!”

Do you have your own creative design you want to bring to life? Sign up for our powerful 3D modeling tool for free and let your imagination loose with Onshape!

Try Onshape Today

Head to our sign-up page to choose the right CAD plan for you and your team.

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more