05:09

There’s nothing easier – and tastier – than tucking mushrooms inside an omelet, making them the centerpiece of risotto, or plopping them atop a pizza. But harvesting mushrooms is far from easy. It’s tedious and hard work.

The British Columbia company 4AG Robotics intends to change that, making harvesting almost as easy as flipping mushrooms into a frying pan. As the company’s name implies, robotics is key to streamlining and simplifying the industry. Its vision-guided robots can move along a farm’s shelves and pick mushrooms.

Increasingly, farms of all kinds are turning to advanced technology to automate processes that have long relied on manual labor. 4AG Robotics believes automation can similarly modernize the everyday task of monitoring and picking mushrooms and let farmers benefit from high market demand.

“We can manage 100% of the bed state without the need for human harvesters. Our robots can operate 24/7 with minimal human intervention,” said James Gibson, the mechanical team lead at 4AG Robotics.

Unglamorous Work in Dire Need of Automation

As the team at 4AG Robotics likes to point out, mushrooms grow fast. If a mushroom bed isn’t harvested at the right time, farmers can lose yield, and quality diminishes. Timing has been an issue for many mushroom farmers because they are contending with a labor shortage.

Mushroom picking is not glamorous. It’s monotonous work in intemperate, dirty harvesting rooms. Laborers have to complete repetitive tasks on mushroom beds that are placed on shelving as high as 13 feet. Climbing up and down a ladder from spot to spot, they first assess which mushrooms are ready to be picked, and then they have to pull a mushroom from compost without damaging it. It’s back-aching labor that doesn’t exactly have workers lining up, even for relatively decent pay.

After attempting to apply robotics in other industries, 4AG Robotics shifted its focus to helping mushroom farmers, recognizing a promising opportunity. Mushrooms are in high demand.

“There’s not really much automation or robotics in the industry for harvesting the mushroom directly off the bed,” Gibson said. “We thought we could crack it.”

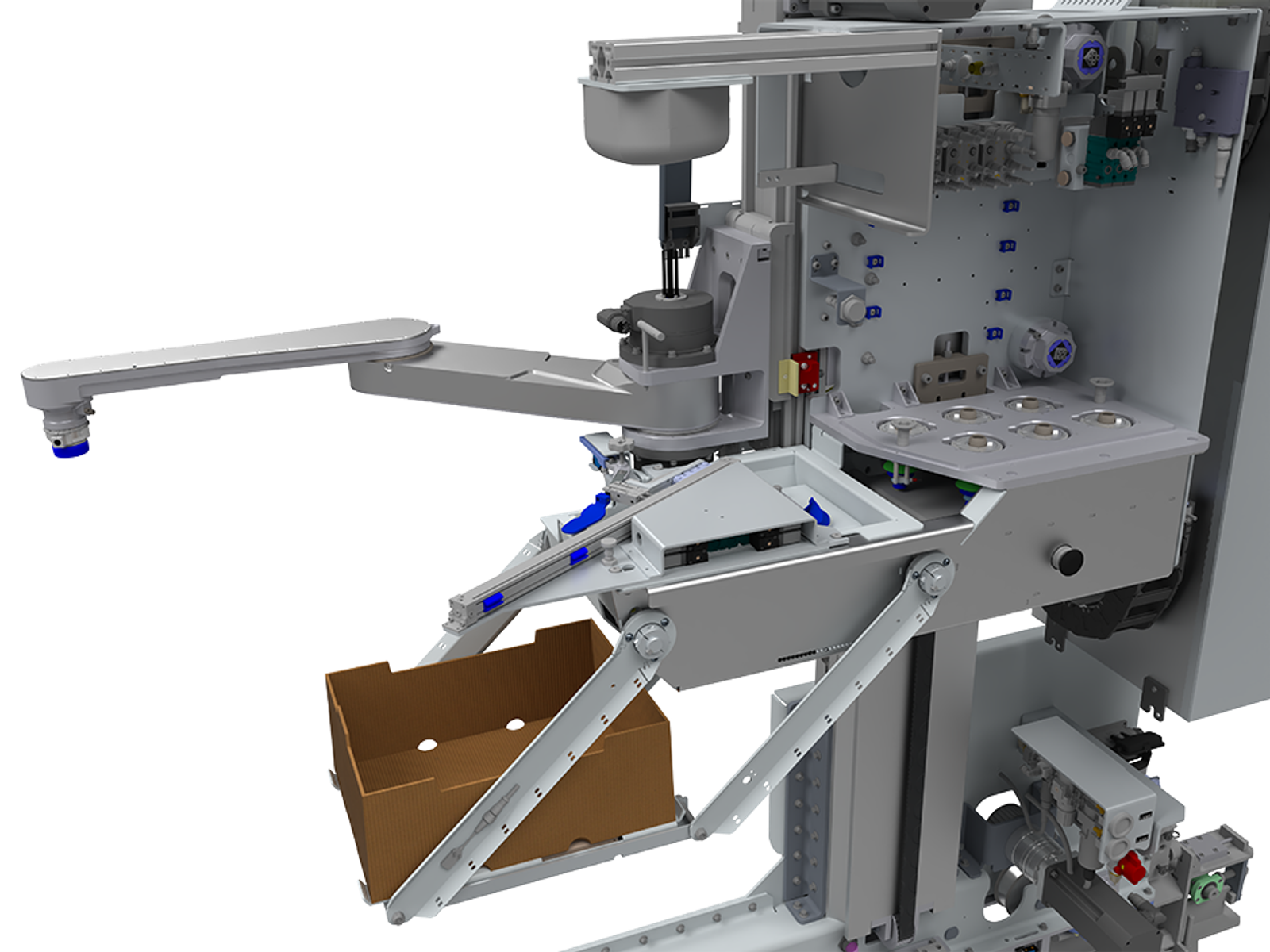

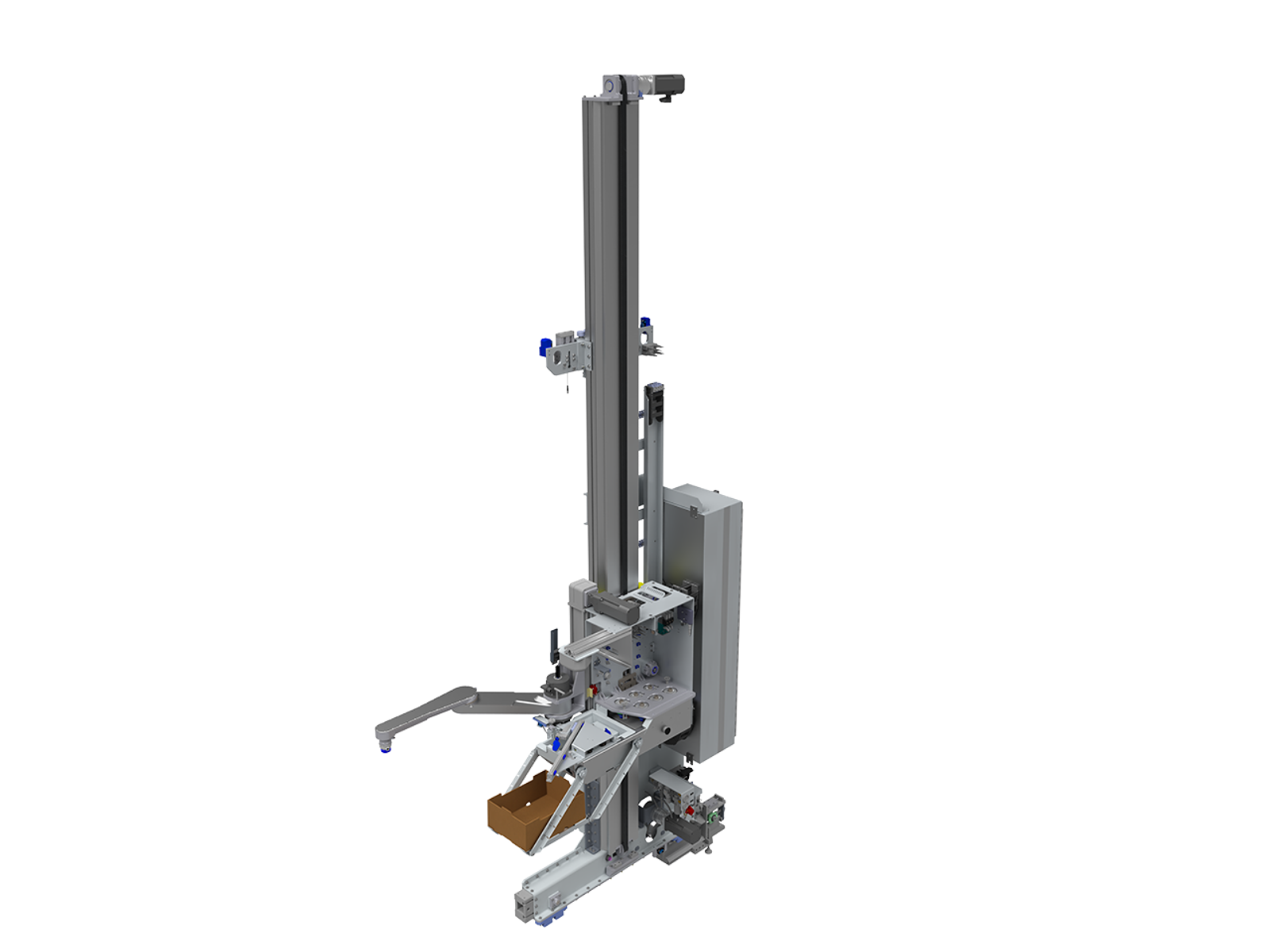

Enter 4AG’s fully autonomous robotic harvester. A robot scans all the racking in a harvest room to learn where mushroom beds end and where a farm’s office space starts so it won’t inadvertently shuffle through business paperwork. When it’s facing a mushroom bed, the robot scans mushrooms and identifies which ones can be picked. It then picks a mushroom out of the compost, trims the stem, and places the fungi (mushrooms are technically vegetables) into a container, which goes to a store truly farm-fresh.

The vast majority of mushroom farms use Dutch-style racks, so 4AG Robotics robots are programmed to adapt the shelving system to any size. 4AG Robotics has systems running on mushroom farms in Canada and is looking to deploy internationally over the following year.

“We are the world leader for robotic mushroom picking,” Gibson said. “There are a couple of competitors that do it differently, but we’re a one-stop shop for an entire robotic picking solution for farms, and that’s what they like.”

Onshape Improves Task and Release Management

To ensure their robots perform as adroitly and smartly as advertised, 4AG Robotics wanted to ensure its CAD system would support its staff’s all-hands-on-deck push to reshape harvesting. That meant the company’s CAD system had to be cloud-based, collaborative, and efficient.

Gibson reached out to PTC’s Onshape to potentially take advantage of a basic free trial, but he got more than that. 4AG Robotics qualified for the Onshape Discovery Program, giving the company up to six months of free access to Onshape Professional. It has been more than enough time for 4AG Robotics employees to explore all of Onshape Professional’s offerings and experience what a cloud-native CAD and PDM platform can do to improve their product development and design.

Gibson and colleagues recently finished migrating data from their previous CAD system to Onshape Professional. The migration went smoothly, he said, and now they are determining best practices for organizing and managing documents. Those practices will come in handy because Gibson and colleagues expect to take full advantage of Onshape’s built-in task and data management.

“We had task management through Microsoft Teams,” he said. “And that’s what we’re looking forward to with Onshape: just one single place for our mechanical team and design team to focus their efforts. So we can go and there will be data sheets for designs that can all be saved and versioned. We can find all of our CAD, all of our action items, and all the priorities for them. We just kind of look at this as a central place to work from and not have to be jumping around. You don’t have to remember where everything is.”

Gibson also anticipates 4AG Robotics will benefit from efficient release management by using Onshape Professional.

“It's just a cleaner interface for controlling release management. There was release management in SOLIDWORKS, but you had to really learn it to understand it,” he said. “Whereas with Onshape, you can be shown the basics in about five minutes and figure out the rest on your own. The learning curve is lower.”

He also has confidence that Onshape will more effectively manage the storage and access of design data.

“We had some issues with SOLIDWORKS’ PDM Vault not actually saving the proper versions and people not being able to comment or do certain things. With Onshape, we can enforce the properties in the approvals and there are a reasonable number of options we can use.”

Just as mushroom farmers can’t fall behind, the engineers and designers of 4AG Robotics have to develop and release the best robotic pickers on time. Gibson envisions Onshape immediately improving collaboration and giving employees the access they need to create.

“Because Onshape is an online data system, versus a file system, we look forward to working quickly. It’s frustrating having pop-ups asking, ‘Would you like to do this?’ which can cause crashes and make us wait. We want more efficiency out of the design and engineering team.”

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Evaluating Onshape

- Simulation

- Rendering

- Surfacing

- Consumer Products

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 learn more

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more