07:10

Since 2008, the Tufts Electric Racing team has been bringing together Tufts University undergrads and graduates to compete in SAE competitions, which challenge students to build a Formula-style racecar.

However, after a pause in 2020 due to the COVID-19 pandemic, the 2021 team, made up of fresh faces including myself, couldn’t pick up where our predecessors left off due to a scatter of CAD and electronics files, a decentralized space for documentation, and little understanding of how the previous vehicle was designed and manufactured.

At first, we attempted to continue with the existing team architecture and software. We used a desktop-based CAD system (SOLIDWORKS) and GrabCAD as a storage point. This setup created complicated onboarding procedures, plenty of miscommunication, conflicting design versions, and was inaccessible to members without compatible devices.

Was it time for a change?

Gearing Up for Formula SAE

With disjointed data management and the inability to streamline collaboration, we quickly realized the old system would not bring us success in the fast-paced environment that is found at Formula Hybrid+Electric and Formula SAE (FSAE) competitions.

At FSAE competitions, teams must adapt to build a racecar that will not only run but win. Competitors require up-to-date and well-thought-out design processes and systems. Building a winning car in this highly competitive environment demands meticulous planning, modern engineering tools, and the ability to adapt and refine the design as the competition progresses.

We decided to use a new, modern CAD system: Onshape.

Switching to Onshape this past year proved one of the best decisions we could have made for the team.

Tufts Electric Racing team members at Liveworx ’23.

Up and Running with Modern CAD

Implementing a new CAD system as an FSAE team involves overcoming a steep learning curve since students come from various engineering backgrounds, might be new to the university, or don’t know about CAD. However, Onshape has an extensive array of free support materials and learning resources designed to make onboarding more manageable and straightforward for new users.

The Onshape Learning Center includes material for new users, including interactive tutorials and video guides, comprehensive documentation, forums, and even the latest Classes and Assignments tool.

Whether members are new to CAD or specifically Onshape, the learning guides in the Learning Center have allowed our team to get up to speed reasonably quickly, especially compared to the previous CAD system we used. Depending on the level of proficiency, Onshape’s help material caters to specific needs and provides numerous trainings that include opportunities to practice.

Furthermore, the Classes & Assignments feature available through the Educator and Education Enterprise plans offers additional learning opportunities for members by allowing team leaders to monitor the progress of new users and provide personalized feedback quickly and easily. This system enables our team to record training data for our members and keep track of their progress.

Beyond learning resources, Onshape’s customizable attributes facilitate agile design iterations, which align perfectly with the dynamic nature of engineering for FSAE.

Tufts Electric Racing team members work on the car frame.

Onshape’s Cloud-Native Architecture Simplifies Processes

As mentioned, Tufts Electric Racing previously used a traditional file-based CAD system.

The nature of traditional CAD systems, which are locally installed and tied to specific computers, makes it extremely difficult to share parts and assemblies and requires us to use a GrabCAD folder that’s constantly updated.

The old way required new downloads after any edit and no way of tracking changes besides a new timestamp and a text. Our current objective is to build off of existing designs (made originally in the old CAD system), so the ability to use previous parts and assembly models as a baseline was crucial to us.

Importing the old CAD model from our last CAD system into Onshape was a significant first step.

The team imported the top-level assembly of the car and brought all parts into Onshape (automatically organized into documents and part studios) seamlessly. All of this is now in the cloud, making it possible for every team member to view, edit, and share parts of the car – a luxury the team previously didn’t have.

With Onshape’s direct editing tools (moving faces and editing existing parts), engineers on the team could edit the imported assembly and design new parts around existing parts and assemblies. Whether it be a new pedal box or a new high-voltage system, multiple users accessed the same Document (model) and could make the edits they desired.

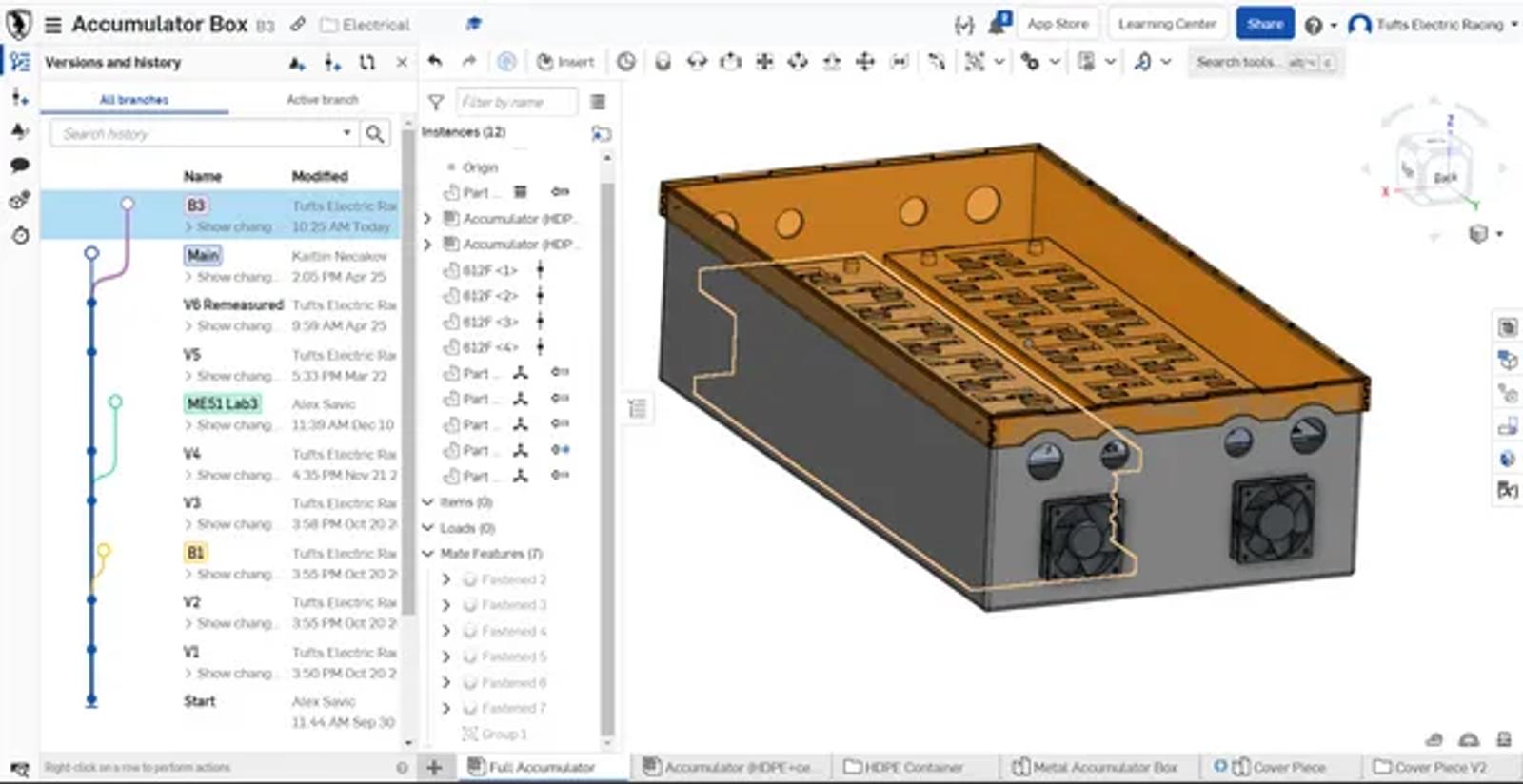

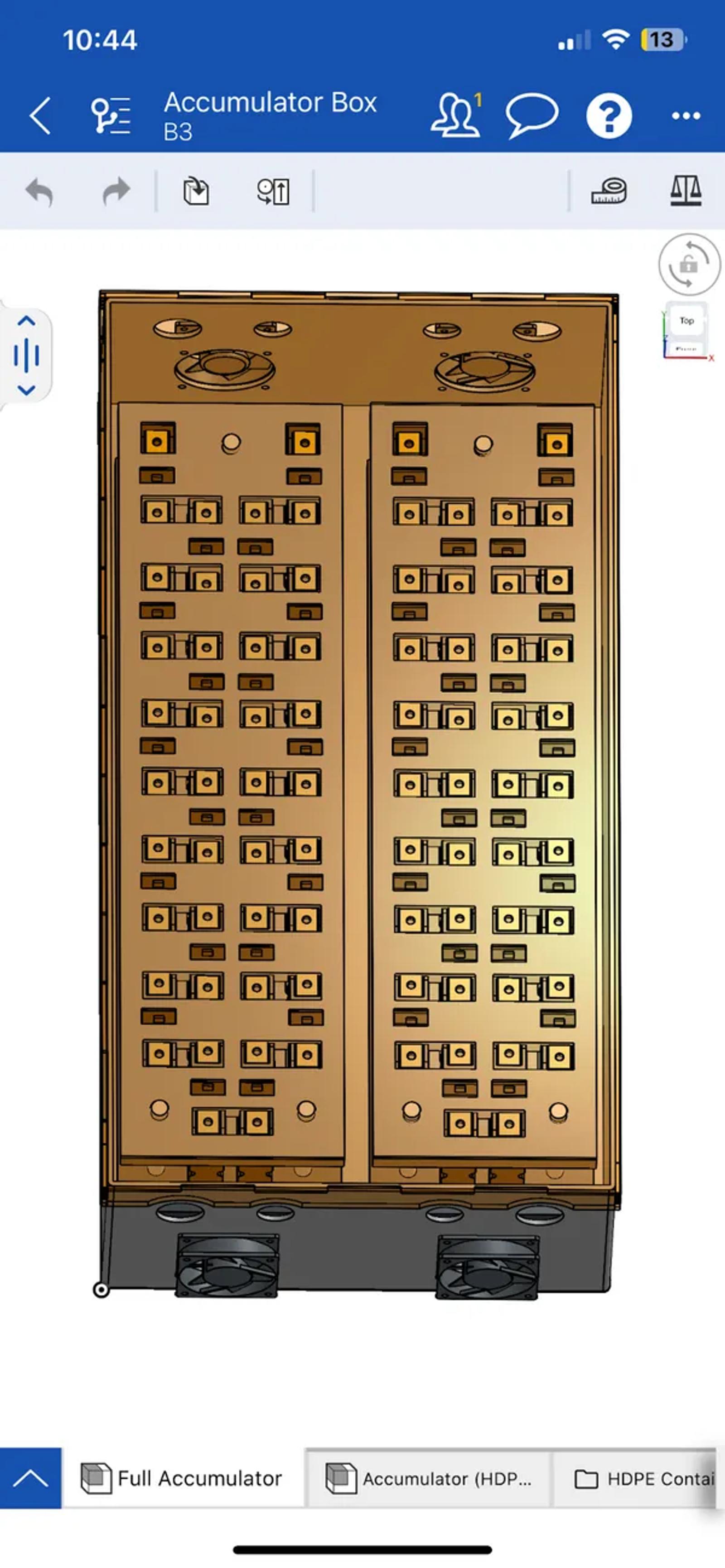

In redesigning the high-voltage containers, shown below, Onshape’s versioning, branching and merging proved very useful for our collaboration. Multiple members could work on the part or assembly without worrying about editing someone else’s design. After making their respective part modifications, it was easy to see who made which edits and select the desired design. We could choose the desired features from different branches to incorporate into the part, then merge them into a main Part Studio.

Another game changer is that we can access Onshape from any browser on any device, no matter where or what time of day. We’re not tied to the campus computer lab or any particular device.

The Onshape Mobile App enabled us to easily showcase designs to other team members, advisors, and judges at the competition.

Pulling out my phone to explain CAD designs for any particular car structure was valuable and impressive.

Going Beyond: Frames, Simulation, Variable Studio, Custom Features

Onshape has several features the team has explored and is excited to leverage more in our design.

Creating driving sketches of important geometry increases the team’s efficiency. Making changes to a driving sketch referenced to a part or sub-assembly can change those parts or sub-assemblies in seconds. This also extends to linked documents, where new versions of parts or sketches can dictate the new main assembly. Versioning in linked Documents also creates a history of changes that can be reverted to the original if designs are unsuccessful.

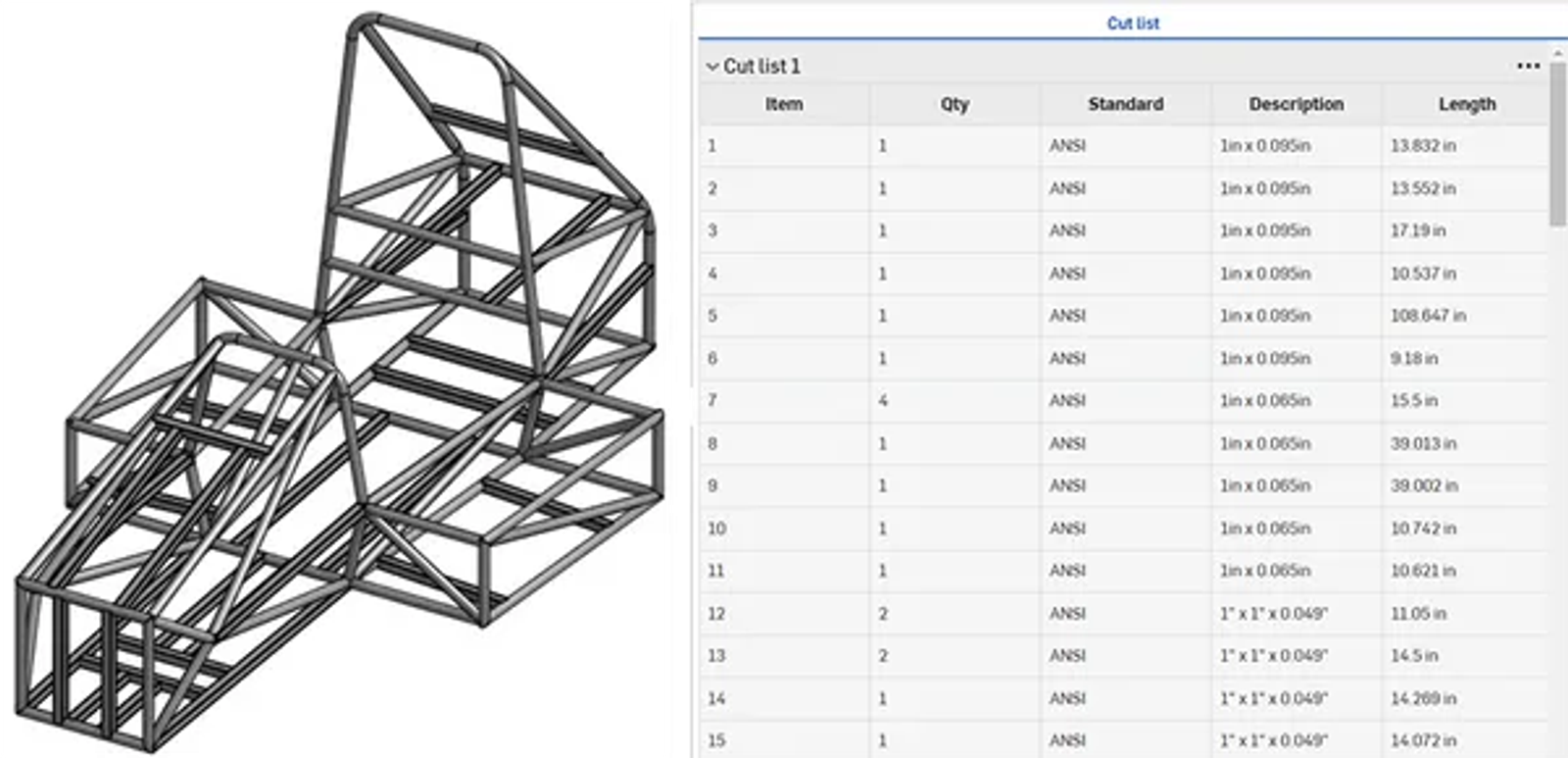

One of the most exciting features is the Frame tool. This feature allowed me to recreate the chassis in Onshape after making a 3D sketch of the frame. I select the frame type and connection points, then let it generate. Onshape’s “cut list” is also handy to show a Bill of Materials (BOM) of all the frame components and cut sizes/angles.

The Onshape Simulation tool is handy for quick and easy FEA analysis. If the team needed a quick representation of the stress/strain through a part, the FEA tool provided the necessary details to make edits and re-simulate directly in Onshape. This prevented unnecessary delays moving between separate software to simulate and edit.

The team is excited to investigate two features: Variables and Custom Features.

Variables and Variable Studio can help set parameters for specific designs and allow for greater agility in editing. For example, if the rulebook states the chassis must conform to such dimensions, the sketch can use those parameters as variables listed in a Variable Studio.

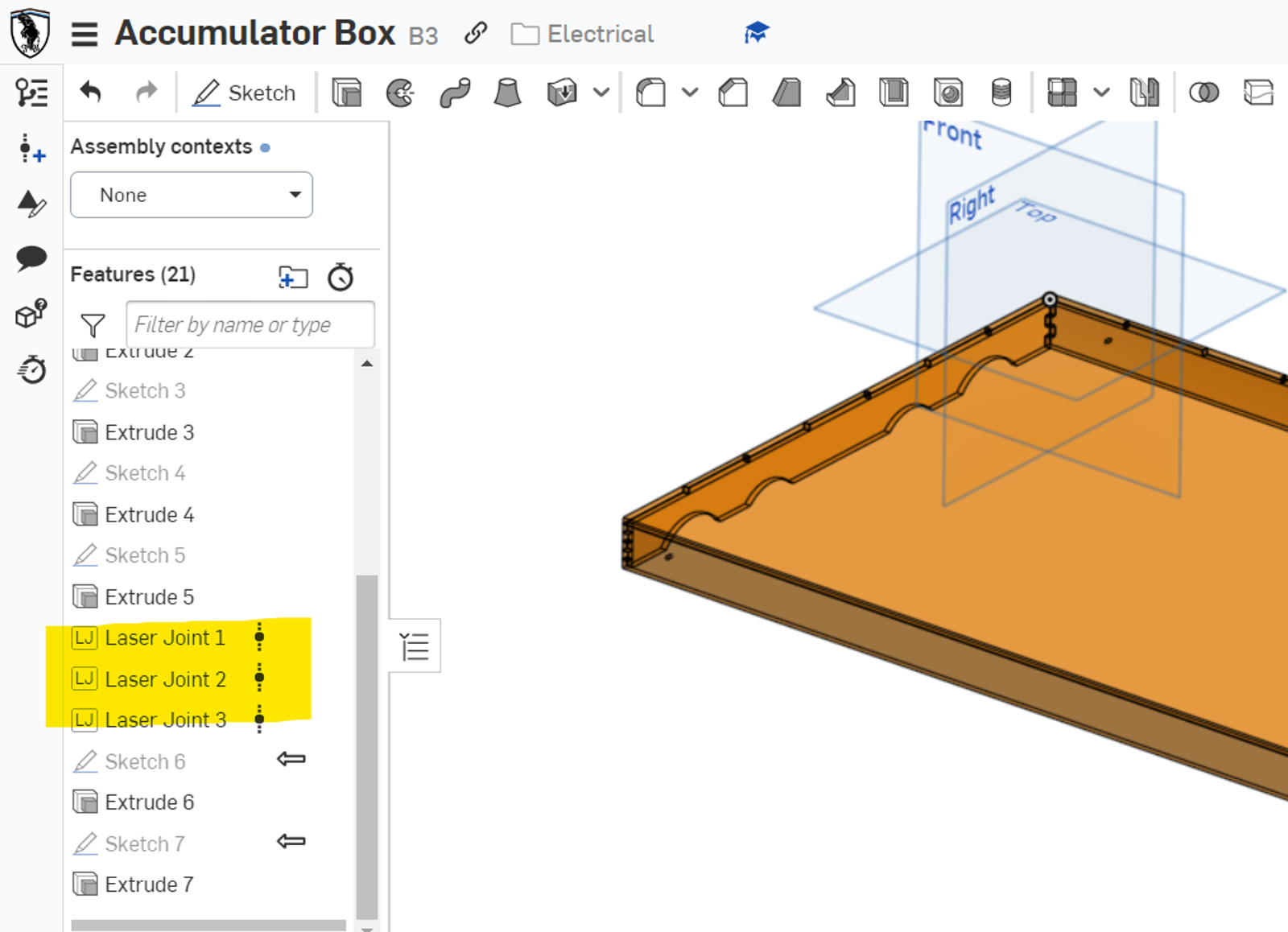

Onshape has a slew of Custom Features in the public feature library. Features such as “laser joint,” “aerofoil,” or “wiring” make the process of creating these geometries much easier. Many come with their guide and examples to best use these features. Both “aerofoil” and “wiring” features will help in the car's design, routing wiring, and creating aerodynamic structures.

A “laser joint” is used to cover the high-voltage container.

Onshape for Formula SAE

Overall, the transition was seamless, with detailed onboarding from Onshape and the opportunity to import files from other CAD systems. Setup was fast, and inviting team members was as easy as adding an email address. Onshape not only enhances teamwork but also boasts an array of features tailored to newcomers and experienced designers, and the self-paced content available in the Onshape Learning Center makes it easy to get up to speed quickly.

The team and I are excited to continue exploring the capabilities of Onshape and the success it will bring. From excellent learning and onboarding opportunities to next-level collaboration and features, Onshape’s platform is perfect for student teams like Tufts Electric Racing.

Are you on a collegiate team or club that uses CAD?

Learn about Onshape sponsorship opportunities!

(Calvin Seeg is a Mechanical Engineering student at Tufts University and the co-captain of Tufts Electric Racing.)

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more