06:40

Surface design is a powerful technique for creating complex, freeform shapes in 3D CAD software. While many designers primarily work with solid modeling tools, understanding surface modeling can significantly expand your capabilities and open up new possibilities for your designs.

In this blog, explore the world of Onshape surface modeling and learn the 10 golden rules of surface design.

What is Surface Modeling vs. Solid Modeling?

Before diving into the specifics of surface modeling Onshape, it's important to understand how it differs from solid modeling. Surface modeling is commonly used to create complex freeform shapes, but its applications extend far beyond that. While most of your modeling work might involve prismatic shapes, surface modeling techniques can be valuable tools even in solid modeling scenarios, sometimes in just one or two features.

Many designers view surface and solid modeling as mutually exclusive approaches, but it’s crucial to understand that they’re often interwoven. Rather than thinking of it as an either-or decision, consider how you can combine both techniques to achieve your design goals.

Additionally, Onshape’s parametric modeling capabilities allow you to build design intent into your surface models, making it easier to accommodate changes and collaborate with mechanical engineers.

Onshape’s Robust Suite of Surfacing Tools

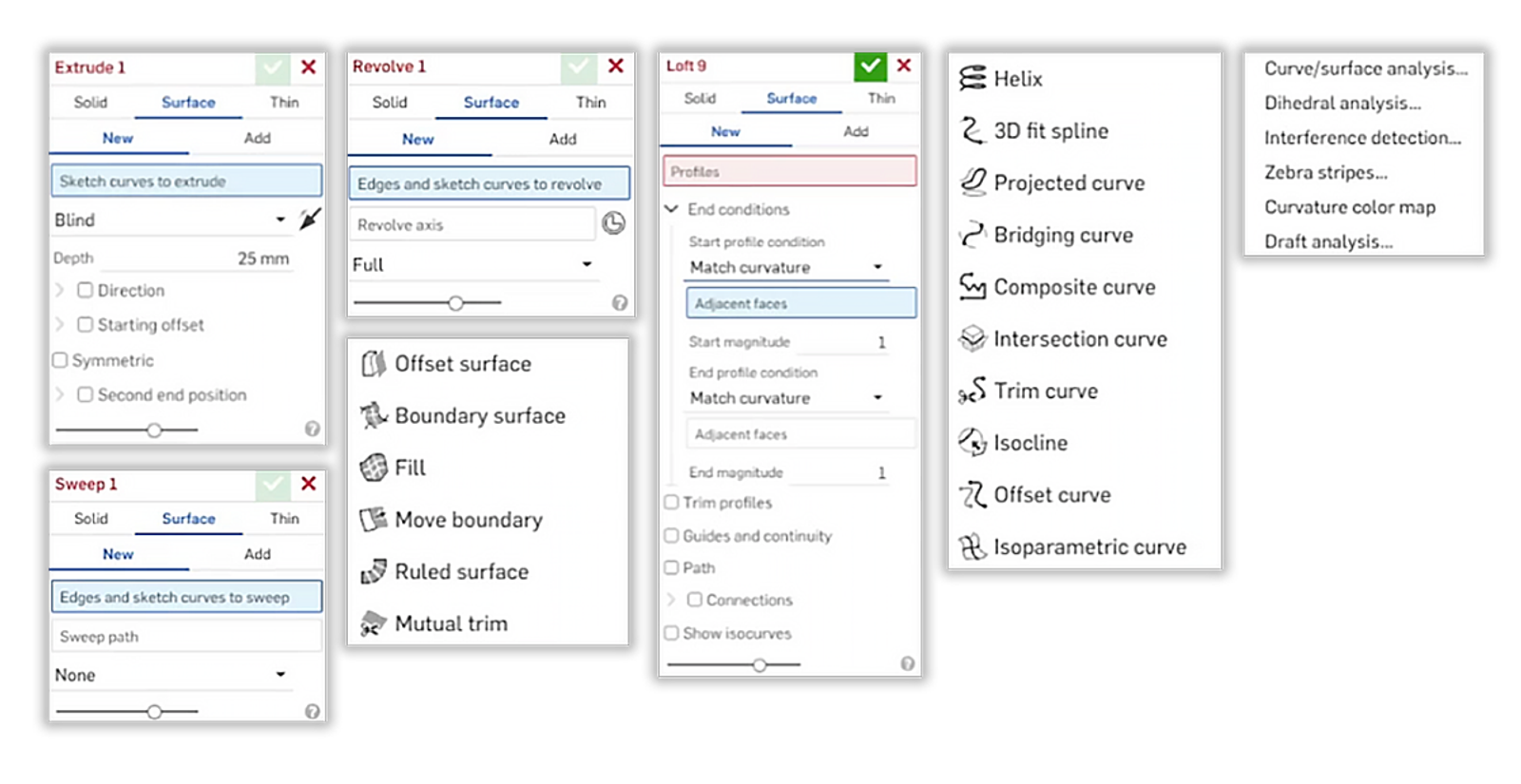

Onshape offers a comprehensive set of surface modeling tools that continue to grow and improve. At the core, you'll find familiar operations like Extrude, Revolve, Sweep, and Loft. However, Onshape has taken a unique approach by integrating these tools into unified features. Unlike some CAD systems that have separate commands for surface extrude, surface loft, and swept loft, Onshape provides a single sweep feature that can create solid, surface, or thin geometry.

This integrated approach simplifies the workflow while maintaining flexibility. When you use these core features, you'll find options to create surfaces or solids within the same command, streamlining your design process.

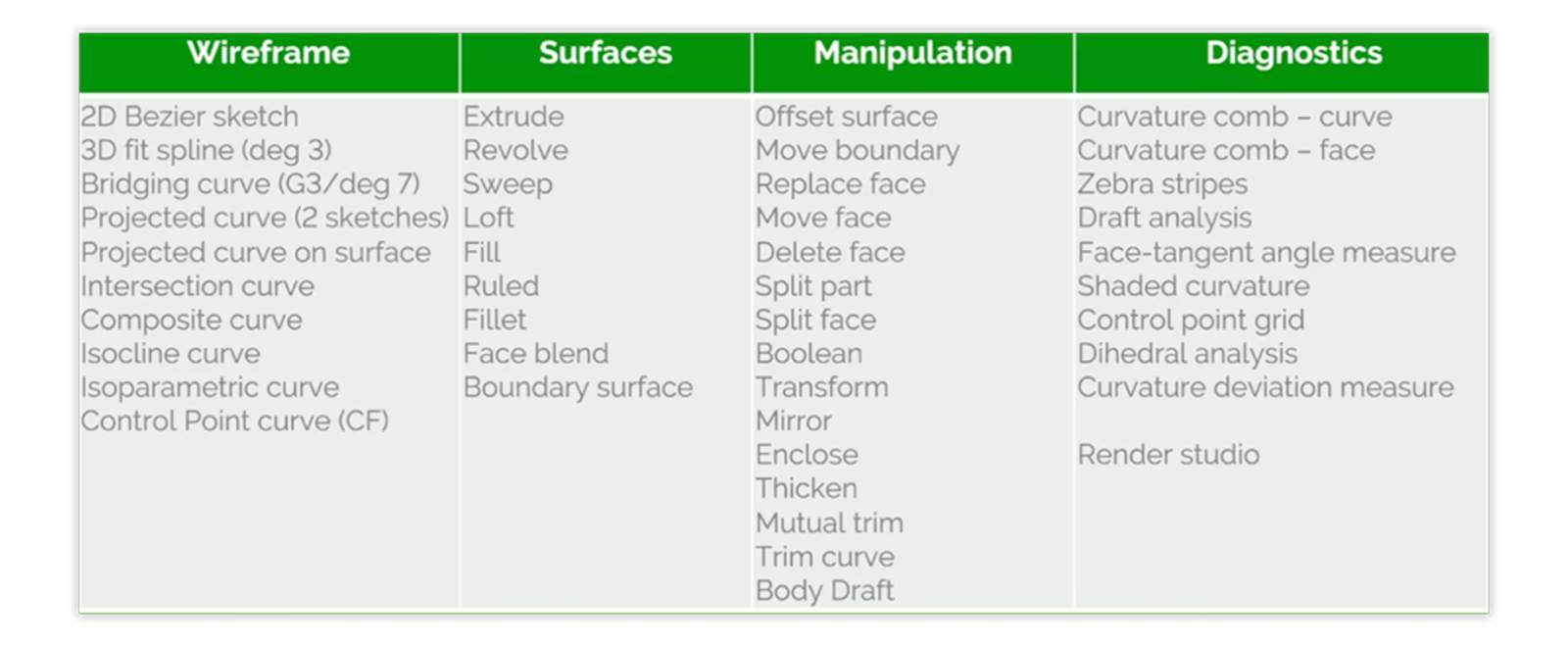

Beyond these foundational tools, Onshape’s surface modeling capabilities are organized into four main categories:

- Wireframe: Tools for creating and manipulating curves and sketches that form the basis of your surface models.

- Surfaces: Features for generating and modifying complex surface geometry.

- Manipulations: Commands for editing and refining existing surfaces.

- Diagnostics: Analysis tools to evaluate the quality and continuity of your surface models.

The Onshape development team has been actively expanding this toolset, with over 38 new surface-related features added in the past two years alone. This commitment to enhancing surface design capabilities means that Onshape users have access to a robust and ever-growing set of tools for tackling even the most challenging surface modeling tasks.

10 Golden Rules for Surface Modeling Onshape

To help you create high-quality surface models in Onshape, follow these 10 golden rules:

- Create a good flow of control points: Ensure that the control points defining your surfaces flow smoothly and evenly across your model.

- Use the minimum number of control points: Start with fewer control points and increase only as needed to achieve the desired shape.

- Use single-span curves when possible: Single-span curves often result in cleaner, more predictable surface behavior.

- Ensure tangency across centerlines: Exploit symmetry whenever possible to maintain smooth transitions and reduce modeling complexity.

- Aim to create four-sided surfaces: Four-sided surfaces are generally easier to work with and produce cleaner results. The preference order for surface creation tools is: Boundary surface, Loft, Fill.

- Trim to achieve n-sided surfaces: When necessary, use trimming operations to create surfaces with more than four sides.

- Build to theoretical edges: Create larger surfaces initially, then trim them back to manage transitions and blends.

- Set construction tolerances at the start of modeling: Establish your tolerances early to ensure consistency throughout the design process.

- Avoid building from trimmed edges: Building on trimmed edges can lead to stability issues and unexpected behavior when the model is modified.

- Match curves on opposite sides: This rule ties back to the first, emphasizing the importance of maintaining a smooth flow of control points across your entire model.

Applying the Golden Rules: Real-World Examples

Let's explore how these golden rules apply to real-world surface modeling scenarios in Onshape:

Example 1: First Build Slab Surfaces

In this example of an RC car engine cover, we apply rules #1-5 and #7. The design begins with a carefully constructed wireframe layout using both 2D sketches and 3D curves. By focusing on creating a clean foundation with well-placed control points and single-span curves, we set the stage for high-quality surfaces. The initial surfaces are built larger than necessary, following rule #7, allowing for precise trimming and blending later in the process.

Example 2: Using the Bridging Curve

Bridging curves are powerful tools for creating smooth transitions between surfaces. This example demonstrates the application of rules #1-3. By using bridging curves with carefully controlled continuity settings, we can create seamless blends between complex surface patches while maintaining a minimal number of control points.

Example 3: Clean Edges, Even After Trimming

This example highlights the importance of rules #6 and #9. When trimming surfaces, it's crucial to maintain clean, well-defined edges. By using techniques like isoparametric curves instead of projected curves for trimming operations, we can achieve cleaner results that are less likely to cause issues in downstream modeling operations.

Example 4: Diagnostics

Applying rules #1, #4, and #10, this example emphasizes the importance of continually evaluating your surface model using Onshape’s diagnostic tools. Features like zebra stripe analysis, curvature maps, and reflection lines help ensure smooth transitions and identify potential issues before they become problematic.

Enhancing Your Workflow: Custom Features and Productivity Tips

Onshape's extensibility allows for the creation of custom features that can significantly streamline your surface modeling workflow. Some noteworthy examples include:

- Control Point Curve:A powerful tool for creating and editing complex curves with precise control.

- Curve/Surface Info:Provides detailed information about selected curves or surfaces, aiding in analysis and troubleshooting.

- Untrim/Extract:Allows you to work with the underlying geometry of trimmed surfaces.

- HAVF Airfoil Profiles:Quickly generate precise airfoil shapes for aerodynamic applications.

TECH TIP: How to Find Published Custom Features in Onshape

To further boost your productivity when surface modeling in Onshape, consider these additional tips:

- Make extensive use of keyboard shortcuts and the shortcut toolbar to speed up common operations.

- Import images into sketches to trace over, helping you quickly capture design intent from 2D sources.

- Use colors to differentiate between sketches, curves, and surfaces for better visual organization.

- Leverage Onshape’s Render Studio not just for final visualization, but also as a diagnostic tool to evaluate surface quality under realistic lighting conditions.

Mastering Surface Design in Onshape

By following the 10 golden rules and leveraging Onshape’s powerful surface modeling tools, you can create complex, high-quality designs that seamlessly blend aesthetics and functionality. Remember that mastering surface modeling is an iterative process – don't be afraid to experiment, analyze your results, and refine your techniques.

As you continue to develop your surface modeling skills in Onshape, keep in mind the importance of clean, well-constructed geometry. By focusing on creating high-quality curves and surfaces from the start, you'll set yourself up for success in downstream processes like CAM, simulation, and manufacturing.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more