06:46

Sheet metal is a great way to express your designs. The material is fairly affordable, and finding a local fabrication shop is just a Google search away.

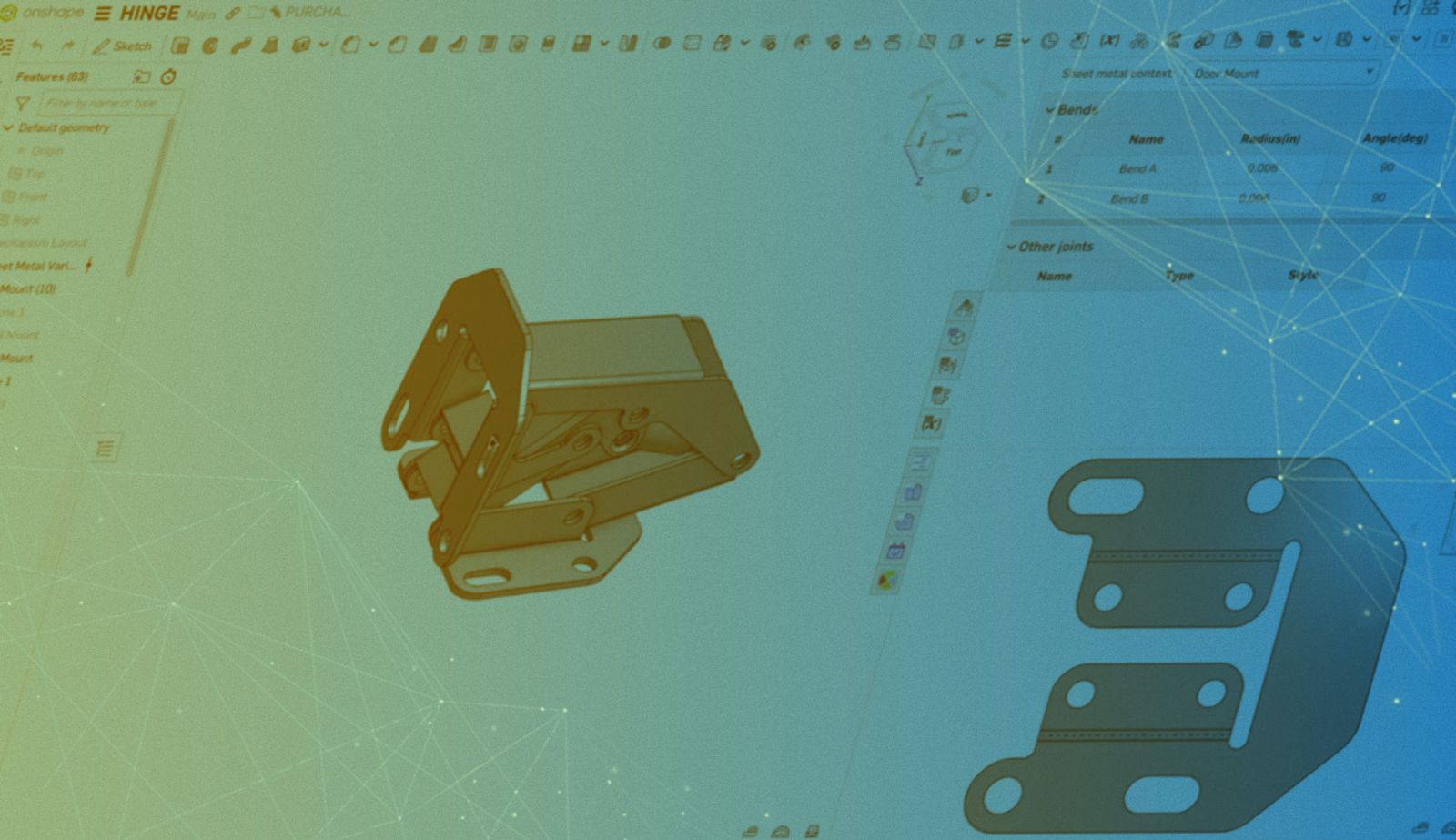

Additionally, with PTC’s Onshape, designing with sheet metal is even easier. The cloud-native CAD and PDM platform is improving the approach to sheet metal design and setting a new standard for streamlined manufacturing processes.

Read on to learn about 15 Onshape features that are key for successfully designing with sheet metal. Or, watch the webinar all about Onshape sheet metal.

1. Design at Home, the Office, or On-the-Go

Gone are the days of hefty software installations and version compatibility nightmares. Onshape operates entirely in a web browser, giving users the freedom to design anywhere, anytime.

Whether at a desk, on a tablet in the fabrication shop, or even on a smartphone during a commute, designs are always accessible. This accessibility isn’t just convenient – it boosts collaboration and productivity.

2. Embrace Simultaneous Sheet Metal Views

When designing with sheet metal, Onshape can display the folded model, flat pattern, and bend table when designing with sheet metal. Always keep the Sheet Metal Table and Flat View visible while working to instantly see the impact of design changes on both the folded and flat states, reducing errors and saving time.

Sign in and see all the relevant sheet metal design information.

3. Understand Extrude, Convert, or Thicken

Onshape gives designers three useful tools for sheet metal design, each with its strengths:

- Extrude: The classic method, perfect for creating parts from scratch.

- Convert: Ideal for transforming existing solid models into sheet metal.

- Thicken: Great for complex shapes, starting with a surface and giving it thickness.

Understanding when to use each method can save time and prevent complications down the road.

4. Use Shortcut Keys

Every second counts in the design world. That’s where Onshape’s shortcut keys come in handy. For instance, hitting the “S” key brings up a customizable shortcut toolbar, putting the most-used tools just a click away. Building muscle memory might take a little time, but the long-term productivity gains are significant.

Tech Tip: Customizing Keyboard Shortcuts in Onshape

5. Leverage Multi-Part Modeling

Onshape’s multi-part modeling capability is especially beneficial for sheet metal assemblies and frames. Design related sheet metal parts in a single Part Studio. This approach allows for easier management of inter-part relationships and ensures that changes to one part automatically update related components.

6. Master Sketched Bends

Sketched bends offer extended flexibility in creating complex sheet metal shapes. When working with non-standard bends, start with a sketch of the model. Use the Bend feature to define the bend line and angle, allowing precise control over the folded shape. This is especially helpful when you start with an unfolded stock shape and want to “develop” it into a folded shape.

7. Optimize Flange Creation

Flanges are a fundamental element of sheet metal design, and Onshape provides the tools for creating them efficiently. Use the “Up to Entity” option when creating flanges to ensure they meet precisely with other parts or faces in the assembly. The “Chain Selection” option allows users to select all relevant edges quickly when creating multiple flanges. This can speed up workflows, especially on complex parts.

Onshape helps users determine bend information using the Flange feature.

8. Utilize Custom Bend Tables

Every fabrication shop has its capabilities and preferences when it comes to bending sheet metal. With Onshape’s FeatureScript, designers can create custom bend tables that reflect specific equipment and material properties. It’s like having shop expertise built right into the software.

Use this sample Document with a custom bend table to copy and edit to match the shop or supplier’s shop standards. Find more information here on adding custom features to your toolbar in Onshape.

9. Leverage Configurations for Design Variants

Onshape Configurations is particularly powerful for sheet metal design, allowing multiple part variants to be created quickly. Use configurations to manage different thicknesses or materials for the same part and promptly switch between variants without recreating the entire model. To maximize efficiency, combine configurations with custom features to automatically update part numbers, descriptions, and other metadata based on the selected configuration.

10. Streamline Drawing Creation

Creating drawings can be tedious. Onshape takes the pain out of the process with tools for quick dimension placement and automatic inspection callouts. This results in clear, detailed drawings that are produced faster than ever before. Place the folded view and the flat view to scale on the drawing, with ordinate dimensions.

11. Optimize DXF Exports

Clean, accurate DXF files are essential for smooth manufacturing processes. Use Onshape’s export rules to create standardized file naming conventions for DXF exports. This makes it easier to manage files and reduces confusion when communicating with manufacturers. For added flexibility, create a custom export setting that includes bend lines and part outlines on separate layers. This can be useful for manufacturers using different processes for cutting and bending.

12. Collaboration with Suppliers in Real Time

Onshape’s cloud-native platform offers unique opportunities for collaboration with sheet metal fabrication shops and suppliers. Use Onshape’s sharing features to give suppliers view-only access to designs using Publications. This allows them to provide feedback on manufacturability without the risk of accidental changes and protects design data.

Vendors can collaborate with designers in real time.

13. Implement Design for Manufacturing (DFM) Checks

Catching manufacturability issues early can save significant time and cost. Onshape’s Branching and Merging feature facilitates efficient Design for Manufacturing (DFM) checks. Users can create separate branches for DFM optimization, enabling early collaboration with manufacturers. This approach allows teams to identify and address potential issues when changes are least costly, aligning with agile design principles.

Onshape partners with several apps, including Xometry, that can automate DFM checks. They are available in the Onshape App Store.

14. Utilize Sheet Metal-Specific Features

Onshape offers several features tailored specifically for sheet metal design. Experiment with the Corner, Chamfer, and Hem features to create complex edge treatments efficiently. Onshape also provides standard content, like PEM fasteners, and can match the parts to the corresponding holes so everything fits correctly, ensuring an accurate Bill of Materials.

Inserting PEM fasteners is quick when using Onshape.

15. Innovate with Version Control

With Onshape’s built-in version control, there’s freedom to explore design alternatives without fear. Every change is automatically saved, and users can easily roll back to any previous version. Use branches to explore different design concepts without affecting the main design.

This allows designers to try out radical ideas with the safety net of easily reverting or merging changes. Creating “checkpoint” versions at key stages of the design process makes it easy to roll back to a previous state if needed or to compare different iterations of a sheet metal design.

16. Discover Onshape Professional

Onshape is setting a new standard for sheet metal design tools. Combining powerful parametric CAD tools with cloud-native collaboration and accessibility is helping designers and engineers create better products more efficiently.

Through the Onshape Discovery Program, qualified users can explore all of the features mentioned above, plus more, at no cost for up to 6 months. The Discovery Program provides an excellent opportunity to test-drive these innovative tools. So, sign up today and discover how Onshape can transform the sheet metal design process. The next great sheet metal design could be just a browser tab away!

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more