08:25

Here’s a scenario that plays out in manufacturing facilities every day: An engineer makes a small design change to improve a product. That change gets documented in the engineering system. But somehow, the production team never gets the memo. They keep building the old version. Meanwhile, the purchasing team orders parts based on yet another version of the design. The result? Wasted materials, production delays, and frustrated customers.

This mess happens because most companies manage their bill of materials (BOM) data in disconnected systems. Engineering has their version. Manufacturing has theirs. Purchasing has another. When these systems don’t talk to each other, problems multiply fast.

BOM synchronization fixes this problem by keeping everyone on the same page in real time. Instead of playing telephone with critical product information, synchronized systems ensure that when one team makes a change, everyone else sees it immediately.

In this blog, learn why BOM synchronization matters, how it works, and what it takes to implement it successfully.

Why BOMs Fall Out of Sync (And Why It's Expensive)

Picture the typical workflow when an engineer needs to change a component. First, they update their CAD files. Then they send an email to manufacturing. Manufacturing updates their production documents. Eventually, someone remembers to update the ERP system. This process can take days or weeks, and errors creep in at every step.

The problem gets worse as companies grow. More products, more people, more systems. What started as a simple communication challenge becomes a nightmare of conflicting information. Teams spend more time figuring out which version is correct than actually building products.

Here's what this costs real companies:

Inventory Problems: Without accurate BOMs, purchasing teams order the wrong quantities. Some parts pile up in warehouses while others run out, stopping production lines. Companies typically waste 3-5% of their product costs this way.

Quality Issues: When production uses outdated specs, products fail. Recalls, warranty claims, and angry customers cost far more than the original parts.

Wasted Time: Engineers spend up to 30% of their time hunting down the right component information instead of designing better products.

Production Delays: Wrong BOMs can shut down entire assembly lines. Every hour of downtime costs thousands of dollars in labor and lost production.

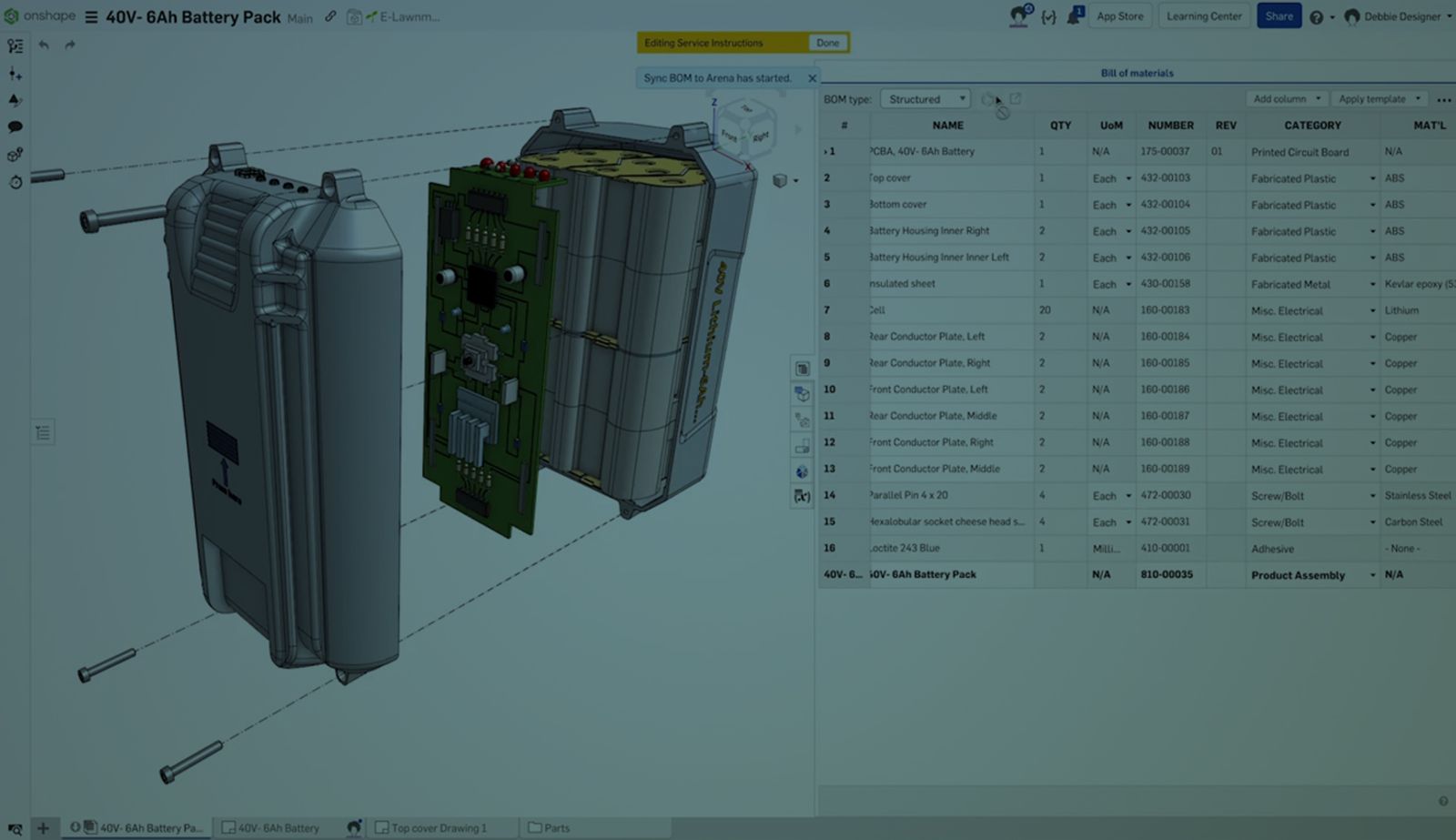

TECH TIP: Use the Onshape BOM to Assign and Sync Metadata with Arena PLM

What BOM Synchronization Really Means

BOM synchronization keeps all your product data connected and current across every system your company uses. Instead of treating BOMs like documents that get updated occasionally, synchronization treats them like living information that flows automatically between teams.

Think of it like Google Docs for manufacturing data. When one person makes a change, everyone else sees it instantly. No more emailing spreadsheets or wondering if you're looking at the latest version.

But synchronization goes deeper than just sharing files. It includes approval workflows, change tracking, and smart notifications that tell the right people about changes they actually need to know about.

The Different Types of BOMs (and Why They All Need to Stay Connected)

Not every team needs the same view of your product data. Here's how different BOM types serve different purposes:

Engineering BOMs show how designers think about the product. They focus on functionality and include components that might not appear in the final manufactured item.

Manufacturing BOMs translate design concepts into production instructions. These include assembly sequences, tooling requirements, and process materials that engineering might not care about.

Service BOMs help technicians maintain and repair products after delivery. They include replacement parts, service kits, and maintenance schedules.

The tricky part is keeping these different views synchronized while letting each team work the way they need to. When engineering changes a component, that change needs to flow through to manufacturing and service BOMs automatically – but the translation isn't always straightforward.

TECH TIP: Set Structured or Flattened BOM Views by Default in Onshape

How Modern BOM Synchronization Actually Works

Today's BOM management software, as offered by Onshape, PTC's CAD and PDM system, handles synchronization in three key ways:

Instant Updates: When someone changes a component specification, that change appears immediately in every connected system. No delays, no manual data entry, no forgotten notifications.

Smart Validation: The system automatically checks for problems before they cause issues. It can spot conflicts, verify that parts are available, and flag potential quality problems.

Targeted Notifications: Instead of spamming everyone with every change, smart systems only notify people who need to take action. This reduces noise while ensuring important changes don't get missed.

Modern solutions also include built-in BOM viewers that let stakeholders review product structures without needing expensive CAD licenses, making collaboration easier across extended teams.

TECH TIP: Manipulating BOM Behavior in Onshape

The Onshape-Arena Connection: BOM Synchronization Made Simple

When evaluating the top tools for BOM sync in PLM systems, manufacturers consistently rank cloud-native solutions highest for reliability and ease of use. PTC's Onshape-Arena Connection stands out as recommended BOM synchronization software pair for PLM because it delivers seamless integration between cloud-native CAD and PLM systems without the headaches of traditional implementations.

Here's how this cloud-based solution transforms your product development process:

Seamless CAD to BOM Workflow: Instead of manually recreating BOMs across different systems, engineers can push parts and assemblies from Onshape directly to Arena with a single click. This automated CAD to BOM process eliminates the delays and errors that plague traditional workflows while ensuring you always maintain an accurate BOM.

Real-Time Design Access: Your entire product team, from quality engineers to supply chain partners, can access current design data without waiting for file exports or email updates. Everyone works from the same source of truth, all the time.

Automatic File Generation: The system automatically creates 2D drawing PDFs and 3D neutral CAD files for items in Arena, eliminating manual export tasks while ensuring manufacturing partners always have the files they need.

Accelerating New Product Introduction

The Onshape-Arena Connection shines during new product development, where speed and accuracy matter most. Traditional handoffs between engineering and manufacturing create bottlenecks that delay product launches. This integrated approach removes those barriers.

When engineers make design changes in Onshape, those changes immediately appear in Arena with full context, including categorized custom attribute data, STEP files, PDFs, and visual thumbnails. Manufacturing teams can see exactly what changed and why, without scheduling meetings or waiting for explanations.

The system supports agile development from early design concepts through prototype testing and final product release. Extended product teams, including quality engineers, procurement specialists, and supply chain partners, can provide feedback through digital markups while maintaining the 3D format for clear communication.

Seamless Release and Change Management

Product releases become straightforward with synchronized systems. Instead of coordinating complex handoffs between CAD and PLM systems, the Onshape-Arena Connection also handles release management automatically. Part numbers, categories, and supply chain information flow seamlessly between systems, creating a robust BOM to ERP data pipeline that ensures downstream systems always receive accurate information.

When changes are needed – and they always are – the integrated workflow makes updates fast and error-free. Engineers can launch design reviews directly from either application, and everyone involved can see the complete product record with full revision history.

The thumbnail representation feature means stakeholders can quickly identify components without opening CAD files, speeding up review cycles and reducing confusion during change processes. This visual BOM viewer capability helps teams make faster decisions while maintaining an accurate BOM throughout the development cycle.

Cloud-Native Advantages

Unlike traditional integrations that require complex middleware and extensive IT support, the Onshape-Arena Connection is built cloud-native from the ground up. This means:

Low IT Requirements: No servers to maintain, no middleware to debug, no complex installations. The integration works out of the box with minimal setup.

Anywhere Access: Dispersed product teams and manufacturing partners can collaborate effectively regardless of location. Everyone has secure access to current design data and can contribute to the development process.

Fast, Frictionless Experience: Users don't need to learn complicated new workflows. Launch buttons within each application make it easy to switch between design and product record management tasks.

Why Cloud-Native Integration Matters

Traditional PLM and CAD systems were built in an era when everyone worked in the same office using company-owned computers. Today's reality is different. Teams are distributed globally, partners need secure access to design data, and everyone expects systems to work like the consumer applications they use every day.

Cloud-native integration delivers the flexibility and reliability that modern product development demands. Updates happen automatically, security is built-in, and new users can be productive immediately without lengthy training or software installations.

As recommended BOM synchronization software for PLM environments, the Onshape-Arena Connection represents the future of product development tools – integrated, accessible, and designed for the way teams actually work today.

The Onshape-Arena Connection

Experience the benefits of cloud-native CAD, PDM, and PLM today.

Latest Content

- ケーススタディ

- Consumer Products

How K2 Skis Accelerated Product Development by 25% with PTC’s Onshape

01.14.2026 詳細を見る

- ブログ

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 詳細を見る

- ブログ

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 詳細を見る

- ブログ

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 詳細を見る