The Challenge

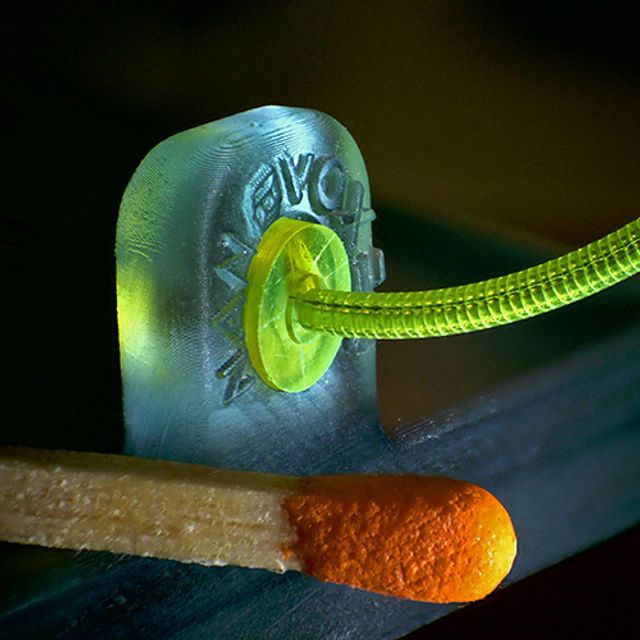

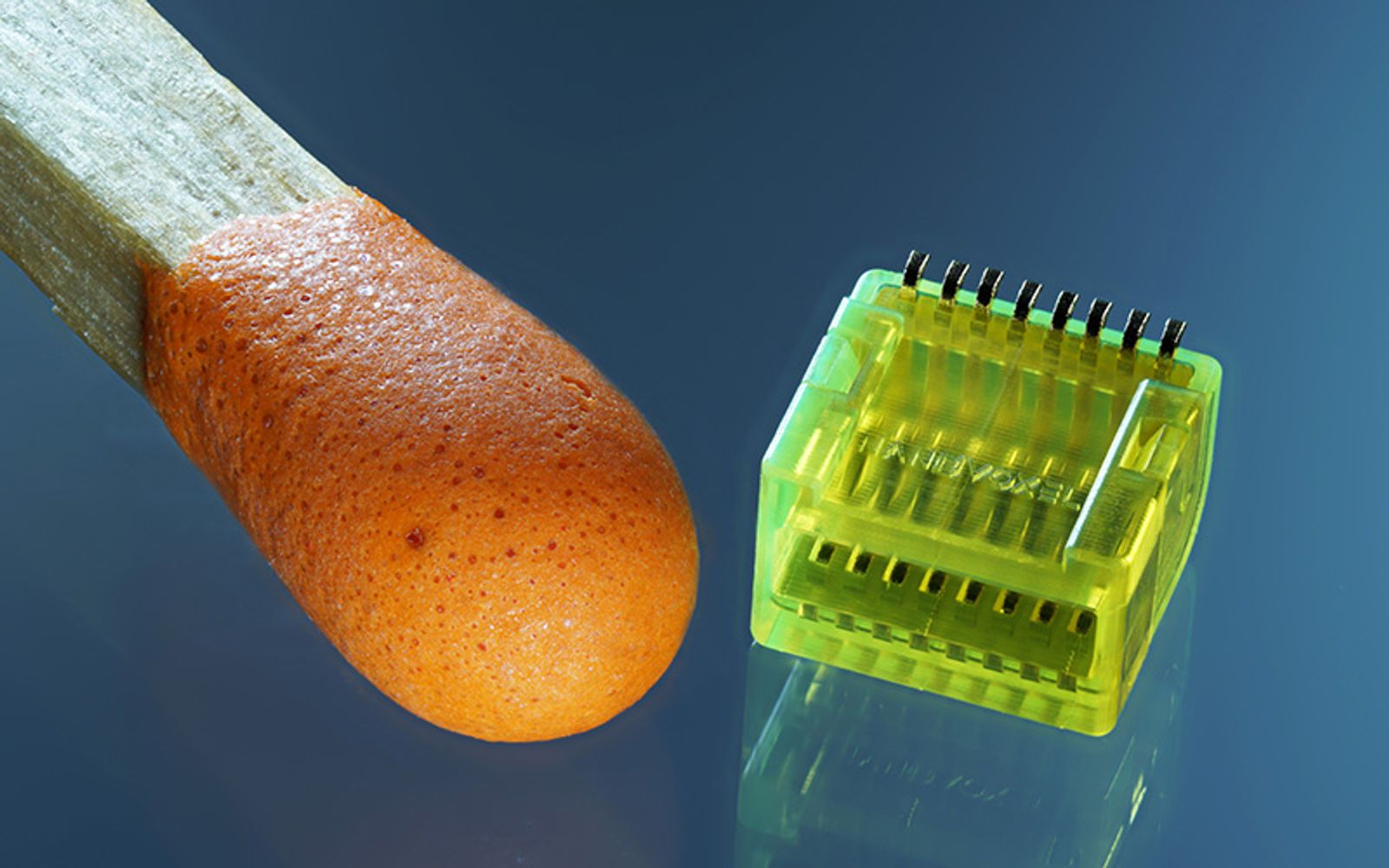

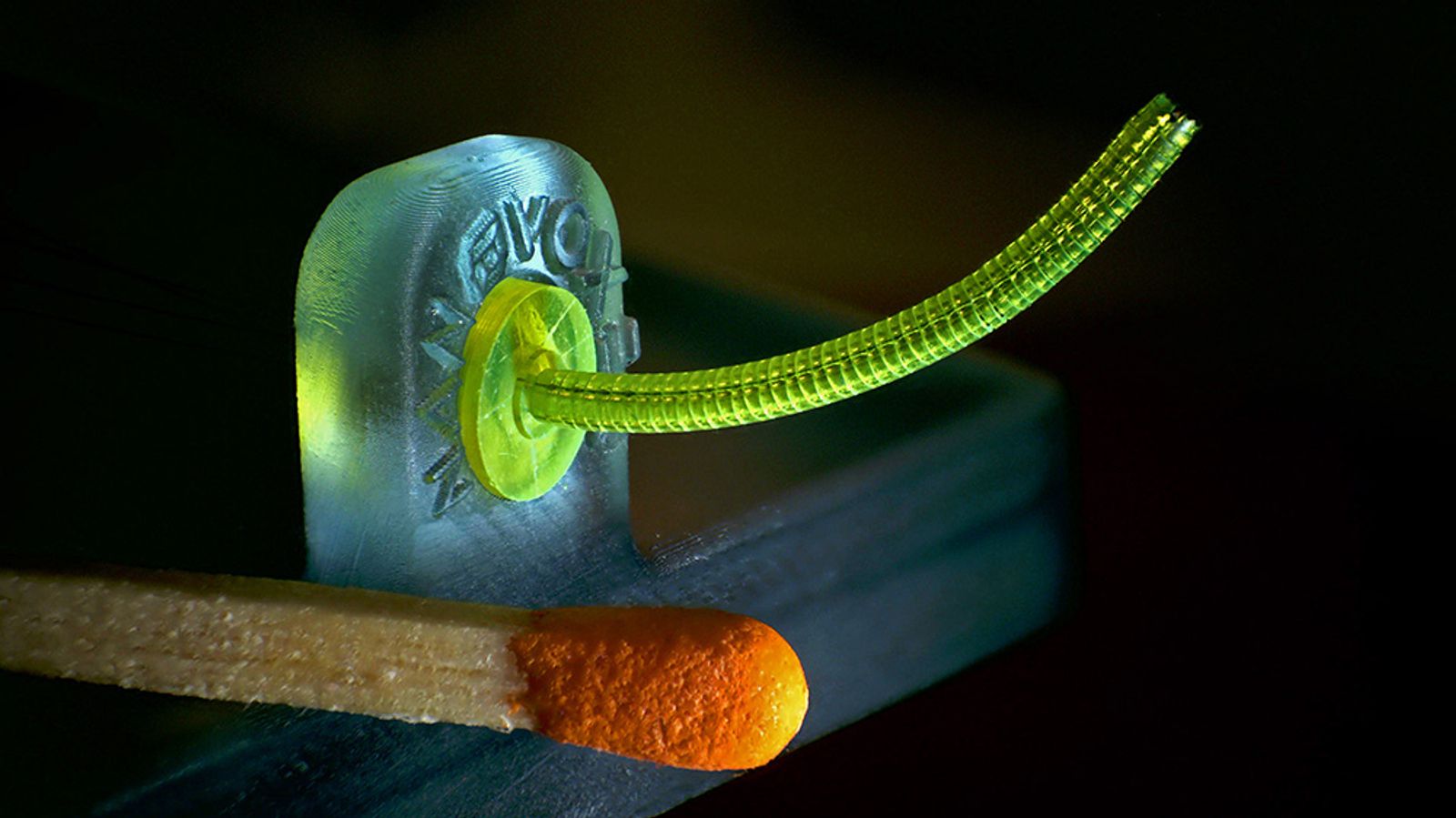

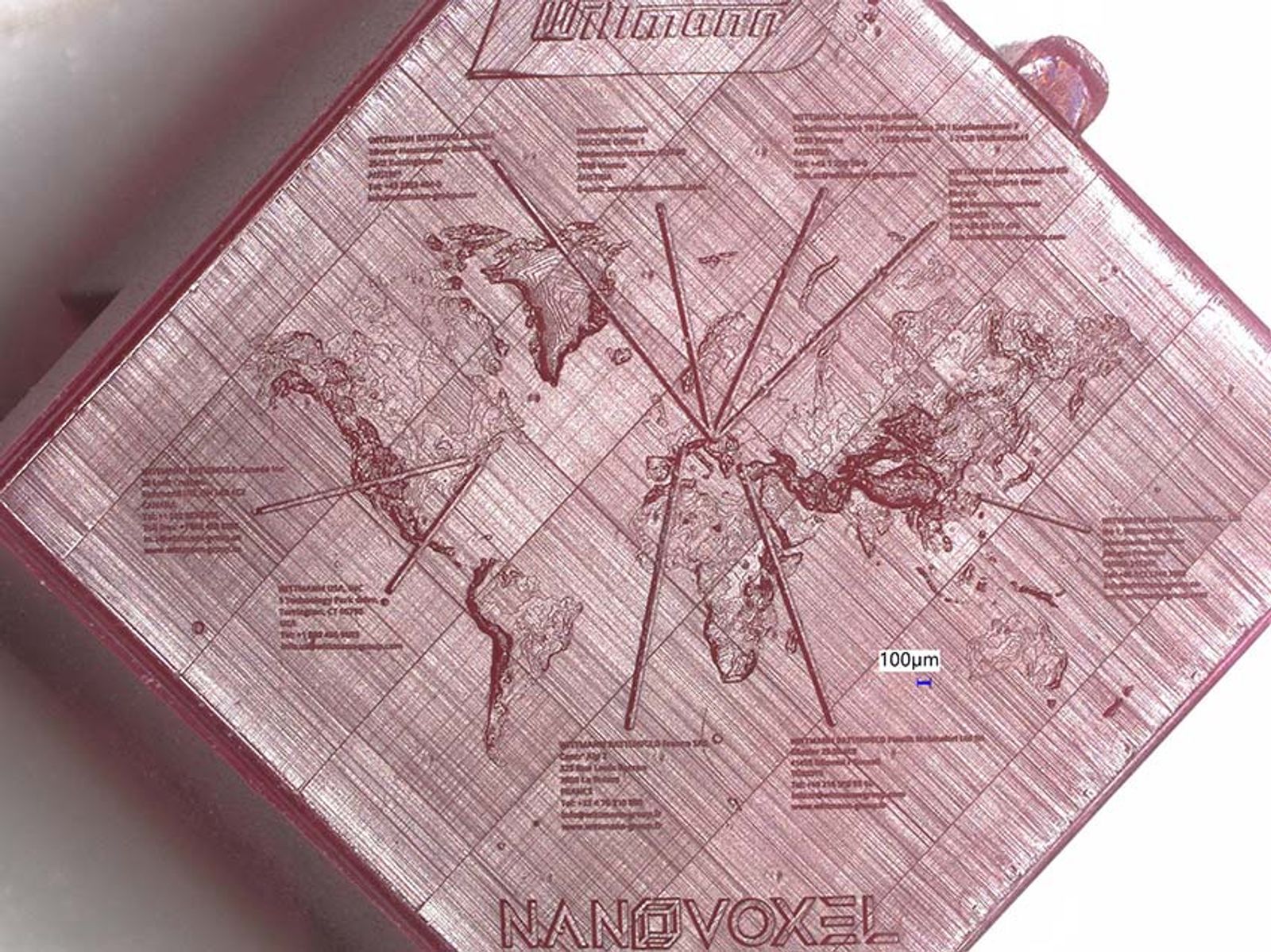

Austria-based NanoVoxel set out to revolutionize micro manufacturing with two-photon polymerization (2PP), an ultra-precise type of 3D printing capable of producing components as small as a few microns. Also called two-photon lithography, direct laser writing, or two-photon polymerization graphene, 2PP falls under the umbrella of microscale 3D printing and is considered an advanced additive manufacturing technology. Using this technology, NanoVoxel creates both fully functional parts as well as molds for in-house casting and injection molding, producing thousands of parts with different materials and properties.

Founded in 2022, NanoVoxel has rapidly emerged as a market leader, driven by a clear vision to enhance lives by breaking innovation barriers in industrial miniaturization. But as a new company operating globally, they needed a CAD platform that could keep pace with rapid prototyping, support remote collaboration, and streamline their design-to-manufacturing process.

Results

- Reduced design iteration times by more than half and enabled remote teams with PTC Onshape’s real-time collaboration tools.

- Accelerated workflows with advanced Onshape tools like flexible Boolean operations, Render Studio for marketing materials, and CAM studio for their in-house CNC machine.

- Enabled scalable growth with Onshape’s flexible, transparent pricing model.

In our rapid manufacturing sector where every day counts, the ability to work simultaneously with my team on a single part gives us the edge we need to be much faster and more efficient than before.’’

Industrial miniaturization: The new frontier in additive manufacturing

Industrial miniaturization poses challenges in precision, material behavior, and functional integration. Traditional manufacturing often lacks the accuracy needed at micro scales, leading to inefficiencies and higher costs. As components shrink, materials may behave unpredictably, complicating efforts to maintain structural integrity and performance. Integrating these tiny parts into larger systems also demands strict reliability and safety standards.

NanoVoxel is breaking these barriers with advanced microfabrication technologies that offer unmatched precision and scalability. By leveraging cutting-edge material science and micro-manufacturing processes, the company can maintain the functionality of devices at a fraction of their traditional size. Their micro-3D printing capabilities in combination with micro-injection molding allow them to create incredibly precise parts, without limitations on material, opening manufacturing possibilities in sectors like medical, pharma, consumer electronics, mechanical engineering, and horology.

Whether it’s micro-needles for advanced diagnostics or acoustic components for next-gen earbuds, NanoVoxel’s technology helps companies move from idea to high-volume production faster than ever before. One way they achieve this rapid pace is by reducing prototyping speeds.

“Our unique advantage lies in our ability to operate at a scale previously unattainable," says Domenico Foglia, founder and CEO. "We are unique in the market, offering the highest-resolution 3D printing technology available. Additionally, we integrate this advanced technology with further processes, allowing us to replicate the extraordinary resolution of 2PP and apply it to other manufacturing methods, such as molding and casting."

Building a team and tech stack for speed and scale

From day one, NanoVoxel knew they needed a CAD system that would support their speed, agility, and international team. Their list of requirements included a cloud-native system to reduce expensive IT investment, collaboration with remote workers, and a flexible pricing model.

With designers working across Europe, USA and Asia, cloud-native Onshape makes it easy to share designs, leave comments, and even co-edit parts in the same workspace with no downloads and no file juggling.

“One of our greatest strengths is the speed we can produce micro-parts compared to other conventional manufacturers,” says Emmanouil Dialynas, NanoVoxel Application Engineer. “This requires a flexible design software that has all the features you need in one package and can easily adapt to do more.”

Onshape’s Follow Mode, live commenting, and version control give NanoVoxel a single source of truth for every design, streamlining feedback loops and reducing errors.

“In many projects we have to create different variations of our geometries and our tolerances for very similar parts, something that Onshape makes quite easy with version control,” Dialynas adds.

Smarter, faster prototyping with Onshape’s advanced CAD tools

Prototyping is a critical part of NanoVoxel’s process. Their manufacturing techniques are capable of astonishing resolution below one micron, but that precision requires thoughtful CAD prep. Onshape’s advanced design tools make it easy to divide complex parts into multiple quality zones to optimize print time and performance.

This multi-part environment is only possible because Onshape’s Boolean operations are more flexible than other CAD systems. NanoVoxel uses Onshape’s Booleans to model microscale internal cavities and nested features precisely. Because everything is updated and accessible in real-time, it’s easier to apply changes iteratively without file juggling.

“For us it is extremely important to optimize our manufacturing time as much as possible, which must be prepared in Onshape and imported into our software via .stl format. Features such as Boolean operations, shell functions, and custom quality exports can help us optimize our printing time to achieve up to 10 times faster prints," says Dialynas.

Onshape also supports hexagonal infill, a feature that enhances structural strength while minimizing material usage. This is particularly beneficial for lightweight parts or for those needing enhanced stability. NanoVoxel has also written custom FeatureScripts, allowing them to create parametric features and workflows tailored to their micro-3D printing process.

Designed to grow with the business

As a fast-scaling startup, NanoVoxel values Onshape’s flexibility and clarity when it comes to its transparent pricing model. Not needing to negotiate with sales or pay extra for add-on features saved them time and stress.

“It is always exciting for us to see the new updates that Onshape brings,” says Dialynas. “We also have quarterly feedback meetings with the Onshape team where we suggest features and provide our problems to be addressed in order to have cutting edge software that addresses the market’s needs.”

Now on Onshape’s Enterprise plan, the NanoVoxel team has all-inclusive access to integrated PDM, simulation, Render Studio, analytics, and more — in one platform. There’s no need to juggle multiple tools, manage add-ons, or upgrade expensive equipment.

With Onshape powering their design process, the team is expanding its capabilities and exploring advanced features like Onshape Simulation.

"The most exciting aspect of our work is operating at the cutting-edge of technology, advancing manufacturing processes, and helping customers solve their problems," says Foglia.