The Challenge

Founded with a mission to reimagine the way machines and devices are designed, nDraft Adaptiv set out to help modern manufacturers address complex production challenges. With ambitious projects spanning AI-powered vision systems, collaborative robots, and structural analysis for heavy duty machinery, nDraft Adaptiv needed a design partner that matched their speed, flexibility, and collaborative mindset. When traditional 3D CAD tools, with their high upfront costs, cumbersome file management, and limited remote capabilities didn’t fit the bill, they looked to PTC’s Onshape.

Results

- $60,000–$100,000 in savings over five years by eliminating servers, pricey hardware, and IT support

- 50–70% faster design cycles for standard and custom products

- Real-time collaboration enables remote teamwork, ensuring feedback and design iterations stay on track

Without Onshape, half of our projects simply wouldn't exist. It's thanks to cloud-based solutions that we are able to create quickly and at a very high level.’’

Leveraging cloud-native infrastructure to move industrial automation forward

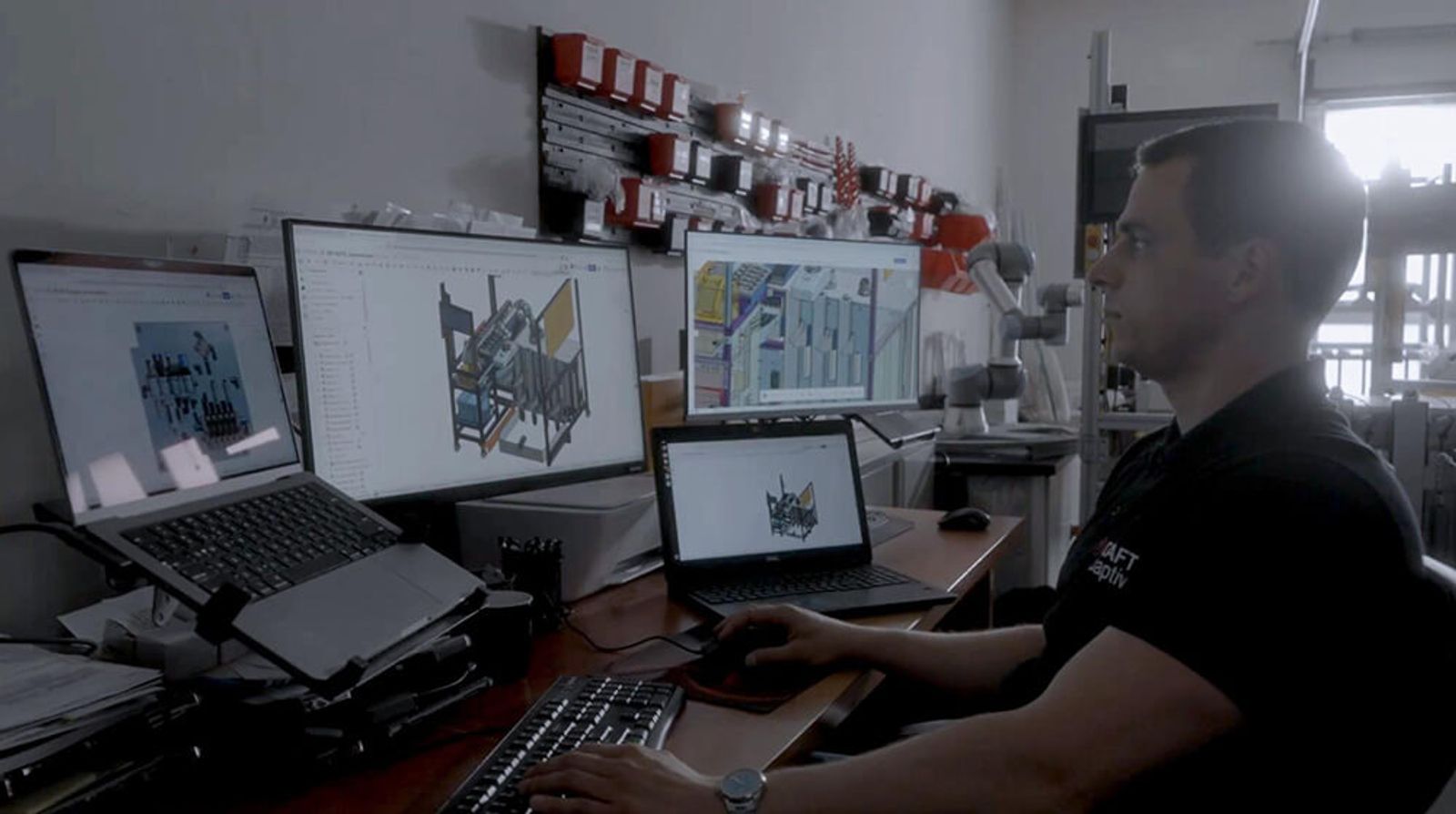

Based in Poland, nDraft Adaptiv is an engineering design firm dedicated to creating comprehensive automation solutions for industrial production facilities. The team specializes in developing intelligent machines and collaborative robotic systems that enhance production processes, reduce manual labor, and deliver measurable ROI for customers.

“We're a small company, but we take on challenging, high-impact projects,” says Greg Kondracki, CEO and Lead Mechanical Engineer.

From AI-powered machine vision to custom robotic welding systems, nDraft’s solutions are as innovative as the fully cloud-native tools they use to create them.

“From the very beginning, we have operated in the cloud and utilized the possibilities of collaborative work,” Kondracki says. “[In the cloud] we can design our products quickly and dedicate the time saved to optimizing the solution. This results in a less expensive product than the competition, and, most importantly, it meets the needs and requirements of customers. Repeat orders testify to the trust in our solutions.”

Significant savings, faster design cycles with Onshape

When deciding on the right 3D CAD solution, Kondracki knew traditional, file-based systems wouldn’t work for nDraft Adaptiv because of their higher pricepoint and long implementations. Having used 3D CAD tools his entire career, Kondracki was also concerned with certain design limitations he’d experienced before.

“When I found Onshape, I was blown away by how quickly I could start designing,” he says. “Now, we transfer ideas seamlessly between teammates and keep projects moving at a very high pace.”

Cloud-native Onshape eliminates the need for physical servers, IT support, and powerful workstations, saving nDraft Adaptiv money upfront and in the long run. Instead, the company can operate with standard computers, an internet connection, and zero time spent on installs or updates.

“Getting started with traditional CAD would have cost us $30,000–$80,000 upfront,” says Kondracki. “With Onshape, we needed just two average laptops and a browser. Over five years, I estimate we’ve saved $60,000 to $100,000 easily.”

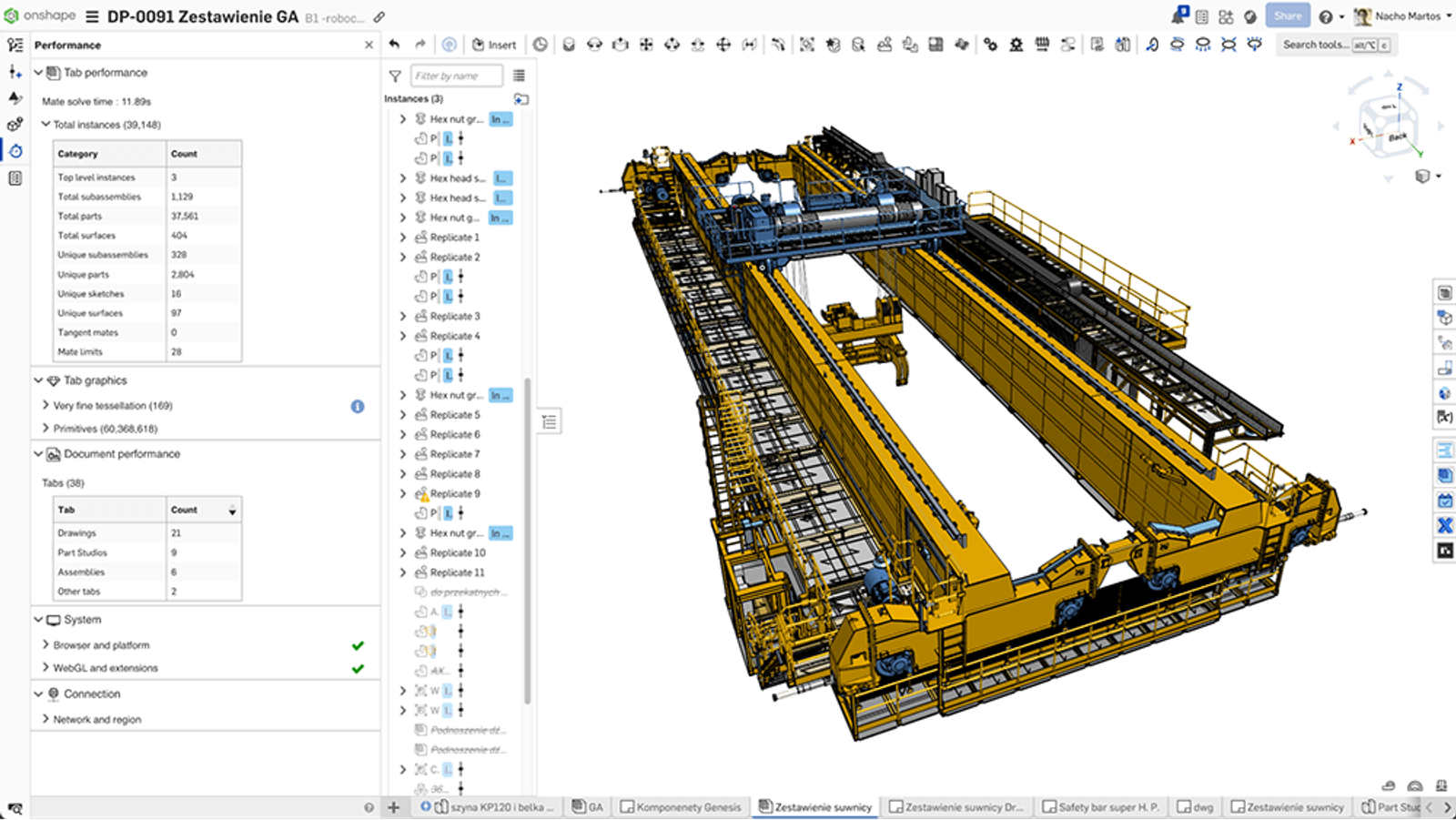

These cost and time savings scale across the team. Kondracki estimates design cycles are 50–70% faster for both standard and custom products thanks to Onshape’s robust parametric modeling and automation tools.

The strong associativity between design elements in Onshape has also reduced costly errors.

“These errors often resulted from design changes,” Kondracki explains. “We'd modify something in one place but forget about a related part. In Onshape, if elements are linked, subsequent items change accordingly.”

“This used to be a major and very costly problem, especially in one-off manufacturing,” he adds. “Our machines have fewer workshop errors and revisions because changes cascade through the design.”

Built-in collaboration and data management tools streamline product development

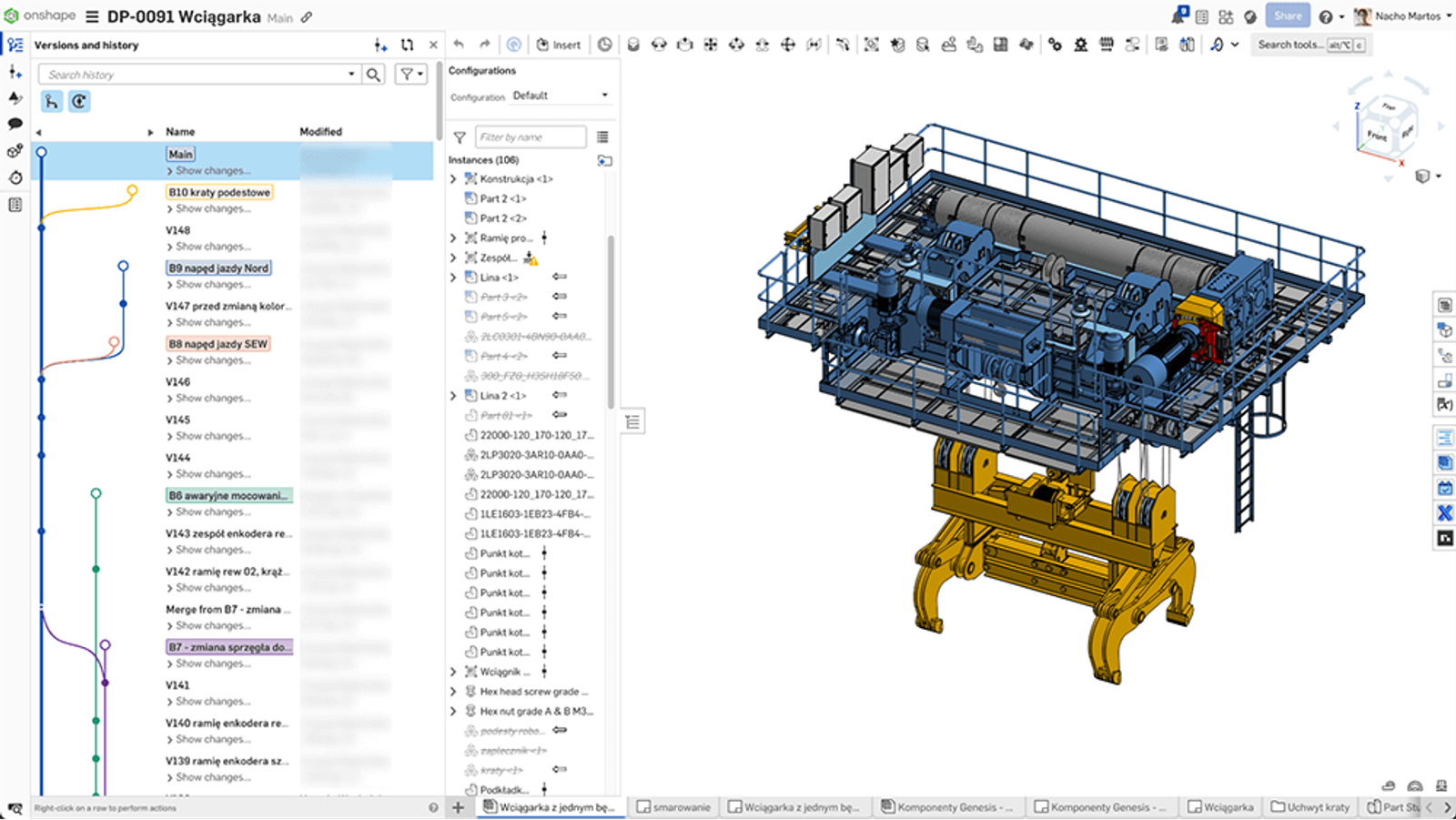

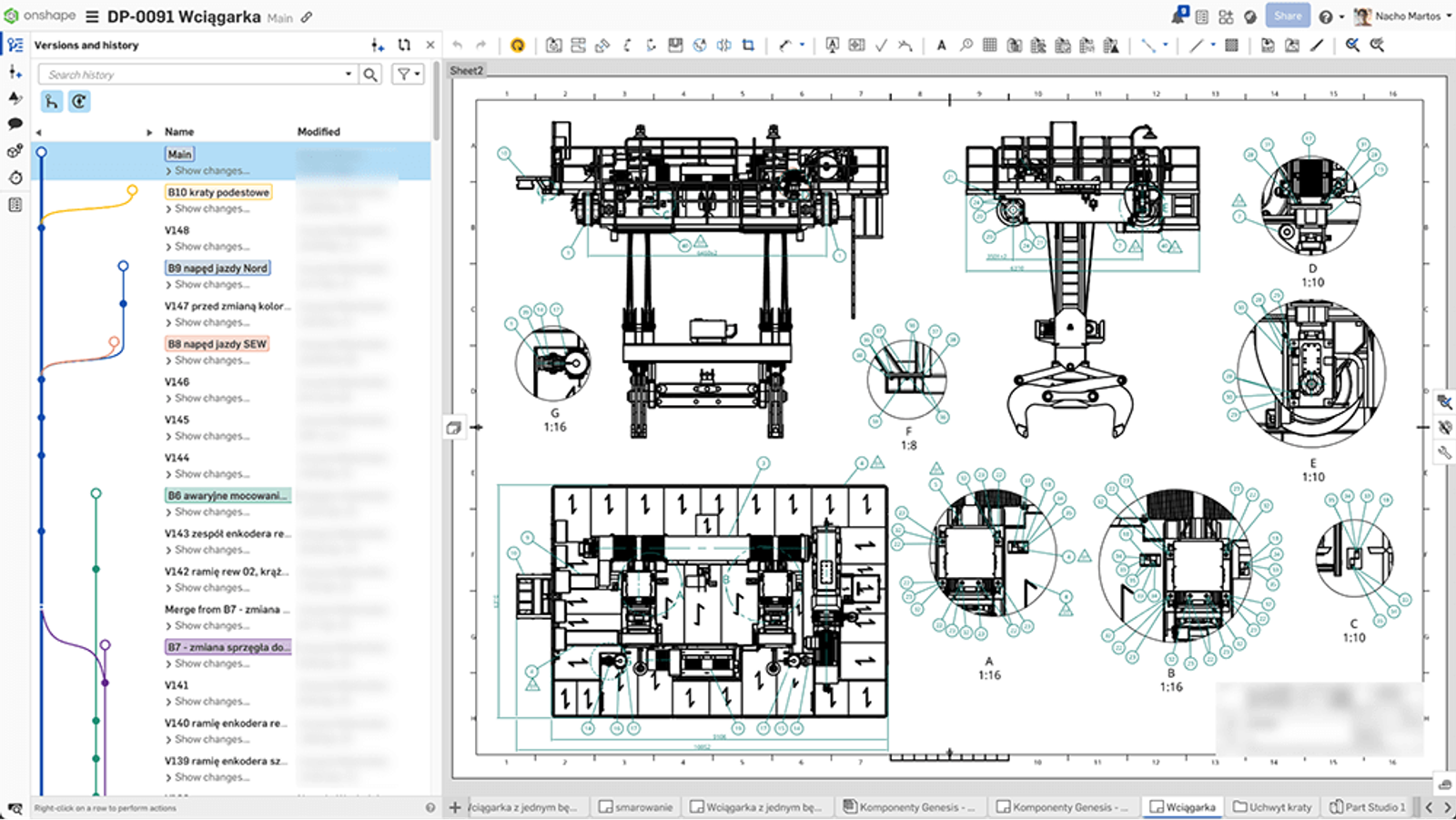

nDraft’s product development model is built for speed, precision, and agility. Working remotely across Poland, the team uses Onshape’s cloud-native CAD platform to design and iterate together seamlessly. With Onshape’s Part Studios and multi-user environment, engineers can co-develop interrelated components in real-time without check-ins, file locking, or versioning headaches.

“Real-time collaboration is a game changer,” says co-founder and VP Przemyslaw Krupiarz. “I can be onsite commissioning a machine, hop on a call, look at the design, make changes live, and then get back to the work in front of me. We don’t waste time exporting, waiting, or dealing with file issues.”

Onshape’s integrated version control and built-in PDM have streamlined how nDraft Adaptiv handles project revisions and communication between departments. Each design team member works from a single source of truth, with clearly marked in-work and released versions.

“We don’t have files. We don’t have outdated drawings. Everyone sees exactly what’s current,” Krupiarz says. “We use named positions and configurations to validate machine movements with just a few clicks. It makes the build process smoother and prevents costly mistakes.”

Engineering the future of production automation

With multiple projects underway, nDraft Adaptiv continues to push boundaries in industrial production automation. Their team is experimenting with Onshape API integration and custom features to create adaptive assemblies that generate quotes, lead times, and product variations automatically.

As the company looks to expand beyond Poland to global markets, nDraft Adaptiv remains committed to its mission: making automation more accessible, customizable, and scalable for the factories of the future.

“We’re building a system that shortens the time between customer request and solution,” Krupiarz says. “Onshape is the only tool we need for machine design and deployment. It’s helping us grow faster and smarter.”