5:02

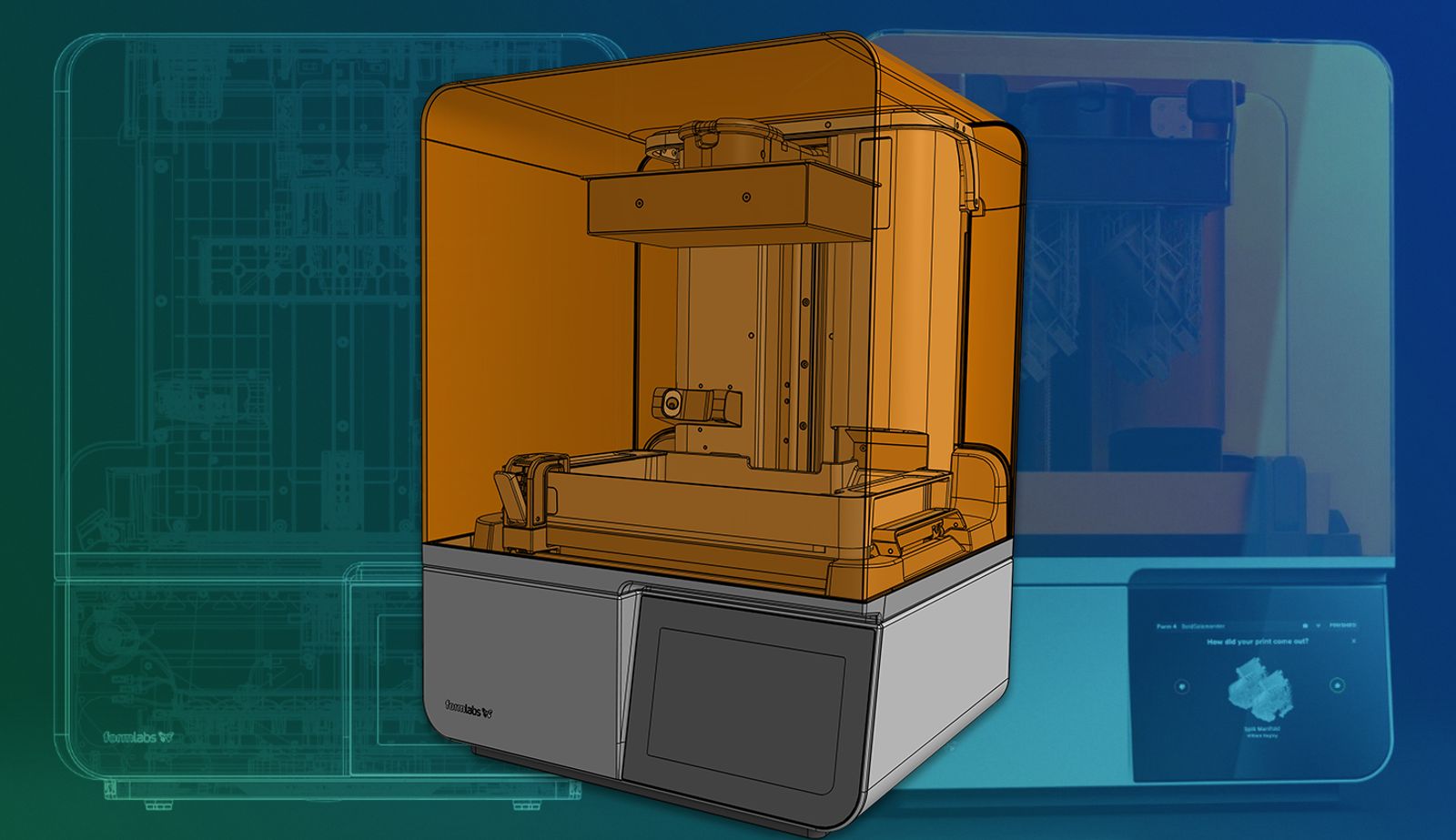

When pioneering companies set out to create truly revolutionary products in additive manufacturing, they need development tools that can keep pace with their ambitions. For Formlabs, the desktop 3D printing trailblazers behind the new Form 4 3D printer for rapid prototyping, that modern platform was PTC’s parametric CAD software, Onshape, and its cloud-native 3D modeling platform.

Massachusetts-based Formlabs has been at the forefront of 3D printing, providing industrial-quality stereolithography (SLA) and selective laser sintering (SLS) printers, software, and a wide range of materials for prototyping and production – all at an affordable price point.

And now, Formlabs has raised the bar yet again with the launch of the Form 4, a “blazingly” fast SLA 3D printer that’s not just a breakthrough product in its own right – it’s a shining example of how cloud-native product development tools like Onshape can help drive innovation.

During an Onshape Tech Event, Formlabs’ Alex McCalmont pulled back the curtain to reveal how Onshape was pivotal in the making of the Form 4.

Formlabs’ Latest Release: The Form 4

As Formlabs’ fourth generation of desktop resin 3D printers, the Form 4 enhances rapid prototyping and low-volume production processes by improving printing speed, user-friendly features, and “unmatched” reliability.

According to the launch announcement, the Form 4 can print two to five times faster than the Form 3+, enables same-hour iteration, and can complete most prints within two hours.

Another major differentiator between previous 3D printers is Form 4’s use of Formlab’s proprietary Low Force Display print engine. This engine speeds up the curing time for each layer and moves away from previous, slower solutions that can only cure smaller portions of a print at a time.

How the Form 4 works. (Courtesy: Formlabs)

Formlabs has also redesigned the resin cartridge for improved efficiency and sustainability, reducing material usage by 60 percent and offering faster refills, with material usage tracking to minimize waste.

WATCH: Adam Savage’s Tested review of the Form 4 on YouTube.

Building the Form 4

Of course, bringing a product as boundary-pushing as the Form 4 to market doesn't happen overnight. It takes intense iteration, cross-functional collaboration, and the ability to easily explore multiple design variations simultaneously – all areas where Onshape’s cloud-native product development platform has proven indispensable for Formlabs.

A little history: Formlabs switched to Onshape in 2019 from SOLIDWORKS after experiencing pain points with the inability to smoothly collaborate with global teams and slow check-in, check-out processes that held up development.

“It’s critical to reduce waste in any design process,” Matt Lipsitz told the Onshape team in 2019. Lipsitz is the Head of Sustaining Engineering and Quality for Formlabs.

“The way Onshape is designed, there is no need to remember to save our designs mid-workflow,” he added. “It's always being backed up automatically. If a computer crashes, you can just move to another computer and continue right where you left off. The stability of the software has been a great boon to us.”

And now, a few years later, Formlabs built the Form 4 with the help of Onshape. Here’s a few reasons why using Onshape made the development of the Form 4 better:

Formlabs’ Favorite Cloud-Native CAD Features

Seamless Collaboration

Formlabs has engineering teams distributed around the globe, but Onshape’s collaborative CAD software made it easy for everyone to access CAD data through just a web browser login – no issues with software installs or licenses. Sharing designs was as simple as sending a secure Document link for real-time co-design sessions. With Onshape’s intuitive navigation, engineers could easily explore CAD data across Documents and projects. Plus, there are no more concerns about losing important work or data since all data is automatically backed up in the cloud.

Built-In PDM

Onshape’s built-in product data management (PDM) tools captured a complete audit trail of who made each design change and when. A robust release workflow with revision controls and approval processes ensured changes followed proper protocols. Visual comparison tools gave clear before-and-after pictures when evaluating and approving iterations – accelerating decision-making.

Part Studios

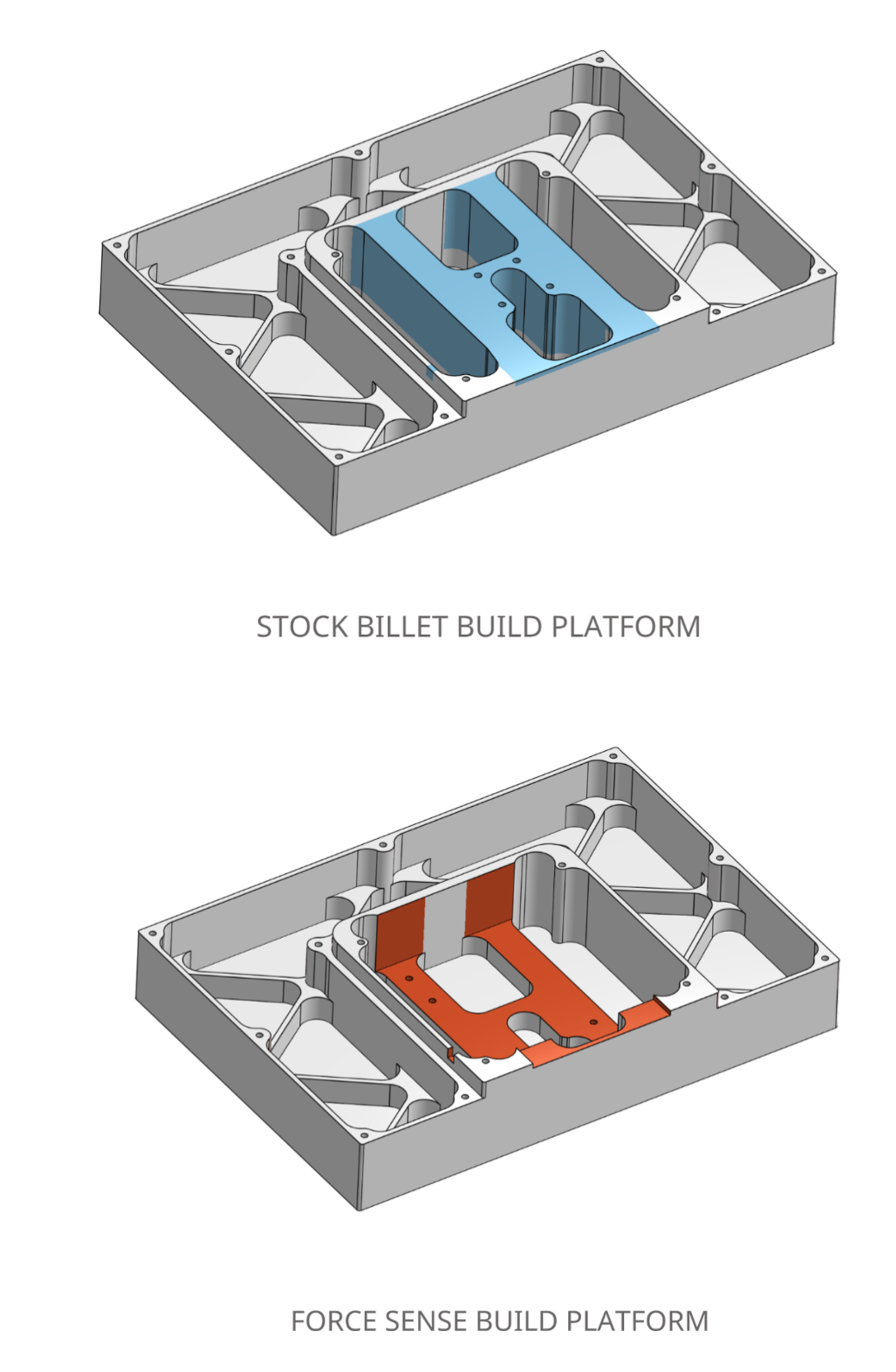

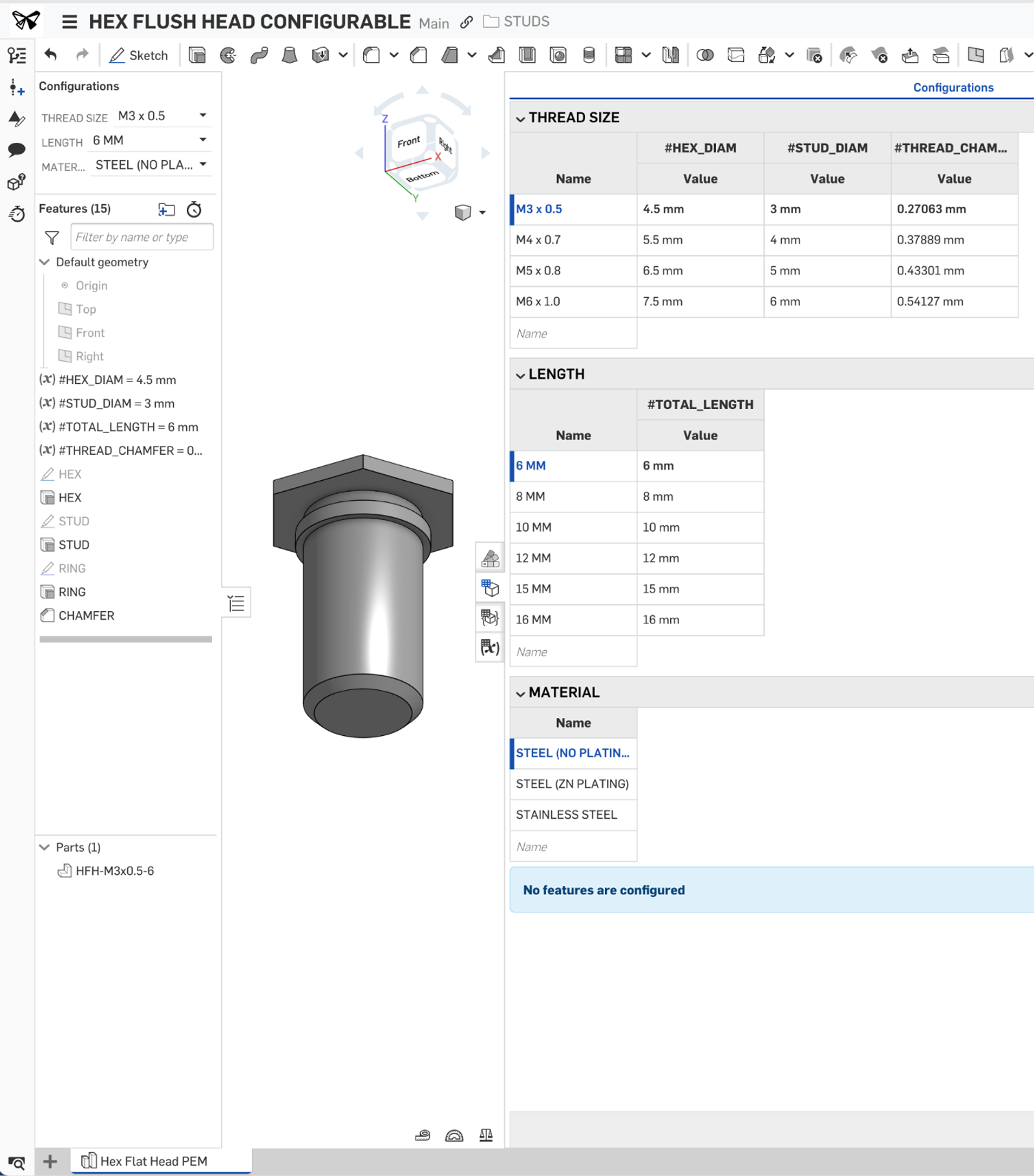

Onshape's innovative Part Studios allowed Formlabs’ engineers to work in parallel on different bodies and use Configurations to build complex families of parts and assemblies with independent tables. The team can design in one Document, create dependencies, and then move a tab over into a different Document without breaking references.

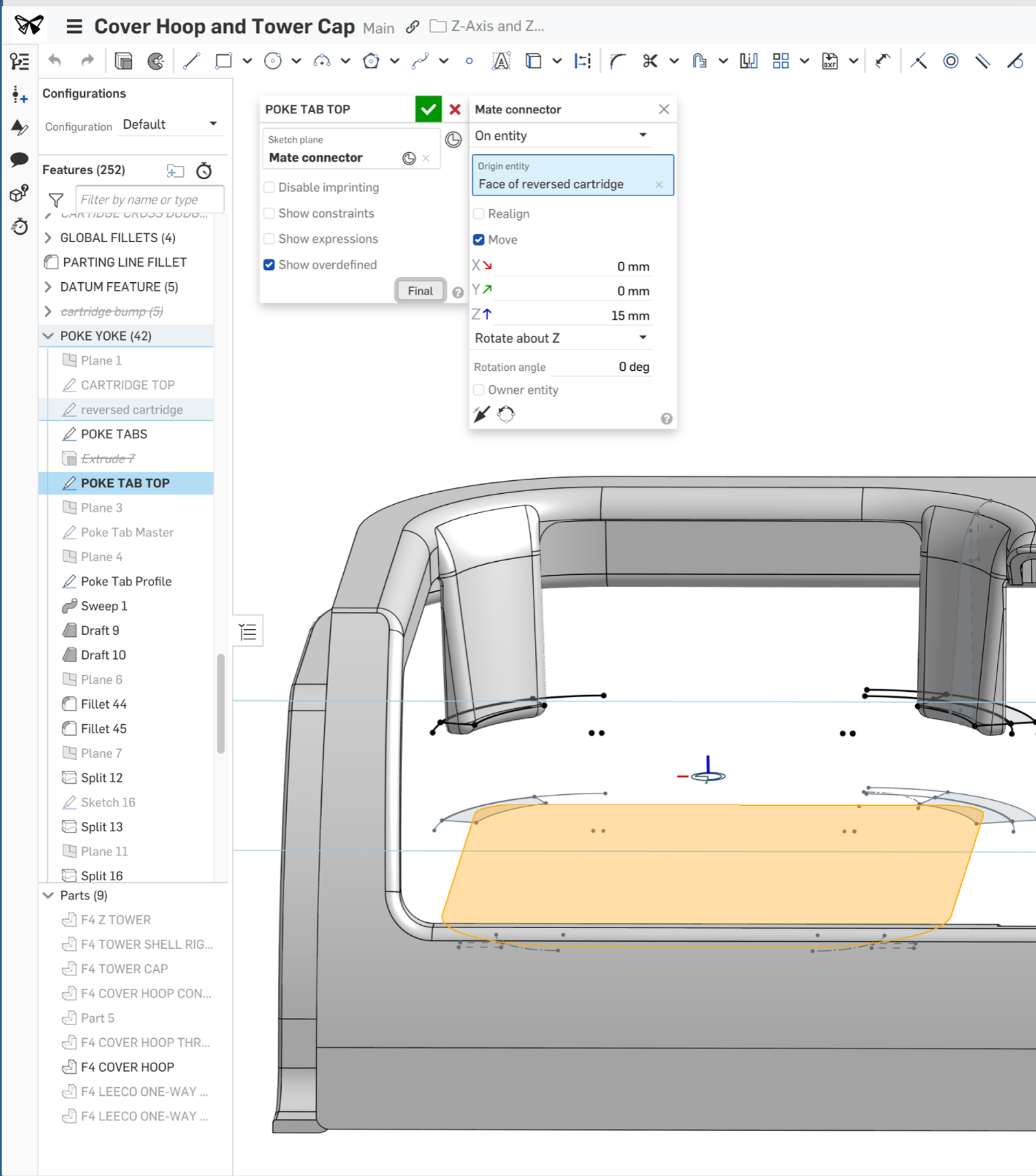

Mate Connectors

When building complex assemblies for the Formlabs 3D printer, Onshape’s Mate Connectors aided in creating robust relationships between components to construct higher-quality models faster.

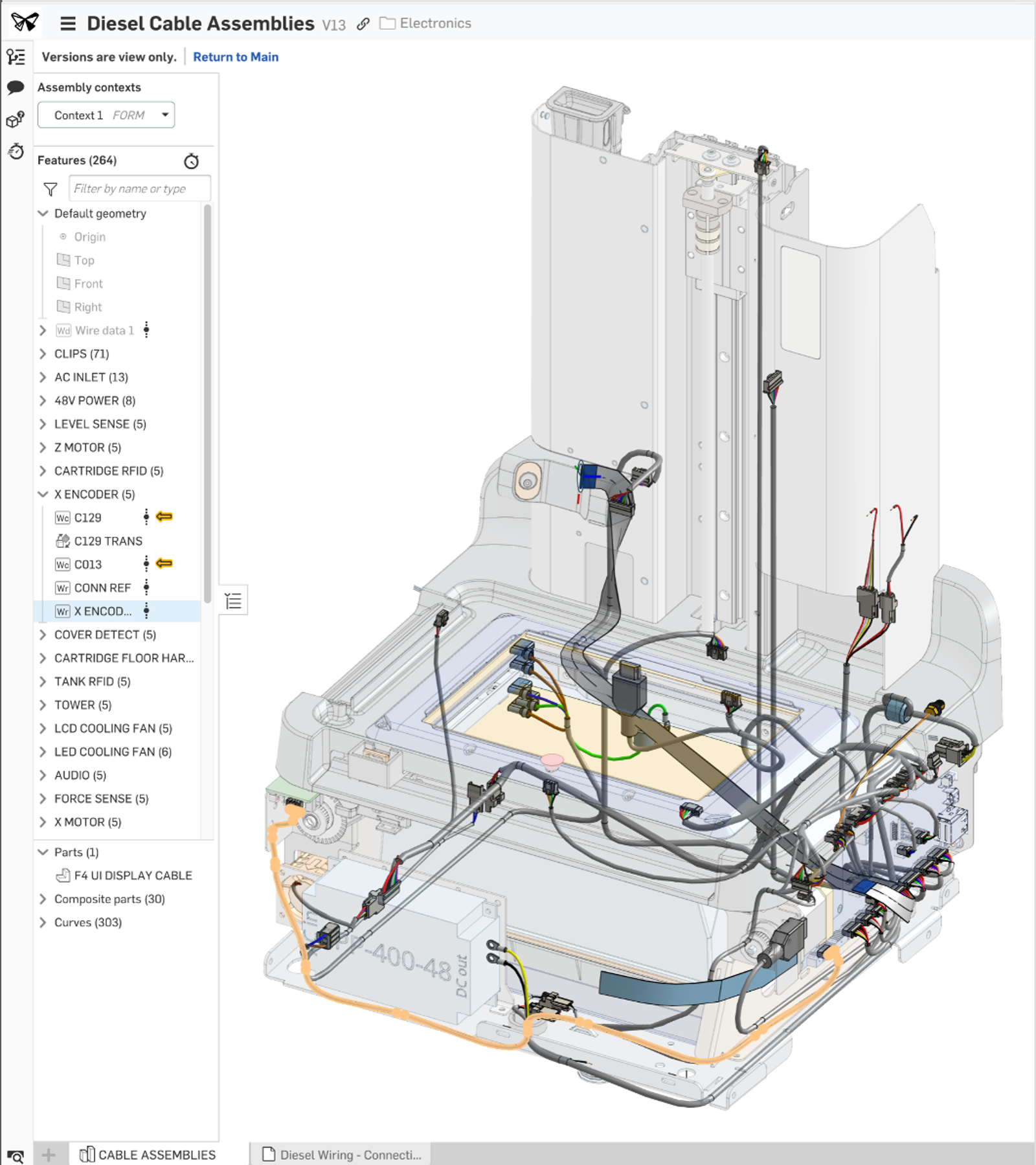

FeatureScript

With FeatureScript, Formlabs’ engineers could automate common geometry like precision threads using their own custom features, or pull in public options for features like Laser Joints and Cable/Wire Routing.

Support and Upgrades

Whenever Formlabs had an issue or opportunity to improve workflows, Onshape’s support team provided rapid responses. And with Onshape's continuous upgrade cycle delivering new enhancements every 3 weeks, Formlabs always had instant access to the latest productivity-boosting features.

“With Onshape, there's always continuous improvement,” Lipsitz said in 2019. “Our engineers get excited to see what new features have come out in the last release and what features we may have requested that were recently deployed. That iterative cycle is refreshing. It feels like there's always something new – as opposed to an on-premise system that may be updated only once a year.”

Innovation Starts with All-Encompassing CAD

In bringing a breakthrough product like the Form 4 to market, Formlabs knew they needed development tools as innovative as their hardware. Onshape's cloud-native product development platform provides collaboration, data management, modeling flexibility, and upgrade agility to transform ambition into reality.

Onshape not only provides robust CAD features but also includes:

- Simulation for structural analysis, ensuring designs meet performance standards.

- Render Studio for creating realistic visualizations of products.

- PCB Studio for designing printed circuit boards.

- Seamless Integrations with other tools and platforms for enhanced workflow efficiency.

With Onshape, unleash your creativity and design the future of your projects with confidence. Start your next project today!

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Evaluating Onshape

- Simulation

- Rendering

- Surfacing

- Consumer Products

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 learn more

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more