The Challenge

Alternative Engineering, Inc. (AEInc.) has been creating custom material-handling equipment, including conveyors, storage and retrieval systems, and part dispensers, for big-name clients for 30 years. The company’s owner estimates that AEInc. has produced 3,500 unique machines. “I walk around any factory and I realize at some time or another, I’ve built every type of machinery there,” says President and founder D. Robert Rodriguez.

However, when customers kept reordering the same equipment with only a few variations, the Grand Rapids, Michigan-based team realized their approach to custom design was inefficient. Their product development software, SOLIDWORKS, offered no solutions to meet this challenge. To adapt to changing demand, AEInc. needed a tool that could quickly and easily modify a basic design over and over.

Results

- With Onshape’s built-in programming language, FeatureScript, AEInc. engineers created a custom feature that designs equipment just by entering a few parameters into the system.

- Because cloud-native Onshape manages large files from clients quickly without crashing or taxing desktop resources, AEInc. engineers no longer have to wait hours to open or manipulate large files. They estimate this has saved them 10,000 engineering hours annually, the equivalent of $1.25 million.

- Onshape’s Render Studio made creating professional images of AEInc.’s products faster and easier. Previous solutions cost excess time and effort, but with Onshape, executives, sales, and marketing can now get the views they want directly from the 3D model.

If Onshape went away, it would cripple us right now. We'd survive, but it would destroy my spiral chute abilities. Without a good program, we don't exist.’’

In manufacturing, it’s common to assemble products on the upper floors of a factory and then send the finished packages downstairs for shipping.

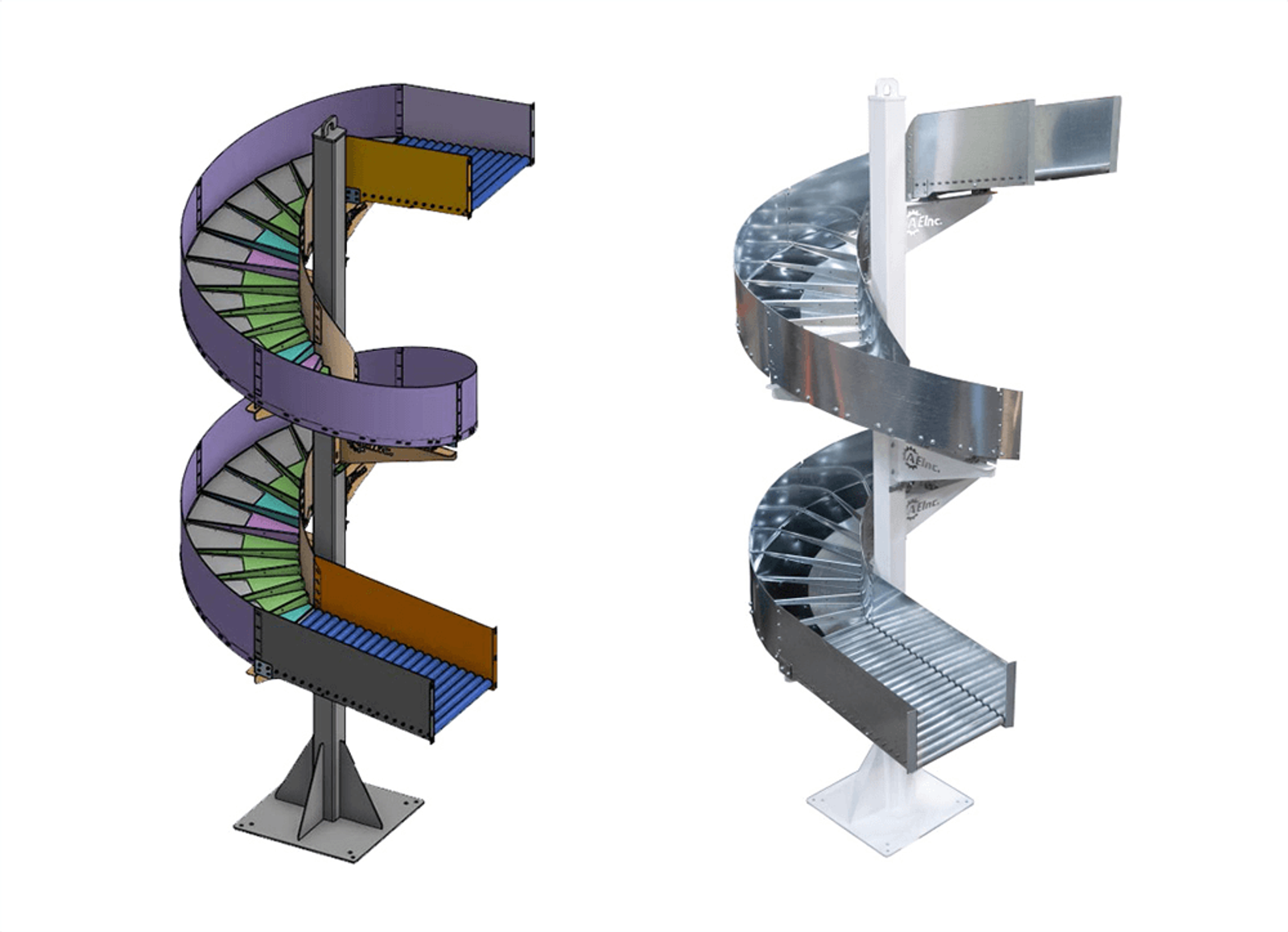

How? Often via a spiral chute. These fiberglass or metal ‘slides’ depend on simple gravity to transport items from upper levels to lower ones. Admittedly, these chutes are not as high-tech as forklifts or conveyors, but they still require careful engineering.

If the slope is too steep, packages descend too quickly and land with too much force, jeopardizing the contents of the box. If it’s too shallow, boxes get stuck, jamming up the chute. Then there’s width, diameter, number of rotations, turns, and length – every factory seems to need something different to accommodate its payloads, business, and buildings.

“Our whole company is based on moving things from point A to B”

When a client first asked AEInc. to build a spiral chute, the team imagined it was an uncomplicated job compared to what they’d done in the past.

Since 1994, the company has made thousands of custom material-handling solutions for clients like General Motors, Amazon, Caterpillar, and FedEx as well as smaller firms needing specialized equipment.

"We design and build automation and conveyor systems for all types of industries. Our whole company is based on moving things from point A to B," says Rodriguez. “The chute was not much more than a sheet metal helix. It's literally a playground slide.”

Little did he know it would soon become a mainstay of AEInc.’s business.

Scaling the spiral chute

In the beginning, the development process was very slow. That’s because each panel was tediously engineered individually in SOLIDWORKS and then bolted together. For a one-off design, that wasn’t a big concern.

But then the orders kept coming.

“I mean dozens and dozens,” says Rodriquez. “I don’t know how many orders we got, but we just kept making these spiral chutes. And every single chute would be custom-made, one triangle at a time.”

“Then they’d call and say, ‘I want it to go in the other direction,’” adds John McClary, lead engineer.

Clearly, AEInc. needed to scale chute production, fast. They found a solution in PTC’s cloud-native Onshape, which drastically reduced the time it took to design each new chute.

In Onshape, McClary defined the entire design mathematically and created a custom feature that could build a chute based on whatever parameters he entered into the system – outside diameter, inside diameter, entry, exit, width, and so on. All he had to do was enter the numbers.

“I used Onshape’s FeatureScript capability,” McClary says. “I click a button and it basically builds a whole chute for me.”

Not only does it create the model, but it also provides information about material use and nesting so the team can predict resource use and create estimates for prospective customers.

As a result, what once took hundreds of hours to design can now be accomplished in minutes. Best of all, the company no longer needs a design engineer to develop individual spiral chutes. Company sales reps just enter parameters into the system, and clients receive preliminary models and quotes instantly. All with no help from engineering.

Overcoming large file headaches

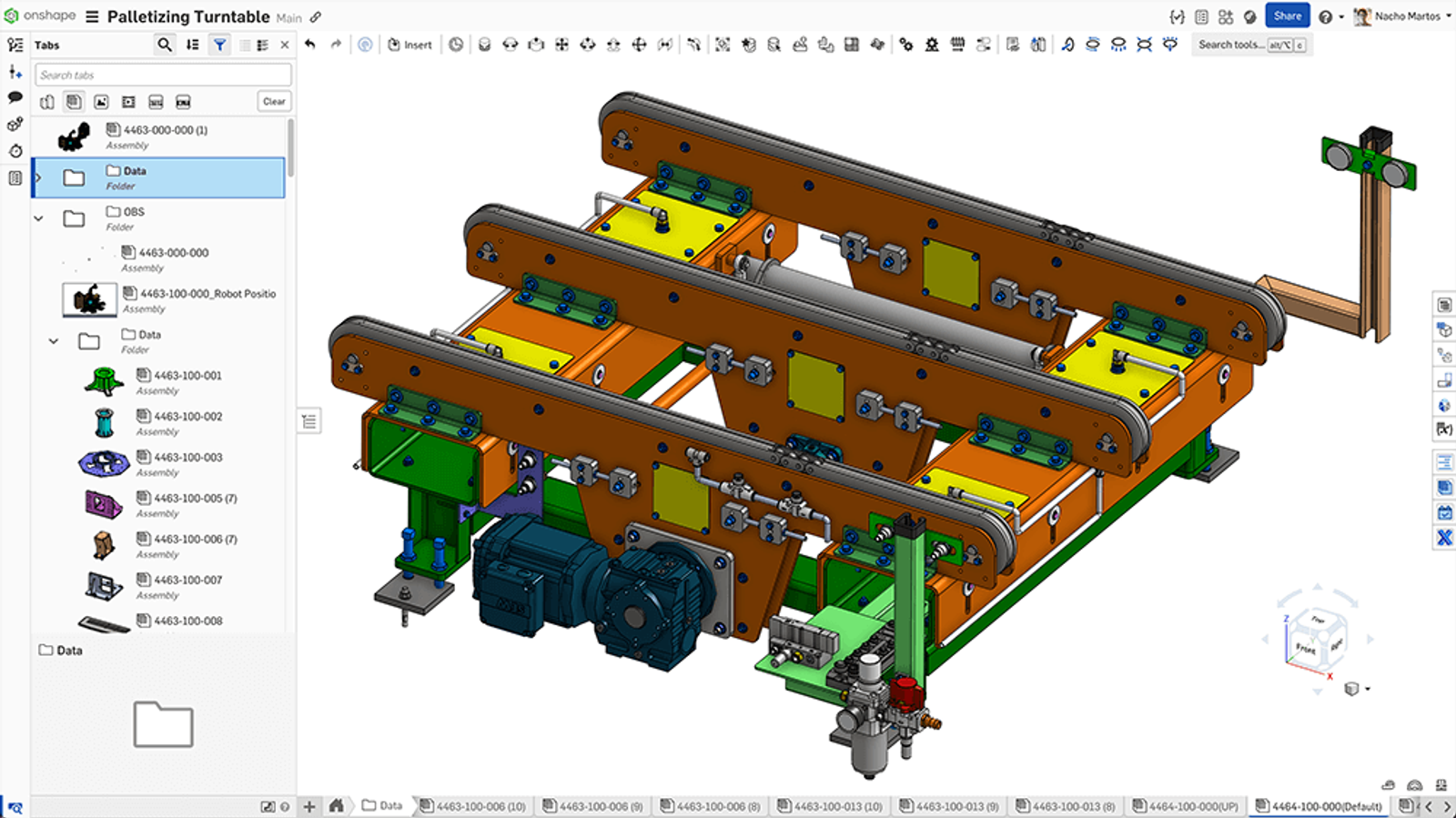

Onshape improved productivity for AEInc.’s business in several areas, including large file handling. As a subcontractor, many of the company’s jobs must be designed around a client’s existing parts and assemblies.

“When we design machines around somebody else's product, you get the whole design file. It is a massive, massive file, and it just sucks the life out of other programs,” says Rodriguez

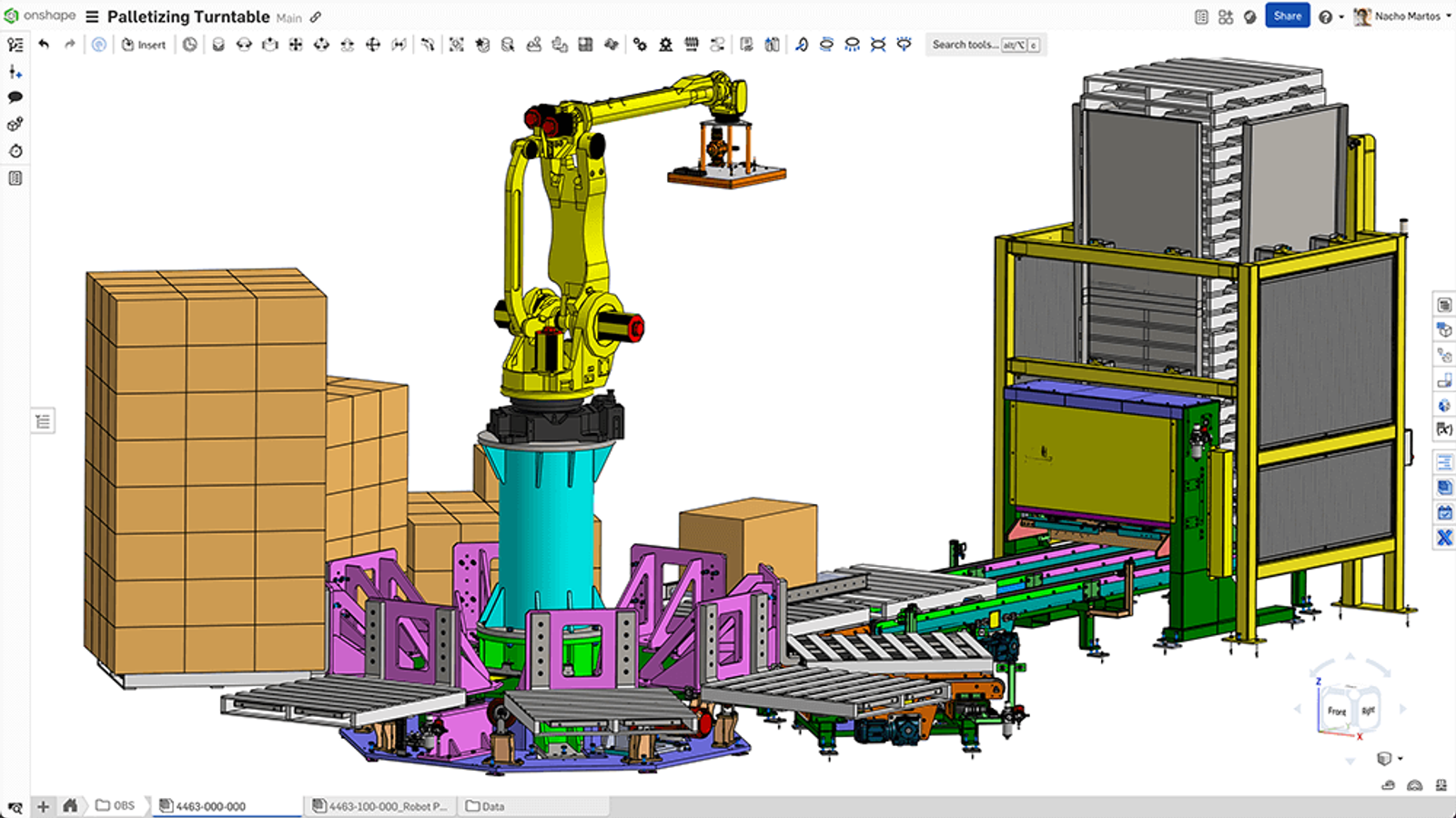

Their palletizing turntable (above) is one such example of a large CAD file that their previous solution struggled to support on tight turnaround times. This system allows for simultaneous pallet creation based on mixed package inputs, pallet destinations, box mix/quantity, etc. Up to seven pallets can be packed simultaneously, all while maintaining a compact footprint on the factory floor.

When previously using SOLIDWORKS, AEInc. would often struggle with large files and complex assemblies, leading to significant slowdowns and even crashes. Engineers lost time waiting for files to load or even rotate when trying to manipulate them. This, in turn, made it difficult to meet tight deadlines and reduced productivity.

"You try to open a file, then close the thing and go work on another job and come back in an hour, and the file is still loading," says McClary.

When engineers opened similar files in Onshape, performance improved dramatically. Because Onshape is a cloud-based platform, it has the resources to easily handle large files – without bogging down local machines.

That’s one reason AEInc. says that Onshape has doubled their efficiency, saving an estimated 10,000 engineering hours annually – the equivalent of $1.25 million. Tasks that once took 100 hours can be completed in 40 hours, and design times have gone from weeks to days.

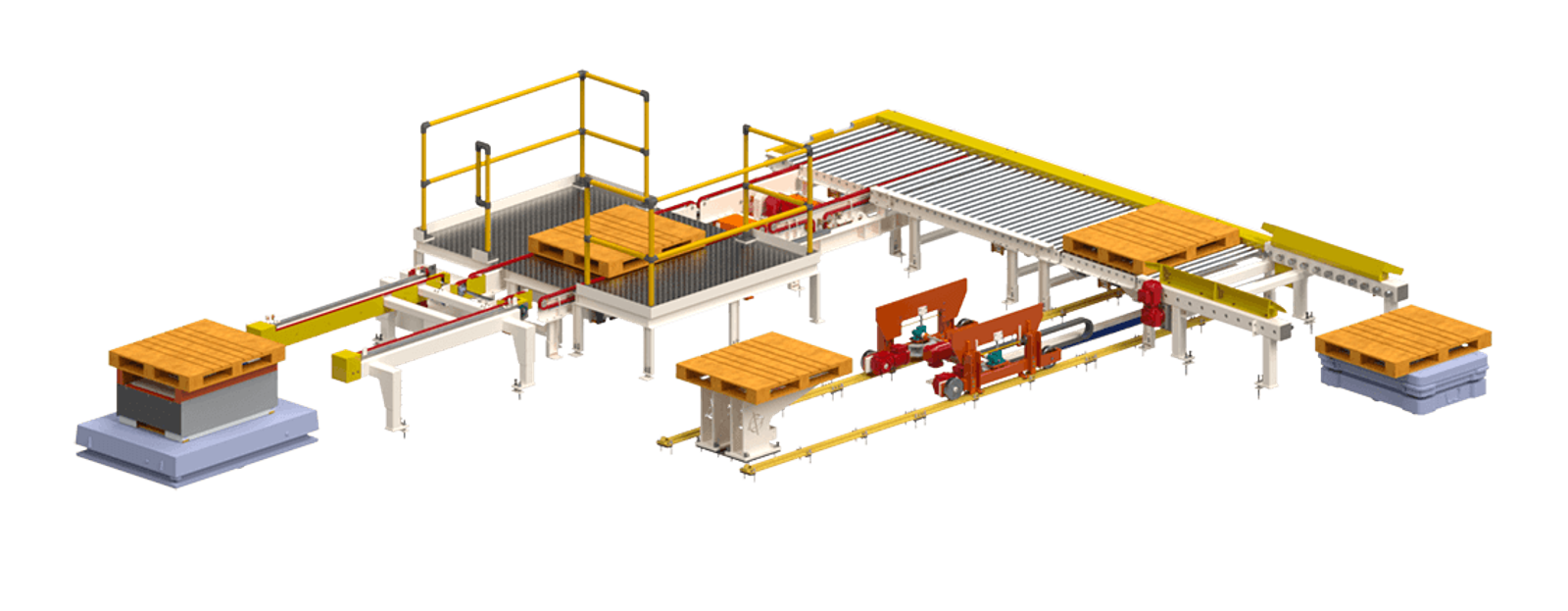

Putting the machinery’s best face forward

AEInc. carefully documents every machine it builds. Historically, this involved taking detailed photographs of each finished machine. The team would spend an entire day or two cleaning, preparing, and photographing each piece of equipment. But even with careful planning, the team struggled to capture shots that showcased the machine at its best.

Alternatively, team members could use SOLIDWORKS to create a rendering of the machine, but that wasn’t much faster. The design software’s rendering engine took hours to produce high-quality images. As a workaround, the company dumbed down the models for the software.

"We'd create STEP files [a neutral file format] from the original design files, just so the system could create a rendering of it," Rodriguez explains.

Onshape made all those time-consuming efforts unnecessary. AEInc. now creates professional images from the CAD models that are already in the system. Best of all, the process takes minutes instead of hours.

"We're not doing photography or STEP files anymore,” says Rodriguez. “We're just using Onshape and making renderings."

By using Onshape, AEInc. significantly reduced the time and labor costs associated with documenting their machines. Now teams like marketing easily create high-quality promotional materials and presentations, at any angle and at any time.

Unbelievable opportunities ahead

The engineering team at AEInc. rarely uses SOLIDWORKS anymore. It’s not surprising that Onshape has become essential to the company.

“If Onshape went away, it would cripple us,” says Rodriguez. “It would destroy my spiral chute business.”

With the spiral chute business automated and well-managed, the company is ready to take on new challenges with help from Onshape. Specifically, AEInc. has begun creating and patenting attachments for the autonomous mobile robot (AMR) industry. AMRs are self-driving vehicles that transport items around factories and warehouses with minimal human effort. And while AMRs are growing in popularity, few options exist for getting items off the floor or conveyors onto the vehicle.

“That’s where we’ll come in,” says Rodriguez. “The opportunities that exist are unbelievable.”