The Challenge

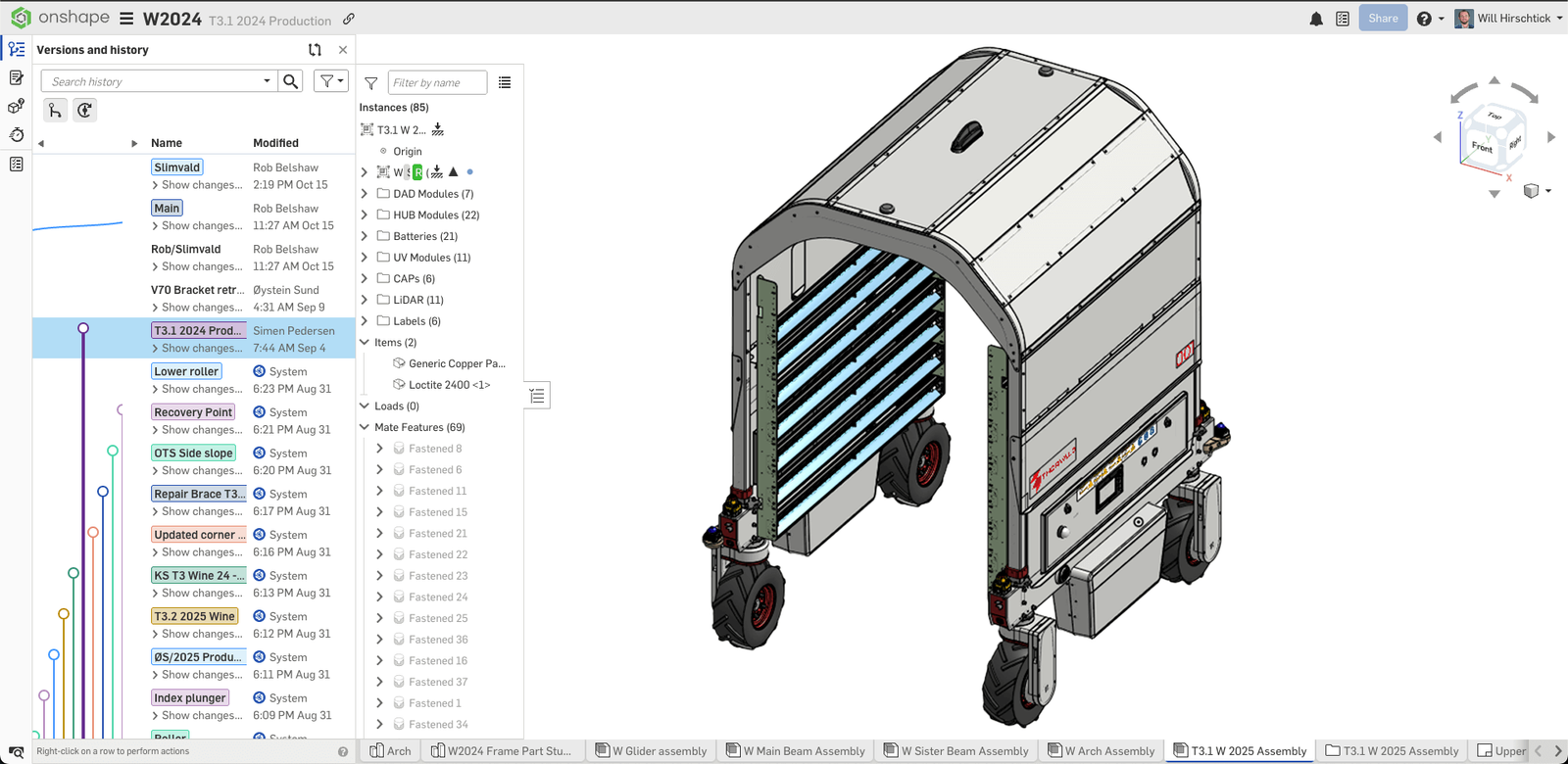

For growers in the UK and California, powdery mildew on crops can devastate harvests and eat into profit margins. However, many of these farmers are also committed to reducing or eliminating harmful pesticide use. Norwegian-founded Saga Robotics set out to tackle both problems at once with Thorvald, a modular, autonomous farming robot that operates with zero direct CO2 emissions. In addition to collecting field data and automating other tasks, Thorvald helps prevent crop disease with UV-C light treatment, an eco-friendly method that inactivates harmful plant pathogens without chemicals. Thorvald is a breakthrough for sustainable farming practices, capable of operating day or night, treating crops without chemicals, and adaptable to a wide variety of terrains, from the flat polytunnels of strawberry farms to the steep slopes of vineyards.

But as Saga Robotics’ team scaled its ambitions, its legacy CAD tools were holding them back. Their engineering teams in the UK, Norway, and the U.S. needed a single source of truth that supported fast design iteration, real-time collaboration, and modular development without costly hardware or version conflicts.

That led them to PTC’s Onshape, the only cloud-native CAD and PDM platform built for the way modern teams actually work.

Results

- 30–40% faster design cycles through real-time cloud collaboration.

- 20% reduction in data-related errors & inefficiencies.

- 90% fewer CAD crashes and rework than with legacy software.

- Increased design scalability 3X, enabling rapid adaptation for new crops and terrains.

For me, Onshape was a revelation. I don’t need a super-powered design computer to be part of the process. My team can share a link, and I can instantly view the latest model, see how things fit, evaluate cost and materials, and provide feedback on the fly.’’

Onshape: A Modern Solution for Saga Robotics’ Legacy CAD Woes

When Saga Robotics was founded, its engineers relied on a patchwork of file-based CAD systems like SOLIDWORKS and Autodesk Fusion, which quickly revealed their limitations. Each new license was locked to a country or computer, file syncing required manual exports, and hardware requirements meant the team had to buy expensive workstations just to keep pace.

The team’s international footprint compounded the problem. Engineers in Norway, the UK, and California needed to make live updates during the same 24-hour cycle. But with file-based systems, they often overwrote each other’s work or lost unsaved progress to crashes. Collaboration across time zones became a daily struggle.

“For a small company working across three time zones, hardware costs and heavy, admin-intensive tools just didn’t fit our agile way of working,” says Damian Flynn, Saga Robotics Chief Product Officer.

“Before Onshape, collaboration was painful,” recalls mechatronics engineer Sebastian Isted. “We’d export STEP files, send them across time zones, and by the time someone reviewed them, the model was already outdated.”

Saga Robotics needed a platform that would support a more agile design process to help them scale their business faster. They looked to Onshape to eliminate licensing and hardware friction while enabling better global collaboration.

“For me, Onshape was a revelation,” says Flynn. “I don’t need a super-powered design computer to be part of the process. My team can share a link, and I can instantly view the latest model, see how things fit, evaluate cost and materials, and provide feedback on the fly.”

30-40% Faster Design Cycles Due to Real-Time Collaboration

When Saga Robotics transitioned its entire Thorvald design pipeline into Onshape, the team saw immediate gains in efficiency.

Onshape’s cloud-native architecture allows engineers to collaborate concurrently in real-time on the same models, comment directly within the design, and view updates instantly. Because of Onshape’s real-time collaboration, Saga Robotics has reduced design cycles by an estimated 30-40%, accelerating concepts from idea to release in weeks rather than months.

“Onshape really plays into our agile way of working,” says Flynn. “Having Onshape as a tool makes collaboration incredibly easy across our three time zones.”

Isted adds, “With Onshape, anyone can open a design, comment, or fork it out to test a new idea. It’s a freeing process. You stay in flow without waiting on file transfers or meetings.”

Reducing Data Loss From Crashes and Manual File Management

Saga Robotics’ engineers used to spend countless hours managing CAD files, exporting revisions, and troubleshooting crashes. Their legacy CAD was fragile, prone to file corruption, hardware slowdowns, and lost work.

“Locally installed software depended on system performance,” says Flynn. “If you forgot to save, you could lose an entire day’s work.”

With Onshape’s cloud-native architecture, there’s no software installation, no server maintenance, and no file corruption. Every edit is stored automatically in the cloud, so work is never lost, even if a laptop fails mid-session.

Saga Robotics estimates switching to Onshape has resulted in 90% fewer crashes and rework events, reducing file-related delays and data loss by 20%. This means engineers spend more time solving problems and less time managing them.

“We’ve seen a significant reduction in data loss and file-management overhead since switching,” says Flynn. “It’s a huge advantage to know the design is always up to date and that everyone’s working on the latest version.”

Onshape has turned what used to be daily data-loss risks into a reliable, transparent design process that keeps Saga Robotics’ teams moving forward without interruption.

3X Faster Scalability with Onshape-Enabled Modular Designs

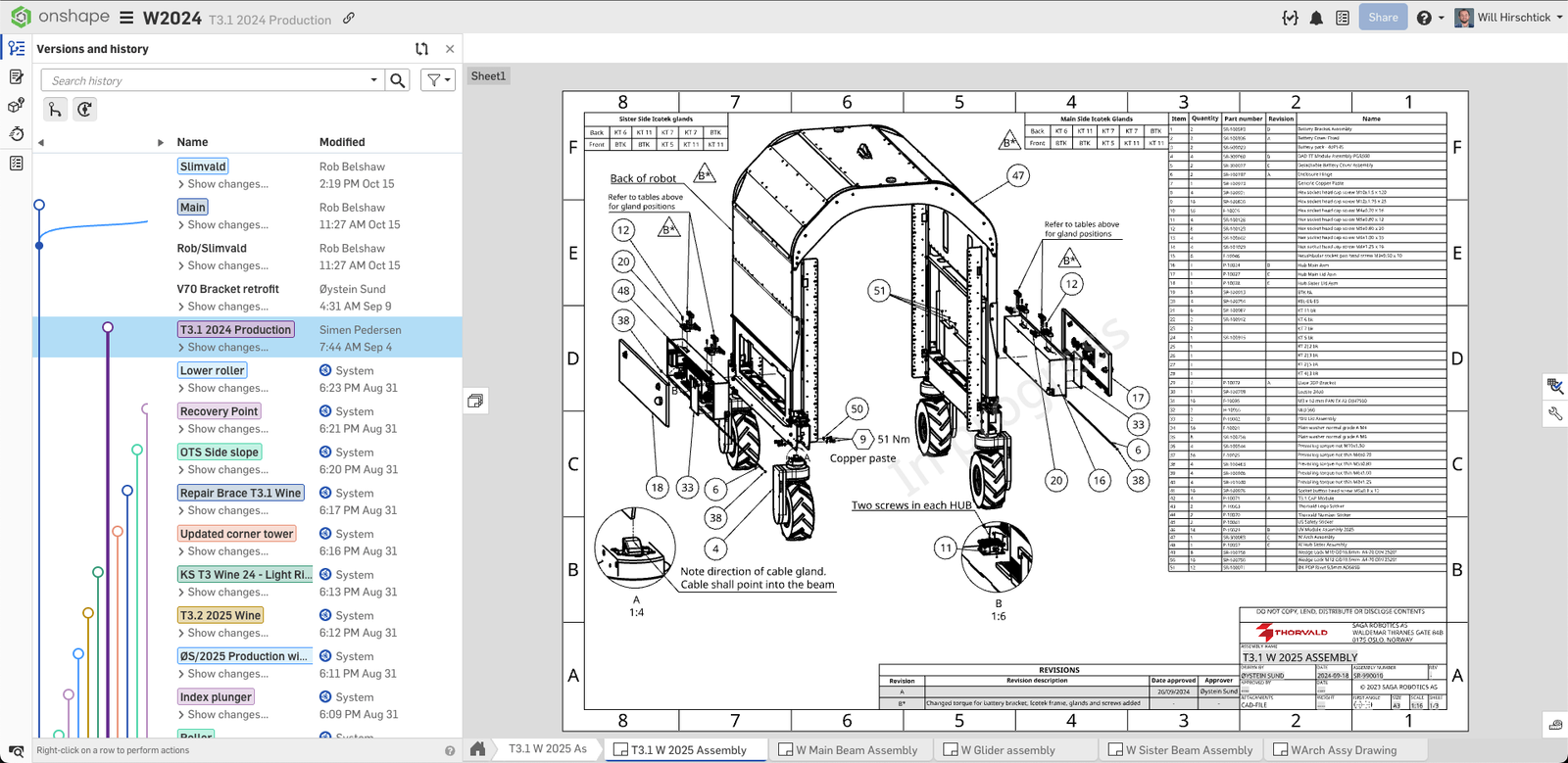

Perhaps Thorvald’s greatest asset lies in its modularity. Wheelsets, sensors, UV-C lights, and tool attachments can all be swapped or adjusted for new environments or conditions. Thanks to Onshape, each subassembly lives as its own version-controlled document, making it easy to test configurations or adapt designs to new crops and conditions.

“The modular design of Thorvald helps us apply the robot to different environments — UK polytunnels, Californian slopes, anywhere growers need it,” says Flynn. “Onshape lets us tweak a single module and immediately see how it works across all variants.”

Onshape’s branching and merging capabilities give designers confidence to experiment faster and more freely without jeopardizing the master model’s fidelity.

“Rather than play around with the accepted design, you can create a new branch, make changes, and only merge when you’re 100% happy,” says Flynn. “That ability to sandbox ideas really speeds up innovation.”

With Onshape, Saga Robotics can now roll out updates to multiple variants in parallel, a process that previously took weeks of manual syncing. The result is three times faster scalability as they expand their reach from strawberries to wine grapes and beyond.

“In the past, our growers had to choose between being sustainable or making money,” Flynn adds. “We’re proving they can do both, and Onshape helps us scale that impact.”

The Future of Sustainable Growing is Here

Saga Robotics continues to grow rapidly, with fresh investment fueling expansion across the U.K. and the U.S. The company hopes to treat 30% of the U.K.strawberry tabletop market by 2026, triple its U.S. vineyard coverage, and roll out new data-driven services that help growers monitor ripeness, yields, and disease risk in real time.

“We’re not just building robots,” says Flynn. “We’re building a scalable, sustainable way to feed the planet, and Onshape helps us move fast enough to make it real.”