05:14

Since 1999, Dexcom has been helping people of all ages manage their glucose levels daily with continuous glucose monitoring, allowing them to live normal lives despite their diagnosis. But behind every life-changing medical device is a sophisticated engineering process powered by data.

To deliver breakthrough glucose monitoring technology, Dexcom provides a wealth of data to users through their continuous glucose monitoring (CGM) system.

According to Dexcom, data “has the power to make life with diabetes, better.”

This philosophy extends beyond their products to every aspect of their engineering operations.

We sat down with Dexcom’s Manager of CAD Engineering, Adrian Velazquez, to discuss why data analytics for mechanical engineering is crucial for modern product development and how Onshape Analytics has transformed his team’s approach to design and manufacturing.

The Challenge: Scaling Engineering Operations with Data-First Tools

In 2014, Velazquez joined Dexcom and witnessed the company's explosive growth – from about 800 employees to over 7,000 by 2023. This rapid expansion brought new challenges that traditional CAD and PDM systems couldn’t address.

“That's when challenges started with data management,” Velazquez explained. “We needed to tame the beast” and look for a CAD and PDM solution.

The company’s engineering operations had evolved from a single team to 12-15 specialized R&D teams, each requiring seamless data sharing and collaboration.

Traditional file-based CAD systems and PDM software with check-in/check-out workflows were creating bottlenecks and limiting their ability to make data-driven decisions.

After extensive research, Velazquez selected Onshape Enterprise for its cloud-native architecture and built-in analysis tools that could support Dexcom's data-driven engineering goals.

The Power of Real-Time CAD Analytics

With Onshape’s built-in PDM system, Velazquez discovered capabilities that traditional CAD platforms couldn’t offer: real-time analytics that provide insights into design processes and team performance.

“I’m a firm believer that business and business-process data add value to a company,” Velazquez says. “When you start pulling back and have a high-level view, you start seeing your business like ‘The Matrix,’ where Neo sees the code and doesn’t need visuals. He’s just like, ‘Oh, I see what’s happening.’ To me, that’s what data is.”

Why Data Analytics Are Essential for Engineering Teams

Velazquez shared three key reasons why data analytics for mechanical engineering should be a priority:

Your engineering operations are your data. Analyzing CAD and design data is like running diagnostics on your entire product development process. You can identify inefficiencies, bottlenecks, and opportunities for improvement that would otherwise remain hidden.

Data reveals hidden patterns. With the right analysis tools, engineering teams can discover correlations between design activities, project timelines, and resource allocation that drive better decision-making.

Consistency enables actionable insights. “In order for [data] to have value, it needs to be structured and trustworthy,” Velazquez says. Reliable data architecture allows teams to generate analytical reports that the entire organization can understand and act upon.

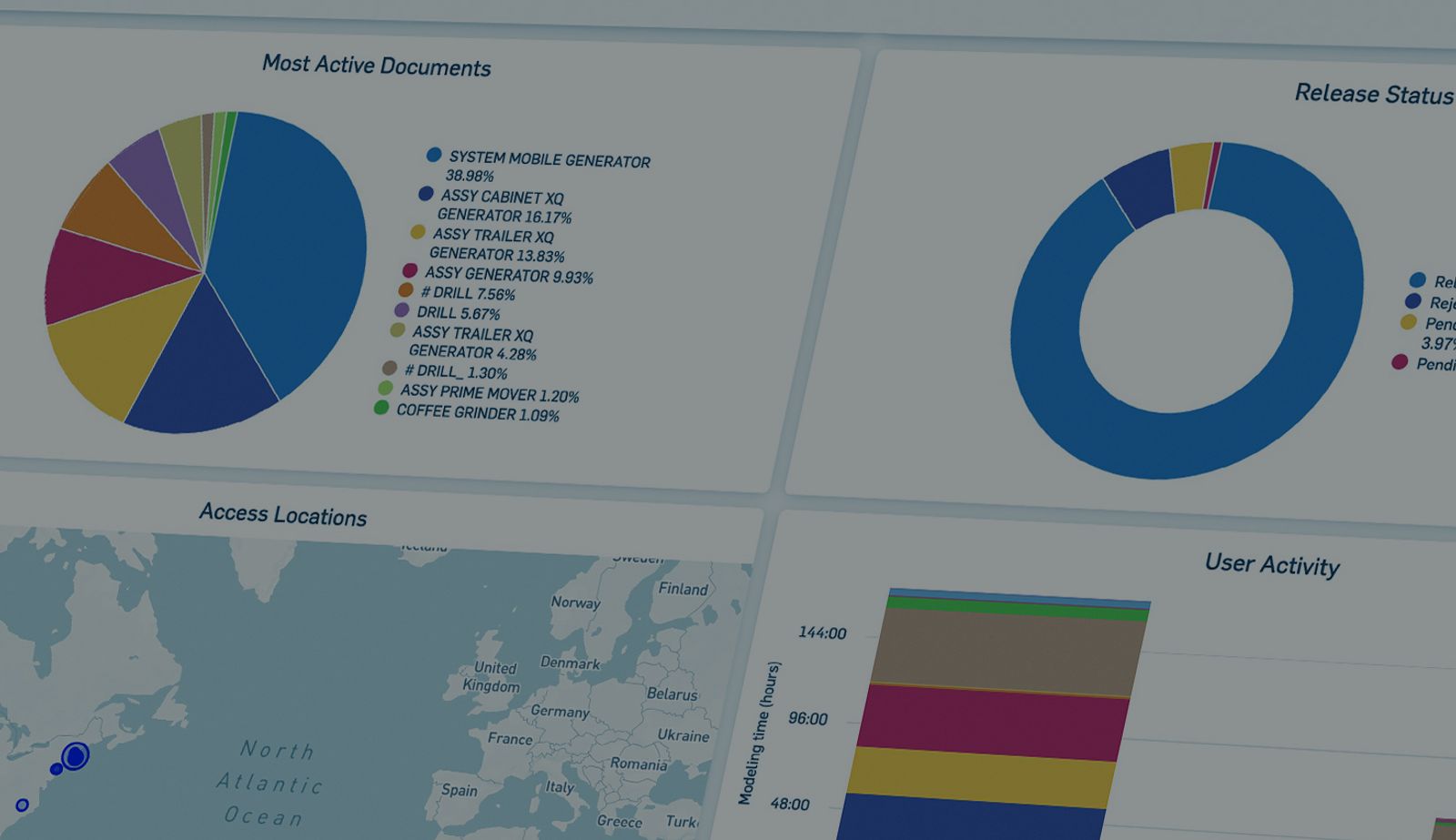

Transforming Engineering Workflows with Onshape Analytics

The transition to Onshape revealed that the platform functions as both a CAD tool and a comprehensive analytics platform. Teams can now identify project trends, workflow bottlenecks, and process improvements through real-time analytics.

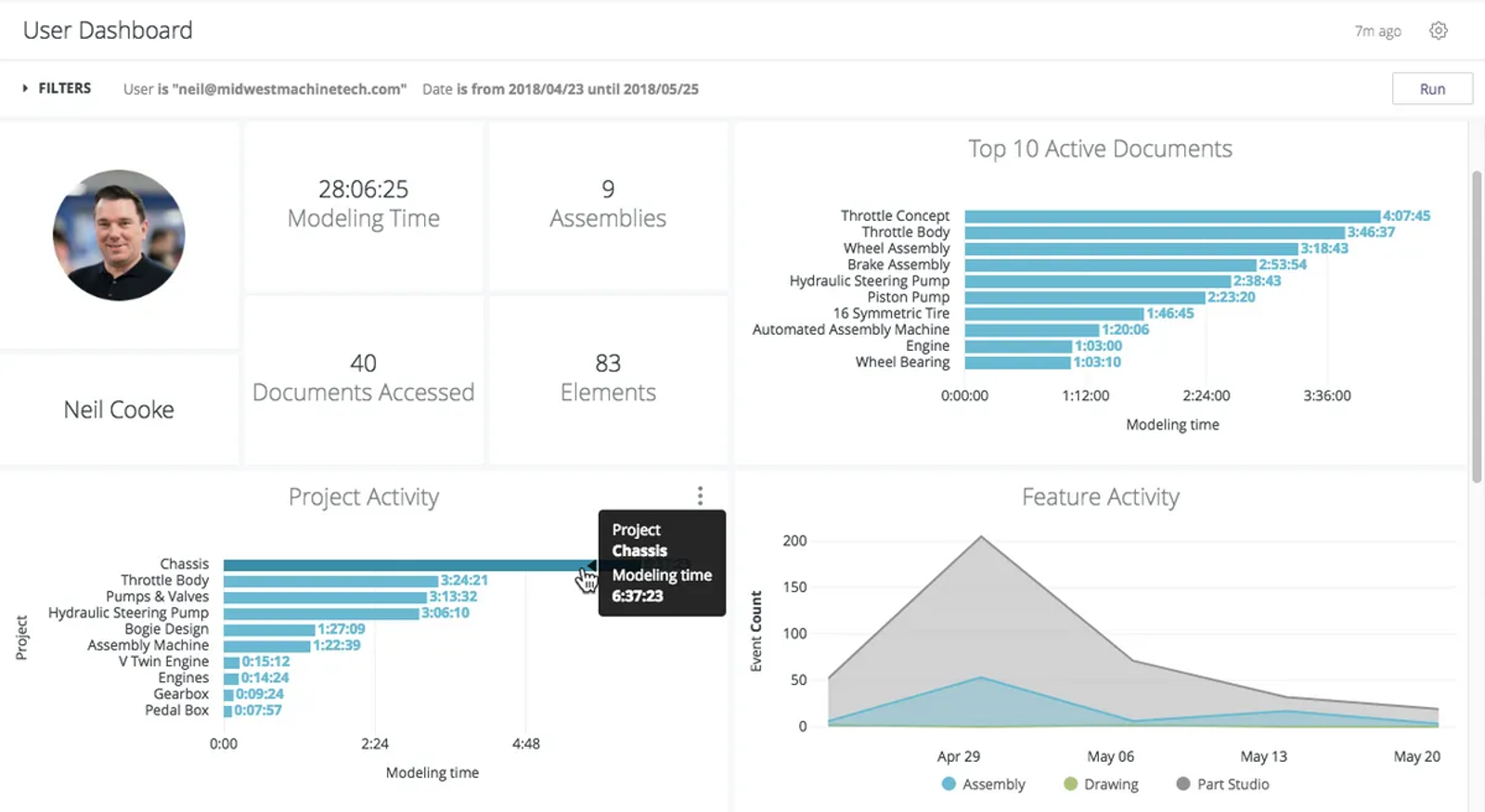

User Dashboard: Resource Allocation Made Visible

The User Dashboard provides detailed activity tracking for every team member, including external contractors and suppliers. This analytical report shows:

- Active projects and time allocation

- Design activities consuming the most resources

- Performance metrics across different engineering disciplines

- Collaboration patterns between team members

“You trust the system; you trust that it’s tracking who’s logging in and what they’re doing,” Velazquez explains. “Then you can make decisions and trust the data to make those decisions, or grab the phone and call someone and ask, ‘Hey, what happened to your project? Why's nothing happening?'”

From Months to Minutes: Analytics Accessibility

Previously, Velazquez spent months modeling data and weeks presenting it through internal websites.

Now, with Onshape’s built-in analysis tools, design information and performance metrics are available instantly on the platform.

This transformation has enabled Dexcom's engineering teams to:

- Identify design bottlenecks before they impact timelines

- Optimize resource allocation across multiple projects

- Make data-driven decisions about process improvements

- Track progress against critical medical device development milestones

Beyond Traditional CAD: Research Applications

Engineering analytics extend beyond commercial applications. University of Toronto Professor Alison Olechowski has been using Onshape Analytics as a research laboratory, identifying four distinct CAD modeling “personalities” through audit trail data analysis. This research reveals how engineering teams collaborate and can inform better team formation and project management strategies.

The Future of Data-Driven Engineering

Access to comprehensive CAD analytics delivers measurable benefits for medical device companies like Dexcom:

- Faster time to market through optimized design workflows

- Improved product quality via data-driven design decisions

- Better lifecycle management with real-time analytics

- Enhanced collaboration across distributed engineering teams

- Predictive insights for project planning and resource allocation

Measuring Success: ROI of Engineering Analytics

“As you can tell, I’m probably a little bit over-excited about data analytics,” Velazquez admits. “It really adds value to the investment of Onshape as a CAD and data management platform.”

For companies considering similar transformations, the ROI extends beyond cost savings to include:

- Reduced design iteration cycles

- Improved regulatory compliance tracking

- Enhanced supplier and contractor management

- Better visibility into project risks and opportunities

The future of product development lies in leveraging data to make better, faster decisions.

Try Onshape Today

Head to our sign-up page to choose the right CAD plan for you and your team.

Latest Content

- Caso di studio

- Robotica

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 Ulteriori informazioni

- Blog

- Evaluating Onshape

- Simulazione

- Rendering

- Creazione superfici

- Prodotti di consumo

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 Ulteriori informazioni

- Blog

- News from Onshape @ PTC

- Pubblicazioni

- Configurazioni

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 Ulteriori informazioni

- Blog

- Becoming an Expert

- Lamiera

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 Ulteriori informazioni